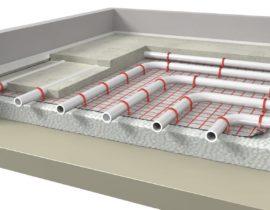

The device of a warm water floor requires compliance with the installation rules and the use of specific materials with special performance characteristics. It is advisable to use special mats as thermal insulation and the basis for pipes. The technology and features of their installation depend on the specific variety.

Content

Appointment of mats for underfloor heating

Mats for water floor heating

Laying heating elements of any type of underfloor heating requires the use of an insulating substrate. Its use makes the system efficient and economical at the same time.

Mats for a water-heated floor perform several important functions at once:

- The special embossed design and applied marking facilitates the correct layout of the heating elements and their secure fixation in a predetermined position.

- Many types of mats have soundproofing properties. The level of noise absorption for a layer of 2 cm is 23 dB.

- Mats are produced with film waterproofing layers that prevent flooding of the lower floors in case of pipe leaks.

- The main function is thermal insulation.Mats direct heat flows upwards, preventing significant heat loss and reducing energy costs.

- Mats withstand and extinguish significant loads, including dynamic (when residents walk on the floor), the severity of the screed and the heating circuit with hot water, the mass of the finish coating.

Types and features

Several types of mats are produced, differing in material, method of fixing pipes, and intended for specific types of premises. Each has some advantages and disadvantages.

foil

They are made of foamed polymers (polyethylene, penofol), covered with a layer of foil on one side. They are necessarily covered with a foil part outward, and pipes for the coolant are laid out on this surface. Cloths of such insulation are laid out end-to-end. To ensure the integrity of the created reflective and waterproofing surface, it is recommended to glue the joints with waterproof foil tape.

The use of such mats for laying a water floor is not the best solution. It is possible to use such a substrate only if the base of the floor already has a sufficient level of thermal insulation, and the warm floor is considered as an addition to the main heating system.

Foil mats are absolutely not applicable on the first floors, under which basements or basements are located. They are also ineffective. with private single storey building.

A significant disadvantage of laying pipes on top of foil mats is the need to use special additional fasteners: metal mesh, “combs”.

Thin mats made of extruded polystyrene

The use of such mats allows you to mount a warm floor, which can become the main source of heating. Flat mats made of extruded polystyrene (EPS) with a thickness of 40 ÷ 50 mm with a foil coating are quite applicable for a water heated floor, but with some reservations. The high density of PPS is important - about 40 kg/m3. This material does not have hydroprotection, so it will be necessary to cover it with plastic wrap before laying pipes.

A slight inconvenience on some mats of this class is the lack of marking lines. They will have to be applied on their own. At the same time, the fastening of pipes is carried out very simply - with the help of special brackets.

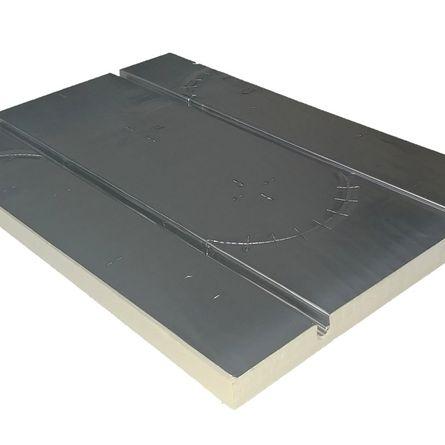

Coated XPS mats

More perfect, in comparison with the previous view. XPS mats are made of high strength material. In addition to the foil layer, they have a film coating with a marked grid, which greatly simplifies the process of laying pipes in accordance with a pre-drawn scheme. Such mats, while retaining all the advantages of polystyrene foam boards, are a complete construction - the foil and film layer applied to them eliminates the need to lay a "penofol" type substrate on top.

These mats are easy to install. They roll on the floor like a tractor caterpillar, turning into a dense monolithic surface without gaps. To pair adjacent rows, special grooves are provided - lamellas. Fastening of EPPS pipes to mats is carried out using brackets or "combs".

