A fireplace is the decoration and heart of any living room, and thanks to modern technology, the owner of any house or apartment can become the happy owner of this piece of furniture.

In the realities of today's life, you don't have to build a heavy brick building with a chimney and a chimney to enjoy the view of the hearth.

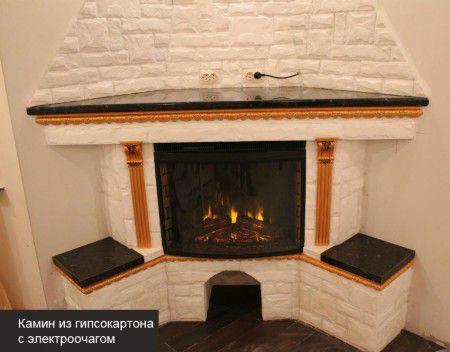

You can build a drywall fireplace with your own hands and install an electric firebox inside with the effect of flame and even smoke - such a fireplace will be inexpensive and decorate the room, and it’s not difficult to make it if you carefully read this article!

Content

Decorative fireplace: description and materials

To make a drywall fireplace, you must first complete the project: draw a sketch of the fireplace, indicate its dimensions, type of finish, and determine its functional purpose. At the same time, one should start not so much from desires as from possibilities - it is unlikely that a bulky frontal fireplace, which occupies a third of the usable area of the room, will decorate a small room. In the article we will give an example of building a corner fireplace - it takes up a minimum of space, and the shelves attached to it allow you to use it as a stand for equipment, an aquarium or trinkets.

A niche is made inside the proposed design of the fireplace.You can build an electric hearth into it or trim it with brick-like clinker tiles and put candles or a backlight there.

The frame of the fireplace can be built from a galvanized drywall profile (the so-called “CD” and “UD” profile) - its trimmings often remain after repair, and you can use them. If you plan to install an electric fireplace inside, it is better to take a stronger profile for the main stiffeners, for example, PN-2 75x40x0.6. For decorative fireplace enough profile PN-2 50x40x0.5.

It is better to take drywall with a thickness of 12.5 mm - it will provide the necessary structural strength. You can use cutouts. When installing an electric fireplace with a heating function, it is better to play it safe and take fire-resistant drywall and additionally insulate it with heat-insulating material.

To fix the GCR, you will need self-tapping screws for drywall, and to assemble the frame - self-tapping screws for metal (they are called "fleas"). And, of course, a screwdriver - it is quite difficult and long to assemble the structure with a screwdriver.

The mantelpiece and side countertops are made of artificial stone with a glossy surface, it can be ordered in furniture stores according to the size of the shelves. Attach the shelves to the screws and corners.

In addition, you will need dry alabaster for the manufacture of stucco, moldings and pilasters or finished items, as well as a finishing artificial gypsum stone. It is attached to gypsum putty, and painted with white acrylic paint on top. Decorative elements are additionally emphasized with Antique Gold acrylic paint and bituminous patina, after which the entire finish is covered with acrylic varnish - this will make it easy to remove dirt and dust.

We create a drywall fireplace with our own hands: step-by-step instructions from frame to finish

By itself, a drywall fireplace is easy to build, everything can be done by hand, it is enough to have basic skills in working with a profile, drywall and finishing materials. The profile is cut to size using metal shears or a hacksaw, the parts are fastened together on self-tapping screws, while one part is inserted into the U-shaped profile of the other. If it is necessary to make an arch, then the sides of the profile are slightly cut with metal scissors and the profile is bent with the untouched part inside the arch.

In order for drywall to take on a curved arch shape, it is enough to slightly wet it with water! After drying, you will get a perfect arc!

Drywall can be easily cut with a sharp knife or hacksaw. Drywall is fixed on black hardened self-tapping screws, sinking the head 1-2 mm into the material, later these places, together with the joints, are puttied or lined with finishing materials.

Gypsum elements are cast in silicone molds or are made by hand molding. You can also use ready-made gypsum stucco. If the hearth in the fireplace is decorative, without heating, you can use polystyrene or polyurethane elements.

To install an electric hearth, it is necessary to provide an outlet at such a distance that the cord does not stretch. The cross section of a copper wire for an electric hearth with a power of 2 kW must be at least 2.5 mm2.

- Draw a sketch of the fireplace and calculate the material. If you plan to install an electric built-in hearth, check the installation dimensions of the selected model. Mark the floor and walls and cut the material.

- The frame of the fireplace is made of a galvanized profile, fastening it with self-tapping screws. Stiffeners should be located in all corners and at the joints of the GKL sheets, in addition, if you plan to install heavy objects on the mantelpiece, make additional struts and vertical racks.

- The frame is sewn up with drywall sheets using self-tapping screws and a screwdriver. The upper planes on which the shelves will be installed are left open. The firewood arch is made from separate strips or thinner drywall is used - 6.5 mm. An electric hearth-firebox is installed in the finished frame, the connection to the network is checked.

- Proceed to fireplace trim. First, a gypsum mortar is mixed from alabaster and water and stucco, pilasters and moldings are cast in silicone molds. Do not knead a large amount of the solution at once - it hardens quite quickly. To extend the life of the solution, it can be diluted not with water, but with milk.

- Attach decorative elements to gypsum putty, leveling and rubbing the seams. It is convenient to do this with a spatula and a soft, damp brush.

- Proceed to facing the portal with stone. It is also attached to gypsum putty with grouting, and the selection of elements is carried out before gluing. It is better to start with small pebbles, setting them in the center of the element. To form corners, the stone is cut with a sharp knife slightly obliquely so that there are no sharp drops.

- Similarly, the wall above the fireplace, imitating an apron and a smoke channel, is also lined.

- After finishing, the final grouting is carried out with the same putty, and the stone itself is painted with white acrylic paint with a brush. Coloring gives the stone a fresh look and a matte sheen.

- Moldings and stucco moldings are painted with “golden” paint using a thin brush, after the paint dries they are aged - they are treated with bituminous patina, trying to paint over hard-to-reach places. After processing, part of the patina from the protruding elements is erased with white spirit. Patina can cover not all elements, but only some of them, for example, a console or pilasters.

- Artificial stone fireplace mantels are installed on the upper planes. Glossy dark stone combined with a plaster finish looks very rich and advantageous, but other materials can be used, such as MDF or natural wood.

- The final chord - the stone and decorative elements are covered with acrylic varnish with the effect of a wet stone, this can be done in several layers. After the coating dries, the surface of the fireplace will acquire dust-repellent properties.

- It's time to test the firebox. They connect it to the electrical network, set the mode, turn it on and enjoy the beauty, safe flame and warmth.

If you do not want to spend money on an electric hearth, it is quite possible to do without it. It is enough to finish the inside of the firebox with stone or tiles, you can also install mirrors.A backlight is installed in a niche - for this purpose it is convenient to use an LED strip by gluing it to the bottom of the firebox and connecting it to the electrical network. A living flame can be obtained by placing candles of various shapes in glass or ceramic candlesticks.

If you do not have the necessary skills or time, you can only make a frame with a niche and purchase a ready-made polyurethane fireplace portal, matched to the size of your firebox.

Fake drywall fireplace looks like a real one - video!

You are on the right track if you decide to give up the services of a master and start trying to do something yourself! We assure you, the main thing for you is to believe in yourself! To make such a fireplace (as in the video) is within the power of any person, it can start as a hobby for you and develop into a real profession that will feed you! Don't be afraid to try something new and you will definitely succeed!