The installation of any solid, liquid or gaseous fueled heating device or structure, stove, fireplace or boiler will require the installation of an exhaust system for exhaust combustion products.

Not so long ago, there was no particular alternative - it was necessary to build a brick structure or resort to the use of asbestos-cement pipes, which have much more disadvantages than advantages. At present, the situation has changed dramatically - a stainless steel chimney shows excellent versatility.

In skillful hands, a set of stainless steel parts turns into a universal toolenabling the installation in the shortest possible time chimney system that fully meets everyone current standards and safety requirements. In addition, the overall estimate for installing a chimney, even with the seeming high cost of components, will always be more attractive than other options. With the right approach and knowledge basic principles installation, assembly similar systems is quite a feasible task for any homeowner.

Content

What is a stainless steel chimney

First of all, a few words about what a stainless steel chimney assembly kit is.

There are three options:

- Components made of single-layer material, thickness from 0.6 to 2 mm, so called, mono systems. They are certainly cheaper, but their scope is significantly limited. They are only used internally. insulated premises, as there is a large temperature difference between the outside and inside the pipe will lead to absolutely unnecessary excessive consumption of energy carriers, to the abundant formation of condensate in the cavity, will affect general performance and durability of the entire heating system. Their only advantage is that they are often used indoors as secondary heat sources - for example, tanks for heating water or outdoor liquid or air heat exchangers can be mounted on them.

- Corrugated stainless steel parts - they are used to create curved transitions, for example, from the heater itself to tough chimney area. However, they do not always differ in the required strength and heat resistance, and often inspectors of regulatory authorities simply refuse to approve projects using corrugations.

- The most versatile - components from the category sandwich tube, in which a layer of fireproof material with high performance is laid between the inner and outer stainless coating thermal insulation - usually, this is basalt mineral wool. Such elements can be safely used for both internal and external chimney laying.

The next question is the grade of stainless steel. Metal black all parts are almost the same, but performance characteristics can vary significantly. Therefore, when choosing, be sure to pay attention to the labeling of products:

- Steel grade 430 - used for parts that are the least exposed to aggressive effects. As a rule, from her are made external casing - Environment humid atmosphere for her not terrible.

- 409 steel - best suited for appliances powered by solid fuel (for fireplaces, stoves).

- Steel 316 - enriched with inclusions of nickel and molybdenum. It raises her heat resistance and resistance to chemical (acidic) attack. If you need a chimney for a gas boiler, then this will be the right choice.

- Steel grade 304 is largely the same as 316, but the content dopeshchih additives below. In principle, it can be a replacement for an analogue, with the advantage of a lower price.

- Stamps 316i and 321 are the most versatile. The temperature limit of their operation is about 850ºC, and this is combined with high acid resistance and excellent ductility.

- Stainless steel 310S– the most "elite" material, which, along with all other positive qualities, is resistant to temperatures up to 1000ºC.

The range of manufactured stainless steel chimney parts is very diverse and is able to meet the needs of almost any designed system.

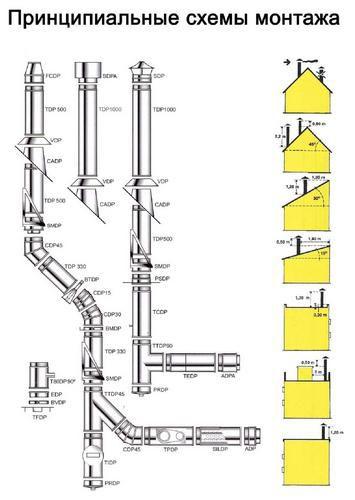

- Straight sections length from 330 to 1000 mm. All of them have special socket connection, requiring no additional elements.

- Elbow (elbow) 45º, used for need changing the direction of the chimney on vertical or inclined sections.

- Elbows 90º - usually used to go from a short horizontal section at the heater to basic parts chimney pipes.

- Tees under angle at 45 or 87º - installed at the installation site of the condensate collector or, in case of installation of two devices, when they are connected to a single chimney system (requires separate approval of regulatory authorities).

- Revision elements of the chimney - designed for regular monitoring and cleaning of the system.

- Condensate collector - is installed in the lower part of the main vertical section and serves to regularly release the chimney from accumulated moisture.

- Elements of the upper part of the chimney - spark arrester, cap, waterproofing skirt.

