A water heated floor is an efficient and economical way of space heating, which can serve as both an additional and a main source of thermal energy. Due to their specificity, such structures are used mainly in private houses and cottages.

Many of them are built of wood, with the manufacture of ceilings according to the traditional method - load-bearing powerful beams and boardwalk. Laying a water circuit on such bases requires compliance with certain rules, since any leakage can cause damage to finishes, furniture, and in the most difficult cases can lead to the destruction of wooden structures. The question is capacious, therefore, it should be considered more carefully.

Content

What is a water heated floor

A water heated floor is a heating element distributed throughout the room and providing heating. In terms of design, this is a pipeline laid on the surface of the subfloor. At the same time, it does not generate thermal energy by itself, its source is a conventional coolant (hot water). It circulates through the pipeline and gives off its energy to the upper layers of the floor heating cake (concrete screed or sheet flooring).

A feature of the warm floor is the low-temperature mode of operation.Simplifying somewhat, we can consider it as one radiator, occupying the entire area of the room. if a coolant with a standard temperature (about 80 ° C) is launched into it, then it will become impossible to stay in the room, as well as walk on such a floor - it will be too hot. The nominal mode of supplying the coolant to the water floor heating circuits is limited to 35-45 ° С. Therefore, as a heat carrier source use own low-temperature boiler, or network heat carrier from the central heating system, mixed with the cooled return flow.

A feature of the warm floor is the low-temperature mode of operation.Simplifying somewhat, we can consider it as one radiator, occupying the entire area of the room. if a coolant with a standard temperature (about 80 ° C) is launched into it, then it will become impossible to stay in the room, as well as walk on such a floor - it will be too hot. The nominal mode of supplying the coolant to the water floor heating circuits is limited to 35-45 ° С. Therefore, as a heat carrier source use own low-temperature boiler, or network heat carrier from the central heating system, mixed with the cooled return flow.

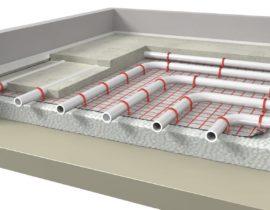

For a water heated floor, the method of installation is of great importance. The traditional option is to lay the pipeline and pour it into a concrete screed. A floor covering is laid on it, which receives thermal energy from heated concrete and gives it to the room. However, if the ceiling is made of wood and cannot accept additional load, it is necessary to install the underfloor heating loops without a screed.

The pipe is laid on a wooden base, separated by wooden planks 2 mm thicker than the pipe itself. Sheet flooring (OSB plywood, chipboard) and a finishing floor covering are laid on top. this is a compromise and forced option, since heat transfer in this case is significantly reduced. Sheet flooring, which must receive thermal energy and give it to the finish coat, acts as a heat insulator and extinguishes a significant part of the heat. Therefore, it is necessary to increase the heating power and spend more resources.

Advantages and disadvantages

What to look for when choosing

The advantages and disadvantages of a water heated floor include:

- high efficiency.Even when laying on a wooden base (without a screed), a stable and comfortable temperature regime of the room will be ensured;

- economy. The equipment itself and the installation of the water circuit cost a lot of money, but subsequent operation requires very little cost;

- safety. Even if leaks occur, there is no risk of getting an electric shock or burn from a hot coolant (unlike conventional radiators or convectors);

- the thermal mode can be smoothly adjusted and set the temperature in the room with an accuracy of 1 degree;

- high thermal inertia. With a short-term shutdown of the circulation, the coolant does not have time to cool down, and the heating mode of the room is practically not disturbed;

- if you use your own boiler, the heating system of the house becomes completely autonomous and practically does not depend on resource suppliers.

- dependence on the presence of a coolant in the system. Without it, a water-heated floor turns into a useless pipeline;

- the risk of leaks that can spoil the finish or interior elements of the lower floors;

- administrative restrictions prohibiting the use of water heated floors in apartment buildings;

- installation of such systems is a rather difficult task, which not every user can handle.

Despite the existing shortcomings, water heated floors are popular with homeowners. They are economical, and this more than compensates for all the disadvantages of such structures. the only condition is the presence of a backup heating system, which can be activated in the event of an emergency on the water circuit.

Types of flooring

In conjunction with water-heated floor systems, almost all types of floor coverings can work:

tile

Usually it feels like a cold and often slightly damp canvas, but working together with a warm floor turns it into a pleasant and very comfortable coating;

laminate

It tends to absorb thermal energy, but within small limits. If a special type of material is used, prepared for laying on a warm floor, a comfortable and cozy atmosphere will be achieved in the room;

linoleum

It is necessary to purchase specialized material with the appropriate marking, otherwise changes in the structure, dimensions, drying out of the canvas are possible;

carpet

It absorbs thermal energy, so it will be necessary to somewhat strengthen the mode of operation of the thermal circuit.

