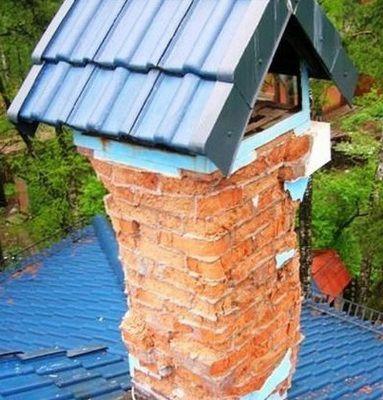

No matter how high quality neither was the work on laying the chimney has been completed, time makes his business, and even the most reliable buildings are unable to resist its influence.

If the first pathological signs of deformation, shedding, cracking appear, it is best to immediately to accept measures to eliminate them, otherwise further happen fatal destruction of the pipe, and then have to build her again. In other words, brick chimney repair becomes urgent task.

Chimney repair work can be varied — from sealing small cracks to dismantling the entire structure and erecting a new one.

Content

Causes and consequences of the destruction of the chimney pipe

It is possible to carry to artificial destructions: poor-quality illiterate masonry; low-grade materials used in the work; improper operation; low qualification of the stove-maker; non-compliance with the rules and schemes for the construction of the structure.

When wrong conducted works in chimney condensate may form in the pipe, and with temperature changes and water freezing ice will break the mortar in the masonry and destroy the bricks. After such processes, a violation of traction is not excluded, and means, it will be impossible to light a fireplace or stove, as smoke will not go into the pipe, but will go into the room.

When using poor-quality or unhardened bricks, it can be damaged by sparks or ignition of gases emanating from furnaces. In the future, these destructions can lead to damage to the entire furnace heating system or even to a fire.

Repair brick chimney is made in cases of its damage for other reasons - for example, due to the consequences spontaneous manifestations or mechanical impact, brought to the violation of the integrity and monolithic masonry.

The natural causes of destruction include the aforementioned long-term use, and, as a result, the general aging of the structure.

Types of repair works

Works enough to repair chimneys laborious, given that part of the processes must be carried out at a sufficiently high altitude, in rather difficult conditions.

The repair technology can be different:

- Dismantling, and then - restoration of the brickwork that has become unusable.

- Installation of sleeves made of special materials in the chimney channel.

- Internal lining of existing channels;

Each of these processes has its own characteristics and difficulties.

Masonry restoration

If the masonry is partially destroyed, then Maybe replacement of damaged bricks. They are carefully freed from the solution and pulled out of the row. Further they clean the place and lay a new high-quality brick on a fresh mortar.

If the chimney bricks are destroyed by more than 15—20%, it must be completely dismantled and a new one must be built. Dismantling is carried out until completely a number of, and from it produce a new clutch.

In case of great damage and the impossibility of making repairs, the chimney is disassembled to the ground and rises again from a new brick. If this is not possible, the chimney is made of steel pipe.

Sleeve installation

Another possible chimney repair option is to vote it, those. installation in the channel of a sleeve made of metal or ceramics.

Sometimes this processss pris produced immediately during the construction of the furnace, and in other cases — in reconstruction purposes.

The positive aspects of installing the sleeve:

- Sleeves for chimney pipes are made round or square With rounded inner corners. Such forms have a positive effect on the efficient removal of combustion products, and do not allow condensate to collect. Unlike round pipes, brick pipes very often collect soot deposits and condensate in their corners.

- In addition, being more one layer of the chimney, the sleeve reduces the heat loss of the furnace, as it increases the tightness of the chimney.

Preparation for work

Before to begin installation, it is necessary to revise the chimney:

- Check the condition of the masonry.

- Make sure reliability design and the absence of obstacles in the channel where the sleeve will be installed.

- Further you should determine the size of the pipe section in order to calculate what diameter the sleeve for her will be needed.

- In the presence of obstacles in the channel have to disassemble part of the pipe in height so that the sleeve can be easily installed;

- Free up space for work.

Installation

When all is ready, you can start the installation process.

- The first thing to be done is to disassemble the masonry, freeing the channel for installing the sleeve.

- The element to be installed must have dimensional parameters corresponding not only to the pipe section, but also her height. In addition, you need to provide a door that will allow you to easily clear chimney area.

- If the sleeve is installed through the top, her gradually lowered down. Bottom first her part is fixed on the ropes and lowered to the desired level. Further into the lowered part of the sleeve, it is necessary to insert the following her Department. In the place of their connection, the masonry should be disassembled, for their better fastening. Thus, the entire structure is assembled, passing through the entire chimney channel.

- Between the walls of the chimney and the installed sleeve, a small space should form, which is filled with non-combustible heat-insulating materials.

- After completion of work, a metal umbrella is put on top of the pipe head, protecting the chimney from dirt and moisture.

- The last step goes sealing brickwork in places where it was dismantled to connect the parts of the sleeve.

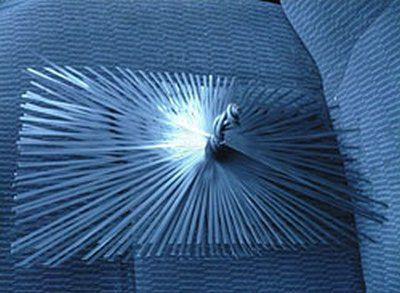

Channel lining

brickwork — this is the treatment of the internal channel of the chimney with special mixtures, to put it simply — plastering of internal walls. With the help of this process, it is possible to put the destroyed walls in order, making them smooth enough, and restore the chimney's performance.

Bricking is carried out with mixtures of "Masan" and "Mordax"who are capable of very fast, without labor intensive disassembly of brickwork, bring the channel into a functional form.The advantage of this technology can be considered that the cross section of the chimney does not become smaller, and all work is carried out in a few hours. The non-combustible composition of the mixtures has good adhesion to any surfaces and can withstand temperatures reaching up to 900 degrees and above.

- "Masan"— this is a Russian development, her made from perlite. Per all period her applications (since 2005 of the year), she showed herself only from the best side.

- Mixture "Mordax", the manufacturer of which is Finland, is manufacturedon on basis of granite chips. It is fireproof and adheres well to the surface. The solution is prepared by diluting with water to the desired consistency of the dry composite "Mordax"mixed with lime and cement.

Work is carried out as follows:

- The area around the chimney must first be covered in order to brickwork do not splash the roof with mixtures.

- Further goes cleaning the chimney channel with an iron brushes, from fromlayered parts of brick and soot.

- After cleaning the channel, it must be moistened.

- Next, using a special brush and winch, produce brickwork.

- Along the way brushes distributed on the walls of the channel brickwork mixture.

- Processss dvizheniya brushes repeated three times, and after each coating it is necessary to give inflicted layer the opportunity to dry the layer.

It needs to be clarified that Maybe, you need not one, but two brushes, since the chimney may have a different cross section for everyone his stretch, and brush must have a size that matches the size of the channel.

Video - Brick chimney. Repair

Video - Replacing and installing a chimney

All of these repair methods are good if it is possible to implement them. But if volume repair work is too large or the chimney has irreparable damage, then the best option would be to completely replace the chimney. And the surest decision would be to invite an experienced, qualified craftsman to perform this work.