The device of stove or fireplace heating of a private house provides for the presence of a chimney. It is a smoke-exhausting structure in which forced draft is created. An improperly arranged chimney leads to the fact that all the combustion products of the stove or fireplace remain in the heated room, and are not taken out into the street.

Content

Chimneys: types, features

The chimney is an engineering system that is compatible with stoves, heating boilers and fireplaces. The pressure difference that occurs at its inlet and outlet occurs naturally in the system. There are various classifications of chimneys.

Depending on the material of manufacture, chimneys are distinguished:

- brick;

- metal;

- ceramic;

- asbestos;

- polymeric.

The first type of structures is made in the form of a straight pipe. The advantage of this type of chimney is that they provide good traction, the disadvantage is large heat losses. Complex structures are equipped with additional channels. Passing through them, the smoke heats up the walls of the chimney, which become an additional heat emitter in the room.

The classic version of chimneys is brick construction. It has a number of advantages, the main of which is a large heat capacity. Such chimneys are the safest in operation, have a long service life, have mechanical strength, but cannot be installed only on certain models of modern heating boilers, stoves and fireplaces. They require simpler and more mobile chimneys.

Steel single-circuit chimneys

The structures have the form of a pipe made of stainless steel. In some cases, galvanized iron is used to make single-circuit chimneys for heating boilers and fireplaces. The wall thickness of this type of smoke channels starts from 0.6 mm. This is not enough to ensure a long service life of the structure. She often burns out. The service life of such chimneys rarely exceeds 10 years.

Despite these disadvantages, steel and galvanized single-circuit chimneys are popular with owners of country houses.

Contribute to this:

- quick and easy installation of the structure;

availability of material and its relatively low cost;

availability of material and its relatively low cost;- light weight.

Due to the smooth inner surface of the pipes, soot does not accumulate in them. Such structures do not require a foundation device.

Among the significant disadvantages of steel or galvanized single-circuit chimneys:

- lack of insulation;

- poor heat capacity;

- difficulties in docking with roofing material.

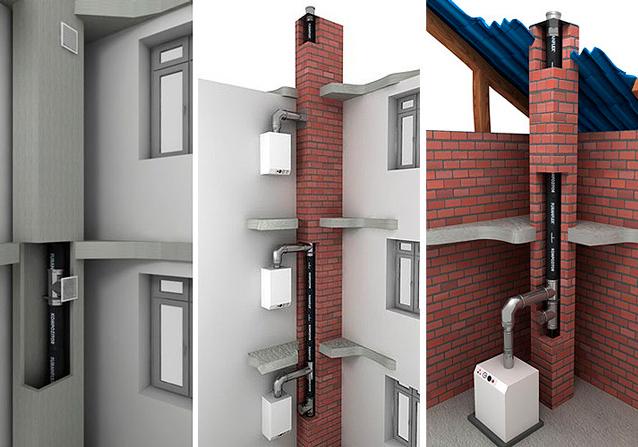

Steel double-circuit chimneys

The main difference from single-circuit structures is the presence of two walls. Between them, a heat-resistant insulating material is laid. Structures can be joined close to the roof. Most often, chimneys of this type are used for a side exit device.

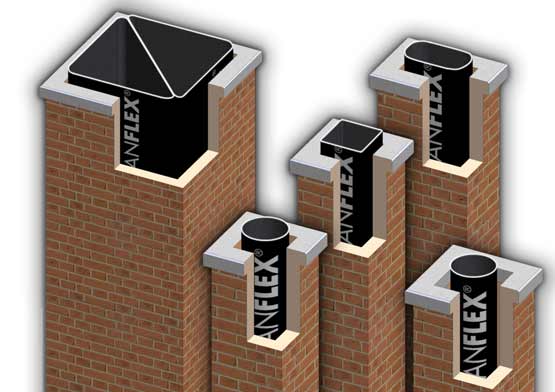

Ceramic chimneys

The structures consist of a ceramic pipe and heat-insulating material. The shell for the ceramic pipe is a tube made of cellular concrete. Most often, the latter has a square section.

The advantages of the design include:

- ease of installation;

- high degree of fire resistance of the structure;

- long service life;

- smooth inner surface.

The chimney is assembled according to the type of designer. The outer walls of the pipes almost do not heat up. A minimum amount of soot accumulates inside the chimney. The main disadvantage ceramic pipes their high cost is considered.

Asbestos chimneys

Single-wall structures have a high degree of thermal stability. Chimneys are a straight pipe with a round section and an internal rough surface. Can be installed on stoves and fireplaces with an upper smoke outlet.

