A significant share in the heating systems of private houses falls on gas equipment. Devices that are easy to maintain at first glance require grounding, which can be done in various ways. Its installation can be done independently, but it is better to resort to the services of specialists.

Content

Why do you need to ground gas boilers

Despite the fact that gas equipment does not belong to electrical appliances, static electricity collects on its surface during operation. It accumulates on the metal casing of the units and forms a strong electromagnetic field, which can disable the electronic "stuffing" of gas equipment.

The reason for this accumulation of energy is the fastening of the units to the wall or their installation on the floor. These are non-conductive surfaces. The accumulation of static electricity reaches its maximum value during the winter heating period. You can get rid of it only with the help of grounding.

If this is not done, the magnetic field created by the static will drive the electronics of the equipment crazy.

Rules and regulations for grounding gas boilers

In addition to the failure of the electronic control unit for the operation of the units, there is a danger of uncontrolled gas ignition. This may cause the boiler to explode.

In addition to the failure of the electronic control unit for the operation of the units, there is a danger of uncontrolled gas ignition. This may cause the boiler to explode.

All requirements for the installation and operation of gas equipment are defined in the PES. This is a regulatory document, the provisions of which are binding.

The heating circuit grounding device begins by measuring its resistance. The requirements for its parameters are defined in clause 1.7.103 of the PES. They depend on the type of unit and the nature of the soil.

The norm for sandy soil is considered to be a resistance of no more than 50 ohms, and for clay soil 10 ohms. In existing normative documents there are no strict requirements for the installed grounding. It can have both industrial and home-made performance.

It is strictly forbidden to use static electricity to drain gas equipment using:

- household sockets;

- pipes for heating and sewerage.

It is allowed to use water pipes for grounding that have reliable waterproofing and are located in the ground or concrete. In all other cases, a separate ground loop is arranged for gas equipment. For its installation, it is better to use ready-made kits, widely represented in the trade.

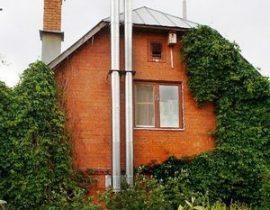

How to arrange the grounding of a gas boiler in a private house

1 m retreat from the outer wall of the heating unit installation and make markings on the ground in the form of an equilateral triangle. The length of the rib should be 2 m. A trench is dug along this marking. Its depth depends on the level of soil freezing, but should be at least 50 cm. At the tops of the triangle, pits are drilled for the installation of ground electrodes.

As a ground electrode installed in the pits, you can use a steel corner or copper-plated plates, which are immersed in the ground by 4.5 m.

Immersion of ground electrodes occurs in stages. They are successively deepened into the ground in segments, which are interconnected as they are immersed using special couplings or welding. After installation, the ground electrodes are connected to the pin fixed on the foundation of the building. This is done using a copper wire, which is fastened with bolts.

Further, it is important to correctly connect the pin to the communication unit of the gas equipment. The connection can be made with steel, copper or aluminum wire. On gas equipment there is a three-pin mains socket or control panel with zero phase current. A wire stretched from the pin is attached to it.

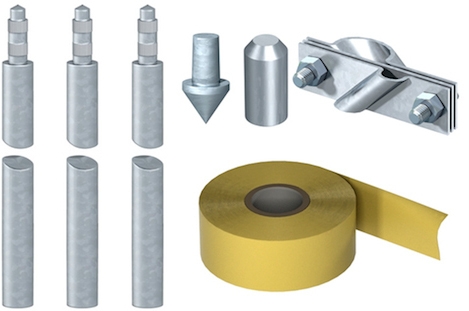

Three types of pins can be used in such ground loops:

- copper-plated;

- galvanized;

- steel.

The advantage of a modular pin grounding system

The main advantage of the device of such a ground loop is the ease of assembly and the possibility of self-manufacturing of structural elements. Installation of the module requires a minimum of preparatory work. Ease of transportation and storage of industrial grounding kits. The circuits have a long service life and a high degree of safety.

