Electric underfloor heating is a convenient and efficient option for heating your home. At the same time, it has a lot of specific features that require taking into account all the working properties of the structures and materials used. Particular attention should be paid to the quality of the flooring.

If you plan to lay linoleum, you need to analyze the conditions of its work and select only the appropriate materials. Appropriate marking must be present, the structure and composition of linoleum are selected based on the mode and characteristics of the heating element. Let's consider this question more carefully.

Content

What is electric floor heating

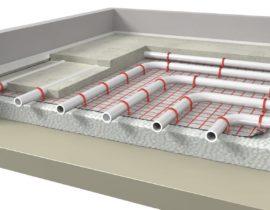

An electric underfloor heating is a heating element that is evenly distributed over the entire area of the room. It can be used as the main source of heating, or as an additional element used to increase comfort. In terms of design, electric floor heating available in two versions:

heating cable

infrared film underfloor heating

The heating cable can be purchased in a roll and laid on the floor yourself.There are other options - for example, heating mats. They are the same cable, but already attached to the supporting structure (fiberglass), rolled up. For installation, you just need to deploy it along the length of the room (the required number of strips is used). Film floor heating is laid in the same way, but with some features.

Both options are united only by the need to connect to the power supply network. The heating cable is one of the options for the implementation of a heating element, a spiral or other varieties of similar elements. When the power supply is connected, the cable heats up and gives off thermal energy to the environment. Infrared floor heating does not produce heat energy. It emits infrared (thermal) rays, from contact with which all surfaces in contact are heated. This is the floor, furniture, partially walls, etc.

Both options are united only by the need to connect to the power supply network. The heating cable is one of the options for the implementation of a heating element, a spiral or other varieties of similar elements. When the power supply is connected, the cable heats up and gives off thermal energy to the environment. Infrared floor heating does not produce heat energy. It emits infrared (thermal) rays, from contact with which all surfaces in contact are heated. This is the floor, furniture, partially walls, etc.

The use of a heating cable is considered to be a more powerful and efficient, but also a more costly heating option. If electricity tariffs are high in the region, the bills for the used resources will be quite significant. However, the power consumption of infrared warm is noticeably higher. If the film heater consumes 220 W/m2, and the cable - 80-150 W /2, the comparison becomes obvious.

However, there is one peculiarity here. The heating cable (or heating mat) can be installed in two ways:

lay on the subfloor and fill with a layer of screed, on which the finish coat is laid

lay on the subfloor, cover with a rigid sheet cloth (plywood, OSB, chipboard, etc.) and lay the top coat

In the first case, the heat transfer from the heating cable will be maximum, which will allow using a gentle heating mode. The power consumption will not be too great. In the second case, the web of sheet materials will play the role of a heat insulator that cuts off thermal energy. You will have to increase the load on the heating cable, which will lead to increased energy consumption.

Infrared film underfloor heating is laid directly under the floor covering, without an intermediate sheet of sheet materials. In addition, the film sheet is not laid under sofas, cabinet furniture - this causes overheating and failure. Therefore, the number of radiating elements is much less, and the work efficiency is noticeably higher. This makes the mode of operation more economical.

Which underfloor heating option to choose

What to look for when choosing

Choosing the right type of heater is a responsible and difficult task. You have to decide what type of underfloor heating to purchase and how to lay it. The heating cable (or mats) laid in the screed is the most efficient. However, this option is not always suitable. For example, in apartment buildings, pouring a screed can cause serious problems with neighbors - leaks are possible that can spoil expensive repairs in an apartment on the floor below.

In addition, it must be taken into account that laying a heating cable can increase the level of the floor. As a result, a "step" will appear - a difference in the level of different rooms. Regardless of how the installation is done - in a screed or under a rigid sheet of sheet materials, the floor level increases slightly.

In addition, it must be taken into account that laying a heating cable can increase the level of the floor. As a result, a "step" will appear - a difference in the level of different rooms. Regardless of how the installation is done - in a screed or under a rigid sheet of sheet materials, the floor level increases slightly.

However, if you choose an infrared film floor, no changes will occur.The film is laid directly under the linoleum, and the floor level remains the same.

If the installation is carried out during the initial construction, it is more correct to prefer a heating cable laid in a screed. If laying is carried out in an operated room, it is more correct to reduce the duration of work and purchase a film infrared heat-insulated floor.

Choosing linoleum

Most users choose linoleum for its appearance. It is difficult to argue with this, since the appearance of the coating is very important, it largely determines the style and overall quality of the room design.

However, for laying on a warm floor, you must choose the right grade of linoleum. There are three categories of material:

domestic

semi-commercial

commercial

All types of linoleum are divided into two groups:

- homogeneous material. This is a single-layer linoleum, which is a homogeneous canvas;

- heterogeneous linoleum. It is a multilayer material consisting of a base, substrate, base layer, outer coating.

Homogeneous linoleum is thinner than heterogeneous. In addition, it has a high thermal conductivity, which is of great importance for working with underfloor heating.

Experts recommend choosing a homogeneous linoleum, since multilayer materials are too dependent on temperature and may begin to delaminate.

In addition, there are varieties made from natural materials or from polymers (PVC). Natural linoleum is called marmoleum, only the original components of natural origin are involved in its manufacture:

- jute base;

- resin;

- wood flour;

- limestone;

- linseed oil.

Artificial linoleum is made of PVC with the addition of plasticizers and various compensators (for example, to protect against thermal expansion or change the linear dimensions of the canvas).