- You can also purchase special elements for passing through a wall, floor or roof. If such parts are not provided by the supplier, they will need to be manufactured independently.

Preliminary calculation of the chimney system

When planning the installation of a stainless chimney, it is necessary to take into account several important criteria that are provided for by special fundamental documents of the technical supervision service:

1. The total height of the chimney cannot be less than 5 m - for ensure normal traction.

2 .It is not allowed to install horizontal sections more than 1000 mm long.

3. In unheated rooms or in open space (on the street), it is prohibited to install elements that do not have their own thermal insulation.

4. Particular attention to the excess of the chimney cut above the roof:

- If the roof is flat - at least 500 mm.

- The same requirements, if the distance from the pipe to the ridge of the pitched roof is less than 150 cm.

- At a distance of 150 to 300 cm - the pipe must be how minimum, flush with the height of the ridge.

- For large distances, the cut of the pipe should not be below the line 10º from the horizon of the height of the ridge.

- There are situations when other buildings are attached to the main building. In this case, the height of the pipe should be, least, above their top level.

5. If the chimney passes through the roof from combustible materials, the installation of a spark arrester is a prerequisite.

6. The most critical areas are the passage through walls, floors, roofs, especially if they are made of combustible materials. If the pipe is not insulated (single wall), then the distance between it and the ceiling must be at least 1000 mm. This, in fact, is not practiced, but even with a “sandwich” thickness of 50 mm, the minimum gap should be 200 mm.

7. Pipe joints in the thickness of walls or ceilings are not allowed. Minimum distance from the floor, ceiling, wall - 700 mm

8. When the chimney passes even through a non-combustible roof, the minimum gap between the pipe and the coating cannot be less than 130 mm.

9. Two basic rules must be taken into account:

- On a horizontal or sloping site from fromheating appliance or furnace pipes are mounted "by smoke", those. so that the combustion products move freely along the internal channel. On practice these are pipes put on the previous one from the boiler.

- On the vertical section of the chimney, all vice versa - mounting goes “by condensate”, so that the resulting moisture that flows off “has no chance” to get into the insulation. Thus, each subsequent section of the pipe is inserted into the lower one.

10. Diametr trubi in none of its mates can be less than the standard outlet pipe of the heater.

eleven.The total number of turns of the chimney, regardless of their angle - no more three.

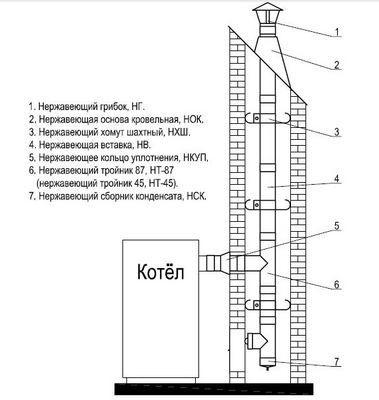

The chimney may have an internal layout, with passage through the premises of the house. In this case, either thermally insulated sandwich pipes, or the chimney itself can be closed with brickwork.

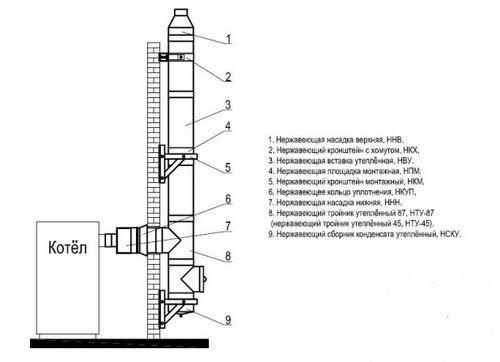

Recently, with widespread two-layer isolated parts, its external placement has become a more popular scheme, with brackets attached to the outer wall,

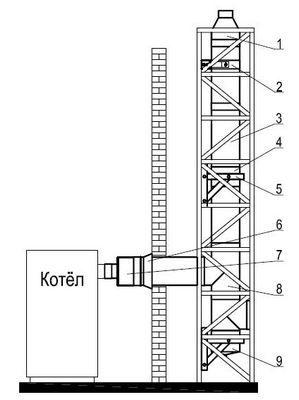

or with the installation of a special supporting structure made of a metal profile.

The advantages of such placement are obvious - there is no need to arrange complex thermally insulated passages through interfloor floors and roofs.

