Today, solar panels have become real sources of alternative power supply for a private house. They are widely represented on the market, and the use of a solar mini-power plant is quite profitable. This situation is due to the constant growth in the production of solar panels and additional equipment, a decrease in prices for system elements and, as a result, the cost of generation.

Content

- The principle of operation of the solar battery

- Types of solar panels

- Monocrystalline silicon solar cells

- Polycrystalline silicon cells

- Amorphous silicon batteries

- Thin Film CdTe Batteries

- Polymer solar panels

- The choice of solar panels

- Type of

- Power and voltage

- Installation of solar panels

- Often asked

- Video review with calculations for solar panels

The principle of operation of the solar battery

Any solar battery is a photovoltaic converter that uses light to produce electrical energy. At present, the photoelectric effect in semiconductor materials has practical value.

The effect is based on the appearance of free electric charge carriers in inhomogeneous semiconductor structures when exposed to light photons. It is observed in various semiconductors - based on silicon, gallium arsenide, cadmium telluride, large polymer molecules.

Due to the appearance of free carriers, the energy of which is not enough to overcome the band gap, a potential difference (voltage) is formed between the electrodes of the element. When external circuits are connected, an electric current arises between them.

Photocells based on various semiconductors convert various parts of the solar spectrum into electrical energy. Thus, crystalline silicon modules capture up to 80% of radiation with a red shift, film elements based on amorphous silicon can also operate in the infrared range, titanium dioxide absorbs violet and ultraviolet rays.

In some laboratory samples, the researchers came close to the 50% mark. If the same results are obtained in industrial production, the cost of generation can be reduced by more than half compared to the current level.

Types of solar panels

The main feature of the classification of solar modules is the semiconductor materials used in the manufacture. Today, more than 80% is occupied by silicon-based solar panels. It is these types that have received the widest possible commercial use, they are offered by the vast majority of sellers working in the industry.

In turn, silicon solar panels are divided into:

Monocrystalline silicon solar cells

Monocrystalline solar cells are electrically connected cells made of thin (240 microns) silicon monocrystal wafers. Optical axes are oriented in the same direction, high purity material (more than 99.99%) is used. This ensures maximum conversion efficiency.With an efficiency theoretically possible for a silicon element of 30%, in serial samples, the figure reaches 18-24%.

Externally, single-crystal batteries are easy to distinguish - they have a deep black color, the element is shaped into a regular square (rectangle) with cut corners during cutting.

The technology for the production of such solar cells is the record holder in terms of cost among silicon cells. The high cost of production is explained by the complex processes of cleaning raw materials, growing a single crystal and cutting it accurately.

As a result, monocrystalline batteries have the highest price - about 0.9-1.1 dollars per 1 W of power.

Such elements also have another serious drawback - due to the precise orientation of the optical axes of the crystals, the optimal return can only be obtained when the sun's rays fall perpendicular to the plane of the element. With a significant change in the angle of illumination, as well as in scattered light, a sharp decrease in generation is observed.

Polycrystalline silicon cells

In polycrystalline batteries, the cell includes a plurality of crystals with a random orientation of the optical axes. Their production does not require raw materials with a high degree of purification - secondary sources (in particular, recycled silicon batteries), waste from metallurgical production can be used.

As a result, the manufacturing cost is greatly reduced. However, this also reduces the conversion efficiency - the best samples demonstrate an efficiency of 15-18%.

Externally, polycrystalline are regular rectangular plates of saturated blue color. The cost of generating "blue" panels is about 0.7-0.9: per 1 W.At the same time, they show significantly less reduction in diffuse illumination and light incidence at angles other than 90 degrees.

Amorphous silicon batteries

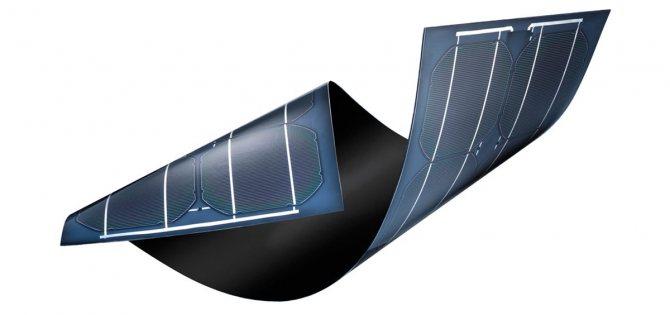

They are made from amorphous (non-crystalline) silicon a-Si by depositing silicon hydride vapor on a flexible substrate. As a result, a stable photoelectric effect is obtained already at a film thickness of several microns.

