During the operation of climate equipment, including household air conditioners, a decrease in cold performance over time is often observed. The reason may be a decrease in the amount of refrigerant in the system. That is why the question of how to fill the home air conditioner yourself is of interest to many owners of split systems.

Content

When is Freon needed?

According to statistics, even the highest quality air conditioner loses up to 8% of the injected refrigerant during the season. This means that at least once every 2 years, the home climate system needs to be refueled with freon.

A clear sign of the need for such maintenance is an increase in the time for setting the specified climatic parameters. However, it is quite difficult to unambiguously judge that it is time to fill the air conditioner.

The reason for the loss of cooling capacity can be not only a refrigerant leak. It is no less affected by the pollution of the evaporator and condenser, radiators, problems with the operation of the fans of the external unit of the split system.

With a high degree of certainty, it is possible to judge the need for refrigerant charging only if the system undergoes preventive maintenance at the correct frequency, and after cleaning the components, the cold performance has not reached the optimum level.

The frequency of equipment cleaning depends largely on the location of the unit:

- Split systems on floors 1-4 need to be cleaned before the start of each season.

- At installation blocks at a height of 5 - 8 cleaning can be done 1 time in 2 years;

- Units on the 9th floor and above need to be cleaned no more than once every 3 years.

Most owners of equipment have no idea how to fill their own home air conditioner. In reality, this process is not so complicated, however, it will require certain knowledge about the device design, the availability of specific instruments and tools, and the skills to use them.

At the same time, some errors (for example, an excess amount of refrigerant in the system) can lead to a completely opposite result - instead of restoring operating parameters, the air conditioner will completely fail. To exclude such an unpleasant outcome, entrust the soul with the work of refueling to the specialists of the service center.

Another weighty argument in favor of such a decision is the very insignificant savings when doing the work yourself (at best, it will amount to 2-3 thousand rubles).

Refueling or refueling

The logical option for restoring the efficiency of the air conditioner in the event of a refrigerant leak from the circuit is to restore its quantity in the system or refuel.

However, in the case of climate technology, this logic does not always work:

Refueling is possible only when the split system works with single-component freon (contains only 1 substance). These include, for example, R22 and R32.

Refueling is possible only when the split system works with single-component freon (contains only 1 substance). These include, for example, R22 and R32.- For multicomponent freons, refueling is unacceptable. This is due to the fact that different components in the composition of the refrigerant have different properties, therefore, in case of leaks, they are also consumed differently.

Refueling causes an additional distortion in the ratio of the components of the mixture, which can significantly affect the characteristics and even the performance of the equipment. Most of the freons used today, including the most popular R410A, are multicomponent. For them, instead of refueling, a full refueling of the system should be carried out.

Refueling preparation

It is necessary to start preparing for refueling the air conditioner with its purges. This will allow achieving optimal performance of all system components and, accordingly, eliminating measurement errors associated with deviations from optimal operating modes.

The filters of the indoor unit of the split system and its outdoor unit need to be cleaned.

The maintenance of the latter is carried out in the following sequence:

- Unplug the equipment.

- Carry out mechanical cleaning:

- remove dirt and dust from the outside of the casing;

- dismantle it;

- remove accumulated debris from inside the case.

- Perform flushing. For this:

- Clean the radiator.To do this, use special brushes, rinse the cells with water under pressure or use a steam cleaner.

- Install the casing, leave the moisture to dry completely.

In order not to damage the electronic unit, the user should not clean it himself. This work must only be carried out by qualified personnel!

The next stage of preparation is to check the system for leaks. If the rate of refrigerant leakage exceeds the allowable one (the same 8% during the season), most likely there are problems with the sealing of the connections. You can find the place of a serious leak in the process of visual inspection of highways and joints.

If it was not possible to find a problem area with a simple inspection, other methods will help using:

Soap solution. Works well if the suspected location of the leak is known.

- halide detector. Uses the effect of changing the color of the flame when interacting with chlorine vapor. It can be used only on equipment with chlorine-containing freons.

- Water. Requires pre-injection of nitrogen into the circuit and immersion of system parts in water, which is not always convenient.

- UV dye. A UV dye is added to the gas pumped into the system, which marks the location of the leak. It is easy to find with UV light.

Pressurization of the system is the pumping of the circuit with nitrogen through a manometric manifold. Injection is carried out according to the permissible pressure in the circuit (indicated in the technical documentation and on the nameplate of the device).

After reaching the pressure, the nitrogen supply to the system is stopped. In a sealed system, the pressure will remain constant; if leaks persist, nitrogen will continue to bleed.In this case, the procedure for finding problem areas and crimping should be repeated.

