Italian gas boilers Baxi have won their trust with excellent performance, rare breakdowns and relatively affordable cost. But, like any other equipment, these devices are prone to malfunction during long-term operation. In some cases, the fault is exclusively human (which is extremely rare).

In the rest, the malfunctions are more likely to be associated with the wear of individual parts. Due to the fact that the digital display gives a specific error code that blocks the operation of the boiler, it is possible to determine which part needs to be repaired or replaced. This is convenient, as you can save time searching the reasonsand try to fix them yourself.

Content

The most common error codes: what are they talking about and how to fix?

Before considering possible errors in the operation of Baxi gas boilers, one important nuance should be noted. Each specific model has its own coding, which is described in more detail in the technical operation manual. Do not be lazy and look into this book to get an answer to your question.However, in some manuals, the instruction with codes is so meager that it forces you to look for information on third-party resources.

E00

The error indicates a malfunction of the electronic board, which actually controls all the processes of the gas boiler.

The causes of malfunctions can be:

The causes of malfunctions can be:

- sudden power surges in the network;

- overloading the boiler and operating it at full capacity;

- burnout of the board itself or its individual parts.

This error appears in the form of a digital value on the display, as well as the termination of the boiler with the impossibility of further ignition.

To solve the problem, you should contact a specialized center for the repair of gas equipment. It is strictly forbidden to independently disassemble, and even more so repair or replace one of the main working elements of the boiler.

E01

Indicates problems with the gas burner, when the device cannot fix the flame and the spark quickly goes out, or ignition does not occur at all. Especially often the problem is encountered after a long non-use of the boiler (in the summer).

The reasons may be:

- Incorrect ignition, when the system does not have time to completely fill with gas and the boiler quickly goes out.

- Lack of gas in the system (the valve on the supply pipe is closed), or the pressure is lower than required.

There is no signal from the flame ionization electrode, which is blocked by the board when a microcurrent leak occurs during gas combustion.

There is no signal from the flame ionization electrode, which is blocked by the board when a microcurrent leak occurs during gas combustion.- The phase on the boiler is incorrectly set, which is easy to check by plugging the plug into the outlet with the other side.

- Malfunction of the control unit, which actually regulates the process of ignition and gas supply.

- Clogging of the draft pipe, which leads to a lack of traction and the inability to properly ignite.

What can be done in such a situation without the help of specialists? The list is small, but in some situations it helps to solve the problem:

- Check the hood for major blockages. Perhaps you had it closed for the summer, and when ignited, they simply forgot to open it.

- Make sure that the valve with the gas supply to the boiler is fully open, and that there is good pressure in the system (set fire to the stove burner).

- Turn the plug over and insert it back into the socket.

If these measures did not lead to the start of the boiler, and the E01 error remained on the display, you should call the wizard and do not engage in self-repair.

E02

This error can be encountered if the gas boiler is operated at full capacity for a relatively long period of time.

The manufacturer made sure that the boilers did not overheat, so he installed special temperature controllers that automatically stop the operation of the equipment as soon as critical temperatures were recorded. This is necessary in order to protect equipment from breakdowns, as well as gas explosions.

This error develops in the following cases:

- There is no contact with the coolant or it has become very weak (with prolonged and frequent use of the boiler without turning it off).

- Incorrect thermostat signal, the operation of which is blocked by the central control board of the boiler.

- Lack of circulation of the heated fluid (faulty pump).

- Local overheating associated with a malfunction of the thermostat and the inability to adequately assess the operating temperature.

The problem is solved by evaluating the health of the thermostat. All repair work is carried out only by specialists who have a permit to work and repair gas equipment.

E03

The problem lies in insufficient air draft, at which the sensors stop the operation of the boiler if there is no necessary draft and the permissible temperature is increased.

This error occurs if:

- closed chimney;

- blockages in the chimney;

- malfunctions in the sensor itself, which incorrectly estimates the pressure and temperature at the outlet.

An error appears in the form of a cessation of the gas combustion process in the chamber. Ignition occurs, but combustion continues for a relatively short time, after which the gas supply is blocked automatically.

