Arranging a chimney in the house, you need to Seriously to approach choice of material from which it will be done.

Not only the durability of the normal functioning of the heater, but also the safety of the residents of the house will depend on this factor. Smoke ducts are built of brick, metal and sometimes asbestos concrete. But recently, the arrangement of a chimney from an asbestos-cement pipe has ceased to be popular, as more modern and reliable materials have appeared that are many times easier and easier to install and operate! To understand in how there are disadvantages of such a solution, and why it is better to refuse asbestos-cement pipes in the arrangement of chimneys - we will tell below, read carefully so as not to bite your elbows later!

Rules SNiP in the fire safety section it is stated that asbestos cement chimneys can only be installed when using heating appliances, the temperature which when burning does not exceed 280—300 degrees, or in those parts of the chimney which also do not heat up above these temperatures. These can be gas heaters with low power, or the upper sections of the chimney channels, into which exhaust gases enter in a cooled state.

Content

- Asbestos-cement pipes often burn through and burst

- Why were asbestos pipes popular before?

- Installing an asbestos-cement pipe as a chimney

- Asbestos-cement pipe insulation

- The main disadvantages and resulting risks of using asbestos-cement pipes

- Video: another confirmation of the inappropriateness of asbestos concrete chimneys

Asbestos-cement pipes often burn through and burst

When using an asbestos cement pipe in the lower sections of the chimney, where the temperature reaches its maximum, it can quickly burn and burst. Wherein have to carry out the reconstruction of the entire chimney channel, so you need to think about this in advance when building or installing a heater.

Categorically it is forbidden to arrange chimneys made of asbestos-cement material for heating appliances operating on solid fuel - coal or firewood, since the heat from them is much higher than the temperature of the products of combustion of natural gas.

Pipes made of asbestos concrete are forbidden to be installed in brick ovens.

This material has a porous structure and well absorbs the resulting condensate, which contributes to the rapid destruction of the pipe at the point of passage. her through the roof. it creates a fire hazard situation, since the base of the roof is most often made of wooden beams and bars, which can easily catch fire.

Why were asbestos pipes popular before?

In Soviet times, asbestos pipes were installed very often, since they were affordable and, using them, it was possible to quickly complete the construction of the furnace. In addition, this building material was produced according to certain GOSTs, and for production was subject to strict technical control.

Today, each manufacturer produces products without relying on strict standards, so it differs significantly in quality from previously produced goods.

However, in our time, in dacha cooperatives, you can see asbestos pipes towering above the roofs. But, it should be noted that in most cases summer residents do not live outside the city all year round, but means, do not heat furnaces in severe frosts, and the pipe is not subjected to daily extreme tests under the influence of significant temperature changes. This allows the material to last a fairly long time.

The same pipes are used for other needs, where they quite show themselves from a more positive side than as a chimney. For example, they make good ventilation and sewer systems, and they are also used in the construction of foundations.

Installing an asbestos-cement pipe as a chimney

If after all it was decided to use an asbestos concrete pipe for devices from her chimney for heating gas appliances, you need to correctly carry out the entire process of installation, insulation and fastening.

It should be noted that it is best to use such a pipe exclusively for the upper part of the chimney, then it will last a longer time.

For the stability of the asbestos part of the chimney, pieces of reinforcement are embedded in the brick pipe in front of the last or penultimate row. After the solution hardens, a head is installed on the pieces of reinforcement sticking out inside, the distance between it and the brick pipe is insulated with cement mortar mixed with expanded clay.To prevent such insulation from leaking into the pipe, you can first lay pieces of any material around the pipe.

If the transition from a brick pipe to an asbestos one occurs in the attic area, then the passage of the asbestos chimney through the roof must be very good waterproof.

For this, today specialized stores, you can purchase roof passages that will tightly adjoin the pipe and roof with any voluminous drawing, thanks to apron elasticity. It is fixed to the roofing material with a sealant.

Asbestos-cement pipe insulation

Since asbestos has a porous structure, the inner surface chimney pipes are very quickly overgrown with soot deposits. And when condensate is added to the soot, which the formed during temperature changes, in the aggregate, these phenomena have a detrimental effect on asbestos cement and lead to its rapid destruction.

To protect the chimney from the formation of German condensate resort to insulating procedures. Heat-resistant heaters arrange outside. Also, pipes can be further reinforced with brickwork - this will significantly increase efficiency. thermal insulator.

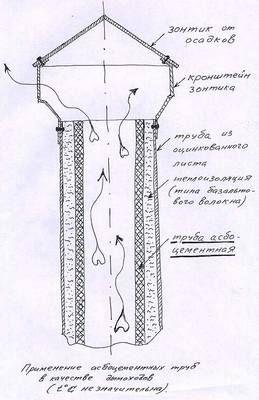

Another option is casing made of metal, which put on an asbestos pipe, insulated mineral wool. Thus, a sandwich is obtained, which will keep the pipe well from sudden temperature changes. To thermal insulation has fully played its role, it must be arranged along the entire height of the asbestos concrete chimney section.

A metal umbrella is put on top of the asbestos pipe, which will not allow penetration inside moisture from the outside.

Exists more one insulation option — with the help of specialized cinder blocks, which are fixed around the asbestos-cement pipe in the form of a box. The distance between these prefabricated elements and the pipe can be up to 10 centimeters or more, depending on the climatic conditions of the region where the chimney is installed. These formed cavities are filled with expanded clay, mineral wool or slag.

The main disadvantages and resulting risks of using asbestos-cement pipes

Not superfluous will be more just to warn you - before giving preference to one or another material for the construction of the chimney, you need to familiarize yourself with all the shortcomings of asbestos-cement pipes for the chimney device in order to be prepared for the occurrence of various situations during operation.

- This material does not withstand high temperatures - at exposed to them, the pipe may burst or even explode.

- The porosity of the material contributes to the absorption of the resulting condensate.

- AT such It is technologically impossible to arrange manholes in the pipe to control the state of the pipe.

- This material is virtually impossible to clean from soot deposits due to the same porosity.

- Asbestos concrete chimney gives the ability to create a sufficiently high thrust due to the lack of heat capacity of a thin-walled material.

Video: more one confirmation of the inexpediency of asbestos concrete chimneys

All of these listed deficiencies can lead to fire or carbon monoxide poisoning, to which would the chimney was not a heater would connected. Therefore, it is worth once again carefully weighing whether it is worth saving on such an important element as the chimney channel, on which the quality operation of the heater and the safety of the house and its residents directly depend?