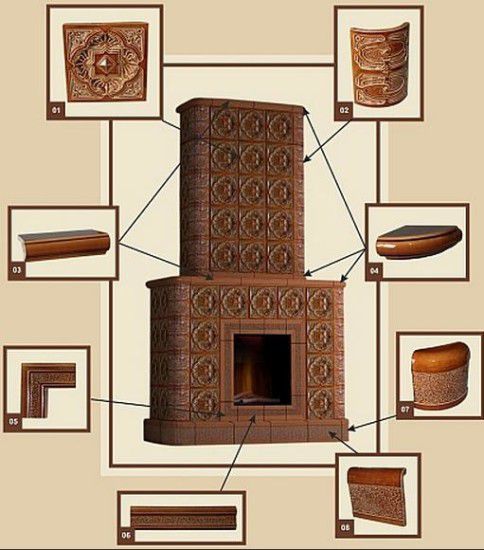

A fireplace with an open fire is a great addition to the interior of any country house. It will become the center of gravity, not only of a particular room, but of the entire home. There are many ways to arrange and build fireplaces. They can be free-standing metal, corner or portal. A portal fireplace is a capital structure built from refractory bricks. However, the brick surface itself does not have good aesthetic qualities, so it is customary to decorate brick portal fireplaces with decorative trim. The easiest way may be painting and plastering, but this will not greatly increase the aesthetic appeal. There is a way to decorate the fireplace, which will attract your views and the views of your guests no worse than the open fire itself, these are the so-called tiles. If you haven’t heard about tiles yet, look at the photo below and you will immediately understand what it is.

Content

What are tiles?

Tiles are ceramic tiles, on the surface of which a pattern is applied in a special way. A decorative coating made using this technology has long been used to decorate heating appliances.Multi-colored tiles were invented in ancient Persia and still delight the human eye. Of particular value are the products of the 18th century, which still retain their appearance, despite many centuries of use.

What are tiles made from?

There is a fairly large variety of ceramic tiles. The starting material - baked clay allows you to make these products of any shape, as a result of which they can cover almost any surface. Flat tiles are laid out on vertical and horizontal surfaces. In addition, there are corner tiles, and if you try, you can find products on sale whose flat surfaces are combined at the most bizarre angle. And finally, there are options that in themselves are decorative cladding elements of a very bizarre shape - from intricate cornices to the most diverse “trinkets” in shape.

You can pick up a set of tiles for facing the fireplace, even the most bizarre shape, and vice versa, decorate the dull rectangle of a brick fireplace portal with decorative elements of a strictly Baroque style.

Also, the tiles may differ in the texture of the front surface. These can be smooth tiles that are slippery to the touch, they can be corrugated tiles or bricks with an embossed geometric pattern.

Tiles also differ in the way they are treated. You can purchase majolica tiles, the surface of which is covered with a smooth glaze. You can decorate the fireplace portal with terracotta tiles, the surface of which resembles rough uncoated earthenware.Naturally, for any type of surface, a pattern can be applied on the front side of a tile, which can also be performed in many variations: from a strictly geometric pattern to an intricate photorealistic painting.

The only visible difference between the tiles and the well-known ceramic tiles is located on the reverse side. This is a "rump" - an open rectangular box that follows the contours of the front side. With it, the tile is attached to the fireplace or stove surface. The ramp is designed to compensate for the solid heating of the furnace surface, which cannot withstand the method of fixing ordinary ceramic tiles. Inside the rumpa, not ordinary tile glue is applied, but a special clay-based solution, which perfectly collects heat from the stove, slowly accumulating and slowly releasing it. Thus, a classic tile not only decorates the surface of a stove or fireplace, but also significantly increases the efficiency of its work.

How to lay tiles on the surface of the stove or fireplace?

Already at the stage of designing a heating fireplace or stove, you should decide on the advisability of using tiles in its lining. The fact is that the total mass of these ceramic tiles, together with the protruding ramps and filling them with clay mortar, is quite high. Therefore, the entire plane of the fireplace or stove portal must rest on a solid foundation so as not to cause destruction of the fireplace structure. The weight of the facing material must be initially calculated when designing the foundation.