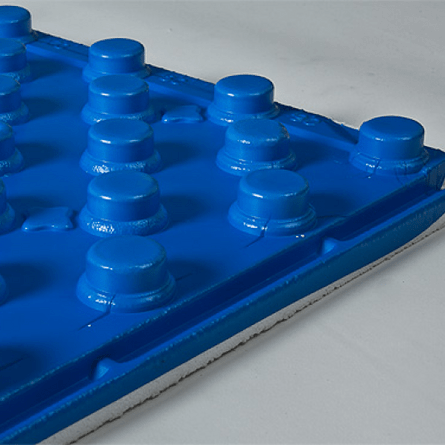

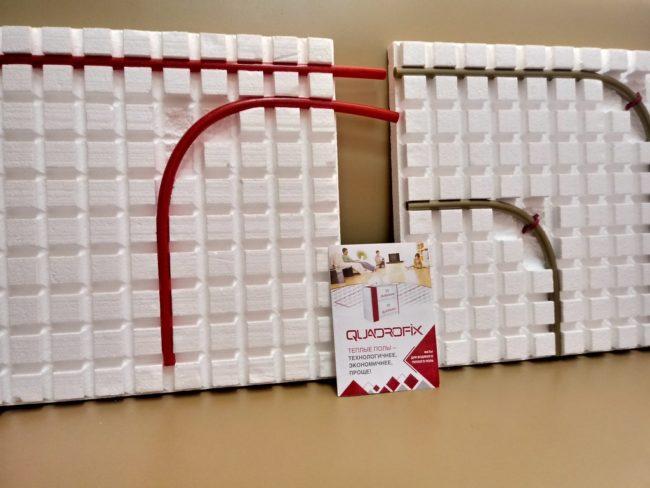

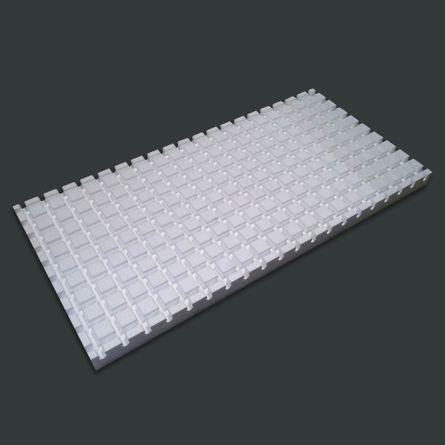

Expanded polystyrene profile (with bosses)

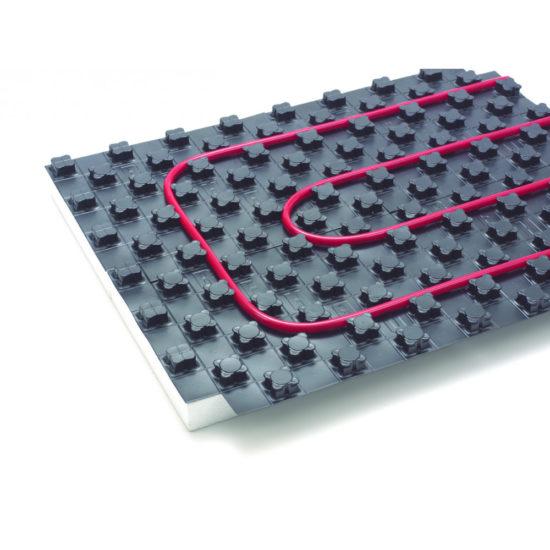

This is the most convenient option in terms of laying pipes for a water-heated floor. Expanded polystyrene profile mats are made using stamping technology, which allows them to be given a complex configuration.On their upper surface there are figured protrusions-bosses of various shapes (rectangular, cylindrical, triangular) with a height of 20 to 25 mm. Heating pipes are tightly laid into the grooves formed between the bosses, obtaining excellent fixation, which completely excludes the displacement of pipes during pouring of the screed.

Such mats have many advantages:

- The density of the expanded polystyrene used in their manufacture is 40 kg / m3, which allows them to easily withstand all mechanical loads.

- The thermal conductivity of the material is low. They perfectly retain heat, preventing unnecessary heating of interfloor ceilings or a flooded subfloor.

- The physical characteristics and complex cellular configuration of the mats make them excellent sound absorbers - the room receives additional sound insulation.

- A special system of end centering mat locks allows you to assemble the mats into a solid surface, without gaps at the joints that can pass moisture.

- The placement of the protrusions allows you to strictly maintain the pipe laying step - from 50 mm or more, with a distance that is a multiple of 50.

On sale there are cheaper foam polystyrene mats with bosses without a laminating film coating. But it is better to opt for coated mats. They are a little more expensive, but more reliable, since they also serve as a waterproofing layer.

Advantages and disadvantages

Advantages and disadvantages of using mats

The use of mats as a heat-insulating substrate provides the following advantages:

- Compliance with fire safety standards, when ignited, they self-extinguish.

