Chimney passing through a wooden ceiling it should be arranged according to all the rules, since the safety of the whole house depends on its reliability.

Chimneys can be made of brick, metal or ceramics, therefore, when they pass through a wooden floor, different materials and technologies are used.

Content

Types of chimneys

chimney pipes are divided into different types according to their location — root, wall and mounted.

- Indigenous chimney pipes are separate, but next to the furnace, and are connected with her help sleeves. Such structures are convenient in that chimneys from several furnaces can be connected to them.

- wall chimneys are most often built into the capital wall, but sometimes they are allowed to wall.

- Shell-mounted chimney pipes are built on top of the furnace structure.

Accordingly, which pipe is arranged in your furnace will also depend on her passage through the roof. Most often, a mounted pipe is arranged for furnaces.

Metal pipe

As mentioned above, the passage can be lined with different materials, but the main condition remains unified — they must be heat resistant.

From metal pipes to date the most popular steels are those made according to the “sandwich” type. They are made of two metal cylinders, larger and smaller. dameterinserted one into the other, and the distance between them is filled with non-combustible mineral wool, which plays the role of both a heater and an insulator.

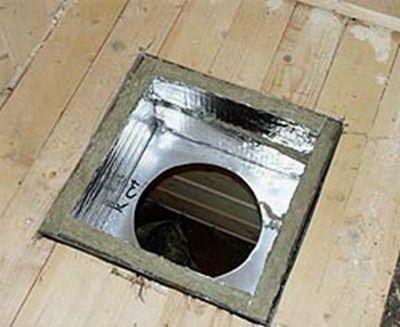

- First thing to do — it is to purchase a ready-made or make your own through pipe (otherwise it can be called a box - because of the characteristic cubic shape). It is made of galvanized iron, based on a diametertr truby and the thickness of the wooden floor. The hole diameter should be slightly larger than the pipe diameter.

- Further, the pipe must be properly prepared for installation, since thin metal will not be able to reliably insulate a heated chimney from combustible materials. For this, an insulating material made of basalt fiber with a foil surface is used. It is glued to the inner surfaces of the pipe and to the parts that will come into contact with the wooden floor.

- next step goes preparation of the ceiling for the installation of the pipe. To do this, you need to take measurements from pipe with already adhesive insulating material. Then a place is marked and drawn on the ceiling, which must be cut out with a jigsaw. Mineral wool is laid in the ceiling.

- Further goes installation of a prepared pipe.

- A special metal panel (usually made of stainless steel) is fixed on the ceiling, having a circle cut out in the middle, which must match the diameter of the hole in the pipe. Through her and carried out chimney pipe.

- The final stage of the passage of the pipe is the design of the chimney on the floor of the second floor or in the attic. This can be done with a metal sheet or a special panel, also with a round hole cut out for the pipe in the middle.

- It is necessary to calculate the location of the pipe in such a way that the junction of two her parts were not located directly in the branch pipe, which is installed in the ceiling. The joint must be located either in the lower room or above the ceiling.

Drywall passage

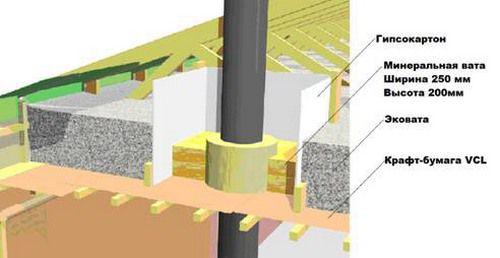

Another option for pipe insulation can be mineral wool, asbestos and heat-resistant drywall. The work process takes place in the same sequence as with a metal pipe, only using other materials.

- A square hole is arranged in the ceiling, which will have from edges to the outer surface of the pipe 20—25 cm.

- A high box is made of heat-resistant drywall, which will close the ceiling from the pipe.

- Further from the side of the ceiling, a steel sheet is fixed to the hole, with a round hole in the middle.

- Installed through a hole in the sheet chimney pipe.

- In the interfloor ceiling around the pipe, mineral wool is laid and fixed along the entire perimeter, for the entire thickness of the ceiling.

- In some cases, above mineral wool or instead her expanded clay is poured.

brick pipes

More labor intensive Work waiting those who make a chimney of bricks, because have to not only make decoration in the ceiling, but also lay out the pipe itself in a special way.

For chimneys, high quality bricks are purchased, as the building is tested by temperatures and soot deposits.When laying this section of the furnace, the seams must be completely filled with mortar, voids must not be allowed. From this, as well as from the arrangement of the passage through the ceiling, the fire safety of the house depends. In addition, voids eventually lead to the formation of through cracks, which significantly reduce traction.

