Reliability the entire heating system, high-quality laying of the furnace or installation of the boiler, the correct choice of the chimney — is the safety of the house and its hosts. In addition, the efficiency of the entire system directly depends on this. Recently chimney pipes were laid out only from bricks, but today a large number of companies have appeared that are engaged in the production of these heating elements from galvanized and stainless steel. One of them is a Russian company Trancol, whose chimneys, thanks to their quality, won wide recognition among consumers.

Content

Trancol history

The company was founded in 1998 and is engaged in the production of chimneys for stoves, boilers and fireplaces, powered by solid fuel and gas. Besides, specialists of this company carry out the development of non-standard complex units chimney pipes, which sometimes have to be used for a high-quality device of this most important element of the heating system.

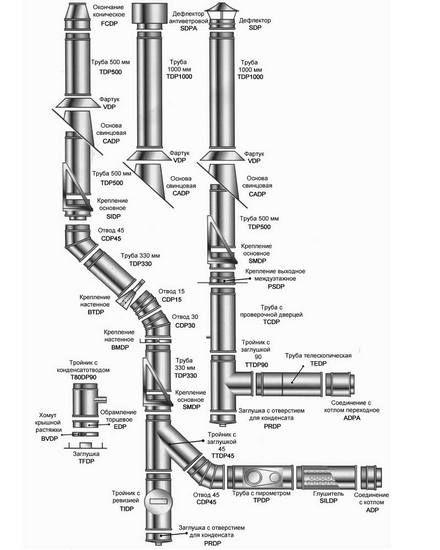

The range offered by the companyTrancol» there are several chimney parts hundreds of titles designed for assembling one- and double-walled pipes made from different grades of steel alloys. Parts and assemblies have different wall thicknesses and layers thermal insulation material. All products manufactured by the company are patented and have the appropriate certificates.

OOO "Trancol» approaches any order received with full responsibility, therefore, an individual project is made for each specific case, and this process is a fundamental step in the further high-quality construction of the chimney. The design of chimneys is carried out by the company's engineers, using the most modern software. security.

This approach ensures the accuracy of dimensions and shape.rm sunex constituents chimney elements. In some cases, the plan of the house in which the steel pipe will be installed is not enough, so the design specialists go to the site to visually assess volumes operation and location of this element of the system. Based on the results of the inspection of the building, a preliminary sketch drawing design and an estimate for manufacturing and installation.

The quality of the materials used

It is impossible not to say about the material from which the products are made. It is corrosion resistant and has a long service life. Such chimney pipes have a perfectly smooth and mirror surface not only on the outside, but also on the inside, which contributes to the free removal of residual combustion products.

The company uses AISI 304 chromium-nickel austenitic steel for the manufacture of chimneys. — 316. This material is designed for long-term service, it is acid resistant and has excellent welding characteristics. Such steel does not change its properties and quality when exposed to her high temperatures up to 500 degrees.

The outer shell of the thermal insulation elements and single wall elements are made of steel with a mirror coating, the thickness of which is 0.5, 0.8 or 1 mm. The inner contour is made of steel with a matte surface, having the same thickness.

It should be noted that a combination single wall and double-walled pipes, they are easily joined with already built shafts and chimneys.

thermal insulation

chimney channel thermally insulated, what gives the ability to maintain the required temperature conditions inside the entire circuit, as well as to eliminate the occurrence of condensate. The thickness of the heat insulator layer produced from mineral basalt wool grades ROB 80 t or MAT 30, usually from a well-known manufacturer Paroc» , being absolutely non-combustible material, ranges from three up to ten centimeters.

Trancol chimney installation technology

To create the necessary draft in the heater, the fireplace pipe has a straight design. If there are difficulties associated with the lack of a gap between the rafters and the overlapping beams, the chimney taken away to the side and special transitions are made for this.

Such a chimney is not covered with a special deflector, so precipitation can enter it. To minimize these negative factors, the chimney connect to heater from the side parts.

At the bottom chimney pipes have a special outlet for condensate, it removes all the moisture that has appeared inside it.

A very important point is the waterproofing of the chimney passage through the roof, and a separate part is also provided for this. The complex structures of this part of the heating system with turns at different angles are performed using tees, bends, fasteners and other elements of the chimney system.

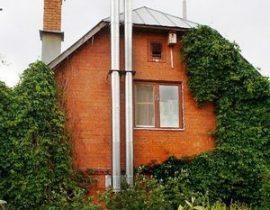

chimney company systemsTrancol» can be located inside buildings, pass inside walls, as well as they are fixed outside on the wall of the building with special brackets. To carry out chimney pipes outside the house, you need to choose options with a thicker heat-insulating layer, otherwise, with temperature changes, condensation cannot be avoided inside them.

Video about the advantages of chimney sandwich pipes

High quality and high tech chimney company systemsTrancol”, produced on the basis of advanced technologies, have excellent characteristics and are in great demand among owners of private houses. They are reliable and have ten-year operation guarantee. Mounting chimney systems are produced by company specialists or this process can be carried out independently. In this case, the company will provide a setct sunex necessary elements and the scheme of their assembly, as well as will produce delivery of the material to the specified location.