Folding the stove is not easy, but when it comes to arranging the correct passage of the chimney pipe through the roof — this is an equally important process.

Fire safety, as well as waterproofing of the furnace and attic floor, depend on how correctly the work will be carried out. An improperly installed exhaust system for gases that are released during the combustion process can cause fire! These gases are also hazardous to health and life of a person, their accumulation under the roof of residential premises creates a dangerous layer, which, reaching a critical mass, can cause irreparable damage to human health and even death!

The consequences are bad carried out work on sealing the chimney when it exits through the roof can be as follows:

- If the pipe is not protected from moisture, dampness will easily destroy the chimney masonry over time, penetrating into the seams and corroding the mortar, which can also lead to attic smoke, and in the worst case — and to the fire.

- Moisture that appeared in leaky sealed holes around the pipe, flowing down the masonry, penetrating inside chimney, and can lead to the formation of fungus. Have to change the pipe and Maybe — even part of the oven.

- Waterlogging of not only pipes, but also vapor barrier and insulation materials can lead to their rupture.

- As a result of the loss of tightness of thermal insulation, the heat loss of the building will increase.

- maybe violation of air circulation in the attic, which will lead to decrease moisture exchange.

- The ingress of moisture into the cracks during temperature changes forms ice, which will expand the cracks, and destructive processes will become more active.

- Due to moisture, the entire roof structure may be broken. — If she will fall on the truss structure and will start her fret.

Such a picture can occur in a pipe, with poorly sealed gaps around her. To avoid such a problem, the installation of the pipe outlet through the roof must be carried out carefully and competently.

Content

Correct passage of the chimney pipe through the roof

Starting this process, you need to learn and follow the established rules SNiP 41—03—01—2003. Chimney installation work will be needed in the following cases:

- during the construction of the roof;

- when repairing a roof;

- when installing a heater or building a furnace.

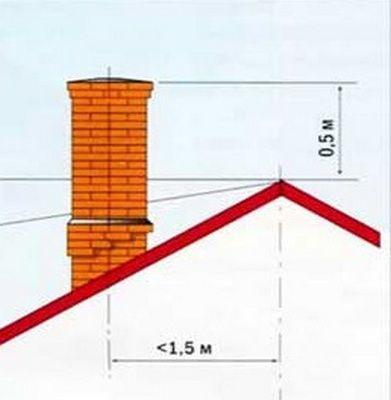

Experienced stove-makers advise placing the outlet of the pipe closer to the highest point of the roof-ridge, and it should rise above it by at least half a meter. This is convenient for those what less snow will accumulate in the area above the pipe, what when it melts, the ri decreasessk prswelling.

If the pipe head is lower on the roof slope, it also must be raised above the coating not less than half a meter.

It should be noted that the type of chimney and its finish is very important during this process, since there are several options for designing this node, which is important for the whole house. The removal of the head has different designs, and depends on the shape and material from which the chimney is made, the place of its exit and size. chimney pipes can be made of metal, brick, asbestos cement or ceramics. For each type of pipe, a passage is arranged certain way.

The design of brick pipes output through the roof has its own type of installation. The plastered head of the pipe is sealed in a completely different way, and a ceramic or metal chimney has several methods for sealing the seams between it and the roof.

The material of the roof also plays an important role in the design of the seams around the chimney.

For different types of roofing materials, it is easy to find a special element that will help make the chimney waterproofing more reliable. The main thing — choose the correct slope of this element. Very important, to the pipe was located in the opening of the roof in such a way that to the distance between it and the roof, as well as the rafters, was at least 5—7 cm. These gaps are filled with non-combustible insulating material, such as asbestos.

Elements for insulating round pipes

To bring out a round pipe, which can be made of metal or ceramic, you need to correctly make a hole in the roof. Around the hole, from inside the roof, it is recommended to fix a metal sheet or a specially made metal panel with a hole for the pipe.If necessary, you need to add additional bars for their fastening in crate.

The roof can have different slopes, and from them it will depend which insulating element, called a roof penetration, should be chosen for waterproofing. In construction stores, there is a large selection of various auxiliary elements designed specifically for this procedure, of different shapes and diameters.

Elastic roof penetration

A pipe leading through a roof with a slope will accordingly require a special sinking slope. Also, you can say, what her The choice will depend on the material with which the roof is covered. This is taken into account in order to achieve the best sealing effect.

Roof penetration is a pyramid, consisting of several steps. The pyramid is locatedon on flexible square or round flange. The entire element is made of silicone or resistant types of rubber, although sometimes one of her parts can also be made of aluminum. Due to the elasticity of these materials, the penetration is well combined with any roof, and does not react to the effects of wind or snow.

The positive characteristics of such products include:

- resistance to chemical and ultraviolet influences;

- resistance to temperature changes, from —50 to + 130 degrees;

- flexibility;

- wide range of colors — they can be matched to any color of the roof;

- aesthetics, opportunity giving completeness of the coating;

- thanks to a good fit to the roof, the penetration guarantees excellent tightness;

- part flexibility gives possibility her installation on any roof slope.

Since penetrations are produced in different sizes, they must be correctly selected according to the diameter of the chimney and the slope of the roof. Dimensions are indicated on the body of the element itself.

- Direct penetration is used mainly on roofs with a slight slope, about 25 degrees, and on flat roofs.

- Corner penetration, the flange of which should be fixed under certain angle, for example, 20 degrees, are used to seal pipes installed on roofs with a slope of more than 25 degrees.

- Universal penetration that can be adjusted to any diametertr truby, looks like this: on each of the steps of the pyramid of penetration, the diameter for which it is intended is indicated. Master only remains cut off the excess top and make her pipe mounting.