The Best Industrial Grounding Kits

The rating is based on customer reviews.

ZandZ ZZ-000-045

Country of origin - Russia. Ground pins are copper-plated and have a connecting thread. The kit includes 30 pins, 1.5 m long. The diameter of their section is 14 mm. Between themselves, the pins are connected by couplings. There are 15 of them in a set.The same number of clamps for connecting the conductor and lugs for the pins. The kit is considered one of the best currently on the market. Can be installed even in sandy soil.

Advantages:

- versatility of application;

- full set;

- quality materials;

- long service life.

Main disadvantage:

- high price.

GALMAR GL-00045

Country of origin - Poland. The kit is intended for the installation of a three-point ground loop. It includes 30 copper-plated pins, having a length of 1.5 m and a cross-sectional diameter of 14 mm. There are 5 guide heads for a jackhammer and 1 nozzle. The pins are threaded, which allows them to be connected to each other by couplings.

Advantages:

- versatility of application;

- reliability;

- high-quality manufacturing materials;

- long service life.

Main disadvantage:

- higher cost than competitors.

EZETEK CN-6

Country of origin - Russia. The kit can be used for domestic and industrial installation of modular pin grounding. It includes 4 stainless steel pins with a length of 1.5 m and a diameter of 16 mm. The pins are connected to each other using steel couplings. The shock-receiving head for a sledgehammer is made of the same material.

Advantages:

- affordable cost;

- versatility of application;

- high quality and reliability of the contour elements;

- long service life.

No deficiencies have been identified.

Bolta

Country of origin - Russia. The kit is intended for the installation of a ground loop in country houses and cottages. It fully complies with the requirements of PES and European standards. It includes 4 steel pins, each having a length of 1.5 m and a section diameter of 16 mm.They have a multi-layer copper coating that has a molecularly strong bond with steel. The connection of the pins is carried out using couplings.

Advantages:

- service life up to 15 years;

- can be used for grounding on difficult soils;

- affordable cost;

- high quality construction elements.

No deficiencies have been identified.

TDM SQ2402-0001

Country of origin - Russia. The kit is intended for grounding of a private house, industrial, warehouse and administrative buildings built on complex, rocky, gravel and other types of soil. The kit includes 6 steel pins-electrodes with a thread. Their surface is covered with a layer of copper. To ensure a longer service life, the pins can be additionally treated with an anti-corrosion paste before installation. It is included in the kit.

Advantages:

- service life up to 30 years;

- universality of installation and application;

- affordable cost;

- high-quality materials for the manufacture of contour elements.

No deficiencies have been identified.

MZK-6-Z

Country of origin - Russia. The modular pin design is designed for grounding of private houses on any type of soil. The set includes 4 galvanized threaded pins and 4 stainless steel couplings. The cross-sectional diameter of the rods is 16 mm.

Advantages:

- affordable cost;

- complete set of the module;

- long service life;

- ease of assembly.

No deficiencies have been identified.

ZGER-6

The country of origin is Germany. The kit includes 4 threaded rods made of galvanized steel, having a length of 1.5 and a cross-sectional diameter of 20 mm. Grounding can be used for private houses and small industries.

Advantages:

- high-quality manufacturing materials;

- long service life;

- affordable cost.

No deficiencies have been identified.

FAQ

Grounding resistance on clay soil should not exceed 10 ohms.

The size of the section depends on the material of the wire. The cross section of copper wires must be at least 10 mm², aluminum - 16 mm² and steel -75 mm².

Based on the results of checking the ground loop, the inspection organization issues an act drawn up in the prescribed form.

The verification can be carried out by companies registered with Rostekhnadzor as electrical laboratories.

The ground loop is checked immediately after the installation of the gas boiler. Without this, it is not allowed to connect PES equipment. Further frequency of inspections is determined by PTEEP.

Conclusion

Gas boilers installed in cottages and private houses must be grounded. It removes static voltage from the equipment case and prevents the occurrence of explosive situations.

Video tips for grounding a gas boiler in a private house