Single-wall structures have a high degree of thermal stability. Chimneys are a straight pipe with a round section and an internal rough surface. Can be installed on stoves and fireplaces with an upper smoke outlet.

Among the advantages of asbestos chimneys:

- low cost;

- light weight;

- fire resistance.

Despite all the advantages, asbestos chimneys have many disadvantages. The main one is a low degree of mechanical strength. Condensation can accumulate in pipes of this type. The chimney can only have a straight vertical shape. Very often it has to be cleaned of soot.

Polymer chimneys

The cheapest design, not distinguished by reliability. Can be used as a temporary solution. Only suitable for connection to gas boilers. Despite this, polymer chimneys have their advantages.

Among the advantages:

- low cost;

- smooth inner surface;

- light weight.

The best chimney models

Kit Ferrum 115 mm, 0.8 mm

The flue is intended for installation on all types of fireplaces.It has a direct connection and optimal inlet diameter. Welding seams of a design have tightness and do not pass condensate into a smoke channel. The chimney has an outer shell made of galvanized steel. Mineral wool is laid between it and the walls of the main structure, which protects the roof from fire.

Advantages:

- all seams of the product are made by laser welding;

- the kit includes everything necessary for the installation of the structure;

- increased fire safety;

- there is a cap that protects the chimney from falling rain and foliage into it.

Flaws:

- small wall thickness of the structure;

- high price.

Smoke set 115 mm, 0.5 mm

A budget option. The internal pipes of the structure are wrapped with Rocwool basalt wool, resistant to deformation. The outer shell is made of galvanized steel. Welded seams are made using TIG technology.

Advantages:

- affordable cost;

- there is a head and an adapter from a single-circuit to a double-circuit design;

- high quality of AISI steel used in the production of the product.

Flaws:

- the kit does not include insulating material for the joints of the structure with the roof;

- there is only one attachment to vertical structures;

- not recommended for installation on wood-burning stoves and fireplaces.

Ferrum 200 kit, 0.8 mm

The large throughput diameter of the pipes allows them to be installed not only in private homes, but also in office buildings. The flue is made of stainless steel. The design has a high degree of strength.

Among other advantages:

- sealed seams;

- good insulation;

- ease of installation;

- high takeaway;

- there are caps for the inner and outer pipes.

Main disadvantage:

- high price.

Phoenix 120 mm, 0.1 mm

Chimneys of this type are great for sauna stoves. They are connected to the rear wall of the thermal units. Chimneys have good draft. It allows you to heat the oven to the highest possible temperature. The upper part of the structure has a narrowing and a cap.

Advantages:

- good insulation;

- high performance;

- the presence of a stand for lateral outlet;

- strong butt joints.

Main disadvantage:

- high price.

Set Volcano 120 mm, 0.5 mm

The structure is made of stainless steel. It is installed vertically through a hole in the roof. Chimneys of this type have a presentable appearance. They are ideal for country houses.

Advantages:

- the presence of an insulated umbrella and a condensate collector;

- can be installed on copper furnace equipment;

- reliability and durability.

Main disadvantage:

- high price.

SNiP

The device of chimneys is regulated by a number of regulatory documents, the requirements of which are mandatory. These include building codes and regulations. They determine the procedure for installing a smoke exhaust system and its operation.

Requirements for the installation of chimneys are set out in DBN V.2.5-20-2001 and SNiP 2.04.05-91. The operating rules and fire safety requirements for chimneys are determined by SNiP 41-01-2003. The basic rule for the arrangement of smoke exhaust channels: one stove - one chimney. It must provide sufficient draft to remove the entire volume of flue gases.

The diameter of the chimney must not be less than the size of the cross section of the outlet pipe of the furnace unit or fireplace. It is strictly forbidden to install metal chimneys with a wall thickness of less than 0.5 mm.Such products must have increased thermal and corrosion resistance. Smoke channels should not have more than three turns.

Do not place chimneys near thermally unstable, combustible surfaces. During the heating season, the chimney must be checked at least 2 times and cleaned as it gets dirty.

life hacks

At arrangement of chimneys in wooden houses it is necessary to protect from excessive heating not only attic floors and rafters, but also walls. Those near their surface must be equipped with protective screens. If they are at least 55 cm from the chimney, then metal sheets can be used. At a distance of 15 cm, only ceramics are used.

In order not to reduce the draft force in the chimney, if there are horizontal sections in it, it is necessary to make them no longer than 1 m.

The joints of the chimney with walls or roofs must be treated with a heat-resistant sealant. Its operating temperature must be at least 1000 degrees Celsius.

The life and health of people depend on the correct arrangement of chimneys. Therefore, it is better to entrust their calculation and installation to specialists.

Video advice on how best to install a chimney