Tiles are a piece of creative product and, unlike mass-produced ceramic tiles, they are quite expensive.Therefore, for lining a stove or fireplace with tiles, you need to have professional skills that are at the intersection of the skills of a master stove-maker and a master tiler. The situation is further complicated by the fact that some rows of tiling must be laid already in the process of laying bricks in the body of the stove or fireplace. Of course, you can take up this work on your own, but before that it is better to carefully study all the subtleties of the process.

Sorting tiles

The piece production of tiles determines some inconsistency in their color and geometric shape. Therefore, even before laying, all purchased tiles must be laid out on a flat surface and sorted. The principle here is simple - the darkest products go to the lining of the lower surface of the stove or fireplace and gradually, to the top, their shade is lightened.

At the same time, it is necessary to take into account a small difference in geometric dimensions, sorting them so that approximately the same products are in the same row. Of course, tiles can also be processed, that is, they can be adjusted with a specialized cutting tool to the desired size!

The easiest way to fit the tiles is to cut them with a steel strip and then carefully grind the edges. Currently, there are specialized electromechanical devices that allow this operation to be carried out without unnecessary labor and with high accuracy.

The most accessible tool is an angle grinder, or grinder. For cutting ceramic tiles, a diamond grinding wheel is used. Professionals use portable stone-cutting machines, in which the cut is cooled by a jet of water. Such a machine allows you to make not only straight cuts, but also cut corners and even make round grooves.

How to properly fix tiles on the surface of a fireplace or stove

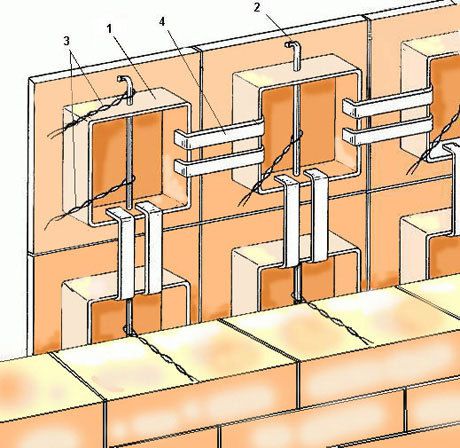

The main way to attach tiles to the surface of a fireplace or stove is to fix them with steel wire. In addition, rows of tiles arranged vertically or horizontally are fixed inside themselves with U-shaped steel brackets.

To fix the tiles, a so-called crutch is used - a piece of steel wire up to 5 millimeters long. It is inserted into a hole drilled in the brickwork of the fireplace, after which its protruding end is bent up. A special hole is usually left in the walls of the tiller of a tile, into which the protruding shank of the crutch is threaded. Another piece of wire is fixed in the middle part of the crutch. All free ends of the wire pieces are attached to the brickwork.

The U-shaped steel bracket is intended for tightening rows of tiles located vertically or horizontally. A gap of up to 3 millimeters is left between individual tiles. The protruding ends of the wire crutches of fastening fit into these slots.

Horizontally, the tiles can also be fastened together with a wire. To do this, after placing one horizontal row of tiles, adjacent crutches are connected by segments of soft wire. Twisting the wire with a hook - the master achieves contraction of the crutches. The remaining ends are also sealed into the seams between the tiles.

The tiling process

The whole complex process of facing the surface of a stove or fireplace with tiles is first done dry, without clay mortar. The laying process starts from the bottom corner. After making sure that the tiles stand up evenly, the structure is dismantled.

When installing “cleanly”, the ramp of a tile is half filled with clay mortar, mixed with the inclusion of fine gravel or fragments of bricks. At the same time, it must be remembered that the brick filler must match the coefficient of thermal expansion with the main design of the thermal device. Therefore, it is preferable to use fragments of the same bricks that were used for laying the stove or fireplace.

Crutches are then inserted into the holes of the ramp of tiles, and when the ramp is completely filled, the tile is fixed on the surface. From above, the space between the ramps of the laid horizontal row is carefully tamped with clay mortar with cog or brick filling. Additionally, horizontal brackets can be installed for temporary fixation.

Step by step - horizontal rows of tiles rise to the very top of the stove or fireplace. The ends of the twisted ends of the wire are sealed under the next horizontal row of tiles. In general, the procedure is quite complicated, but the end result will make you remember the best palace interiors - after all, stoves lined with tiles could only be found in luxurious mansions before.

Video of the process of decorating the stove with tiles