A modern autonomous heating system consists of many elements. Its composition may vary depending on the type of coolant or on the method of heating it.

When heating the coolant in pipeline systems or in heat exchangers with an open fire, heating furnaces operating on various types of fuel can be used. Regardless of the material of combustion - the heating boiler must provide a system for removing combustion products, or a chimney. This design can also be built in different ways. So in the presence of a gas heating system, a coaxial chimney will be a good choice, for gas boilers they are:

- wall (vertical);

- horizontal (insertion through the wall).

Content

What is a coaxial chimney?

The very concept of "coaxial" involves the placement of one cylinder inside another cylinder. Thus, a coaxial chimney system for gas boilers is one pipe that is placed inside another pipe. Thus, the system will have two circuits created from a pipe of larger and smaller diameters.So that the distance between the large and small pipes remains the same throughout their entire length, they are fixed with jumpers that prevent the walls of the pipelines from touching.

Purpose of coaxial chimney system

The main area of use of coaxial chimneys are heating systems with gas heating boilers equipped with closed fireboxes for fuel combustion. It can be represented by a gas boiler, convector or radiator. The two circuits of the coaxial chimney perform different functions:

- The first circuit is responsible for the removal of gas combustion products from the boiler furnace.

- The second circuit is responsible for the influx of fresh air into the furnace, which is necessary for efficient combustion.

In order to ensure efficient draft and uniform combustion of gas, boilers with closed combustion chambers must be equipped with coaxial chimney systems with a length of not exceeding 2 meters. Otherwise, turbulences will form along the pipe, which will prevent the free removal of combustion products and the flow of fresh air.

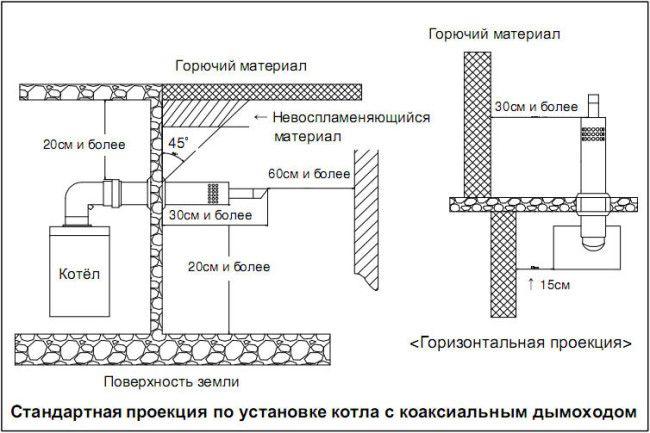

Rules for the placement of coaxial chimney systems

The short length of coaxial flue systems dictates a strict framework for their placement. The most common installation method is direct penetration through the wall to the street. More rarely, during installation, the passage of coaxial chimney systems through ceilings or through the roof is observed. The coaxial chimney pipeline works most efficiently if it has a strictly horizontal arrangement. In the event that the gas heating boiler is located in an inconvenient place for such a conclusion, it is possible to draw a conclusion through the roof using the vertical sections of the structure.

The structure of the coaxial chimney

The standard design of a coaxial chimney for gas boilers consists of the following main parts:

• Straight pipes - they form the channel of the chimney system

• Connecting elements (tee or swivel), designed to connect straight sections and connect the chimney directly to the gas boiler. • Cleaning area, designed for regular routine maintenance,

• A place for collecting water condensate - the products of gas combustion carry water vapor, which, as it cools, can accumulate on the walls. To prevent it from entering the combustion chamber, such a section is formed.

• The upper outer section of the chimney is designed to protect the internal contours of the chimney coaxial chimney system from the effects of atmospheric conditions: snow or rain, as well as to protect against wind.

What materials are coaxial chimneys most often made of?

Industrial production of elements of coaxial chimneys for gas heating boilers is carried out from many materials:

• Pipes made of stainless steel. This is perhaps the most long-lived material, but such equipment has an increased price.

• Galvanized steel pipes - such devices are sold cheaper, but they are more susceptible to corrosion.

