When deciding to purchase a new gas appliance for heating, you should immediately decide which type will help save not only on its purchase, but also on the installation area and gas consumption.

On sale are single-circuit boilers that work only for heating the house, and double-circuit ones, which will provide you not only warmthbut also hot water.

Floor double-circuit gas boilers are both small in size and quite massive. Almost all modern devices are equipped with an automation system that constantly monitors the operation of the installation and turns off the fuel supply if the set temperature is reached or if any malfunctions occur. Thanks to this, fuel is used very economically, increasing both efficiency and general efficiency boiler.

Content

How is a double-circuit gas boiler arranged?

The figure below clearly shows how a two-circuit heating device is arranged. In the lower part of the combustion chamber there is a gas burner, which provides general heating.

Around the combustion chamber goes water jacket — This is the heating medium for the heating circuit. A coil is installed in the upper part of the boiler body, which is located in a water jacket. Water intended for domestic needs circulates through it, taking certain the amount of thermal energy in the coolant. That is, at lit boiler house is provided with both hot water and heating. Between the water jacket and the walls of the housing there is a layer thermal insulation, which is not gives heat is wasted, thereby increasing the efficiency of the apparatus.

heat exchanger in different models of boilers has various shapes and is installed in different hull locations. They also differ in the material of manufacture, the main thing is that the metal has good heat dissipation.

In this scheme, the heat exchanger is installed on the rear wall of the apparatus case. Here you can also clearly see the distribution of heated consumer water and heat carrier.

What is the function of heat exchangers?

In order to have an idea about this most important structural element of the heater and to know which of them better and more durable, need to consider a few of them.

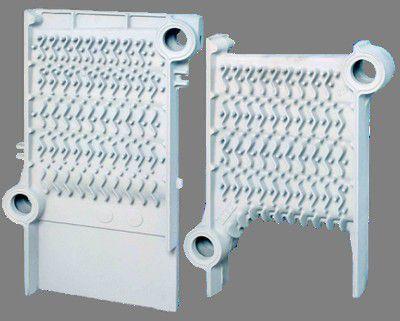

Installed in double-circuit boilers bithermic or separate heat exchangers, lattice type or serpentine type.

- Most often, a separate structure of the heat exchanger is used. It consists from plates of stainless steel, which serve to heat domestic hot water. And for heating needs in given The complex uses a copper heat exchanger. This model is more durable than bithermic, So how does it last longer does not get clogged.

- Bithermic heat exchangers consist of two copper pipes. outer pipe — this is the heating circuit, and the internal — for flow heating of water for consumer needs.

Such boiler cost much cheaper than the first one, German there is practically no second heat exchanger and no three-pass valve. Minus — this system cannot be used tough water, too much enriched salts.

In addition, heat exchangers are steel or cast iron.

- The steel heat exchanger is lightweight and affordable. An element made of this material easily perceives possible hydraulic shocks and is not subject to deformation.

But its disadvantages include susceptibility to corrosion that occurs under the influence of condensate, which can form at low temperatures inside the boiler body, as well as the possibility of rapid burnout. These problems usually occur when the device is used incorrectly, but if you follow all the manufacturer's recommendations, you can avoid such unpleasant consequences. For example, it is unacceptable that in a boiler with a steel heat exchanger the temperature drops to a critical one, those. below the dew point.

In some models, stainless steel or alloy steel heat exchanger elements are used, and, in addition, other modern technological solutions are used that do not allow condensation to form. boilers, equipped such heat exchangers are significantly more expensive than conventional ones.

- The cast iron heat exchanger is considered the most reliable and durable — it is not subject to deep corrosion and burnout, as the body has sufficient thickness. But you need to remember that cast iron is fragile, and even with a slight impact on German cracks may form. In addition, such damage can also occur when cold water enters a heated heat exchanger, for example, when the system is supplemented with water.

If the water has a high percentage of salt concentration rigidity, a large scale layer can quickly form in the boiler, which leads to overheating of individual parts of the heat exchanger, and as a result — the formation of cracks and failure of the entire heating apparatus. Thus, it is imperative to install a water softening system before the heating circuit.

In expensive boilers, heat exchangers made of cast iron of special grades are installed, with a special plasticity of the material, resistance to corrosion and uniformity of the structure. Such elements serve in boilers for about fifty years.

But, it should be noted that for gas-powered devices, a cast-iron heat exchanger is not particularly desirable. The fact is that cast iron, due to its massiveness, has a large thermal inertia and cannot quickly change the temperature in the circuit, even if the automation has switched boiler to another power. And this –not too good either for the automation of the device, or for other structural elements.

What is the difference between a gas boiler with open and closed camera?

Divide boilers more and camera type — it can be open or closed.