When laying a water-heated floor on a wooden base, it is possible to use any finishing coating. The only condition will be a properly performed installation and a sufficiently dense laying of all elements of the underfloor heating pie.

Rules for installing a water heated floor

Installation of a water heated floor on a wooden base

classical scheme assembly of a water heated floor is as follows:

- subfloor surface preparation;

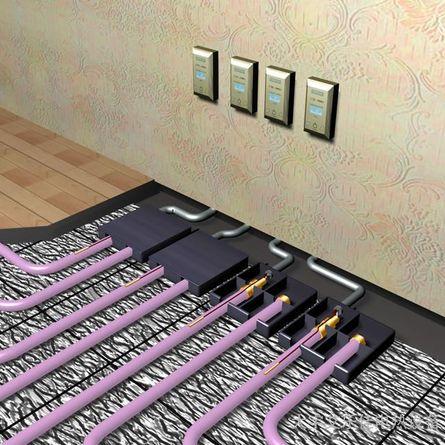

- assembly of elements for connecting and controlling the water circuit (installation of a collector and a mixing unit, connection to a heat carrier source);

- laying a heat-insulating layer;

- installation of fiberglass mesh and distribution of water floor heating pipes. They are attached to the grid with nylon clamps or ordinary wire;

- connecting the pipeline, applying pressure and checking for tightness;

- filling the pipeline with coolant under operating pressure and pouring the screed;

- holding the screed until completely dry, laying the flooring.

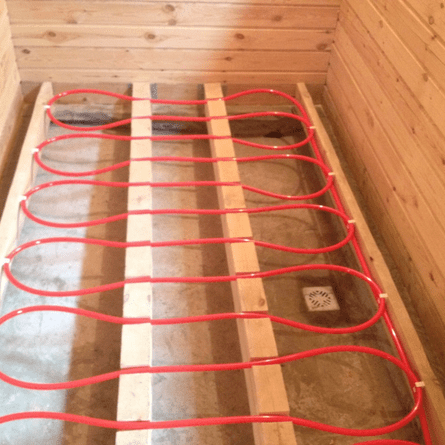

This method is used on concrete floors.However, in wooden houses or cottages with wooden floors, this option is not always suitable. Since the load from the screed for wooden floors can be too high, the water-heated floor has to be laid without it. This method is called the floor system. Let's consider it more carefully.

Laying system for laying a water-heated floor

Floor laying system

According to this method, the screed is not used, and wooden planks (logs) are attached to the surface of the wooden subfloor. They are arranged so that the pipelines pass between the planks. The joists must be distributed over the entire surface with maximum uniformity and without large gaps, since they serve as support elements for the sheeting.

Sometimes the pipeline is laid directly on the subfloor. Wood is an excellent heat insulator, so purchasing and laying an additional layer in this case is impractical. There is a very effective way to increase heat transfer floor heating pipes and partially compensate for the absorption of thermal energy by the sheeting.

For this, heat-reflecting plates are used. They have a section in the form of an inverted letter "Ω" with developed horizontal shelves. The pipe is laid in a round central part, and the shelves are tightly pressed against the sheet flooring. This creates conditions for efficient heat transfer and reduces the mode of heating the coolant.

Benefits of a deck mounting system

The decking system is a completely competitive alternative to the traditional installation method, it has important advantages:

- relatively low weight of the heating circuit, which does not have a serious impact on the wooden floor;

- simplicity and high speed of assembly - there is no need to wait for the screed to harden;

- high maintainability of a water-heated floor. Here, the entire structure is collapsible, which allows you to access the problematic section of the pipe at any time.

This system has no fundamental drawbacks, except for its lower efficiency and inevitable heat losses. However, the absence of excess load on the ceiling and the high speed of installation in the eyes of most users look like quite convincing arguments in favor of this installation method.

Questions

This will require partial dismantling of the water floor heating pie. You will have to remove the flooring and sheeting, re-lay all the loops of the warm floor. If this procedure does not seem too difficult, then it is possible to temporarily lay the water circuit loops without plates.

Yes, it's needed. It allows you to protect wooden parts in the event of leaks. Experienced craftsmen additionally make drainage that removes water from the warm floor cake and prevents it from getting wet. In addition, the appearance of water in the drainage system signals the need for urgent repairs.

Yes, if there are gaps between the boards of the subfloor, the presence of a heat insulator becomes mandatory. Otherwise, too much heat loss will occur, creating an excessive load on the heating boiler.

Here it is necessary to be guided by the state of the subfloor.If there are irregularities, but the floor itself is strong and reliable enough, you can level the surface with logs. If the floor is weak, you will have to not only level it, but also strengthen it, eliminate the mobility of the floor.

If there is sufficient bearing capacity of the floor, pouring the screed is quite possible. It is only necessary to provide high-quality waterproofing, which excludes the possibility of leakage of the solution into the premises of the lower floor (or into the basement, basement). The best option is to lay a sealed polyethylene sheet with a twist of the edges on the walls.