The chimney is an important part of a heating stove, fireplace or boiler, and high demands are placed on its construction. A ceramic chimney pipe is a safe and effective design solution to this issue, because it has high performance characteristics, meets all safety requirements, and is easy to install and maintain.

Content

Why is ceramic better than brick?

For centuries, the chimney was built from bricks plastered with clay mortar. Why are ceramic pipes so popular in recent years? The answer is simple: in terms of its characteristics, a ceramic chimney pipe is significantly superior to brick. Ceramic chimney has the following advantages:

- Good traction. Unlike brick, which has a rough surface, ceramic pipes are covered with heat-resistant glaze from the inside. A smooth surface contributes to better traction, so the owners of stoves with a ceramic chimney do not have problems with smoke at home when burning.

- Strength. The glaze has low water permeability, so the pipe does not absorb water, and all condensate, as well as moisture from precipitation, drains into a specially designed sump.Traditional brick pipes, when moisture settles on the porous surface of the brick, absorb it, which at low outdoor temperatures leads to freezing of water and cracking of the brick and masonry mortar.

- Soot resistance. On a smooth surface, soot practically does not settle, and most of it flies into the atmosphere along with smoke. On a brick, the formation of soot occurs much faster, while the clearance decreases and there is a possibility of it catching fire, which threatens with a fire. Even if soot settles on ceramic pipes, it is easily cleaned by mechanical or chemical methods.

- Fire safety. Ignition of soot in a ceramic pipe is unlikely, but even if this happens, a fire will not occur - the inner coating of the pipe has the necessary heat resistance for this, and its outer walls practically do not heat up due to low thermal conductivity.

- Resistance to chemically aggressive substances. The smoke contains sulfur and nitrogen compounds, which, when interacting with water - condensate or precipitation - form acids. It is because of them that brick and metal chimneys are destroyed. Glazed ceramics is free from this drawback - it does not interact with acids.

- Ease of installation. To fold a brick chimney with your own hands, you need knowledge, experience and time. Anyone can install a ceramic pipe, it is enough to carefully study the instructions. Ceramic is easy to work with, can be cut, drilled, ground and installed with a normal tool within one to two days.

Ceramic pipes are not without mandatory requirements that complicate their installation - this is a rather large weight compared to stainless steel pipes and the need for a foundation. However, if we take into account their warranty period of operation from 30 to 40 years, this feature is insignificant.

Ceramic sandwich chimney

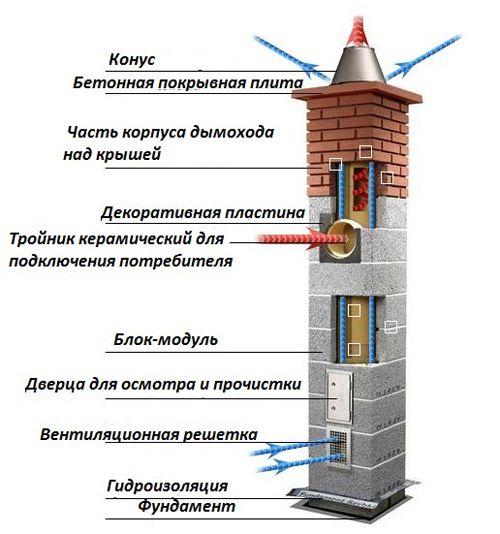

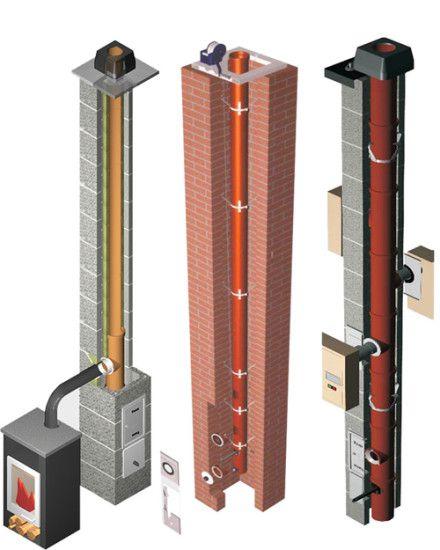

Ceramic pipes for the chimney, as a rule, are installed in a box of ceramic or concrete blocks, filling the gap between them with mineral-based insulation. Such a multilayer design is called a sandwich pipe and allows you to solve several problems at once:

- Thermal insulation of the pipe reduces the temperature difference between its outer and inner surface, which reduces the formation of condensate. As a result, traction improves, the formation of soot and harmful smoke acids is reduced.

- In places where the pipe passes through the ceilings and roofs, fire safety requirements are met due to thermal insulation. At the same time, the chimney itself does not heat up to dangerous temperatures from the outside, which is important when it passes through the residential upper floors of the house.

- The appearance of such a chimney is attractive and, with minimal decoration, will not disturb the harmony in the interior.

Installation Requirements

Ceramic chimneys are produced in the form of ready-made prefabricated elements, which are selected depending on the type of heating device - stove, fireplace or boiler - and have different operating conditions. Therefore, when buying a ceramic chimney pipe, be sure to tell the expert sellers the type of your heater, the fuel you use and the diameter of the pipe recommended by the boiler manufacturer.You will also need a plan of the house and its geometric dimensions: the height of the ceilings, the height and shape of the roof, and the place where the pipe exits through the roof. All this information is important for the correct selection of the height of the pipe and its type.