There are other varieties:

alkyd or glyptal linoleum

nitrocellulose, or colloxin. Thin material without base. It has high working qualities, but is highly combustible;

rubber linoleum (relin). Double layer material. It does not tolerate heat well, it is used mainly in public or office buildings.

Not all varieties of linoleum are suitable for laying on a warm floor. Experts recommend choosing a homogeneous (baseless) linoleum with a thickness of 2-3 mm. At the same time, marmoleum is considered one of the best options, although it has a jute base.

In addition, it is necessary to choose specialized brands of linoleum. They must have a base with antistatic treatment. In addition, the material must maintain working qualities when heated, not dry out, crack or change color. Linoleum, designed to work in conjunction with electric types of underfloor heating, has a special marking on the reverse side - the underfloor heating icon (a snake with arrows). If there is no such designation, the buyer runs the risk of soon getting considerable problems with the flooring.

Mounting order

Underfloor heating can be installed in three different ways. Since any option can be used under linoleum, it will be useful to consider all methods:

Laying the heating cable in the screed

Laying the heating cable in the screed

This laying option requires cleaning the subfloor to concrete.It is not recommended to pour a screed on a wooden floor, as there is an extra load and the possibility of leaks.

Procedure:

- subfloor preparation. Remove wood flooring or old flooring. Clean the surface of all foreign objects - brackets, supports, screws and other hardware;

- heat insulator installation. Penoplex or polymer heat insulator is used. You should not choose a layer of large thickness, otherwise the screed may crack under load;

- a fiberglass mesh is laid on the heat insulator. It is fastened with staples;

- a heating cable is attached to the grid with nylon clamps. If mats are used, the previous paragraph is not needed, the rolls are simply unwound over the area of \u200b\u200bthe room;

- a layer of screed is poured onto the heating cable. There must be at least 30 mm of solution above the cable surface;

- when the screed hardens (the exposure time must be found on the packaging of the dry mix), a substrate is placed on the surface and linoleum is laid.

Sometimes linoleum is placed directly on the screed so as not to cut off thermal energy from the coating.

The procedure for laying a warm floor under a hard sheet flooring

A layer of heat insulator is laid on the surface of the subfloor

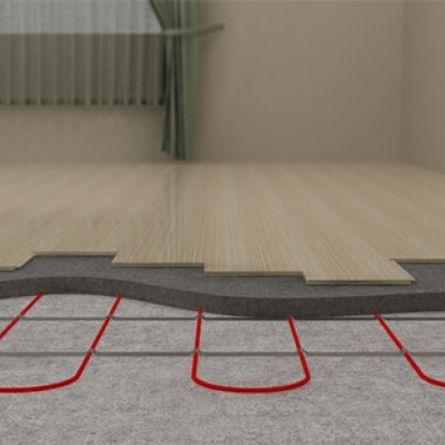

Laying a warm floor without a screed is much faster, since for this there is no need to wait for the mortar layer to dry.

Procedure:

- a layer of heat insulator is laid on the surface of the subfloor. If there is a wooden deck, you can use it as a base for the heating cable;

- dividing strips are laid on the heat insulator. They perform a dual role -

separate the coils of the heating cable, and at the same time serve as supports for the sheet material; - a heating cable is laid between the slats.If heating mats are used, they are unwound directly onto the heat insulator (or wooden base), and the strips are fixed between the cable zigzags;

- a hard coating of plywood, OSB or chipboard is laid on top of the cable;

- linoleum is laid on the floor.

This option requires a greater load on the heating element, since the rigid sheet layer cuts off thermal energy. However, linoleum here is in milder conditions and can maintain working qualities for a long time.

Underfloor heating film installation

Laying a layer of polymer heat insulator with a reflective surface

Laying a film under linoleum can be done quickly, in almost one day.

Procedure:

- subfloor preparation. It is necessary to remove nails and screws, foreign objects;

- laying a layer of polymer heat insulator with a reflective surface. It is not recommended to choose foil materials, as they conduct electricity;

- a warm floor film is laid on the heat insulator. Pieces of the required length are cut from the roll, selected so that there are no emitters under sofas, cabinets and other pieces of furniture;

- a substrate is placed on the film (the best option is isolon (substrate for laminate);

- linoleum is being laid.

To lay the wires in the heat insulator, recesses are cut out. In general, the installation is quite simple and easy to do by hand.

Frequently asked Questions

This is the recommended option. However, sometimes, when laying heating mats, a thin layer of tile adhesive is used instead of a thick screed. It only hides the mats without creating a thick surface layer.However, this option requires skill from the master - it is very difficult to provide a flat horizontal surface with this technique.

Here it is necessary to be guided by the permissible load on the electrical network (wiring condition), as well as the needs of the room. Most often, the cable is chosen to create the main heating circuit, and the infrared film is chosen for comfortable floor heating.

Yes, it's a must. Otherwise, the linoleum will not be laid on a flat and solid base, but on dividing strips with 2-centimeter gaps (or more), which is unacceptable.

In the manufacture of a dry screed, a sheet covering of plywood, chipboard, OSB, etc. is laid on top of the backfill layer. Under such conditions, it will be difficult to transfer heat to linoleum. You will have to increase the heating power, which will cause an overrun of electricity. therefore, dry screed is not recommended here.

Basically, you can. if the old coating is strong enough, without breaks or holes, you can use it as a heat insulator.