Baxi is a line of gas boilers from an Italian manufacturer. The best option for maintaining a comfortable temperature in the room.

Gas boilers of this company are safe, environmentally friendly, durable, almost silent, durable and economical, have high performance and are quite easy to operate, in addition, they are distinguished by an affordable price. Even if a decrease in gas pressure is noted in the network, the boiler will not stop working. Baxi boilers run on liquefied natural gas. Modern design allows you to organically arrange the boiler in the interior of any room.

In order to choose the right spare parts for the boiler after a breakdown, you need to know its series and model. The most common: Baxi Luna (Comfort, Comfort Combi, Silver Space), ECO, Nuvola (comes with a stainless steel boiler), Slim, Main.

The volume of boilers is from super-compact to 80 liters. They can be floor-mounted or wall-mounted. Structurally, boilers are divided into: single-circuit and double-circuit.

Content

- Operating principle

- Possible breakdowns of baxi boilers

- Do-it-yourself Baxi boiler repair - Video lesson

- Boiler does not start

- Burner flame does not reach maximum power

- Boiler starts and stops immediately

- Weak heating of the coolant in the heating system

- modulation not working

- Temperature sensor values become inaccurate

- Weak heating in the hot water system

- When igniting in the boiler, "pops" are heard

- How to adjust the gap between the burner and the igniter

- A sharp decrease in the temperature of the coolant in the circuit

- How to clean the primary heat exchanger with your own hands (video)

- Cleaning the secondary heat exchanger (heating circuit)

Operating principle

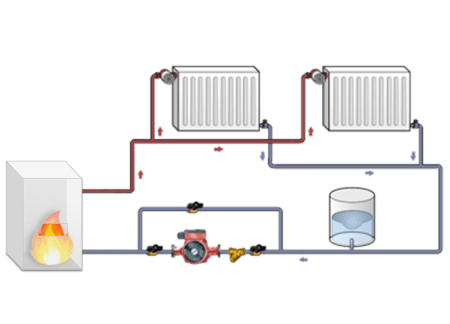

The combustion chamber of baxi boilers is made of metal. Outside, it is covered with a layer of thermal insulation. A copper heat exchanger is placed above the combustion chamber, and the burner is located under the combustion chamber.

When the air temperature in the room changes, the thermostat automatically starts, transmitting a switch-on signal to the pump, which creates a vacuum in the return pipe. At the same time, heated water begins to flow into the supply line of the heating system under a pressure of no more than 0.45 bar (in the event of an increase in pressure, the microprocessor sends a signal to the relay, the contacts close, and the burner ignites). The operation of the boiler starts at low power, which gradually increases until the temperature of the heat carrier reaches the set temperature. After that, the heating mode changes to the modulation mode. As soon as the temperature of the coolant deviates from the set value in the direction of decrease, a signal is received from the temperature sensor, the inlet fuel valve opens, the burner ignites again and heats the water.

In the event that the boiler output is too high at the beginning of operation, the burner automatically turns off and the system can only be restarted after three minutes.

When there is no need for heating, the boiler is switched on to the DHW mode. In this case, cold water through a three-way valve that shuts off the heating line enters the secondary circuit. From the gas valve, fuel is fed into the burner, gradually increasing power. When the water heats up, the temperature control mode turns on.

Possible breakdowns of baxi boilers

Repair work in baxi boilers should be done with your own hands only if there are visible and easily eliminated causes of failure. In the absence of experience in handling the units or in the absence of special tools, it is better to entrust the repair of the boiler to a competent master.

Possible breakdowns:

- - the boiler burner does not turn on or goes out;

- - ignition becomes impossible;

- - pops are heard in the combustion chamber;

- — the boiler overheats;

- - the maximum heating temperature of the coolant becomes insufficient;

- - the operation of the boiler becomes noisy;

- - one of the sensors or elements of the system fails.

Causes of breakdown of baxi boilers:

- - moisture has entered the boiler;

- - water (coolant) of low quality;

- - there was a drop or decrease in gas pressure in the gas pipeline;

- - there was a voltage drop in the mains;

- - the heating system was installed incorrectly.

Do-it-yourself Baxi boiler repair - Video lesson

Boiler does not start

It is possible that during installation the phase and zero are connected incorrectly or air has accumulated in the system.

Burner flame does not reach maximum power

The cause of the malfunction may be an incorrect pressure setting in the heating system, a malfunction of the gas valve modulator, or a breakdown of the diode bridge.