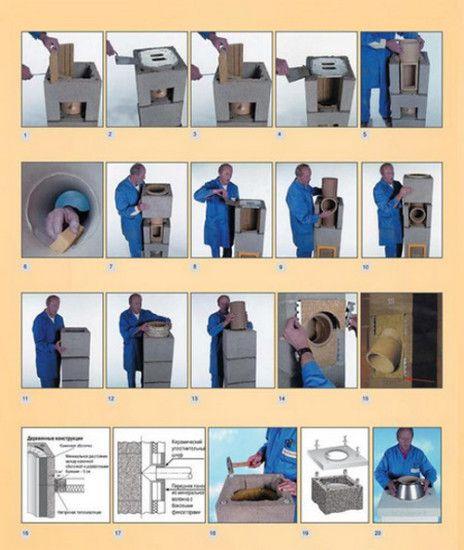

The chimney can be installed both inside the building and outside, near one of its walls - this is convenient when taking the boiler room into a separate room. Ceramic pipes and chimneys must be installed on the foundation, as ordinary ceilings may not support their weight. The foundation is poured in the usual way from concrete grade M250 and above, kept until the concrete matures. The base for the chimney must be flat and not sloped. Double rolled waterproofing is laid on top of the foundation - this is a prerequisite that protects the walls of the sandwich chimney from contact with moisture from the soil and foundation.

The steps for installing a ceramic chimney are shown in the figure.

Installation of a ceramic chimney - step by step video

Depending on the number and placement of heating devices, smoke channels from several consumers can be discharged into one chimney, so its shape may be different. But in any case, the lower element will be a module designed to collect condensate and a ventilation grill. In addition, it is necessary to provide tees for connecting smoke channels and for installing a cleaning door.

A pipe passing through heated rooms in a house with constant heating may not be insulated. But in places of passage through ceilings and in unheated attics, a sandwich chimney is required.An uninsulated ceramic chimney pipe should be no closer than 0.6 meters from any combustible structures - this fire safety requirement cannot be neglected!

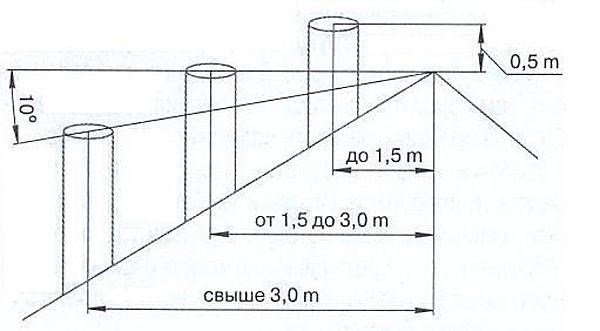

The part of the pipe that is above the roof surface must also have a certain height, which depends on its distance from the roof ridge. Many people make the mistake of thinking that the higher the pipe, the better the pull. In fact, the draft in the chimney is a complex aerodynamic process, the calculation of which requires special knowledge. It is much easier to use the simple scheme shown in the figure.

The top of the pipe is necessarily crowned with a head, which prevents precipitation and foreign objects from entering it. Its shape is also important - it participates in the aerodynamics of gas removal, so you should not cling to the pipe the first construction that comes across, it is better to purchase a cone specially designed for this.

All elements of the chimney are attached to a special acid-resistant solution. It is prepared strictly according to the instructions from a dry mixture and water. In no case should you dilute a solution that is already ready and beginning to harden with water! The mixture is applied with a trowel or with a construction gun to all seams between the elements of the chimney and carefully rubbed with a slightly damp sponge from the inside to remove excess mortar.

How to brick a ceramic chimney pipe

If necessary, make holes for the removal of pipes, the blocks can be sawn with a grinder.

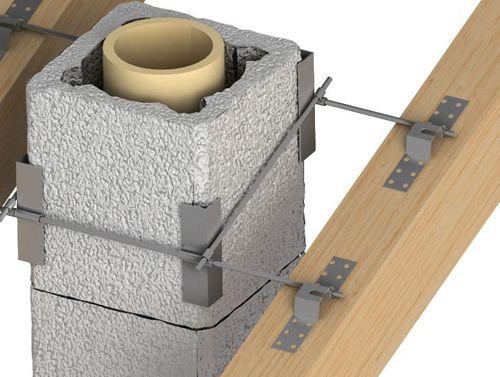

You can not install joints of elements in the places of passage through the floors.That is why it is so important to initially have a house plan in order to select the appropriate sizes and sequence of elements. If the pipe is installed separately, without a sandwich box, it must be fastened to rigid structures with clamps every 1-1.2 meters, and above the roof surface - with wire braces or studs.

Maintenance of ceramic pipe

Due to the features of ceramic pipes, their maintenance is greatly simplified compared to brick pipes. Once a year is necessary clean them of soot mechanically or using special tools. Twice a year, all joints are checked for cracks, chips, deformations and distortions. With each firebox, it is necessary to evaluate the draft, if it is violated, look for and eliminate the cause. You also need to monitor the cleanliness of the ventilation duct of sandwich chimneys and drain excess condensate in time.

A ceramic chimney pipe is a reliable and technologically advanced way to remove combustion products from furnaces and any boilers. Installing such a chimney will cost a lot, but the long service life and excellent safety performance will more than justify your investment.