Creating a stable room temperature may require the use of redundant air conditioning systems. They have problems with the timely connection / disconnection of backup devices. It is solved by an additional device - an air conditioner rotation unit.

Content

- Reservation and rotation of air conditioners

- Performance redundancy

- Cold redundancy

- Hot standby

- The purpose of the rotation unit of air conditioners

- The device of the rotation system of air conditioners

- Features of installation and configuration

- Questions and answers

- Video instruction for setting up the BURR-1M rotation unit

Reservation and rotation of air conditioners

In some rooms, strict requirements are imposed on the level of temperature and its stability.

Examples are:

- enterprises of chemical, food, pharmaceutical industry, production of electronic components, etc.;

- server rooms;

- scientific laboratories.

For them, a change in the microclimate parameters due to an increase in the load on the climatic equipment or when it fails becomes critical. To avoid emergency situations, climate systems are often used, including several air conditioners that are constantly in operation and additional (backup) units.

Reservation allows:

- Create a power reserve in case of an unpredictable change in the temperature of the indoor or outdoor air, which cannot be compensated by the total performance of the working units.

- Restore overall system performance when working units fail.

- Provide system power and temperature stability when stopping part of the working units for preventive maintenance.

- Simplify the scaling of the climate control system, for example, when expanding production or increasing the number of servers in the data center.

When organizing such systems, several methods of redundancy are used.

Performance redundancy

With this method, the total performance of air conditioners in the system exceeds the calculated one by 10-100%, and all devices work simultaneously. In this case, when one or several blocks fail or are taken for maintenance, the performance loss is compensated by an increase in the load on the rest. The calculation is made in such a way that the increased load does not exceed the nominal values for each unit.

The advantages of such a system are:

- High speed of response to emergencies, limited only by the speed at which the air conditioner reaches a new steady state when the room temperature or the setpoint changes.

- Uniform wear of all devices.

- Ease of organization of the system, which practically does not require additional equipment.

Cold redundancy

With cold redundancy, only a part of the system blocks are constantly in operation. The rest (reserve) are put into operation manually in case of accidents, preventive maintenance of working devices or the need to change the overall performance. Disabling "extra" devices is also performed manually.

The main advantages of such a system are simplicity and low cost of operation.

Flaws:

- The commissioning of redundant units and their shutdown takes time, during which temperature changes in the serviced premises and its level may go beyond the permissible limits.

- Each device requires individual wear monitoring and a preventive maintenance schedule.

Accordingly, such a redundancy scheme can only be used in cases where the cold reserve input rate is guaranteed to be less than the time for temperature change to critical levels.

In most cases, the processes of changing the microclimate are quite inertial, and cold backup is quite enough. However, in conditions where the volume of premises is limited, and the intensity of heat release is high (this is typical for large server companies and data centers), the reservation system should be more dynamic.

Hot standby

With hot standby:

- commissioning of reserve units is carried out automatically;

- they are in "standby" mode, receiving signals from the reference and sensors.

Such organization of the system allows to reduce the reserve output to the operating level before the start-up time of the air conditioner units (compressor and fans). At this time, the lack of productivity of failed or put out for maintenance units is easily compensated by workers.

Wherein:

- All devices in the system operate in modes close to nominal, which ensures maximum energy efficiency.

- Just uniform loading and wear of devices - rotation algorithms are used in which there are no permanent backup and working modules (each of the blocks will perform these functions alternately).

The purpose of the rotation unit of air conditioners

The air conditioner rotation unit is a multifunctional device that, in general, performs:

Temperature control in the served room;

Temperature control in the served room;- Managing the operation of each of the air conditioners installed in the system or their groups;

- Condition monitoring of air conditioners;

- Switching of climatic devices according to a given program (output of working ones to the reserve and input of reserve ones);

- If necessary, increase the overall performance of the system if the working modules can not cope with providing a given temperature level.

- Issuance of messages for personnel and / or heads of departments about emergency situations.

This organization achieves:

- Stabilization of room temperature with high accuracy.

- Alternate operation of devices, even distribution of wear.

- Timely connection of backup equipment to replace the failed.

- The possibility of carrying out preventive maintenance for any of the air conditioners at any convenient time.

- Notification of responsible persons about emergency situations.

- Use in the system of equipment of different manufacturers and performance.

The device of the rotation system of air conditioners

An obligatory element in the system of rotation of air conditioners is the basic module. He is responsible for:

- Temperature control;

- Condition monitoring of air conditioners;

- Issuance of control signals for them;

- Setting the parameters for switching devices of the climate system;

- Receiving commands from personnel to turn on / off a specific module;

- Issuing alerts.

As a rule, such a device is based on a microcontroller.The output of control signals can be carried out directly to the evaporative unit of the air conditioner or an additional monitoring and control device.

The first option is less expensive (does not require additional modules), but has less versatility - as a rule, such a central module only supports a limited number of models or equipment from specific manufacturers.

The second one is more versatile, because it allows you to work with almost any equipment. However, the cost of the system due to the presence of additional blocks in it may be too high.

Communication of the central unit with air conditioners (control modules) can be carried out via:

- radio channel;

- wire lines;

- through an infrared emitter.

The first option, as a rule, is used only in the case of using a bunch of central - control module.

The last two allow you to control the air conditioner directly. In these cases, the signals are sent to the connectors intended for connecting a wired remote control to the climatic equipment, or directly to the photodetector receiving a signal from the infrared remote control.