Remedy: adjust the system parameters using the boiler instruction manual.

Boiler starts and stops immediately

The reason is the low gas pressure in the gas pipeline.

Remedy: reduce the value of the incoming gas pressure to five mbar (standard - twenty-five mbar).

Weak heating of the coolant in the heating system

Remedy: check the pressure value on the gas valve, most likely, the min and max values failed.

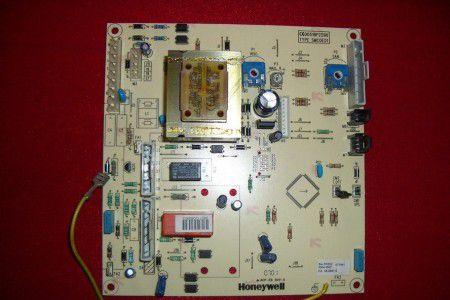

modulation not working

It is obligatory to change the board, as well as the valve.

Temperature sensor values become inaccurate

Replacing the sensor with a new one will help fix the problem.

Weak heating in the hot water system

The reason for this is the incomplete opening of the three-way valve or its breakdown. To confirm a valve malfunction, allow the system to cool down, close the shut-off valves of the heating system, then turn on the boiler in hot water mode. If the valve is faulty, then simultaneously with the DHW heating will occur in the heating system.

When igniting in the boiler, "pops" are heard

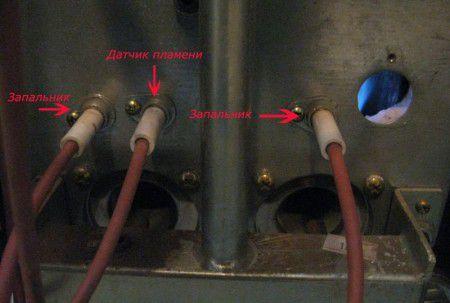

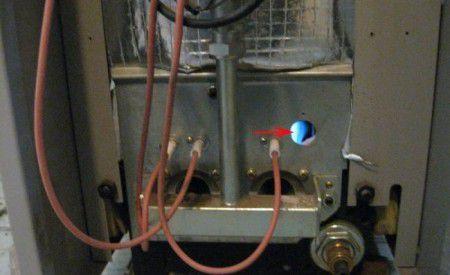

Such noise appears due to: insufficient gas combustion (adjustment of the minimum pressure is necessary); changes in the distance from the gas supply to the igniter during inaccurate transportation of the baxi boiler (you should adjust the gap by setting it to 4-5 mm); excessive draft (using a damper to reduce draft in the boiler).

How to adjust the gap between the burner and the igniter

Open the front panel and completely remove it from the boiler. Remove the shutter from the viewing hole. Behind him is an igniter. To change the gap, it is necessary to unscrew the screw on which the igniter electrode is attached, then remove and carefully bend the electrode. Then we install it in place and close the shutter of the hole.

A sharp decrease in the temperature of the coolant in the circuit

The reason for this is: clogged filters (they need to be cleaned or replaced); damage to pipes, radiators, their clogging or freezing (the malfunction must be identified and replaced or the defective section of the pipeline must be cleaned).

How to clean the primary heat exchanger with your own hands (video)

We drain the water by unscrewing the tap on the boiler on the right. If possible, it is necessary to drain the water from the heating system. For cleaning, we use a device called Gel. We connect the nozzles of the device to the Baxi heating pipes. We unscrew the cap on the device, fill in the liquid for cleaning. We include Zhel in the power supply network. Within a couple of hours, with the handle on the device, we switch the direction of the flushing liquid “forward - backward”. After two hours, turn off the device, unscrew the tap to drain the water from the baxi boiler. We remove the hoses, making sure that the washing liquid of the glass is back into the device. We connect the boiler to the system, fill it with coolant. Boiler cleaning will remove scale from its parts and prevent clogging and breakage.

Cleaning the secondary heat exchanger (heating circuit)

We use the washing machine again. We connect it to the boiler, turn it on. Close the gas valve and open the hot water supply valve. And then turn off the device for cleaning. Thus, the liquid will be driven along the short circuit of the system.

Before installing the boiler, its operation and repair, be sure to consult a specialist. Despite all the positive qualities of baxi boilers, they, like all equipment, have their own margin of safety and service life. In this article, we reviewed main types of breakdowns, and also saw how to repair Baksi boilers with their own hands. We wish you and your boilers success.