The technological process is significantly cheaper due to the minimum amount of required silicon raw materials, reduced requirements for its purity, and the absence of complex operations, such as growing a crystal and cutting it.

The conversion efficiency is about 8-11%, the cost of generation lies in the range of 0.5-0.7% per 1 W. The main disadvantage of such batteries is the low conversion efficiency, which requires a large area to provide the required power. However, it is more than offset by the ability to install on any surface - a flexible substrate does not require even bases and special structures for installation.

In addition, modern polymorphic modules can operate in the infrared range, which significantly reduces efficiency losses under diffuse illumination. As a result, the share of amorphous elements today accounts for about 10% of the world market.

Thin Film CdTe Batteries

Solar cells based on cadmium telluride (CdTe) can become a real alternative to silicon cells. Currently, they demonstrate conversion efficiency, on average, 20% higher than similar amorphous silicon at a cost of 20% lower.This is achieved due to the unique characteristics of the semiconductor, which provides the optimal band gap.

Such panels are made by applying a layer of semiconductor material to thin films. The technology is still available to a limited number of manufacturers, but the serial production of such batteries has already been launched by the American company First Solar.

Polymer solar panels

In polymer solar modules, the photoelectric effect is provided by a layer of "polymer semiconductor" - large molecules of organic compounds. At present, the technology of such products is close to the deployment of large-scale production (some European companies have already established commercial production).

The conversion efficiency of such devices is estimated to be in the range of 8-11%. Due to record-breaking cheap production, the use of flexible polymer materials, and the absence of problems with disposal, in the near future, polymer solar modules will be able to seriously compete with already manufactured products.

Manufacturers are also actively developing solar panels based on:

- gallium arsenide, copper-indium-gallium selenides (CGIS);

- hybrid technologies, in which several semiconductor elements on a different basis work in different parts of the solar spectrum;

- photosensitized cells, with Gretzel flasks as a working element;

- nanoantennas, in which sunlight as electromagnetic radiation induces EMF, etc.

The choice of solar panels

When choosing solar panels, it is necessary to determine not only the type, but also the electrical parameters - power and voltage.

Type of

Choose the type of solar panel from the insolation conditions (number of sunny days, radiation intensity):

- So, monocrystalline silicon batteries are quite suitable for installation in the southern regions.

- In the Middle lane and other Russian territories, the best option would be polycrystalline panels, which have proven themselves well in diffused lighting conditions.

- In northern latitudes, more attention should be paid to amorphous modules, which allow creating a significant battery area without additional installation work.

The category of quality also requires attention. In the marking of batteries, this parameter is indicated as Grade A, B or C. Ceteris paribus, Grade A products should be preferred - they will last 20-30 years with little (no more than 20%) degradation.

Lower quality categories are assigned to products based on the results of factory tests, which reveal a deviation from the nominal parameters of no more than 5% (Grade B) and 30% (Grade C) during operation.

Power and voltage

The power of the panels is determined as follows:

Calculate the average total power consumption (according to the indicators of the electric meter, electricity bills). For average daily consumption, monthly figures are divided by the number of days.

Calculate the average total power consumption (according to the indicators of the electric meter, electricity bills). For average daily consumption, monthly figures are divided by the number of days.- 20-30% is added to the result obtained in order to obtain a margin, taking into account the conversion factor (losses in battery charge and inverter operation).

- Based on the data obtained, the output power of the panels is calculated taking into account the duration of daylight hours. For calculations, it is taken equal to 6 hours, respectively, the battery power should exceed the average consumption by 4 times.

- Select panel voltage. As a rule, manufacturers offer batteries with an output voltage of 12V.However, in order to charge storage devices and increase the efficiency of converting direct voltage to alternating voltage on the inverter (especially at high power), it is more profitable to have higher values.

Standard use:- 12 V for systems up to 1 kW.

- 24 V or 36 V - up to 5 kW.

- 48 V - more than 5 kW.

