The presence of errors on the display of the Ariston gas boiler indicates the presence of malfunctions that do not allow the equipment to function correctly. Our task is to respond in a timely manner and make repairs, otherwise in the future we will not be able to do without large expenses.

Some errors are simply inattention of the user himself. Others indicate a breakdown of a particular part. Thanks to coding, you can quickly identify the area that needs a thorough inspection and repair.

Content

Varieties of errors

Ariston gas boilers are convenient in that all errors generated are grouped directly by nodes. This facilitates the troubleshooting process, since one error cannot have several different causes in different parts of the boiler. Accordingly, the search for the problem is accelerated, and the repair is simplified.

The manufacturer divided all possible malfunctions into several nodes:

- Heating circuit - errors in this part of the boiler are most common, associated mainly with improper operation of the device, or failure of individual parts. Errors start at one.

- Hot water circuit - errors start with a deuce, pop up in double-circuit boilers when there is a malfunction in the supply and heating of water.

- The electronic unit - in errors, the first digit is 3. These errors are the most difficult to solve and often lead to the need to replace expensive parts, boards and controllers.

- Faults in the ignition - are marked with the initial number 5.

This division simplifies the repair process as much as possible. It makes no sense to look for a problem with error code 301 in a faulty ignition, when such marking makes it clear that the fault is in the electronic unit.

The most common errors in the operation of the heating circuit

This block in the boiler fails more often than others, especially if preventive maintenance is not carried out. cleaning. If the code appears on the display, where the first digit is 1, then the problems may be as follows.

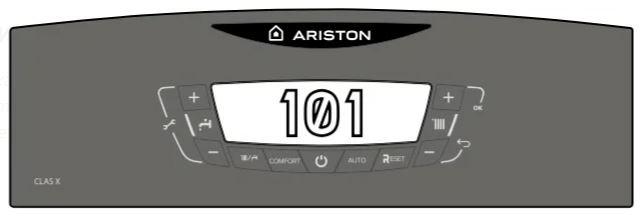

Code 101

The error occurs when the coolant overheats, which prompts the automation to completely block the operation of the boiler until the temperature indicators return to normal.

The reasons may be:

- Dirty coarse filter.

- Scale on the heat exchanger, lack of preventive cleaning.

- Malfunction of the pump that drives water through the system.

- Damage and malfunction of the NTC sensor.

- Malfunctions of the electronic control board, which generates a false high temperature signal.

Often with error 101, you can notice an increase in pressure at the outlet of the gas valve. Repair and search for the cause is possible only by experienced specialists.The maximum that can be done at home is to check how well the pump is functioning.

Code 102

Problem with the heating circuit pressure sensor.

This error occurs if:

- there is a short circuit;

- chain break;

- malfunction of the sensor itself.

You can check the malfunction by measuring the voltage at the sensor terminals. Doing it yourself is not recommended, as special tools and skills are required.

Code 103

The error is associated with too rapid heating of the coolant, which can be caused by the following reasons:

- airiness of batteries;

- thermostat malfunction;

- board problems.

In the event of such an error, you can try to bleed air from all available batteries. In most cases, this helps fix the problem. If after such actions the code continues to be displayed on the display, then the problem is deeper and one cannot do without the help of specialists.

Code 103-107

Errors in this range are associated with an increasing temperature difference in the supply and return pipelines.

There are several reasons for this:

- batteries are aired;

- pump defective.

Code 108

It is characterized by a sharp decrease in pressure in the heating system, which is recorded on the pressure gauge. In this case, the operation of the boiler stops.

It is characterized by a sharp decrease in pressure in the heating system, which is recorded on the pressure gauge. In this case, the operation of the boiler stops.

There are several reasons:

- Lack of water in the expansion tank - the liquid evaporated and the person did not notice.

- The water left through the supply system - the person forgot to close the tap with the water supply, and when the water supply was turned off, the water from the heating system left automatically.

- Water leakage directly in the heating system - pipes leak at soldering or twisting points.

What can be done in such a situation?

- First, check the water level in the expansion tank, top up if it is below normal. Do the same procedure if you take water into the heating system from the central water supply, then close the tap tightly.

- Secondly, check if your pipes and batteries are leaking. If there is a leak, then it must be repaired.

