High-temperature sealant for furnaces allows you to seal holes and crevices, which is essential for the correct and safe functioning of the heating unit. The main feature of such a sealant is that it is able to adapt to different temperatures without changing its properties.

There is an extensive selection of high-temperature sealants from various manufacturers on the market, each of which has its own advantages and disadvantages, which are better to evaluate before buying, and not during operation of the furnace.

Content

- Scopes of thermo-sealants and what is the danger of ignoring cracks in stoves and fireplaces?

- Varieties of high temperature sealants

- Rules for choosing a heat-resistant sealant for stoves and fireplaces

- The best heat resistant sealants for stoves and fireplaces

- Working principle with high temperature sealants

- Tips & Tricks

- Frequently asked questions and answers

- Video review of heat-resistant sealants

Scopes of thermo-sealants and what is the danger of ignoring cracks in stoves and fireplaces?

Fireplaces and stoves in the course of frequent and prolonged operation give cracks to the facing layer.

This is ugly from an aesthetic point of view, and also dangerous to health:

- Fuel consumption increases – additional air from the outside enters the combustion chamber, which accelerates the combustion process. You will have to throw up fuel more often, the consumption will increase by 2-3 times.

- Soot and soot - through even the smallest cracks, soot gets out, which settles on the ceiling, floors and furniture around the fireplace. You will have to clean several times a day.

- The release of carbon monoxide into a dwelling - through the cracks, the smoke, which should completely go into the chimney, seeps into the house. This is dangerous for the development of carbon monoxide poisoning, especially in the absence of proper ventilation.

The most dangerous condition that can develop when the heating system is depressurized is the formation of combustion in the chimney. Due to the high concentration of oxygen and the decrease in the combustion temperature in the combustion chamber, flammable soot forms on the inner walls of the chimney.

To prevent these negative consequences from overshadowing the process of operating a stove or fireplace in a house, a heat-resistant sealant is used for minor repairs. This is convenient, since you can cover up a gap or crack yourself at any time, postponing the overhaul until the summer.

Also, heat-resistant sealants are used for:

Also, heat-resistant sealants are used for:

- Sealing chimneys during installation and repair: sealing small and large cracks along the contour and on the chimney itself.

- Waterproofing of places of contact of the roof with chimneys from various materials.

- Gluing heat-resistant gaskets with metal fittings.

- Sealing cracks outside the combustion chamber made of brick or metal.

Some sealants can be used to repair refractory masonry if there is damage, but it is not possible to remake the masonry.

"Craftsmen" argue that it makes no sense to spend money on sealants, since clay successfully copes with their function. But not one kaolin composition can dry out so quickly and so reliably close up all kinds of cracks.

Varieties of high temperature sealants

High-temperature sealants differ in the composition of the thermal paste. It is this factor that allows the production of sealants with different temperature gradients used for finishing various parts of stoves and fireplaces.

silicate heat resistant sealant

silicate heat resistant sealant

The base is sodium silicate. Outwardly, it looks like a black plastic mass, which is convenient to work with. When solidified, it forms a dense inelastic heat-resistant layer.

Characteristics:

- Long-term use temperature - 1300°C.

- Short-term use temperature - 1400-1500 °C.

- Hardening time - 15 minutes at the recommended ambient temperature.

- Seam thickness - 15 mm.

- Deformation without destruction of the thermal layer - 7%.

Advantages:

- Quickly hardens, activates in the temperature range of 1-40°C.

- Does not have a pronounced toxic odor.

- The mass is plastic, easy to apply and knead.

- Long service life.

- It does not expand the crack when the already solidified composition is heated.

Flaws:

- It is better to use in those stoves and fireplaces that have already shrunk, otherwise there is a risk of cracking the sealant when the stove materials expand from heating.

Silicate sealant is recommended for use in the following cases:

- Sealing cracks and gaps that formed during the operation of fireplaces and stoves between the metal elements of the plates and brickwork.Adhesion in this case is better than any other sealant, paste or kaolin mixture.

- Sealing gaps in combustion chambers and surfaces that are in direct contact with fire and high-temperature gases.

- Sealing joints between the roof surface and the chimney.

- Sealing cracks and eliminating leaks from heating boilers.

Not all silicate sealants are fire resistant. When sealing cracks in combustion chambers, choose those sealants that indicate that operation near a fire is allowed.