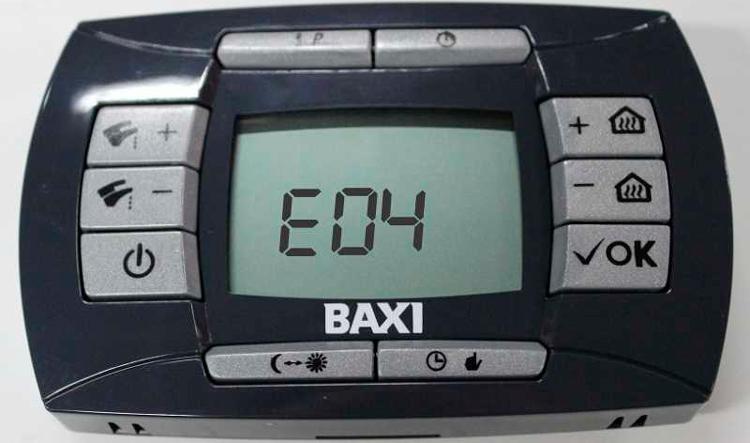

E04

The error occurs when the flame sensor gives a signal about the periodic disappearance of the flame on the burner.

This can be caused by the following faults:

- violation of insulation and tight contact between the wire and the ionization electrode;

- violations in the operation of the chimney, which is associated with a lack of traction or clogging;

- sudden power surges in the network, as well as interruptions in the gas supply.

Often, error E04 appears when the central board malfunctions. In solving the problem, first of all, the chimney is checked, after which the contact density of the wire and the insulation electrode is checked. The work is carried out by the service department.

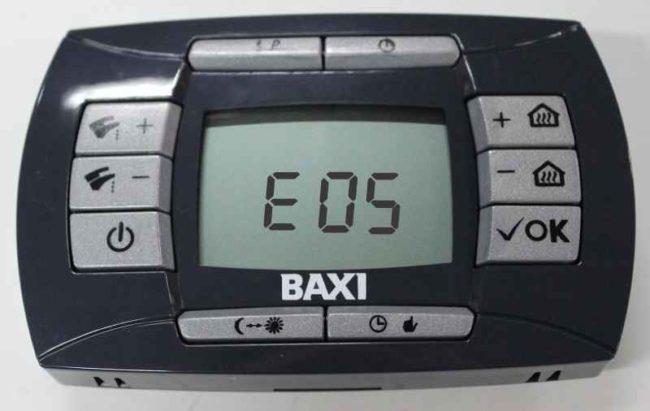

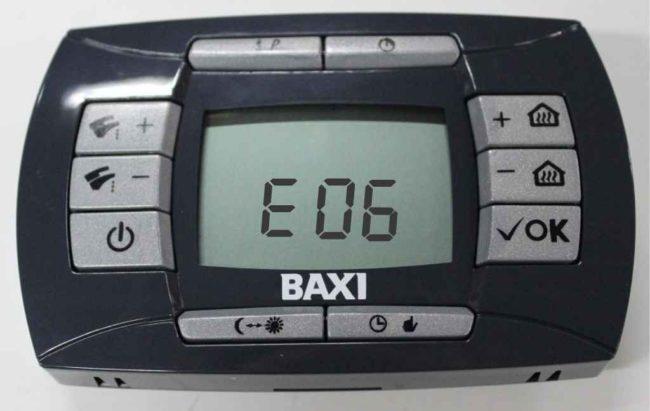

E05 and E06

These errors are more common in Baxi double-circuit boilers that have a water heater function. They arise due to a malfunction of the temperature sensor, which is unable to adequately assess the existing temperature of the circulating and heating water, due to which there is a signal conflict on the central board, which leads to the forced shutdown of the boiler.

First of all, they check the presence of an isolated contact between the thermal sensor and the board itself, after which they pay attention to the condition of the electronic board and the correctness of its operation.

E08 and E09

Errors occur when individual components or the entire board fail. Manifested in the complete blocking of gas equipment and the absence of a reaction to ignition. In this case, deep diagnostics using special devices is needed. Usually indicates the need to replace the board with a new one.

E10

The error is associated with a sharp drop in the level of water pressure in the system, which is recorded by a pressure gauge and leads to blocking of the boiler.

It occurs in such situations:

- There is no contact of the pressure sensor directly with the board.

- Pressostat malfunction.

- Water left the heating system (evaporated from the expansion tank, or went into the water supply system with an unfixed make-up tap).