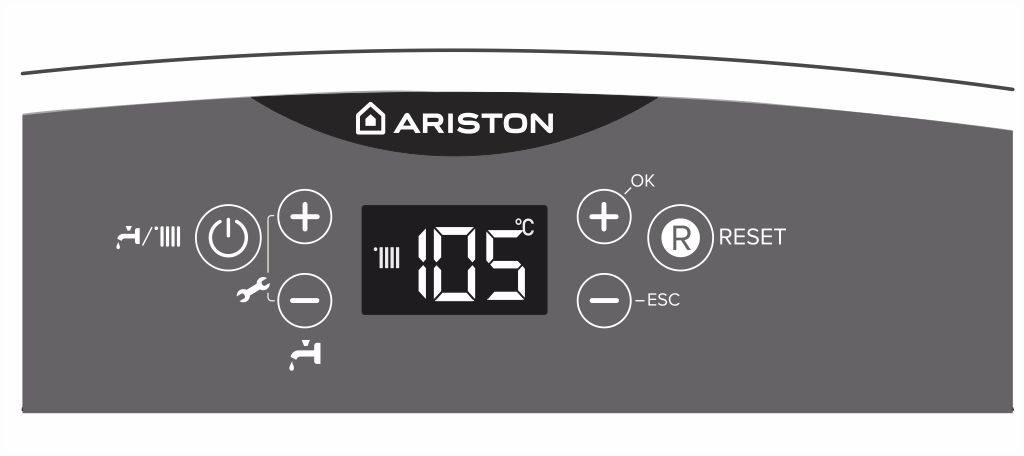

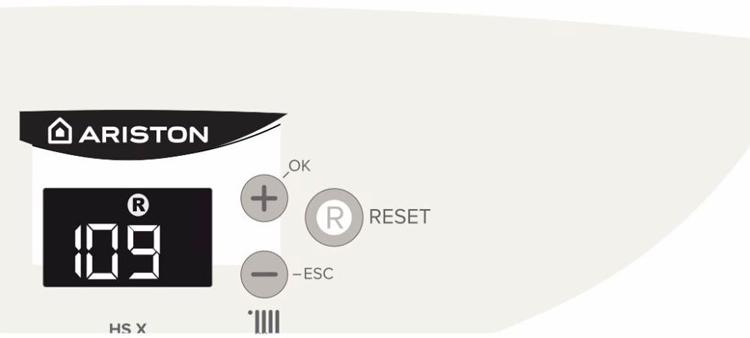

Code 109

The error appears when the system has a critically high pressure (more than 3 bar). This is possible in such cases:

- Too much fluid in the system.

- Battery airiness.

The problem can be solved by forcibly draining part of the water from the heating system, as well as bleeding air from all available batteries.

Frequent errors in the hot water circuit

Malfunctions starting with the number 2 appear only in those models that have two circuits working for heating and water heating.

Code 201-202

There is no contact or there is a short circuit on the NTC sensor. The problem occurs due to frequent power surges in the network. Solved exclusively with the help of specialists.

Code 207

Overheating of the solar collector pipeline, which is due to a malfunction of the thermostat. It is determined using special tools. The repair requires the intervention of experienced craftsmen.

Code 209

Exceeding the maximum allowable temperature in the water heating tank, which happens when the thermostat itself malfunctions, as well as a sharp decrease in water pressure in the system. The boiler is blocked, after which you can try to restart it. Frequent repetitions of such an error are a signal that it is necessary to test the thermostat board and replace it if necessary.

Errors in the electronic control unit of the boiler

Problems in this category can occur both during a power surge in the network, and when the contacts of the working elements deteriorate. All codes start with the number 3.

Code 301

Malfunctions in the display, which cannot correctly display all the data on the processes occurring in the boiler. Sometimes it helps to solve the problem by turning off and restarting the boiler. If the problem is not solved, then you can not do without intervention in the electronics.

Code 303

The most difficult error to identify and fix, which indicates the presence of problems in the electronic control unit. It occurs for a number of reasons, including the factory marriage of individual wiring elements. To eliminate it is necessary to check all parts of the computer for faults.

Errors and malfunctions of ignition and detection

These errors occur when the spark disappears or the boiler goes out spontaneously. There are a lot of reasons: from a clogged hood to a breakdown of the central control board.

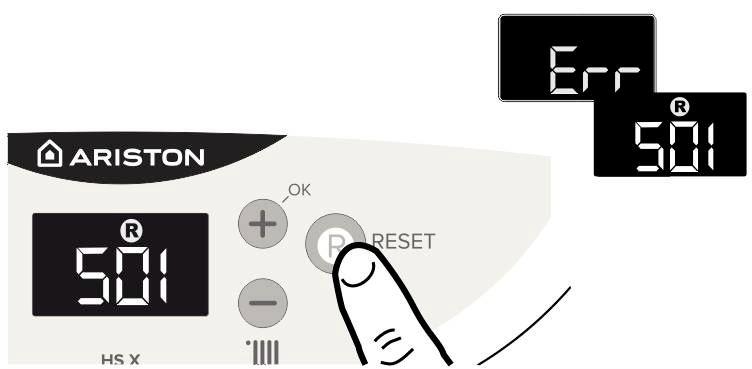

Code 501

When igniting, there is no flame or the flame disappears quickly. There are several reasons:

- There is no gas supply, the valve on the pipe is closed.

- The ionization electrode has oxidized or moved away from the board.

Need to check through the viewing window whether the flame appears at all or there is no spark? Experts can fix the problem.

Code 502

Indicates the presence of a leak when a flame appears with the gas supply valve closed. If the error is displayed on the display, but in fact there is no flame when the gas supply is closed, then the problem is in the ionization electrode, which gives incorrect signals to the board, from where, in fact, this error “pops up”.

Code 601

The error occurs when the gas duct overheating sensor in open combustion chambers is triggered.Usually the cause is a malfunction of the sensor itself, or insufficient ventilation (blockage, cover closed).

What to do when errors occur?

Here are some tips from experts in gas equipment that will help if the boiler display shows the appropriate code:

- Be sure to look at what this or that code in the service book means. Usually the answer to the question is simpler than it seems.

- Check all communication systems: whether the gas supply valve is open, whether the water level in the heating system is sufficient, whether there is air in it, whether the hood is open.

- Contact the service center, where they will help you and instruct you on what to do next.

Often the first ignition is difficult for customers. If this procedure is so complicated, then you can call a special service that, for a moderate fee, will completely eliminate problems. Remember that rebooting the boiler is not always effective in solving certain problems. If the same code pops up quite often, then this is a clear signal that you need to call the wizard.

In conclusion, it is worth noting that Ariston gas boilers are prone to faults just like other brands. Various malfunctions are signaled by error codes that are displayed on a digital display. In order for the operation of gas equipment to be correct and safe, it is necessary not to ignore errors, but to eliminate them.

Video advice for repairing a gas boiler from Ariston