Gas heating boilers are a great way to create a space heating system.

They are quite economical and are able to demonstrate a decent efficiency. However, such heating systems are sources of increased danger and, therefore, during the construction process, it is necessary to follow the rules for installing a gas boiler.

Is a specialist required?

First of all, please note that all equipment designed to work with gas (be it a boiler, pipes, connecting fittings or other devices) must have the appropriate certificate. It is impossible to use equipment designed, for example, for plumbing systems to create gas communications. As a rule, the installation of gas boilers and heating systems based on such devices also requires the involvement of workers with the appropriate permit and training. But in extreme cases, you can install a heating system based on a gas boiler yourself.

Uniform rules for installing gas boilers in homes

To ensure the trouble-free and safe operation of gas heating equipment, a number of strict, but fairly simple rules must be observed.

Requirements for a boiler room

First of all, remember that natural gas is an extremely flammable substance and its use in unprepared and inappropriate premises can lead to very unpleasant consequences.

However, gas heating boilers with a capacity of up to 60 kilowatts can be installed in any, even unprepared premises. But at the same time, the boilers must be single-circuit. In the event that the heating boiler has a second circuit, its installation in the kitchen is prohibited.

However, it is not recommended to install gas appliances in residential areas. It is advisable to allocate a separate room for the boiler room in a private house and provide that it has a window in the outer wall of the building.

To install gas heating boilers with a capacity of up to 150 kilowatts, you can choose any floor of your home. However, if you plan to install a more powerful heating system, then it can only be placed in the basement or basement.

Please note that according to existing standards, for 1 kilowatt of gas boiler power, there should be 0.2 cubic meters of the volume of the room in which it is installed. Also, the gas boiler room in a private house should have a ceiling height of at least 2.5 meters and provide convenient access to any of the elements of the heating system. The walls of the gas boiler room must be fire resistant with an indicator of at least ¾ hours. As with other placement options, a separate gas boiler room should have natural light, that is, it should have a window in the outer wall of the house.

Requirements for chimneys of gas boilers

Chimneys of gas boilers of heating systems also have their own installation rules.Incorrect operation can lead to the accumulation of combustion products and to tragic consequences.

The required minimum chimney diameter is indicated in the specification for your gas boiler. At the same time, its inlet section must coincide with the section of the outlet of the gas boiler.

To ensure the removal of combustion products, the upper edge of the chimney must be placed at least half a meter from the roof ridge. As a rule, round chimneys are used for gas heating, the walls of which are made of ferrous metal or stainless steel.

When creating a project for a heating system, it is necessary to ensure that the chimney of a gas boiler has no more than three bends or turns. The initial section of the chimney directly adjacent to the gas boiler must be at least 25 centimeters.

Obtaining permits

Due to the fact that gas heating is a source of increased danger, a number of permits must be obtained before its installation.

At the initial stage, it is necessary to secure the connection to the gas supply pipe by contract. Before the construction of the heating system, a gasification project is developed and approved. Only after the approval of the project in the authorized organization, it is possible to proceed with the purchase of equipment and directly with the installation.

Rules for installing a wall-mounted gas boiler

After the approval of the project, at the stage of purchase, be sure to check the availability of mounting devices in the scope of delivery. If the manufacturer did not include them in the kit, they must be purchased separately. Be sure to ask for a certificate for the purchased gas boiler. Check the marking of the boiler and the information specified in the safety certificate.

At the preliminary stage of installation, carefully blow out the internal piping system of the boiler. Remove all transport plugs. The pipes are cleaned with a low pressure water stream, the water will remove small debris and dust.

Make sure that the material of the wall on which you plan to place the gas boiler is made of non-combustible material. Otherwise, it must be reinforced with a fireproof coating with a thickness of more than 3 mm. The boiler itself, with this placement, must be taken out no less than 45 mm from the wall surface.

The installation height of the gas boiler is 80 to 160 cm. At a distance of at least 20 cm from it, there should not be other electrical or gas equipment, or any flammable materials.

When installing mounting brackets, check with a spirit level that they are horizontal and vertical.

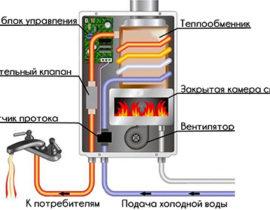

In the event that the design of a gas boiler requires draft in the chimney, we form and check the ways for the output of combustion products. There are also so-called "non-chimney" boilers, in which combustion products are removed by forced air circulation through an exhaust fan.

Gas connection to the boiler is carried out with the obligatory participation of a certified specialist. During installation, only metal pipes and special connecting devices are used.

If your gas boiler has electrical appliances, we connect it to the mains through a separate circuit breaker for short circuit and overheating.

The first start-up of a gas heating boiler must be carried out in the presence of a specialist from the gas company, after carefully checking that all installation rules have been complied with.

Rules for installing a floor-standing gas boiler

Floor gas boilers have more power than wall-mounted ones and require more stringent installation rules.

When installing a floor-standing boiler, as a rule, an extensive heating system is also installed, distributing heat to several rooms or several floors. Therefore, even before buying a boiler, it is necessary to draw up a project of the heating system and understand the location of all its elements, including the correspondence of the location of the outlet pipes of the floor-standing boiler to the inlet pipes of the heating system.

The floor boiler can also be installed on a solid wooden floor, however (unlike concrete) it must be protected with galvanized iron or clinker tiles. In this case, the non-combustible base must extend beyond the front side of the boiler by at least half a meter.

As well as the wall-mounted version, floor-standing gas boilers are carefully calibrated according to the building level during installation. When installing such boilers, a high-quality chimney system is necessarily equipped.

Water heating systems based on gas boilers require the installation of a hardness filter for the incoming water flow.

Please note that each water supply and intake pipe must be equipped with devices that facilitate their dismantling. This is done in order to replace any of the elements of the system in case of repair. Valves are also installed on all pipes.

The rules for installing a floor-standing gas boiler also require its connection and first start-up only with the participation of a specialist from a gas company.

Gas boiler installation rules: training video