- Non-toxic and environmentally friendly.

- Elasticity - shape retention throughout the entire service life;

- resistance to temperature fluctuations when turning on and off the warm floor (from +180 to -180 degrees);

- Chemical inertness, resistance to bacteria, decay, oxidation.

- Water repellency. The mats will prevent water from leaking to the lower floors in the event of a pipe rupture.

- Ease of installation. The presence of additional fastening sections, where underfloor heating pipes are placed, facilitates the process of their laying. Installation of the pipeline according to any chosen scheme does not take much time.

- Due to the presence of mounting markings on mats for a warm water floor, the efficiency of heat distribution in the room increases.

- long service life.

The only drawback of quality mats is the high cost. But if we take into account the entire "budget" of a warm floor, it is very acceptable, since the costs will fully justify themselves in the near future with significant savings when paying energy bills.

Expanded polystyrene mats for a warm water floor with bosses reduce the noise level in the room up to 25 dB.

Criterias of choice

What to look for when choosing

When choosing mats, first of all, you need to verify the authenticity of the material. The construction market is saturated with various fakes, and with strict requirements for the properties and functions of heat insulators, an error in this matter will be very expensive. Therefore, do not neglect the verification of certificates of conformity and safety, as well as the availability of a guarantee for the product.

In order not to make a mistake when choosing a suitable option, you should pay attention to:

- level of waterproofing;

- the ability of a particular model to withstand static and dynamic loads;

- pipe diameter suitable for laying on a given view;

- requirements for the room in which the installation work will be performed.

The double lock at mats reduces heat losses and increases durability of connection. Installation of such material is very easy and fast without much difficulty.

There are also a number of additional options:

- Thickness. When choosing a material, take into account the height of the screed layer and the decorative coating. In rooms with already installed insulation, you can take a material of small thickness.

- If there is a choice, without any doubt, mats with a foil or laminating top layer should be preferred. This will immediately solve the issue of waterproofing before pouring the screed, and in addition, it will increase the efficiency of the floor heating system.

- Pay attention to the compliance of the mat parameters with the planned diameter of the pipes of the circuit and the step of its laying - mismatches are not excluded here.

- Consider the area of \u200b\u200bthe room in which the pipes are planned to be laid. If the area is large, then it is worth giving preference to the material with "bosses".

Overview of the best brands and manufacturers

Which brands are trustworthy

Quality products are offered by many domestic and foreign manufacturers. According to experts and buyers, products manufactured under trademarks deserve special attention:

- Oventrop;

- Rehau;

- Energoflex;

- Ecopol.

The following brands of mats are in greatest demand among buyers:

Knauf Therm PRO

Designed for laying the water circuit with a step of 50 mm. The bosses of the material have special protrusions and securely fix heating pipes with a diameter of 14 - 17 mm. Additional rigidity is provided by a rigid polystyrene film covering the mats. Marking is applied on both sides of the plates. Locks are located around the perimeter.On the reverse side of the plates there is a soundproof surface. Material thickness - 45 mm. Base 25 mm. The size of the plates is 1.2 × 0.6 m.

Varionova REHAU

The price of these mats is slightly higher than that of analogues offered by other manufacturers. This is due to the design features of the model and high quality. The material has high strength, can withstand a significant load. On top is a black polystyrene film that provides the necessary level of waterproofing. Marking is on the reverse side. The step of laying pipes with a diameter of 14 - 17 mm is 5 cm. The height of the mat is 24 mm.

Foam board WF16-50

Proposal from a domestic manufacturer. It is intended for the device of a water floor with pipes with a diameter of 16 mm. The plates have a dense base with a thickness of 30 mm, which provides the necessary level of thermal protection. Mounting openings are arranged in 50 mm increments. The size of the plates is 100×100×5 cm.

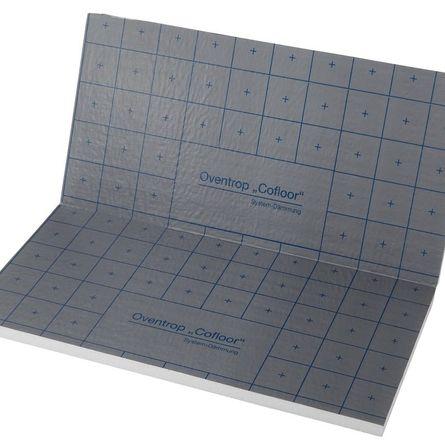

NP-35 by Oventrop

Mats recommended for the installation of self-leveling floors and for the arrangement of a concrete screed. They have increased heat and sound insulation.