After the tightness has been restored (the system has been pressurized), evacuation is performed:

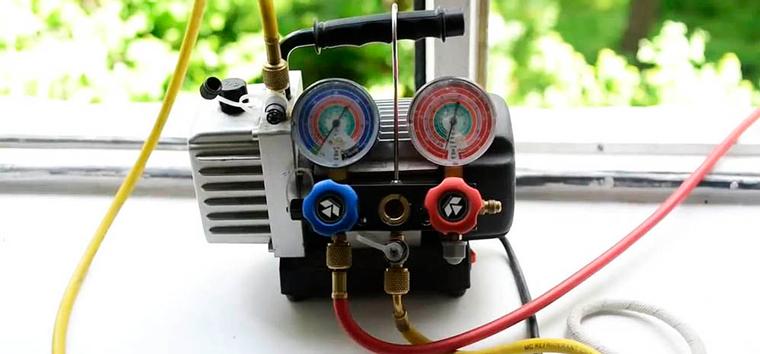

- Connect a vacuum pump to the gauge manifold.

- Start the pump, open the gas valve.

- I control the pressure in the system according to the readings of the manometer.

- When the minimum is reached, the pump is turned off.

- Close the gas valve.

During operation, a vacuum pump with a check valve is used, which will prevent oil from entering the freon circulation circuit. After pressure testing and evacuation, the collector is not turned off to prevent air from entering the system.

Refueling the air conditioner

Charging the air conditioner is carried out only after removing all the old refrigerant from the circuit. If the preparation was carried out with crimping and evacuation, this stage has already been completed. Otherwise, it is necessary to open the locks of the service fittings and wait until the old freon is completely removed from the circuit. Close locks when finished.

To charge the air conditioner, you need to know how much refrigerant you need to pump into the circuit.

The two best options for such control are:

- Refueling by weight.

- Pressure filling.

In the first case, the mass of freon specified in the technical documentation is pumped into the system. For this:

The refrigerant bottle is connected to the manifold.

The refrigerant bottle is connected to the manifold.- Install the cylinder on electronic or mechanical scales.

- Set to zero.

- Open the gas valve and fill the system with freon.

- Control the weights.

- Upon reaching a given change in the weight of the cylinder (pumping a given mass of freon into the circuit), the valve is closed.

- Disconnect the cylinder from the manifold.

- Remove the manifold, close the service fitting on the highway.

Filling by pressure

In this case, the sequence of actions remains the same, but the freon cylinder is not installed on the scales, and the supply is carried out not in a continuous stream, but in portions. The pressure in the system is controlled by a manifold pressure gauge. The supply is continued until the nominal pressure value is reached.

The pressure in the system depends on the temperature. The optimal values are indicated in the technical documentation or in the table on the nameplate of the unit. If necessary, for a specific temperature value, it is easy to calculate corrections from tabular data.

By pressure, you can also refuel the system. After connecting the gauge manifold, the instrument displays the current refrigerant pressure. Injection from the cylinder is carried out until the nominal value is reached.

Refueling on measuring glass

It is used, as a rule, by specialists of the service center. Refrigerant is added to the system until freon displaces air from the system pipelines. This is evidenced by the absence of gas bubbles (it is precisely their presence that is observed through the viewing window). After that, the excess pressure is released to the nominal value.

Refueling on overheating

The method is based on reducing the temperature difference in the circuit and the boiling point of the refrigerant. For work:

- Turn on the unit.

- An electronic thermometer is installed on the gas pipe. It shows the temperature of the freon in the circuit.

- According to the readings of the pressure gauge on the manifold, the boiling point of the refrigerant is determined.

- Calculate the difference. Limit exceeded 5-8aboutC indicates an insufficient amount of freon and the need to refuel.

Open the valve on the cylinder, slightly open the liquid valve of the collector to bleed air (time - no more than 1 s).

Open the valve on the cylinder, slightly open the liquid valve of the collector to bleed air (time - no more than 1 s).- Open the manifold gas valve.

- Carry out measurements of temperature and pressure in the system, calculate the temperature difference.

- The process is continued until the difference is within acceptable limits 5-8aboutFROM.

- Close the manifold gas valve.

- Close the valve on the bottle.

- Disconnect the manifold.

- Close the service port.

Questions and answers

It is recommended to do this in small portions, waiting for the indicators to be established on the devices. This improves the accuracy of the calculations.

Freezing of taps, most often, indicates an insufficient amount of freon in the system. You need to refuel again. If the situation does not change, it is necessary to look for a refrigerant leak.

The amount of freon depends on the model of the air conditioner (primarily its power) and the length of the routes. So in a device with a power of about 7 kW, with a minimum length of highways, 750-800 g of freon is contained. In powerful systems, this figure can exceed 1.5 kg.

Calculating the mass of the refrigerant remaining in the system is a very difficult task, it will not be solved even in most service centers. You should choose another method of refueling or release all the freon and carry out a full charge.

Insufficient amount of refrigerant will only affect the performance of the unit - it will slowly gain temperature or not reach the limit values. Excess freon leads to equipment failure.

Home air conditioning can be charged or refueled with freon yourself. The operation is not so difficult, but requires the use of special tools and some skills. In addition, in case of a serious error, you can generally disable equipment. Accordingly, it is better not to chase after savings of 2-3 thousand rubles, but to entrust the work to the specialists of the service center.

Video tips for refueling the air conditioner with freon