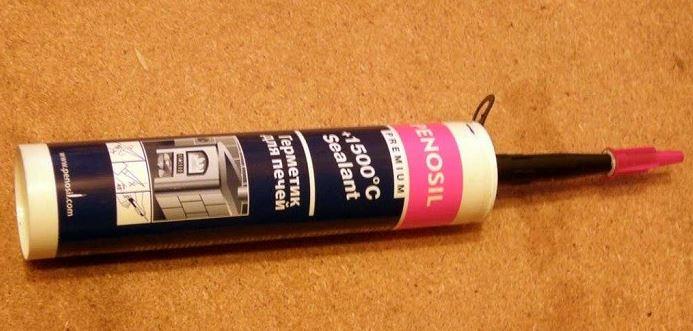

Silicone heat resistant seal

This category of sealants is distinguished by the addition of iron oxide to the silicone composition, which has a characteristic pink tint. Their main advantage is zero deformation, which allows the use of sealants not only in repairs, but also in the installation of heating appliances.

This category of sealants is distinguished by the addition of iron oxide to the silicone composition, which has a characteristic pink tint. Their main advantage is zero deformation, which allows the use of sealants not only in repairs, but also in the installation of heating appliances.

Characteristics:

- Complete drying time - 20 minutes.

- Operating temperatures – up to +300°С.

- Possibility of sealing narrow, but deep cracks, which is facilitated by convenient packaging in the form of a tube with a thin spout.

- Can be applied on a cold or warm base without worrying about the quality of the paste.

- Increased resistance to UV radiation, which allows the use of the composition for sealing joints on the roof.

Advantages:

- Long service life

- Waterproof

- Does not change shape during fluctuations in furnace temperature, does not deform under increased loads

- The cost is lower than that of silicate, convenient packaging

Flaws:

- It is suitable only for those surfaces, the working temperature of which is within +300°C.

Silicone heat-resistant sealants have found themselves in the following areas of application:

- sealing chimneys on the roof;

- processing of smoke exhaust paths of a chimney made of metal and brick;

- sealing non-through cracks on the surfaces of fireplaces and stoves made of stone.

Rules for choosing a heat-resistant sealant for stoves and fireplaces

In order for the purchase to be successful, and the repairs made to be of the highest quality, when choosing a sealant, it is important to determine the following nuances:

- Working temperature - it is necessary to evaluate in which part of the furnace the sealant will be used. If it is a chimney and exterior cladding, where the temperature index is in the range of + 300 ° C, then silicone-based paste is suitable. Silicate sealants, on the other hand, have a much higher operating temperature and are suitable for treating combustion chambers.

- Contact with open flames and gases – The sealant must be fire resistant if used inside a fireplace or stove. For outdoor repairs, the usual composition is suitable.

- Degree of environmental friendliness - the composition of sealants should not contain components that, when heated, provoke the formation of toxic compounds. Otherwise, when inhaling such vapors, there is a risk of intoxication.

Naturally pay attention to the brand and price. Unknown brands at suspiciously cheap (2-3 times lower) prices are a reason to think about possible risks.

The best heat resistant sealants for stoves and fireplaces

Experts recommend buying heat-resistant sealants from those manufacturers who have earned a name for themselves with decent quality. It is better to refuse to buy cheap options that do not have detailed instructions, as there are risks of acquiring a fake.

TYTAN Professional

Refractory silicate sealant. Suitable for minor repairs of stoves and fireplaces, chimneys.The composition contains an admixture of fiberglass, which forms a dense smoke and gas-tight layer. It has good adhesion to metal, concrete and brick.

Advantages:

- Relatively low cost.

- Operating temperature up to +1500°С.

- Contains no asbestos.

- Can be stored in a tube at sub-zero temperatures.

- Can be used to seal cracks in any part of fireplaces and stoves.

Flaws:

- Complete drying takes at least 24 hours.

The average cost per tube, weighing 300 g, is 250 rubles. After use, the sealant is closed with a threaded cap. It can be stored for a long time, retaining its qualities.

Fire 1600

Sealant allows you to effectively seal gaps and glue surfaces together. A distinctive feature is the need to wet the treated surface with water, which improves adhesion.

Advantages:

- Bonds concrete, glass, brick, stone, ceramics.

- Waterproof, suitable for outdoor chimney sealing work.

- The highest operating temperatures, which allows it to be used in all parts of the heater.

- Easy to apply with a spatula, convenient to work with.

- Can be painted with varnishes and paints with a natural composition.

