The film floor is distinguished by a whole set of positive consumer and technical qualities. It forms a favorable temperature background, is easy to install, and works with almost all coatings. You can arrange an infrared warm floor under linoleum yourself, just study the rules and some of the nuances of installation.

Content

Why IR film is the best warm floor under linoleum

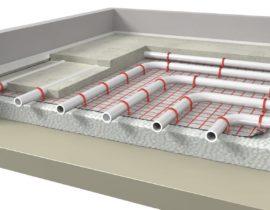

The warm floor is divided into 2 groups: water and electric, one of the varieties of which is infrared film. The name "film" material received because of its appearance. This is a two-layer polymer film, in which carbon heating elements with a unique nano-structure are mounted. They emit infrared radiation that heats the surrounding surfaces.

The heating elements look like black strips 15 mm wide connected by contact copper and silver bars. The structure is additionally protected from damage by a layer of polymer. The system has a number of advantages:

- The film works in a temperature range favorable for linoleum, therefore, it is the IR warm floor that is considered the perfect choice for mounting under this type of coating. The optimal power for linoleum is about 150 - 230 watts per square. The infrared film provides these parameters. When mounting other options, there is a risk of overheating. Even if its consequences are not immediately obvious, over time they will manifest themselves as deformation, softening, swelling.

- The film can be laid in rooms with a non-standard layout, on the balconies, loggias. Its small thickness makes it possible to use in buildings with low ceilings.

- The installation process is simple, since "wet" work on pouring the screed is not required. The system provides uniform heating of the room, is perfectly amenable to automatic adjustment and can be integrated into a "smart home" type system.

- IR warm floor has a long service life. Most manufacturers give a guarantee for effective operation for 15 to 20 years.

A significant positive point is the easy dismantling of the system. If necessary, it is enough to remove the flooring and lay the film on a new base or in another room. Electricity consumption when using film systems is 30% less than when using an electric heating cable on a similar area.

Cons of IR underfloor heating

Connecting the system with your own hands without basic skills is difficult

There are relatively few disadvantages of the system:

- After laying the film, you can not rearrange the room.Bulky furniture and household appliances should not be installed at the locations of the heating surfaces - this can lead to overheating of the film and its failure.

- It is difficult to lay and connect the system with your own hands without basic skills. It is not always possible for a non-professional to connect a contact to a film. It has to be cut and connected to another contact.

- Laying a warm floor under linoleum on a concrete floor with defects leads to its deformation. Therefore, sometimes a new screed is still necessary.

- The need to install thermostats in each room.

- If infrared heating is used as an auxiliary to stationary, the level of humidity in the room may be too low.

Criteria for choosing linoleum for a film floor

The question of choosing linoleum for laying on a warm floor must be approached with all responsibility. Materials that do not meet the requirements react poorly to heating: they deform and emit harmful substances.

The following types cannot be used in tandem with an IR film floor:

alkyd or glyptal

nitrocellulose (coloxylin)

rubber (relin)

To achieve the optimal result of heating the room and not harm your health, choose vinyl (PVC) or natural (marmoleum) linoleum. These materials have important characteristics:

PVC linoleum.

Not dangerous, suitable for residential premises. When buying, study the labeling of the material: there should be a mark on the packaging that the coating is intended for installation on underfloor heating systems. Ordinary linoleum can be equipped with an additional layer of heat-insulating material, which is completely unnecessary over a warm floor. This option is not worth buying.

Marmoleum (natural linoleum).

The best option for installing underfloor heating. The composition of the material includes only natural components. When heated, this linoleum releases harmful substances, does not change color over time, and effectively resists fire. Marmoleum has the only drawback - a high price. But its durability and safety fully justify the cost.

Marmoleum is sensitive to strong heat, so the choice of temperature for such a coating has to be approached very responsibly. However, this is also true for PVC materials.

Stages and laying technology

Installation of the infrared floor system not complicated, but requires attention and has certain features. Work is carried out using the power supply system at home, therefore errors are not allowed.

Tools and materials

Set of infrared film underfloor heating

To install a warm infrared floor under linoleum, you need to prepare:

- heating kit: infrared cloth, insulator, contact clamps;

- temperature sensor and thermostat, hollow corrugated tube;

- wiring;

- double sided tape;

- polyethylene film;

- plywood sheets;

- heat-reflecting substrate;

- nails;

- knife, scissors;

- pliers, pincers;

- screwdriver;

- wall punching tools.

To fix the material, you can use a construction stapler or furniture nails. if a large number of small pieces of film (up to 1 m) are planned, additional terminals are purchased.

Layout of the premises and preparation of the base

The film must be placed along the entire length of the room

Before starting laying, they draw a plan of the room and mark the places where stationary pieces of furniture or large household appliances will be installed, tightly fitting to the floor. It is not advisable to lay infrared film in these areas. When planning, consider the following points:

- The film must be placed along the entire length of the room. This will avoid a large number of connection points for mounting wires.

- If there is electrical wiring inside the floor, it should be at a distance of about 50 mm from the IR film and insulated from the floor or wiring with heat-insulating material.

- Between heat sources (pipes, ovens, fireplace) and the film must be a distance of at least 200 mm.

- The base for the IR underfloor heating must be clean and even. Often it is enough to make a small repair of the surface. But if there are significant irregularities, it is necessary to fill in a fresh concrete screed.