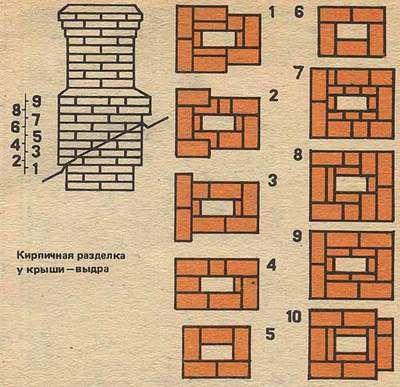

masonry, located in the area of pipes passing through the roof or interfloor overlap is called otter and fluff. Plot chimney the pipe that connects the cutting and the furnace is called the neck, on it and establish valve. The height of this section should be three or more rows.

fluff

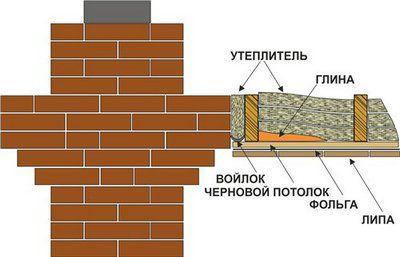

fluff called the expansion of the chimney on the way to the ceiling, interfloor and attic. She is gives essential protection of floors from heat coming from the furnace itself and chimney pipes.

This element stthe swarming of the furnace must have a thickness of at least one brick and insulation of asbestos sheet or construction felt, which is impregnated with a solution of clay.

When erecting a stove and arranging fluff, you should know that any brick structure is required gives shrinkage. Therefore, after laying the furnace, it is necessary to give it time to shrink, and only after that proceed to the spreading device. If the furnace has given a sufficiently large shrinkage, then the fluff should be placed with a small margin from below.

Interfloor or attic floor, at the place of the pipe passage is filled with non-combustible materials, for example expanded clay, and a concrete plinth is laid on top.

Sometimes fluff is arranged from a concrete slab or box, which is filled with expanded clay, sand or medium-sized pebbles.

- For to build a reinforced concrete fluff, a wooden formwork is made around the pipe, thus to the flooded structure had a thickness of one brick and a height of 5—7 centimeters. The formwork is attached to the chimney, and reliability fastenings can be provided with the help of reinforcement pipes embedded in the masonry or thick wire.

- The formwork box is treated with clay mortar from the inside so that the concrete does not stick to the wooden walls when it hardens. Inside, a reinforcing mesh is necessarily arranged, hard connected with masonry pipes. Reinforcement should be at filling completely covered with mortar.

- The solution is prepared from cement, crushed stone or broken brick and sand, mix well and pour into the formwork.

- When the formwork box is filled to the top, the concrete on the surface is leveled. The wooden box is removed after the concrete has completely solidified, and then the fluff on the finished slab is finished with bricks.

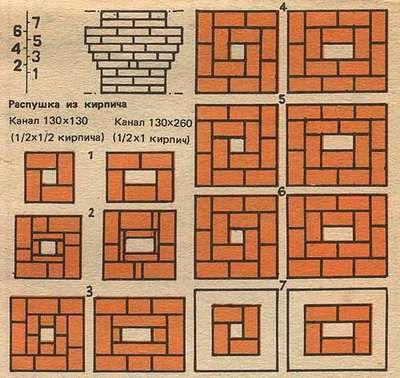

Perform raspunka and brickwork. This diagram shows a fluff in two sizes, having a channel of 13 × 13 and 13 × 26 centimeters. She goes all out ordinal:

- For a smaller size, the neck of the pipe is placed from four bricks, more — out of five.

- In the second row, each side of the first option consists of four whole and four halves of bricks, and the second option of five whole, two halves and two quarters. Wherein, the bricks are shifted outward from the center.

- The next row of the smaller pipe consists of six whole and six ¾ pieces of bricks, and a large chimney put out of eight whole and four halves. Bricks are also shifted to the outside by one fourth bricks.

- Fourth the fluff row of the smaller pipe consists of twelve bricks, and the larger one of fourteen bricks with an outward shift.

- Fifth and sixth, same as fourth a row is laid of twelve and fourteen bricks, but without shifting to the side.

- The seventh row is laid out, like the first of four and five bricks.

- Further riser put the same as the seventh row, only each whole brick should overlap the seam between the bricks of the previous row.

Otter

otter called the expanded part of the head of the pipe, rising above the roof, it is arranged in the form of a small ledge. Her laid out to protect the chimney from precipitation and moisture, which can penetrate into the cracks at the junction of the roof and the pipe head.

An otter, as well as a fluff, can be arranged in two ways — lay out of brick during the construction of the pipe, or pour from concrete.

In the case of brickwork, it is made ordinal in the following way:

- The first row of the otter is laid on the pipe riser coming out of the roof, and it consists of six and a half bricks, (in the diagram they are shown on the left side of the riser). Bricks are shifted outward by ¼.

- On the second row, the masonry is made exactly along the first row and also consists of six and a half bricks.

- The third row is laid according to the pattern of the first row of the otter.

- Fourth the row is laid out without shifting the bricks, those. the size returns to the size of the riser.

- On the fifth row, the riser is returned to the laying of five bricks, which are laid out along the channel opening.

- The sixth row repeats the fifth.

- The seventh row is again laid with a shift outward at a distance equal to ¼ brick.

- The eighth row is laid according to the size of the seventh, following the scheme.

- The ninth consists of seven bricks laid evenly along the outer row of the eighth.

- The tenth row is laid without deviating from the scheme.

Video advice - simple installation of a chimney through a wooden floor

Posting work chimney pipes - not as simple as it seems at first glance, but the meaning her quality performance is very important. That's why this operation is best entrusted to an experienced stove-maker who folded in his practice more than one pipe and easily cope with similar work.