• In addition, the various sections of the chimney, as well as the external and internal pipelines, can be made from a wide variety of materials, up to high-strength polymers.

What does the installation of a coaxial chimney give?

The most important advantage of placing a coaxial chimney for a gas heating boiler is the fact that fresh air is taken in to constantly maintain combustion in the furnace from outside the room. In this case, you will not experience discomfort due to the burning of oxygen in the room, you will not encounter excessive dryness of the air. The use of coaxial chimneys will avoid frequent ventilation of the room in which the gas boiler is located. This is especially important in cold weather, because when you ventilate through the windows, you cool the air in the premises, and for reverse heating, an increased consumption of heat carriers and energy is required.

In addition, the air entering the coaxial chimney circuit when moving from the street to the combustion chamber is heated, which facilitates the combustion reaction and increases the efficiency of your gas boiler. With a constant influx of fresh air heated to room temperature, the gas in the furnace of your boiler is completely burned, significantly increasing the efficiency of the entire heating system.

It is worth noting that the complete combustion of fuel also increases the environmental friendliness of the heating system - you do not pollute the surrounding air with unburned elements.

Also, the combustion products, when passing through the emission circuit, give up part of their heat to the fresh air coming from outside. This reduces the risk of fires inside the pipe in areas with accumulation of unburned particles. The coaxial pipe has an outer surface temperature much lower than a classic chimney, which reduces fire protection. requirements to its installation. Thus, coaxial pipes (with appropriate insulation, of course) can be carried through wooden walls or ceilings, which is impossible for a conventional steel chimney.The gas heating system with a coaxial chimney creates a completely closed fuel combustion circuit, in which oxygen for continuous combustion is taken from the outdoor air and combustion products are removed there. This creates a comfortable atmosphere in the room where the gas heating boiler is located. This is important, since gas water heaters are often located in habitable areas, such as kitchens.

A wide range of

The selection of a coaxial chimney is possible for almost any gas heating system, regardless of its power: pipes of various diameters, made from a variety of materials, are on sale. Installation of such a system is relatively simple and can be easily performed even by an untrained specialist.

Installation of a coaxial chimney

Please note that improper construction or installation of a coaxial chimney system can negate all its advantages. For proper installation, follow the step-by-step instructions:

- Make sure you have all the necessary materials and tools. To do this, you will need a set of coaxial pipes and fittings, wall linings to form seals, and an outdoor tip.

- Before proceeding with the installation, make a markup, calculate the path of the chimney, remove unnecessary items, make a hole of the appropriate diameter in the wall. When designing the installation, make sure that there are no flammable objects near the pipe.

- The best choice would be the simultaneous installation of a gas heating boiler and its corresponding coaxial chimney.

- The exit point of the chimney should be located about a meter and a half above the level of the gas combustion chamber.To achieve the optimal location, the chimney system can be extended, but installing more than two elbows in it will lead to the formation of turbulences with a sharp decrease in its efficiency.

- The coaxial pipe is connected to the outlet pipe of the combustion chamber of the gas boiler using a clamp. It is fixed with two screws.

- After that, we assemble the chimney system in accordance with the designed configuration.

- Between themselves, the knees of the chimney are also fixed by means of clamps.

- At the outlet section of the chimney, we form a slight downward slope, so that the condensed moisture is removed by gravity from the system.

- A protective vane can be put on the upper outer part of the coaxial chimney.

We insulate the coaxial chimney

At low negative temperatures outside, some sections of the coaxial chimney may well freeze through, which adversely affects its efficient operation. In order to avoid negative moments - such areas must be insulated. It would seem that this is a reasonable solution, but the “pipe in pipe” design itself negates any insulation.” Instead, the best solution would be to reduce the cross section of the chimney system. In the event that frost is observed on the chimney head, try to make the inner pipe of the system shorter. In this case, freezing of condensate can be avoided. In extreme cases, it is practiced to install two separate steel pipes, one of which takes in air and the other removes combustion products.

Coaxial chimney for a gas boiler video