- A layer of heat-insulating material is placed on the prepared base. If it is a rolled material, the strips are laid end-to-end and the joints are fastened with adhesive tape. The heater must lie very evenly.

Film cutting

The film is cut in lines along the heating strips every 250 mm

After drawing up a plan for laying the film, they begin to prepare it. The procedure is as follows:

- The film is cut in lines along the heating strips every 250 mm. It is forbidden to cut along any other trajectories! Otherwise, the warm floor will not work.

- Contact clamps are installed on the finished heating elements. In places where current-carrying copper strips and a two-layer film pass, the wire tip is installed on the contact strip inside the thermal film.Then an eyelet is inserted into the hole, it is riveted with a special stapler or hammer.

- The cutting lines of the contact strip are insulated on both sides with a waterproofing strip. Protected copper wires with a cross section of 1.5 square meters. mm is brought to the tip and clamped with pliers. After that, the junction of the copper bus and the electric wire with a lug on both sides is insulated with a waterproofing strip.

IR film can be laid along or across the room. Optimal placement of strips lengthwise. In this case, the number of connection points will be minimal.

Laying and connecting the film

Parts of the heating film are connected in parallel to each other

After cutting the film, thermal insulation with a reflective layer is laid and fixed with adhesive tape. Heating elements are laid down on the thermal insulation with copper strips down. They should be positioned so as to avoid contact between adjacent strips! Rules and order of laying:

- Heating elements are fixed with adhesive tape, a stapler or furniture nails. This will minimize the chance of strips shifting during paving. The heating elements should be attached through a transparent rim located on the sides of the element.

- The heating element must be located 5 mm from any supply section of the element that includes copper busbars. The wires are arranged so that the main ones are under the plinth. In places where the contact strips are isolated and there is a thickening of the system, cuts are made in the thermal insulation to level the surface for the final coating.

- Parts of the heating film are connected in parallel to each other.The highest total power of the heating elements that are connected to the thermostat should not exceed 3500 W. At the time of connecting the heating system, it is imperative to take into account the presence of other electrical appliances that will be connected to this network.

- If the total power of the heating system is more than 3500 W, it is advisable to connect it using a separate electrical wiring protected by a separate auto switch. Connection of heating devices should be carried out using a magnetic starter.

- After laying, you need to inspect the system, check the reliability of the insulation and fastening of the wires. Then it is necessary to measure the resistance of the heating strips. If there are sources of a possible short circuit in the system, they should be eliminated and the performance test repeated.

- Under the cut line, where there is no heated section of the film, a temperature sensor is attached with adhesive tape. It is placed under the film and connected to the thermostat with wires. Heating elements and a sensor are attached to the thermostat.

- The thermostat itself is hung on the wall in an easily accessible place. Its connection must be made in accordance with the diagram. Those inexperienced in electrics should consult a specialist. Temperature sensors Then you need to turn on the thermostat and leave it for a few minutes.

- To hide the cable leading from the thermostat, you can make a strobe in the wall. If the repair is already completed, the cable is placed on top of the wall and covered with a decorative plastic box. At the bottom, a plinth is used to mask the cable. The edges of the cable that provides power are attached using connectors and pressed with pliers.

- The final test is to check the degree of heating of the film. Rest your hand on the heating element: the warm floor under the linoleum should emit heat at a pleasant temperature.

- In conclusion, the infrared film is covered with a vapor barrier material, the joints are fixed with adhesive tape.

Sheets of fiberboard or plywood are laid on the vapor barrier. They are fastened with screws through a transparent rim located along the cut lines of the IR film and the sides of the element. The element should not be attached closer than 5 mm from the feeding sections of the elements. The finished warm floor is covered with linoleum.

Possible mistakes

The film floor should evenly warm up. If there is no heat or some areas are colder or hotter than others, then the installation was not done correctly. Possible errors should be found and eliminated. Problems usually arise with the following violations:

- Overlapping film strips. This position of the heating material is unacceptable.

- Cut film too close to copper bar. This may cause insulation failure. Complete or partial lack of insulation is one of the most common causes of underfloor heating malfunction.

- Using mastics to fix linoleum. All these compounds are sources of harmful compounds. In addition, during uneven heating, they will form swelling on the surface. Removing such defects is difficult, and often impossible.

Questions

This will cause negative consequences. Due to more intense heating, linoleum can become vulnerable to tearing and soft, it will begin to move away from the base and expand.The most dangerous thing is that in places where the thermal film is laid, the release of harmful substances in fairly large volumes will begin.

Can. But you need to take into account their total power: it should not exceed the power for which the regulator is designed (3-3.2 kW). It is also worth understanding that only one floor temperature sensor comes out of the regulator. If the rooms are very different from each other in heat loss, then the same temperature cannot be achieved. Therefore, such a connection is recommended to be used exclusively for large areas in one room, or adjacent ones, without a door partition.

It is forbidden. They have different performance characteristics that require individual adjustment.

Paul works correctly. It is the temperature of + 28 degrees that guarantees the energy efficiency of the infrared floor. If you select a higher temperature, the energy efficiency will become negligible. If you think the floor isn't warm enough, test it with your hand to make sure it's warming up properly. Linoleum surface should not be hot. If you want to get hot air in the house, you should think about additional heating on the walls and ceiling. But in any case, it is the warm floor that will help you achieve the recommended performance.

Useful video