Underfloor heating is an efficient and comfortable method of space heating that can provide maximum comfort with minimal heat loss. The specifics of the operation of this type of heating system requires the supply of a coolant (hot water) and the presence of control equipment. The ability to change the temperature of the liquid in the floor heating loops is a prerequisite for the normal operation of the system, otherwise the temperature in the home will become comparable to the sauna heating mode. There are several options for connecting a warm floor, which are used in different conditions and provide certain opportunities for users. Let's take a closer look at them.

Content

Features of connecting a water heated floor

Scheme of connecting a water heated floor

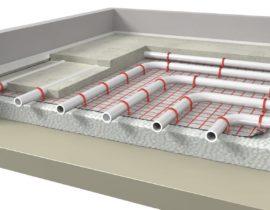

A water heated floor (VTP) is a closed pipeline through which a coolant circulates (usually ordinary hot water). This pipeline is laid in a certain order on the surface of the subfloor so that the thermal energy that it gives off is evenly distributed over the entire area.

At the same time, the temperature of the coolant cannot be the same as in the radiator system.This will create unbearable conditions in the room, and it will be impossible to walk barefoot on the floor. VTP refers to low-temperature heating systems, where it is necessary to limit the degree of heating of the coolant.

The maximum allowable temperature of the liquid in the underfloor heating loops is 55 °, and in practice it is rarely increased above 40-45 °.

To adjust the mode of operation of a warm floor, different methods are used. Basically, mixing units are used, where, using a 3-way valve, the cooled return flow is mixed into the direct flow. This is one of the most popular methods that provides an effective result and allows you to adjust the heat automatically.

In addition, there is an easier way to connect, with the supply of an already prepared coolant with a given temperature to the system. Typically this option used in private homes, and the liquid is prepared in its own boiler. This option is more difficult to adjust, but for many users it seems to be more reliable and convenient.

Part of the equipment

Elements of the water floor heating system

The VTP system consists of the following elements:

- a pipeline divided into equal segments (loops). They are connected in parallel to the source.

- coolant to reduce the degree of cooling of the liquid during the passage of one circulation cycle;

- mixing unit. This is a separate device that is installed between the direct and return lines before being fed into the ECP loops. The task of the mixing unit is to regulate the temperature of the liquid by mixing the cooled stream with a fresh, hot one;

- circulation pump. This is a device that gives the liquid an impulse and makes it circulate in the system at a given speed and under a certain pressure;

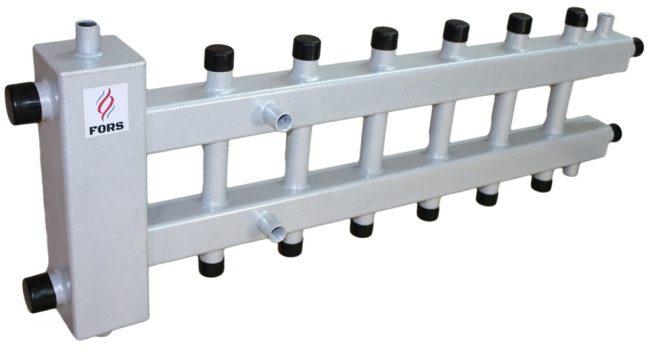

- collector.This is a device to which the underfloor heating loops are connected. A prepared coolant is supplied to the inlet, and pipelines are connected to the outlets. Each loop can be individually turned off, which allows you not to heat unused rooms.

In addition, the system uses measuring devices (manometers and thermometers), temperature sensors and valves. All these elements work in close interaction and serve to solve a common problem.

Connection methods

Connecting a water heated floor to a heat carrier source is a procedure that determines its performance and efficiency. Usually, several of the most reliable and convenient connection options are used, which should be discussed in detail:

Direct connection to the heating boiler

Use low-power boilers at low modes

This is one of the simplest and most economical connection options. The heating boiler becomes part of the underfloor heating system, which provides the preparation of the coolant, as well as its circulation using its own pump. The boiler outlet is connected to the direct pipeline of the ECP, and the return pipeline is connected to the inlet.

However, there are some difficulties. The main one is the adjustment of the operating mode of the boiler. It must produce liquid with a given temperature, which is not implemented in the design of a conventional heating boiler. Therefore, they use low-power boilers in low modes, or slightly complicate the composition of the system by connecting a storage tank.

The temperature in it is adjusted using a temperature sensor and a control valve. Since the intake of liquid is carried out constantly, as well as the replenishment of the volume from the boiler, it becomes possible to create a given operating mode.With this option, it is possible to almost completely automate the mode of operation of the ECP, but even in this case it is necessary to constantly monitor the state of the system.