- High level of environmental friendliness.

Flaws:

- Not identified.

The cost of a domestic product is about 240 rubles. When properly stored, it is not afraid of freezing and thawing cycles.

MASTERTEKS PM

Polish silicate sealant in black. Easily applied to the surface, without requiring its preliminary preparation. Suitable for filling various gaps and sealing joints. Dries relatively quickly.

Advantages:

- A convenient plug on the spout with a thread, which prevents air from entering the tube during storage.

- Dries quickly at the recommended layer thickness.

- Does not crack when the surface is cooled.

- Excellent adhesion

Flaws:

- Not identified.

Sealant is good in every sense and is literally perfect when working with a chimney.

Working principle with high temperature sealants

In order for the repair or installation to take place at the highest level, the master should divide the work into several stages, and then perform each one, taking into account some nuances. The more correctly this is done, the longer the thermo-composition will last.

Silicone compounds

Such a sealant helps to connect two surfaces of different materials, as well as close up fairly large gaps.

We will divide the work into several stages:

- Surface preparation: Treat the metal surface with sandpaper, remove dust, if water was used for cleaning, then you should wait for it to completely evaporate.

- Sealant preparation: the bottle is carefully opened and placed in a special construction gun, which makes the application of the product more comfortable.

- Applying sealant to the surface: the thickness of the extruded layer should be slightly less than the crack itself. During polymerization, the sealant will fill all the microcracks and slightly increase in size.

- Cleansing smudges: until the mixture has set, the excess should be removed with a spatula.

The drying time depends on the temperature and humidity in the room. The warmer and drier, the faster the sealant cures. Accordingly, in a cool and damp room, the manufacturer's recommended 20 minutes in practice can stretch for 40-50 minutes.

Silicone pastes

The main difference is the need to work quickly and accurately, since silicone thermal pastes harden very quickly, and there will be no way to fix anything in the future.

We work according to the following scheme:

- Surface preparation: sand all treated surfaces. If there are seams, then their outer part should be glued with masking tape so as not to stain the surface.

- Sealant preparation: the tube is inserted into the gun, the tip is cut diagonally.

- Application: apply a thin layer quickly enough, the excess is removed immediately.

Tips & Tricks

Experienced experts recommend the following:

- Never misuse sealant. If it is not intended to repair combustion chambers, then there is no point in using it there. Saving a penny - a large-scale loss, plus harm to health and danger to life.

- Make repairs after stopping the combustion process, taking into account the operating temperature of the sealant, as indicated on the package.

- Remember that the sealants must dry well. Give them the time recommended by the manufacturer.

- To improve adhesion between surfaces, they should first be sanded well. A rough surface will improve the adhesion of metal and brick.

- Remove excess thermal compounds before they harden, otherwise it will be extremely problematic to do this later.

- Do not buy products of dubious brands that do not have instructions for use.

- Always follow the precautions stated by the manufacturer.

Remember that repairing cracks and insulating individual sections of stoves and fireplaces is a responsible job. If there is no skill, then it is better to entrust it to professionals.

Frequently asked questions and answers

It is not always possible to find complete information in the instructions on how to properly use the sealant. Hence a number of errors and problems in the future, which does not depend on the quality of the thermal paste itself.

All work with sealant is best done in a dry and warm season, then its adhesion will be as strong as possible. Look for sealants that work at low temperatures, but keep in mind that they will take a long time to dry. If it is -2°C, then most likely the process will succeed. If we are talking about severe frosts, then it is better to wait for a thaw, since the mixture will not be able to polymerize correctly.

Specialists go to the trick, forcing the sealant to work thanks to heat guns. The latter are located in close proximity to the place of processing, increasing the temperature by 10-15°C.

This picture occurs if the ambient temperature tends to zero. Accordingly, in order to solve the problem, the surface and air should be slightly warmed up. But best of all, the coupling of two surfaces occurs when all work is completed in the summer.

If we talk about those sealants that are used for combustion chambers, then in their composition there are no elements that can somehow influence the combustion process. But such a sealant must have the obligatory mark "fire resistant". This means that it can be used in places of active combustion.

In conclusion, it is worth noting that heat-resistant sealants have a different composition and can be used for different purposes. Before buying, it is important to assess at what temperatures it will be used in order to determine the desired composition.Please note that the sealant does not contain hazardous components that, when heated, can release toxic substances.

Video review of heat-resistant sealants