Mantel tiles, natural minerals or porcelain stoneware - the most popular and durable type of finish.

A huge selection of colors and textures of these materials allows you to make a fireplace in any style, from classic to modern. At the same time, facing the fireplace with your own hands can significantly save money not only on its decoration, but also on masonry, because the requirements for the appearance of bricks are significantly reduced.

Content

Fireplace Cladding Materials

Facing a wood or gas fireplace can only be done using fire-resistant materials and a mortar with a coefficient of thermal expansion similar to brick, otherwise the lining layer will begin to peel off and crumble over time. Most often, fireplace lining is performed using the following materials:

- Clinker or terracotta tiles made of baked clay;

- Natural or artificial stone;

- Porcelain tile.

The cladding technology depends on the chosen material, and in order to better understand which material is right for you, let's take a closer look at each type of finish.

Ceramic tiles: terracotta and clinker

Fired clay tiles are similar in composition to refractory red bricks, from which fireplaces are usually laid.Due to the similar structure and manufacturing technology, ceramic tiles expand when heated along with the material of the fireplace. The top layer of ceramic tiles can be additionally coated with glaze, which will give it water-repellent properties - such a finishing material is not afraid of either water that accidentally hits the fireplace or soot, which is easy to wash off from a smooth surface.

Ceramic tiles come in different shapes and sizes, they also produce elements for facing ledges, corners, shelves. The color range of terracotta tiles, as a rule, is close to natural materials. Laying tiles is quite simple and does not require the use of special tools, fitting and cutting is performed using a grinder with cutting and grinding wheels.

Tiles can be laid on a special heat-resistant adhesive designed for stoves and fireplaces, or on a solution of clay with sand and the addition of table salt - 100-200 grams per bucket of solution. Salt gives the solution greater plasticity, which prevents it from cracking when the fireplace is fired.

Laying and tiling technology:

- The surface of the fireplace is cleaned of old lining: whitewash, plaster, paint. The seams between the bricks are embroidered 1 cm deep, after which the dust is removed with a brush. In this case, the surface of the brick can be moistened with a spray bottle.

- If there are small irregularities and depressions, they are sealed with heat-resistant mastic or clay mortar, and then dried.

- If the quality of the brickwork is not high and the layer of mortar for laying the tiles is more than 5 mm, it is recommended that the surface of the fireplace be leveled with a grinding wheel beforehand.

- Before finishing, the fireplace must be heated for several hours at low heat so that the brick warms up evenly. Its surface should not be hot, the optimum temperature is about 30 degrees.

- Cover the masonry surface with a primer using a conventional paint brush or roller. The primer reduces dusting, provides good adhesion and uniform drying of the adhesive solution. Dry the primer for one to two hours.

- Tiles begin to be laid from below. Lay out a row of tiles in advance, selecting them according to color and texture, if necessary, trim and sand the edges. If corner elements are used, they are glued first.

- The glue is diluted according to the recommendations on the package and thoroughly mixed with a construction mixer. You can use a drill with a hard wire attachment.

- Apply the solution to the surface of the fireplace with a flat trowel, draw it over the surface of the adhesive with a notched trowel and press the tile tightly. It is more convenient to glue from three to five tiles at the same time, checking them for level and plumb. In order to have equal distances between the individual tiles, you can use plastic corners for tiles or trimmings of terracotta of the same thickness, inserting them into the seams.

- Dry the tiles at room temperature for 1-2 days, after which they proceed to grouting. As a grout, you can use special solutions or a mixture of clay with fine washed sand, as well as add various dyes to it.

- If the tile is not glazed, its surface can be treated with a heat-resistant varnish - this way it will be easier to wash off the soot and dust from the finish.

Finishing the fireplace with natural and artificial stone

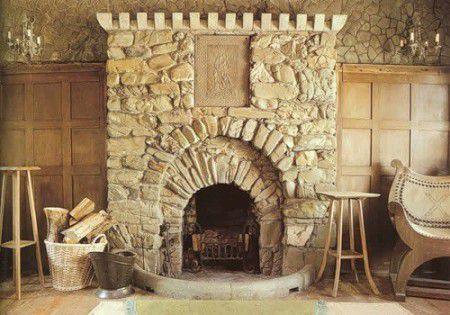

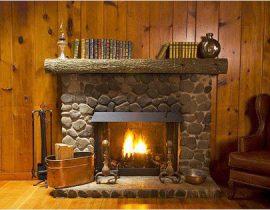

Natural stone used for facing fireplaces is an expensive pleasure, especially when it comes to marble or granite. To process these materials, special tools are required, especially for granite, which is difficult to cut and grind, as well as special skills. A simpler stone: shell rock, limestone, rubble stone, it is quite possible to use it for facing the fireplace with your own hands.