Installation of a soft roof penetration for a chimney pipe

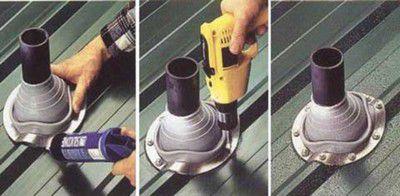

Installation of this waterproofing element is quite simple:

- if purchased universal option, the excess part is cut off from it;

- Further the penetration is put on the pipe and pressed against the roof. If the roof is ribbed, waterproofing should to accept form ribs coatings;

- then on the move goes sealant, which smears the edges of the flange and firmly pressed against the roof;

- last step goes fixing the penetration along the flange to the roof using self-tapping screws or rivets.

In the presented photos, the process of installing waterproofing is clearly visible.

Metal penetration

Another option for waterproofing metallic pipes can become metallic the same penetration, which is also for sale in finished form.It has excellent characteristics, but can only be installed on a roof that does not have a relief pattern, for example, soft. More one condition necessary for a tight installation of the flange to the roof is a perfectly matched angle of the element to the roof slope.

- There are different models of metal penetrations. On some of them, the pipe is fixed and soldered from the inside, and the upper head of the chimney is put on and welded on the outside.

- May be and another option, when the pipe passes through the penetration through and from above to her is fixed detachable metal part that does not allow moisture to penetrate inside.

- The flange is glued to the roof with a sealant, and then screwed with self-tapping screws.

Square, rectangular tube

A brick chimney is almost always square or rectangular in shape. Passing through the attic, it is brought to the roof. Further a hole is made in the roof, which should be decorated from the inside with a metal sheet with a hole made in the middle in the shape of a pipe. Through this window, the head is also displayed on the surface of the roof. This option is convenient when removing the chimney through frequent crate in the roof, for example, when a soft roof is being installed.

If a crate installedon on certain distance (for example, slate roof), well, if pipe will pass between the rafters. But it also happens that the pipe rests against one of the beams supporting the roof, or they are too far from the walls of the pipe. In this case, it is necessary to arrange additional details of the rafter-beam system, which will allow you to fix the heat-resistant insulation and waterproofing around the chimney.

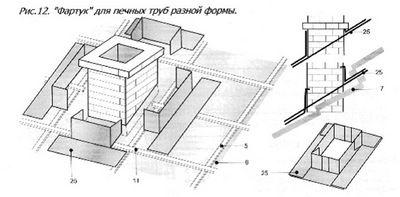

When the square pipe is run through the roof, the seams around her are sealed with non-combustible materials, and a penetration-casing made of metal, cut in a special way, is installed on top.

The figure shows an apron consisting of four parts, which is assembled in a simple way. Such a penetration is arranged under the roof covering, and the roofing material is laid on top of it. The cracks formed in the area where the metal adjoins the pipe and when connected to the roof are sealed with sealant.

If sealing is carried out on top of the roofing material, then it is made with a layer of soft waterproofing, consisting of a special tape, which is made on the basis of aluminum and lead. It is well fixed with a sealant on any flat surface or having definite relief.

On the pipe itself, soft waterproofing is also planted on the sealant, and fixed with special metal strips. The photo clearly shows the design of such protection.

One of the options for the passage of the chimney pipe through the roof - video tutorial

Passage of a chimney pipe through a tiled roof

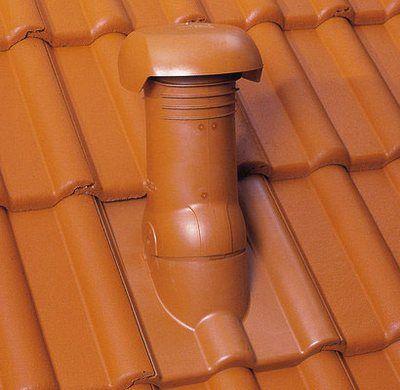

Separately, I would like to say about the passage of the pipe through the tiled roof. Manufacturers have thought of a special element that repeats the relief pattern of the tiles, and has a hole arranged for the pipe. A pipe of the same material is also selected for it.

These elements of a tiled roof are made of highly resistant plastics. They are produced in the same colors as the tiles, and you can always choose the right shade suitable for a particular building.But such plastic roof parts are installed only for ventilation ducts, since they are unlikely to withstand the high temperatures that accompany the smoke emanating from any stove.

Safety criteria for the passage of the chimney pipe through the roof

Impossible on the scale of one publication how to cover everything chimney options through the roof, and tell about all the important tricks in these works. But, there are some things that you really need to know.

- In the construction of some roofs, there are layers of different materials that do not have pronounced fire-resistant properties. Therefore, it is very important to provide fire safety rules.

To to secure wooden floors and other combustible materials, special boxes are built around the chimney of any shape.

This option is very convenient for roofs covered with slate, tiles or other materials that have volume drawing, as well as for soft roofing. The box is aligned with crateon which the roofing is laid. He must have certain thickness to reliably protect the whole layer battens and installed on German vapor barrier and insulation from possible overheating and fire. It is not bad if there is also a distance of about 5—7 cm

- When purchasing a penetration, you must make sure that her reliability and resistance to temperature extremes and increased heat, and only then on waterproofing qualities.

- Proper installation of the pipe is very important and her passage through the roof, as it is not only a decorative element, but also a functional one.We must not forget that the safety of your health and property will depend on the correct installation of this unit.

- The materials used in such work must meet the necessary requirements for this particular device. It is not possible, for example, to use ventilation pipes for smoke removal from heating appliances. Be sure to know the characteristics of the purchased materials, and it is better to consult a specialist if something is in doubt.

Anyway, if you never didn't deal with this type of work, it's not worth the risk. The best option would be to invite the master who produced the process more than once. It will quickly cope with the task and will not spoil the overall appearance of the roof.