In any case, for use with specific models of equipment or lines of specific manufacturers, the system must support the appropriate exchange protocols.

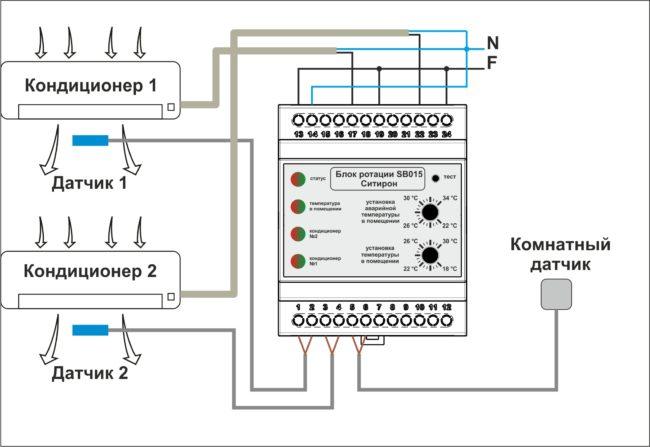

The central unit must be equipped with a temperature sensor to control the climatic parameters in the room.

Condition monitoring of air conditioners can be carried out by various methods. The most common is individual temperature measurement at the outlet of the air flow from the blinds unit.To do this, the control and management units or the central unit are equipped with temperature sensors installed in the immediate vicinity or directly on the air conditioner housing.

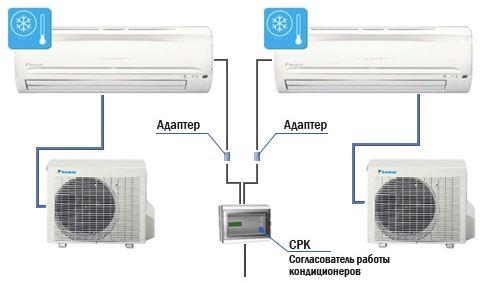

An example of the implementation of a direct control scheme can be considered the rotation unit URC (URC-2). It consists of the main unit, the temperature sensor of the serviced premises, temperature sensors at the outlet of the air conditioners. The control signal is transmitted by wire. The latest models can simultaneously control up to 15 medium power devices.

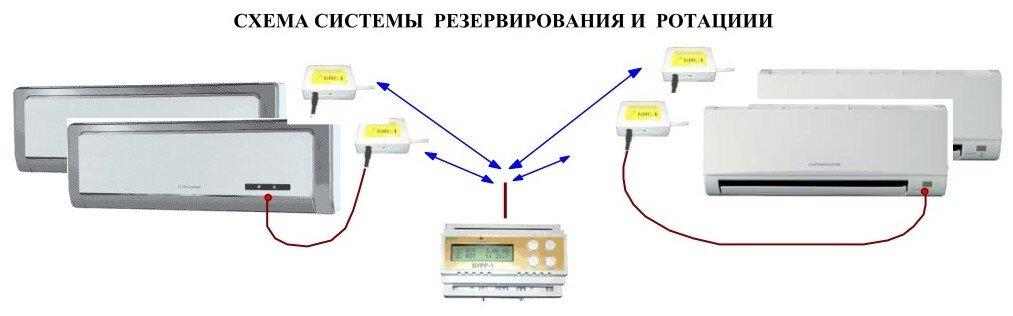

A separate version with a central unit and control-management modules is implemented in the BURR-1-IS system. BURR - the rotation and redundancy control unit stores the control program, controls the temperature in the room, exchanges data with interface modules (LIS) via a radio channel. BIS (special executive unit) receives a signal from the BURR, controls the operation of the air conditioner via the IR interface, controls the state of the climate device, receiving a signal from the output sensor.

Features of installation and configuration

When setting up the rotation system, the user performs the following operations:

Registration of air conditioners or control modules installed in the system.

Registration of air conditioners or control modules installed in the system.- Setting the temperature level in the room, tolerances.

- Criteria for assessing the performance of the air conditioner (set temperature at the inlet of the operating device, its deviation from the set value, at which the situation is perceived as an emergency).

- Setting notification modes, emergency shutdown of the system.

- Entering the rotation program (switching intervals, sequence of connection and output of air conditioners).

Installation of the system is also not a problem. When installing, consider:

- The central unit should not experience extraneous thermal influences (for example, from the heating system). A good option is to install it in the adjacent room with the served room, if the range of data transmission channels allows.

- The room temperature sensor is installed in such a way as to control the average parameter in the volume and not experience local influences.

- Individual sensors / control modules are mounted in close proximity or on the air conditioner housing. The installation location and requirements (for example, the orientation of IR emitters on photodetectors) are given by the manufacturer in the technical documentation.

Questions and answers

The temperature sensor is installed in the serviced room. In this case, an error naturally appears due to the loss of the signal level during transmission over a considerable distance. However, it is not so significant, and it is quite easy to take it into account in the system settings.

Rotation blocks are used for all redundancy systems - according to the N + 1 and kN schemes (N is the nominal number of air conditioners).

Of course you can, but the difference in their performance should be taken into account when compiling the control program. In addition, you need to be sure that any device in the system is able to receive control signals and respond to them.

Undoubtedly. In any case, it can be taken out of service by the rotation block simply by canceling its registration in the control program.

It is enough to combine air conditioners into groups and use the same algorithms for them as for individual devices. The only issue that needs to be resolved is determining the status of individual air conditioners in the group.

Video instruction for setting up the BURR-1M rotation unit