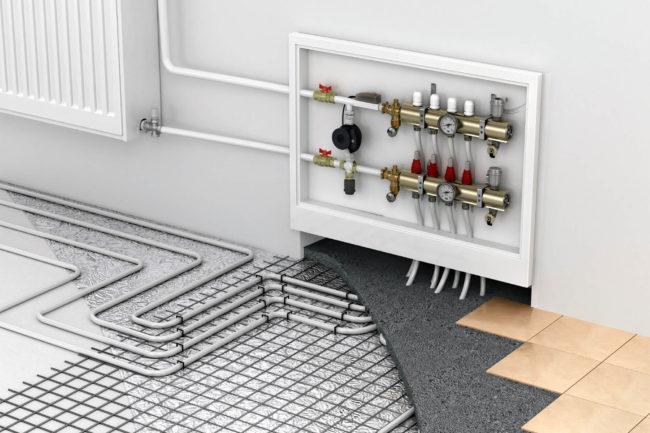

Connection via mixing unit

Connections via mixing unit

For more reliable and stable operation of the ECP system, a connection scheme to the boiler through a mixing unit is used. If we somewhat simplify its design, this is a closed loop connecting the output and input of the heating boiler. A mixing unit is installed in the gap, consisting of a three-way valve and a bypass pipeline. After installation, an assembly occurs in which a direct hot flow is directed to the inlet of a 3-way valve. The cooled reverse flow is supplied to the other input, and the output is connected to the ECP collector.

A mixed coolant flow is directed to the loops, the temperature of which is determined by the ratio of the mixing indicators. If the return flow prevails, a relatively cold liquid will go into the warm floor. If the advantage is on the side of the hot flow, the temperature of the liquid in the loops will increase.

If a temperature sensor and an automatic control valve are connected to a 3-way valve, it is possible to maintain a set liquid supply even with unstable inlet flows. This is an important advantage of this connection method. The operation of the heating boiler may depend on various external factors, and the ability to automatically adjust the heating mode of the ECP is highly appreciated by users.

Connection to the radiator of the heating system

Connection option from a heating radiator

This connection option is used when there is no own heating boiler.As a rule, it is used at your own peril and risk, since the underfloor heating system becomes an additional heating device. The mode of supply of the coolant is changing, from which other subscribers of the network may suffer.

There are other difficulties as well. The use of VTP in apartment buildings is prohibited (at least in living rooms). However, this rarely stops users, as it is not easy to detect the connection. In addition, with proper connection of the ECP to the radiator network, there will be no problems for other subscribers.

The principle of connection is almost identical to the option with the addition of another radiator. Only one loop can be connected if the connection is made to a radiator, which acts as a bypass for the network. The underfloor heating loop receives a certain amount of coolant through the control valve.

This option is rather doubtful, since the temperature of the incoming coolant is too high, as is the pressure in the pipeline. There are overheating zones, and the warm floor itself is under excessive pressure. In such cases, it is necessary to assemble the loop by soldering a copper circuit with fittings, which is difficult, expensive and does not guarantee durable operation.

Power supply of a water heated floor from a heat exchanger

This option allows you to physically separate the coolant flows

Often the connection to the radiator system, with all the efficiency and reliability, is impossible. The reason for this is too high pressure in the source system, which is unacceptable for the ECP. In such situations, a hydraulic separator, or heat exchanger, is used. This option allows you to physically separate the flows of coolant under operating pressure, and hot water in the water floor heating system.

This results in significant savings in resources, since the heat loss in the heat exchanger is much lower than in direct connection to the radiator system. In addition, the danger of a conflict between the operation of two pumps located in a single flow disappears - one can suppress the operation of the other, putting it out of action. In this scheme, the circulation pumps of the radiator system and the underfloor heating operate in separate closed systems and do not affect each other.

In terms of design, this scheme is quite simple. There is a container inside which there is a liquid and two independent coils are placed, one is connected to the break of the radiator system, the other is connected to the direct and return lines of the underfloor heating.

A coolant with a standard temperature of 80-85° circulates through the first (radiator) coil. The liquid inside the container is heated from it and transfers thermal energy to the second coil connected to the warm floor. In this case, the inevitable heat losses are even useful - a slightly cooled coolant enters the ECP system, which makes it possible to more efficiently and finely regulate the operating mode.

Which way to choose?

It is important to pay attention to the specifics of your specifications

Choosing a connection option is a task that is usually solved by comparing the technical capabilities and the efficiency of the system. If you have your own heating boiler, the best option is a scheme with a mixing unit. If there is no boiler, it is most convenient to use a heat exchanger with heating from the central heating network. It is possible to feed the warm floor directly from the boiler if it produces a coolant with a low temperature.

In any case, the main selection criterion is the reliability and stability of the ECP operation.To stay in winter without heating at home in our country is an extremely undesirable situation, therefore, you should choose the most efficient option. In addition, it is recommended to have an additional option for heating the house, in case of problems with the main heating circuit.

Questions

From a system design point of view, this option is not possible. However, separate floor heating loops connected to different sources may operate in different rooms. Different connection options can be implemented here, for example, in one room, power is supplied from a radiator, and in the second, from a boiler through a mixing unit.

The size of the container must correspond to the size of the coils and ensure high-quality transfer of thermal energy. Here, heat losses should not be present, since the temperature difference during transmission is already quite large. The size is also chosen taking into account the pressure and temperature of the coolant in the central heating system - the higher the indicators, the larger the tank size can be.

It depends on the total length of the pipeline (in all loops). If a small area is served and 1-2 loops are operated, you can get by with your own circulation pump of the boiler. However, if the boiler does not have a pump (this is typical for atmospheric gas boilers), a separate circulation pump will need to be installed on the return line.

The highest performance can be obtained from a mixing unit with an intensifying circulation pump.However, in this matter, the power of the boiler and other features of the system are of great importance.

Experts believe that systems using a mixing unit and supplying coolant from their own boiler are the most reliable and stable. However, it is strongly not recommended to be limited only to the VTP - backup heating capacities are required.