WLG-045

Plates of roll type covered with polypropylene film. Applicable for pipes with a diameter of 1.4 and 1.6 cm, as well as for a laying step within 5-30 centimeters. The area of one roll is 10 sq/m.

Energoflex Super TP

Roll mats for warm water floor. Foiled, a coordination grid is applied with a step of 5 centimeters. Roll dimensions - 0.5x120x150 cm.

Laying technology

Technology and styling features

The sequence of actions for laying mats for underfloor heating directly depends on the type of insulation used.

When laying any kind, you must comply with the general requirements:

- Waterproofing is necessarily arranged under the mats.This can be a film coating of the surface of the subfloor, insulation of a coating or penetrating type. It is important to exclude capillary penetration of moisture from below, and also to create a barrier that will not allow leakage down if the integrity of the circuit pipe is suddenly broken.

- A damper tape must be glued around the entire perimeter of the room and at deformation gaps.

- The mats are laid on a waterproofed surface and fastened together with locking joints (if they are provided for by the design).

- Thin and light mats require fixing to the floor. This can be done using glue. But it is strictly forbidden to use metal fasteners for this - both the waterproofing of the floor and the strength characteristics of the mat will suffer.

- If flat mats (slabs) are used that do not have locking joints, it is also advisable to glue them to the floor surface. The joints between the sheets must be glued on top with waterproof tape.

- Lay the first mat so that the two sides, on which there are no locks, adjoin the wall. Accordingly, subsequent mats will be nested with their locks on top of the nearby mat. If trimming is required, then we can use the markings on the back, which is also duplicated on the outside.

- When laying, make sure that the mats are pressed against the damper tape. If there is no such technical possibility due to wall irregularities or irregularly shaped corners, it is ideal to fill the distance with some material, for example, mounting foam, that is, one that can fill these seams. This will avoid the spreading of "milk" when pouring concrete.

- The damper tape should be made of soft materials. It can be polystyrene foam or polystyrene.Ideally, there should be no extruded materials, because then in the process of expansion, after heating, the screed will not have the opportunity to expand somewhere, it will simply come to a standstill.

- The further course of laying the mats is in a run, as this will ensure the strength of the structure.

Pipe laying: rules and nuances

Pipe laying features

It is possible to proceed to the laying of underfloor heating pipes only after the entire surface of the room has been completely covered with mats. The pipe can be laid using two methods: a snail or a snake.

A more effective method is a snail, since we twist the pipe during the laying process, and due to this, heat is evenly distributed. With such scheme laying there is no temperature difference between the flow and return lines. If you use the snake method, first the coolant enters the supply line and, in the process of circulating the coolant, it also gives off this heat, and the cooled coolant remains on the return, and if it is in some room, then there may be underheating.

Once the underfloor heating pipe is completely laid, no additional fixation is required. The bosses are shaped with a reverse angle, so one anchor bracket can be enough for 50 meters of pipe.

The final stage of laying is testing: pressure testing of the system. It can be done both hydraulically and pneumatically. In the first case, we pump with water, in the second - with air. Optimum hydraulic tests.

Next, you can proceed to the arrangement of the screed after setting up the beacons and relevant preparations, namely ensuring construction readiness. The pipe is left under pressure and filled with a solution.

A warm floor on mats with bosses can be laid in steps of 200. However, there is an opinion that a step of 150 is optimal.It is rather a myth, since the truth is revealed only thanks to thermal engineering calculation. To achieve the desired heat transfer coefficient at a step of 200, it is enough to increase the coolant temperature by 3 degrees, while you can significantly save on the pipe. The difference between winding with a step of 150 and a step of 200 is approximately 1 p. / m X 1 sq. / m. So you can save up to 20% of the pipe.

Frequently asked Questions

Expanded polystyrene becomes harmful only when heated to temperatures above 100 degrees. This is why PS or XPS food pads must not be heated in the microwave. In the system - a warm water floor - the water heats up no more than 80 C. Therefore, at this temperature, the mats do not emit anything.

No. The base under the tile in this case will be unstable. For laying without screed, dry polystyrene systems with heat-distributing aluminum plates or with foil elements are used.

No one will guarantee that the mats will be pressed down to the base, and if they do not press down immediately - after applying loads, the screed laid above may collapse. Attaching umbrellas is not the best way out. It is more correct to level the base so that there are no significant voids between the base and the mats, even if the solution can be added immediately before laying the mats.