The first thing to pay attention to is the presence of a sufficient water level in the heating system. Add water to the expansion tank if it is low. If water is drawn into the system automatically, then you need to turn the tap and allow the system to fill up on its own, then close the tap. In the absence of results, the help of specialists is indispensable.

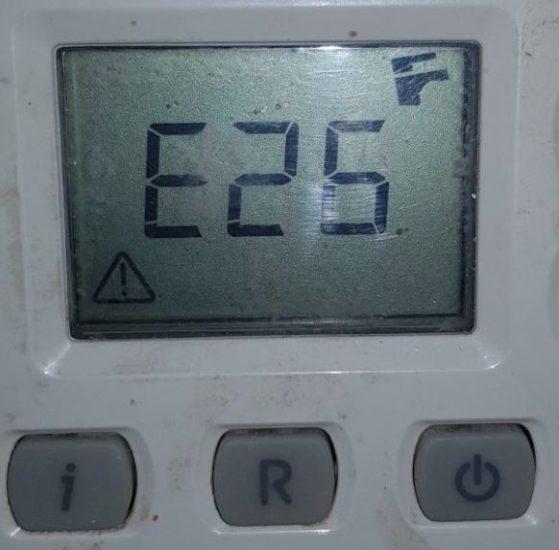

E25

The problem lies in the rapid increase in temperature in the system by more than 1 degree per second.

The problem lies in the rapid increase in temperature in the system by more than 1 degree per second.

It appears in such cases:

- The batteries are fully aired.

- The pump is faulty and there is no water circulation in the heating system.

- There is no contact between the board and the cable of the pump itself.

You need to check if the pump is connected and if it works at all. Other repair work can only be carried out by a specialist.

E32

The error indicates that a large amount of scale has accumulated in the heat exchanger, which interferes with the full operation of the heating system. The problem is solved by cleaning.To do this, a special liquid is launched into the heat exchanger, with the gas and water supply turned off. The reagents break down scale and help remove it from the system.

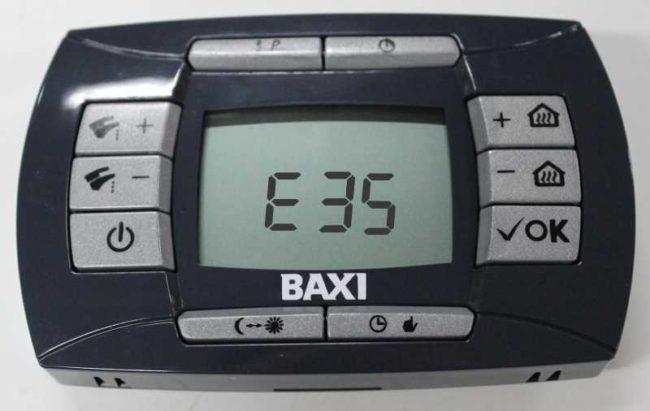

E35

One of the most insidious errors that occurs when fixing a flame when turning off the gas supply.

This happens for two reasons:

- A malfunction of the board itself, which fixes false signals and prevents the boiler from working.

- Lack of tightness of the gas valve, which forms a leak.

E168

The error occurs in those houses where there are power surges in the network in a big way. Experts recommend that gas boilers always be connected through voltage stabilizers. This will extend the life of the equipment and protect against the occurrence of corresponding errors.

What to do when an error occurs?

If the boiler has stopped working, and the error code “flaunts” on the display, you must:

- Write down the code, then turn off the gas and electricity supply to the equipment.

- Look in the service book, what it can mean and what ways to solve the problem are.

- Call a technician who is authorized to repair this equipment.

- Purchase the necessary parts for replacement, if necessary.

It is not recommended to completely open the boiler, and even more so to get structural elements. Without proper knowledge and experience, this can lead to a complete malfunction of gas equipment.

Usually, the presence of an error code on the display causes the boiler to stop functioning. If this does not happen, then you should independently turn off the equipment and call a specialist.

It is very dangerous to use faulty gas equipment.The user assumes full responsibility for his own safety, therefore repairs and maintenance should be carried out as often as required by the manufacturer.

In conclusion, it is worth noting that Baxi gas boilers, despite their high quality and long service life, may be faulty, fixing error codes on the display. Timely cleanings and monitoring the health of equipment will not only save you from expensive repair, but will also allow you to be completely safe.

Video tips for troubleshooting Baxi boilers