Artificial stone is a finishing material based on Portland cement, the filler in which is natural stone chips, expanded clay or other solid component. An artificial stone is obtained by vibrocasting or vibrocompression, as a result of which it is not inferior to natural stone in terms of strength and moisture resistance. Artificial stone can have a completely different texture and color, which allows you to create a unique fireplace design.

The technology of laying natural and artificial stone is almost the same. They are placed on heat-resistant glue or mastic, and especially heavy stones are additionally fixed to the anchor.

- The preparation of the fireplace surface is carried out in the same way as for terracotta tiles. The brickwork is cleaned, the seams are expanded and dust is removed, and irregularities are leveled.

- Before laying, the stone is sorted by color, with a difference in tone, a full layout is performed on a flat surface and the stones are numbered. A darker stone is better to put in the lower rows. If necessary, the stones are cut with a grinder with a circle around the stone, the cuts are polished.

- The fireplace is heated with a slow flame and its surface is cooled to 30-35 degrees. The brick is treated with a primer and dried for half an hour.

- Mix the adhesive in the specified proportion until smooth. Keep it for 10-15 minutes and mix again.

- Laying starts at the corner from the bottom row. The glue is applied with a spatula in an even layer on the stone, applied to the fireplace wall and rubbed tightly, turning and slightly shifting on the surface. Excess mortar may appear from under the stone, if they do not protrude above its surface, they do not need to be removed. The next stone is laid, leaving a seam of 2-5 mm. So they put the entire bottom row, checking it for level and plumb.

- For laying the next row, it is necessary to set the tile corners to ensure an even seam. After the glue has set, they are removed. The next rows are laid using the same technology.

- After the glue dries, the seams are filled with mortar using a construction gun. The solution between the seams is leveled with a spatula - embroidered. If you want to create a natural stone texture, the seams can be left uneven.

- It is recommended to cover the stone with a matte or glossy heat-resistant varnish - this will extend its service life and improve its appearance.

Porcelain stoneware

Porcelain stoneware is a durable finishing material with a wide variety of colors. When finishing with porcelain stoneware, you can achieve the effect of facing the fireplace with marble, granite, serpentine and other valuable types of stone. At the same time, the price of porcelain stoneware is much lower, and its processing is easier.

Facing the fireplace with porcelain stoneware is possible both on adhesive solutions and on a frame made of a metal profile.The technology of laying on glue is generally similar to facing a fireplace with terracotta tiles, so we will focus on the second option in more detail - fixing porcelain stoneware on a profile frame.

- For the manufacture of the frame, a profile for drywall is required. It is installed around the perimeter of the fireplace in such a way that porcelain tiles are joined on the profile. The frame is attached to the fireplace in several places with the help of anchor bolts, the profiles are fastened together with metal screws.

- Porcelain tiles are attached to the profiles using special brackets.

- The space between the cladding and the fireplace is filled with a thick mortar of clay, sand, fine brick gravel and water.

- The joints between the tiles are rubbed with a mixture of clay and fine-grained sand with the addition of color.

- The fireplace is heated for several days with moderate burning, during which time the clay is sintered, forming a strong “fur coat”, which significantly increases the heat capacity of the hearth.

This cladding method is good for fireplaces with a lot of chips, uneven masonry, and an extremely unattractive appearance. It allows not only to give the fireplace a new look, but also to even out all the flaws in the masonry at no extra cost.

There are other ways to finish fireplaces and stoves: plaster with subsequent painting, tiling, mosaics. Knowing the technology of finishing and facing the fireplace, you will surely choose a design to your liking.

We use plaster

If your old fireplace doesn’t look very good anymore, and there isn’t a lot of money in your pocket, you can breathe new life into it using only plaster.If your fireplace is decorative, you can use Rotband, Knauf, Fugenfuller starting putty. If you have an existing wood-burning fireplace, you need to use a special fireclay plaster solution to finish it.

First imagine what it will look like. In this case, there are a lot of options, you can create any structure from good plaster:

- under the tree;

- under a stone;

- brickwork;

- old english style.

Apply the first layer of plaster and wait until the solution has completely dried.

The second layer already needs to create the selected texture. Don't be afraid to mess it up, sometimes fancy shapes end up looking really nice, you wouldn't be able to do it even if you wanted to.

Next, you should paint the resulting structure in natural colors, it is recommended to use natural paints. You can even paint in two or three layers to achieve an uneven effect, in the end you should get something like this:

Fireplace finished with special plaster