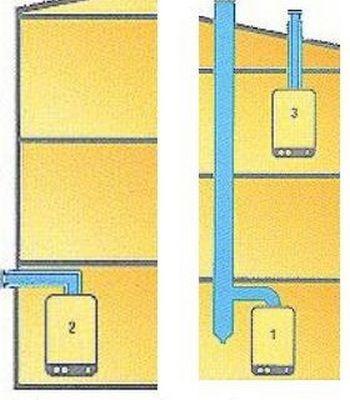

The figure shows two types of boilers:

1. A heating device with an open firebox, which attached to the chimney.

2. The second picture shows the type of boiler with a closed chamber and turbo ventilation, those. using a fan and coaxial chimney.

3. The third picture also shows boiler with a closed firebox and turbo ventilation, but connected to the vertical chimney.

- The open type of the chamber provides for the operation of the boiler using natural draft — this is a classic scheme in which air for burning fuel enters boiler from the room where the device is installed. This type of boiler takes in the amount of air that it needs for full operation. Chimney in given must be connected to the chimney.

The main disadvantage of such a boiler is that it is not recommended to install it in a residential area, since poisoning with combustion waste is possible. Therefore, it is necessary to equip a separate boiler room with a good ventilation system for its installation.

The positive aspects include the price of open-fired boilers — it is much lower, and also the fact that this type of device can work completely autonomously, in the absence of power supply.

- The closed combustion chamber in the boiler allows it to be installed in any room with a good ventilation system, and it does not require a separate room. However, a device with a closed combustion chamber requires a forced ventilation system, those. fan, and means, it is energy dependent. For this type of boiler fit both a vertical chimney and a coaxial horizontal chimney that exits through the wall.

Types of burners and what do they affect?

Double-circuit boilers can have two types of burners — it's atmospheric and supercharged. How are they different and which one is better?

- Burners supercharged types are equipped with a fan that draws air into the firebox. They are most often installed in boiler power of 100 or more kW.The efficiency of the heating device with supercharged burner increases to 92—95%. Such boilers not demanding to the pressure in the gas line and to the height of the chimney.

This type of burner will help to significantly save on fuel and is often used even in boilers with combined heating. However, models of boilers of this type are quite expensive, and more one drawback can be considered quite loud noise during their work.

- Atmospheric type burners have a less complex design. gaseous fuel served in her simply under the influence of the existing certain pressure in the line, and the air enters through conventional draft. The burner has an affordable price, which reduces the cost of the entire device — this factor makes such boilers popular and in demand.

True, the efficiency of a boiler with an atmospheric type of burner is lower than that of a closed one. inflatable, and is 85—90 %, so the energy savings will be lower.

But these types of burners are easy to operate, operate almost silently and do not require maintenance costs.

Power level difference

Floor heating boilers are divided into operating:

- at the same power level, they are called single-stage;

- at two power levels, called two-stage;

- continuously adjustable, called boilers with modulation.

Practical observations show that for the entire cold season at full capacity boiler only 15 are used—20 time and the rest of it remains unclaimed.

From this circumstance, we can conclude that the best acquisition would be boiler with modulation or with two-level power, which will allow you to adjust her under a specific temperature outside the window. The positive qualities of these options for heating devices include:

- longer life, which is achieved by reducing power at the right time;

- increase in environmental qualities, as the emission of combustion waste into the atmosphere is reduced;

- it is possible to connect, if necessary, additional water heating equipment.

The undoubted advantages of double-circuit gas boilers

Positive qualities in the operation and maintenance of boilers of this type are enough:

- Double-circuit heating devices, thanks to the second heat exchanger, provides not only heat in the house, but also hot water in the taps. Therefore, this type of boiler is more in demand among owners of private houses.

- An automatic sensor built into the body of the device will provide reliability and the safety of his work. When the flame in the burner goes out, the thermostat blocks the fuel supply.

- Ease of use.

- Fuel economy for check automation.

- The combustion chamber is cleaned automatically.

- Very often a special filter is immediately installed in the casetr dlI purify water, which prolongs the operational life of the boiler.

All these qualities determine the attractiveness of using these devices in autonomous heating circuits.

There are many advantages to dual-circuit devices, but there are also disadvantages:

- The first, and sometimes decisive when choosing a boiler — this is a rather high price.

- Large dimensions, compared with mounted boilers.

- Some of the double-circuit boilers must be installed in separate rooms for safety reasons. This increases the cost of building a boiler house and installing equipment.

To increase the efficiency of the boiler, a circulation pump is built into the heating circuit. This is especially important if heating circuit is large enough and ramified, as well as if connected to it water floor heating system.

Overview of the floor double-circuit gas boiler Aton

As an example, we recommend that you familiarize yourself with the videos that tell about two interesting, popular with private housing owners and fairly inexpensive models of floor-standing double-circuit boilers:

Boiler KLZ Protherm

Choosing boiler for a home, you need to weigh all the nuances of its operation, maintenance and installation, evaluate the dimensions, familiarize yourself with the technical characteristics. Only in this case it will be possible to achieve clarity on the issues what specifically you need what pay attention when buying.