Modern gas boilers are reliable mechanisms. But there is no eternal technology, so the equipment needs regular maintenance. The procedure includes checking the performance of all parts and systems, and most importantly - cleaning them.

The procedure is not particularly difficult. Therefore, if there is no desire or opportunity to turn to professionals, it is quite possible to cope with it on your own. It is only important to understand the structure of the boiler and follow the technology for cleaning all parts.

Content

How to determine the need for cleaning

Boiler manufacturers recommend servicing equipment once every 1 to 2 years. But the need for cleaning may occur more often, since it all depends on the operating conditions and the specific model. Most often, the heat exchanger needs unscheduled maintenance.

But disassembling the boiler according to the schedule, just because the time for cleaning has come, is not worth it. In order not to take unnecessary actions, it is important to know the signs of clogging of internal parts and systems:

- slow heating;

- power loss;

- increase in gas consumption;

- pops during ignition;

- constantly working burner;

- extraneous noise during the movement of water;

- uncharacteristic odors from the boiler;

- difficult ignition;

- decrease in pressure in the water circuit;

- incorrect readings of sensors;

- no reverse thrust.

The boiler should be inspected if at least one of these signs appears. But most often there are several symptoms of contamination of parts at once.

Cleaning technology

The process of cleaning the boiler consists of sequential steps:

- Turn off the boiler, shut off the gas supply and remove the cover (casing).

- Remove and clean successively the igniter, burner block, filter, heat exchanger.

- Install all dismantled parts in their places.

- Check the functionality of the boiler.

When disassembling and assembling threaded connections, be careful not to apply excessive force. Many components of the boiler are made of copper, so they are easily deformed and easily damaged if handled carelessly.

Igniter cleaning

The main sign of clogging of the igniter is that the boiler does not start or periodically fades. At the same time, during ignition, the part produces a yellow flame with an unpleasant odor. It is easy to restore the igniter to working capacity: it is enough to remove the part from the boiler and punch a hole with a thin wire or a sewing needle.

Blowing out burners and jets

The need to clean these parts rarely occurs, however, during scheduled maintenance of the boiler, it is worth freeing them from accumulated dust and debris for prevention, without waiting problems.

Action algorithm:

- Parts are removed from the boiler, having previously marked their position with a marker.

- The holes are blown with a pump and additionally cleaned with a brush.

- Return the nozzles and the burner to their original place, focusing on the marks.

Filter cleaning

It is installed in front of the shut-off valves of the gas supply line and performs the function of filtering the gas from impurities and contaminants that increase soot formation, accelerate the pollution of the combustion chamber and chimney.

To clean up, do the following:

To clean up, do the following:

- Remove the cover.

- Unscrew the cap from the flange.

- Pull out the hair cassette or metal mesh.

- Shake well and blow it out. You can wash the filter with solvents.

- Assemble and install the filter in reverse order.

Methods for cleaning the heat exchanger

The gas heating system works on the principle of converting the energy potential of the burning fuel into the energy of the heat carrier circulating in the system. This function is performed by water, which has the highest heat capacity. However, it is non-toxic and has the lowest cost.

But water has a significant drawback - in its unpurified state, it contains alkaline earth metals, which, when heated, form insoluble carbonate deposits - scale. It significantly reduces the thermal conductivity of the metal walls of the heat exchanger and disrupts the operation of the entire heating system.

Soot deposited on the outer surfaces of the heat exchanger negatively affects the operation of the heat exchanger. This is typical for natural draft boilers with an open combustion chamber. The reason for the accumulation of soot is the dustiness of the air in the room. Soot, like scale, reduces thermal conductivity, hinders equipment operation, and can lead to premature equipment failure.

The frequency of the heat exchanger cleaning procedure depends on the type of water used in the boiler. If the salt content is high, the water is considered hard and scale builds up very quickly. In this case, descaling is carried out at least once a year. With a decrease in thermal conductivity, unscheduled cleaning may be necessary.

You can clean the heat exchanger in several ways:

You can clean the heat exchanger in several ways:

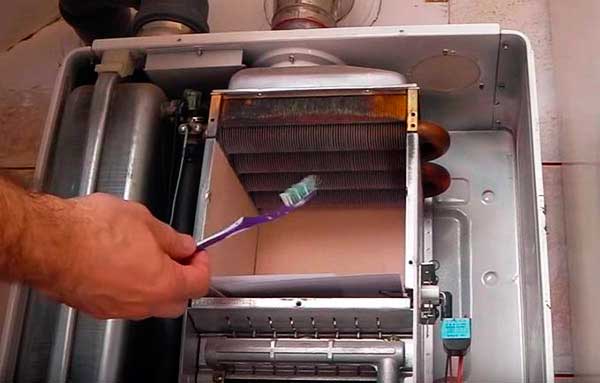

- Mechanical. Scale and soot are removed manually using metal brushes or scrapers.Places inaccessible for surface treatment are blown with a vacuum cleaner.

- Chemical. Washing parts in various solutions that dissolve deposits.

- hydrodynamic. This method does not require dismantling the boiler, but it will require special equipment. Its essence lies in filling the system with a cleaning solution under pressure. The disadvantage of the method is the danger of critical pressure in the pipes. Therefore, experts do not recommend using hydrodynamic cleaning on their own.

Dry cleaning procedure

This method is more effective than mechanical cleaning. Chemical solutions remove deposits even in places where it is impossible to reach with a hand tool.

For the procedure, you will need a specialized device - a booster. It consists of the following elements:

- Reservoir for pouring reagents.

- Pump.

- Electric heating element. It is not available in all boosters. But experts advise flushing the heat exchanger with just such an apparatus, since the heated reagents wash the internal surfaces of the part better.

The cleaning process itself looks like this:

- The heat exchanger is placed in a container of suitable size.

- The booster tank is filled with reagent and connected to the heat exchanger: one hose to the inlet, the other to the outlet.

- Start the booster. A chemical solution begins to circulate inside the heat exchanger, and deposits are washed out.

Under the influence of chemicals, all deposits inside the heat exchanger are completely dissolved. If the part is cleaned every 2 years, the reagent filling procedure must be repeated and the heat exchanger flushed again.

What solutions to use for cleaning

Acids and special products do a good job of removing scale accumulated on the walls of the heat exchanger:

Detex

Special liquid designed to remove traces of oxides, scale, salts. It interacts well with products made of steel, cast iron or copper, increasing their service life.

Oxalic acid

Cleans scale and rust marks, does not damage painted parts. It is applied to all types of metal. A special agent based on oxalic acid - "Solita".

Differs in aggressive influence on metal. It is permissible to use this substance as a last resort only for processing stainless steel and copper products.

The aggressiveness of the solution is reduced by additives that prevent the destruction of the metal shell of the product. Extremely toxic, and when working with it, you must strictly follow the safety rules.

Regular cleaning and maintenance of the gas boiler will ensure its smooth operation and significantly extend its service life.

Video tips for cleaning a gas boiler