Content

Russian stove - the dream of every Slav

This artifact is a symbol of our country, a hallmark of its villages. In fairy tales, this device could even move independently, but even without fantastic conjectures, the home stove is the center around which the entire dwelling is built. It provides a unique comfort in the house and, if necessary, is a very multifunctional device: it heats the house, cooks food, and even served as a bath before. Brick ovens in a country house will become an integral part of your home. A well-built oven will serve you and your family faithfully for decades.

The main function of any stove is to heat the house. Its construction is justified if a central heating main is not connected to your site. Also, the possibility of year-round heating of the house increases the reasons for building a high-quality home stove. If the fireplace can warm you on chilly autumn evenings, then only a solid stove can disperse the cold on a winter night.

Of course - the construction of a stone oven in a country business is a certain art. The profession of a stove-maker has been very respected in Russia since ancient times.But with minimal skills in stone construction and detailed step-by-step instructions, you can build a small oven for the house yourself. And, starting small, then you can build a classic Russian stove yourself.

The main types of brick ovens

So, depending on the functions performed, brick ovens in country houses are divided into the following main types:

- Heating stoves. As you know, such a device is intended exclusively for heating the air in the room. It can heat one room or the whole house if it is built into the wall.

- Cooking ovens - are created with exclusively utilitarian purposes for cooking. In addition, mushrooms, berries and fruits can be dried on a brick cooking oven. Often such stoves are installed in summer kitchens.

- Cooking and heating furnaces. A classic building that can not only heat a room or the whole house, but also be used for cooking food. A multifunctional multicooker with a solid history.

The technology of building brick ovens, proven over the centuries, allows you to create a highly efficient device that will quickly heat up the room, be safe to use and become the center of gravity of the whole house.

The process of building a brick oven in a private house

So, the process of building a brick oven for a house should first of all begin with drawing up a project. After determining the functional tasks of the furnace, it is necessary to estimate its geometric dimensions. Perhaps in a small country house it does not make sense to build a full-size Russian stove with a stove bench. The best option would be to create a combined cooking and heating stove with burners.It will completely cover your needs for heating the room and allow you to enjoy food cooked “piping hot”.

There are quite a few on the Internet brick oven drawings with step by step instructions. In addition, you may like the design of the stove, peeped from friends.

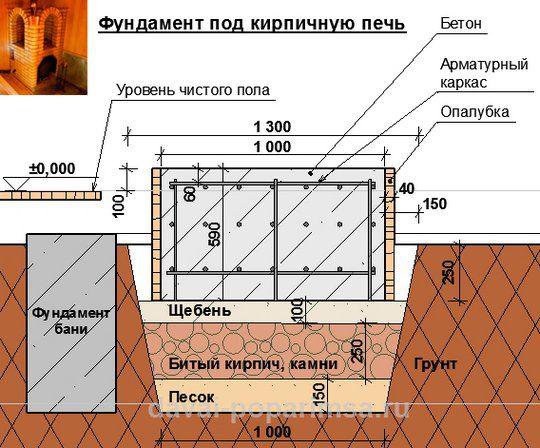

After drawing up the project - decide on the foundation. A brick oven is a rather massive structure and it must be placed at least on a strip foundation that can withstand a fair amount of weight. In this case, the geometric dimensions of the foundation are calculated based on the estimated weight of the brick oven.

Usually, the foundation for the stove is laid at the stage of building a house, but it can be built later, after dismantling part of the floor.

How to build the simplest brick oven for the house?

So, let's look at how to build an elementary brick oven.

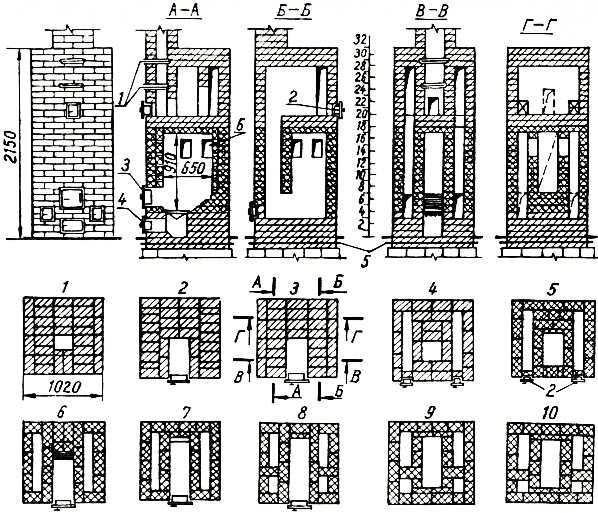

To do this, it is best to use a step-by-step guide that will describe how each row of bricks will fit.

- Especially carefully when laying a brick oven, the first row is being laid. The ideal state of the entire furnace depends on its geometric correctness.

- The second row will have a blower door in its front side.

- On the third row of bricks, the formation of an ash pan begins.

- On the fourth row of bricks, the ash pan is finally formed.

- When laying out the fifth row, it makes a ledge to accommodate the grate.

- Next, the formation of the furnace itself begins, therefore the fifth to fifteenth rows of the furnace must be made of refractory bricks connected with a refractory mortar.

- The combustion chamber door must be installed in rows of six to eight.It, like the blower door, grates and other metal parts, is better to buy before starting to lay the furnace in order to adjust the dimensions of the masonry to the existing equipment. When installing the door, the adjacent walls of the furnace are lubricated with a thick layer of refractory mortar.

- Starting from the ninth to the twelfth row, a firebox is built, these walls must also be connected with a refractory mortar.

- The vault of the firebox is formed in rows of thirteen-fifteen. For insurance, the top of the firebox closes the sixteenth row of bricks. The next element will be the convector. It is mounted in the seventeenth and eighteenth row. Until the end of the twentieth row, carefully monitor the smoothness of the formed walls.

After that, a chimney is formed. It can be made of brick or of labor with appropriate thermal insulation. It is also possible to arrange a combined chimney - asbestos-cement or metal labor is placed inside the brickwork and the space between it and the bricks is filled with sand-cement mortar.

So, for the construction of a brick pipe, you will need to prepare the following materials:

- Refractory bricks and sand-cement mortar,

- Asbestos-cement pipe or ceramic pipe. Also, the chimney can be made of a sandwich pipe, which is a multilayer combination of metal pipes and a heat insulator placed between them.

- Also, for the construction of a furnace, or rather, for coating walls, refractory clay may be required.

Helpful Hints

In order to cut the bricks to size, you can use the "grinder" - an angle grinder.Choose a brick with a regular and uniform geometric shape - this will make it easier for you to display correctly located surfaces of the stove.

It is necessary to lay out bricks on the stove gradually, without haste. A reasonable solution would be to lay up to 25 bricks per day, while it is mandatory to align each row with the help of a building level and a plumb line. You can also achieve an even geometry of the stove using steel corners or wooden templates.

Even such a small brick oven will effectively heat a small garden house in cold weather. Such structures collect heat from the fire for a long time and store it for a long time. Thus, they are practically insured against temperature deformation. Also, the service life of such a furnace largely depends on the quality of the brick used, especially in the area of high heating - the furnace compartment. Try to use quality building materials.

This option is an economical solution. If you have experience in design and construction, you can mount a brick stove that will intervene for itself a hob-burner or a fireplace compartment with an open fire. At the same time, you can close the niche of the fireplace compartment with a special door with heat-resistant glass.

A well laid out stove can retain heat after one fire for a day at an outside temperature of at least 20 degrees. When the temperature drops, the furnace will have to be heated twice a day.

In two-story houses, two stoves are usually installed on each of the floors of the building.

Trial laying of a brick oven for a novice stove-maker!