Installation of a stainless steel chimney

Actually, if the chimney layout is carefully thought out, the approval of the regulatory authorities has been obtained (it is a prerequisite), all the necessary details of the future system are purchased, then installation is not particularly difficult. All elements are equipped with adapted mating areas, and connecting them one to another is a simple and intuitive task.

Pipe joints, especially inside a dwelling, should be further reinforced with a special sealant that can withstand temperatures up to 1000—1500º - it is easy to find it in specialized stores that sell accessories for chimneys. This will allow guaranteed avoid the penetration of combustion products hazardous to health into the premises and reduce the draft in the system.

When fixing the chimney on an external wall on the brackets, the distance between them should be no more than 2 m. A bracket (support) is obligatory in the places where the pipe passes through the wall and where the condensate collector (revision compartment) is fastened.

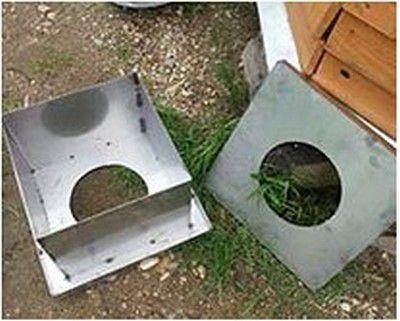

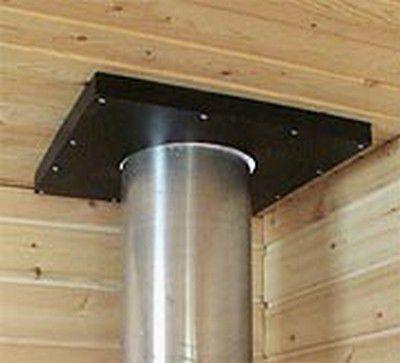

If installation ongoing indoors, the main attention is paid to the places of passage through the floors. Some manufacturers chimney systems include in their assortmentnt spspecial elements for these purposes. But, if there are none, it is easy to make them yourself.

In fact, this is a box with a central hole for the passage of a pipe of the appropriate diameter, and a wall length that provides the required distance of the chimney from the floor material. Very often it is also made of stainless steel.

It is attached in the thickness of the ceiling, free space in German filled with non-combustible material (basalt wool or expanded clay). From above and below it can be closed with a decorative plate.

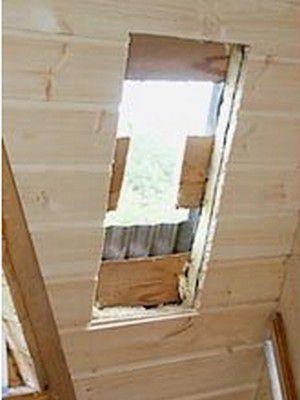

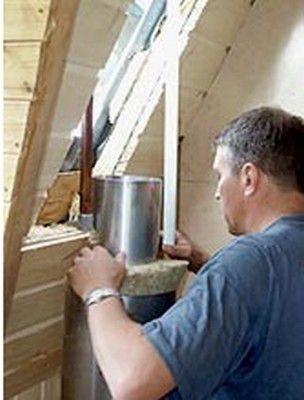

On the roof - a slightly different approach.

- Firstlyif she has definite angle with the horizon, the hole for the pipe will have not round, but an elliptical or rectangular elongated shape.

- Secondly, you should immediately take into account the location of the ceiling beams and rafters - it is necessary that the chimney pass approximately in the center of the distance between them.

- Thirdly, in addition to thermal insulation, it is necessary to provide waterproofing from above - so that precipitation or condensed moisture does not penetrate into the attic.Today it is easy to purchase special flexible elements that fit any roof profile.

- Useful for chimney the pipe will be put on a “skirt”, which will protect the joint with the roof from direct rain.

From above, the pipe is crowned with a head - an umbrella. In some cases, which have already been mentioned, it will be necessary to install a special element - a spark arrester.

Video. Master class for installation of a stainless chimney

In fact, if the installation scheme is thought out to the smallest detail, agreed with regulatory organizations, then the installation itself turns into light "A game of children's constructor." Of course, you shouldn't take it that way. simplistically - appropriate skills in reading drawings, locksmith work, the ability to use power tools, accuracy, consistency in work will be required to the fullest.