Such voltages are obtained by connecting panels in series.

- Peak power is determined by summing up the power of all consumers in the house.

- The peak power is determined with a margin of 10-20%, for example, for the starting currents of electric motors and the operation of the heating elements of the hot water system, washing and dishwashers, etc.

- Peak power determines the maximum current of the panels.

- The reference books find the coefficient of insolation (in summer and winter) for the area.

For further calculations, use the formula:

P = Kc * Wn * Ki, taking into account

P = Kc * Wn * Ki, taking into account

- Кс – seasonal coefficient, for summer time it is taken equal to 0.5, for winter — 0.7;

- Ki is the insolation coefficient for summer and winter time;

- Wn is the rated power of the panel.

Having selected several battery models in the manufacturers' catalogs, for each of them, the generation power is calculated in winter and summer.

Then the required number of panels is determined by dividing the average power consumption calculated above (with a margin) by the generation power. Calculations are carried out for the winter and summer periods, as a result they take a larger value.

After calculations check:

- Maximum current load on the panel by peak consumption. If the maximum current is greater than that provided by the batteries connected in parallel, more powerful ones should be selected.

- Budget. The total cost of the panels is determined and compared with the amount allocated for their purchase.

- Square. The total area of the panels is calculated and compared with the area of the place allotted for installation. If there is not enough space, they are recalculated for more powerful batteries.

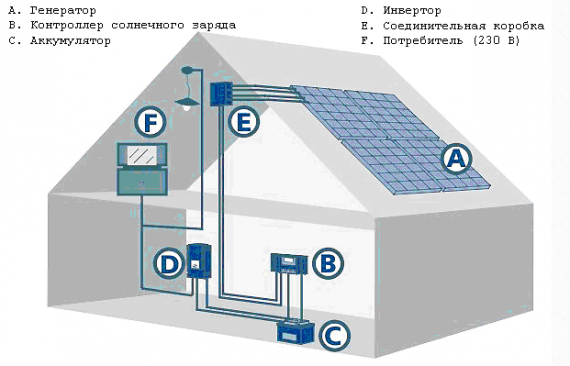

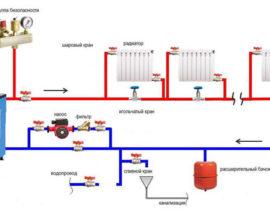

Installation of solar panels

There are no stringent requirements for installing solar panels. The solar collector can be mounted at an angle, on a vertical or horizontal surface. At the same time, rigid panels (mono- and polycrystalline) are installed on a rigid frame, fixed at the attachment points using complete fasteners. Batteries on an elastic backing allow laying on uneven surfaces (for example, a wavy roof).

The connections between the panels are carried out with stranded conductors with end fittings. The cross section of current-carrying elements is calculated from the value of the rated and maximum current.

When choosing a location and installation angle, one should take into account the main condition for maximum generation - the incidence of sunlight perpendicular to the plane of the battery.

This can be achieved:

- Orientation of modules in the south direction.

- By placing them at an angle equal to the geographic latitude of the area.

- The change in the angle of inclination within +/- 20%, respectively, in winter and summer.

In addition, for single-crystal panels, it is critical to take care of the absence of shading - in diffused light, their efficiency drops dramatically.

Often asked

Grade A batteries are usually guaranteed for 15-25 years. During this time, the decrease in indicators from the nominal does not exceed 20%.

Insolation in these regions does not contribute to the efficient operation of monocrystalline batteries. The position can be slightly improved by means of rotary tracking devices for the luminary, but their implementation significantly increases the cost of the installation as a whole.

Not necessarily, most manufacturers say that natural precipitation is enough to wash away dust for normal operation. However, several times a season it will not be superfluous to spray with water from a hose. Of course, be sure to remove the snow in the winter after snowfalls.

With the correct calculation of the number of panels and additional equipment (batteries, inverter), the solar power plant will completely cope with the power supply of the house without duplicating sources.

Most small manufacturers use modules from companies in the TOP 10. The reputation of a manufacturer can be easily checked on the website of California (https://gosolarcalifornia.org/equipment/pv_modules.php) or European TUV (https://www.tuev-sued.de /industry_and_consumer_products/certificates) laboratories.

Video review with calculations for solar panels