Roof cutting of the chimney is a prerequisite for its safe operation and a guarantee of warmth and dryness in the house.

Mistakes in the removal of the chimney through the roof usually lead to leaks, rotting and destruction of the wooden structures of the roof, and improper fastening of the chimney itself can cause a fire. Following the technology described in our article, you will be able to sort out this issue and, if necessary, install the roof section of the chimney yourself.

Content

Types of roof cuttings

The type of roof cutting directly depends on several factors: the material of the chimney, the type of roofing and the structure of the roof: its type, angle of inclination, the location of the chimney relative to the ridge. The main quality of roof cutting is the ability to protect the roof from leaks and overheating, which determines the choice of materials for roof cutting.

Roof cutting for metal pipes of the "sandwich" type is a metal cone rigidly fixed to a metal apron at a certain angle. For a slate roof, the apron must be made of lead, which, due to its plasticity, easily takes the form of roofing sheets. The angle of the roof cutting is selected depending on the angle of the roof.The pipe is inserted into the cone and sealed with a sealing collar.

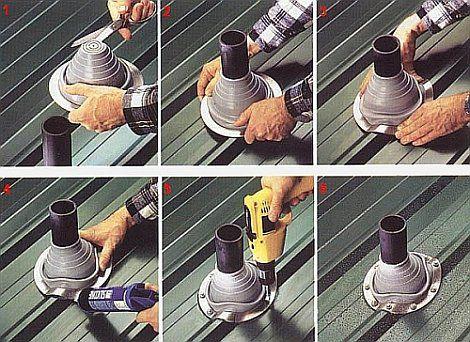

For round pipes and roofs with a corrugated metal coating, along with metal roof grooves, penetrations made of polymeric materials on a metal frame can be used. They consist of a sheet of metal - steel or aluminum, with a hole larger than the diameter of the pipe and a silicone or rubber cap. A hole of the desired diameter can be cut in the cap, and the base sheet can be bent to fit the shape of the roofing. After fastening to the roof, this cutting ensures the tightness of the passage through the roof.

Prefabricated ceramic sandwich chimneys or traditional brick chimneys, which have become popular in recent years, lead to the roof in a slightly different way. For their sealing, metal aprons, junction strips and heat-insulating boxes are used. Sealing is achieved by gluing the elements with special films and using sealants, while the correct sequence of work, described in the following sections, is important.

Roof cutting of round pipes

To seal stainless steel sandwich pipes or round ceramic pipes, roof penetrations with a metal or polymer cap are used. In addition, to protect wooden structures from overheating, it is necessary to install a heat-insulating box made of non-combustible material at the place where the pipe passes through the roof, and fill the space between the walls of the box and the pipe with a non-combustible heat insulator. Stone or basalt wool is used as a heat insulator, their melting point is much higher than that of a chimney in operation.

Conclusion of the pipe to the roof and installation of cutting

Purchase or make your own thin-walled metal pipe. Its dimensions should provide a fire-prevention distance from the pipe to flammable structures - at least 25 cm in any direction. The branch pipe has the form of a box with a lid, with holes on both sides equal to the diameter of the pipe. The branch pipe must be finished with fireproof insulation - the figure shows the finish with basalt wool with a heat-reflecting layer. You can fix it with a heat-resistant sealant and metallized tape.

They mark the place where the pipe passes through the ceilings and cut a hole in it according to the size of the pipe using an electric jigsaw for the entire thickness of the heat-insulating "pie". Install the pipe.

The chimney is removed from the sandwich pipes through the hole in the pipe, the gaps are treated with a heat-resistant sealant with a working temperature of up to 1000 degrees. Between the walls of the box and the pipe, a heater is laid - basalt wool. From below and from above, the passage is closed with lids and fixed with self-tapping screws.

Mark the place where the pipe passes through the roof and cut it out in the same way. In this case, the hole will not have a square, but a rectangular shape due to the slope of the roof. Install the bottom cutting apron. It is chosen depending on the slope of the roof - the steeper the slope, the more elongated the hole will be.

Continue installing the pipe through the sawn hole, the apron can be temporarily lowered down. The pipe must be tightened with clamps and fixed to the roof structural elements on the brackets.

Bring the pipe to the roof to the required height. At the same time, it is important to follow the rule: the connection of elements should not be located at the point of passage through the roof or ceiling, if the dimensions of the pipe do not allow it, one or more elements must be cut. It is better to install the clamps that secure the pipe at the joints, and put the joints on the sealant - this achieves maximum pipe stability and fire safety.

After the pipe is installed and brought out, the lower apron is fixed, and the roof cutting of the selected type is put on the pipe. The figure shows a roof cutting with a metal apron, laid on top of the roofing - corrugated board. The upper edge of the apron is brought under the overlying sheet of corrugated board, and its side parts are cut so that they are in the upper part of the wave of the metal sheet. Water with such a design and a large slope of the roof will not flow under the apron.

For other types of roofing, roof cuttings of a different type can be used, for example, metal-polymer or with a lead apron.

When using a flexible cut from silicone or rubber, a hole is cut in the cap 1/5 less than its diameter. The cap is pulled over the pipe and the flexible apron is shaped into a sheet. Fix on self-tapping screws, having previously smeared with sealant. For a more durable fastening, it is sometimes necessary to strengthen the roof sheathing - this is done at the stage of cutting a hole in it.

A flexible lead apron can also be bent to the shape of a roofing sheet, but when buying it, you should take into account the slope of the slope.The upper edge of the apron must be led under the overlying sheet of slate or metal.

Roof cutting of rectangular pipes

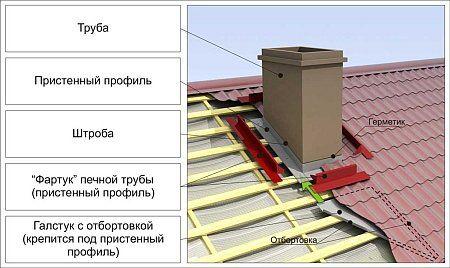

For roof cutting of pipes made of bricks or blocks, special elements are used - metal aprons, ties, wall profiles. Self-adhesive film and sealants are also used to seal joints.

A pipe made of bricks or blocks, as a rule, is placed on the foundation, so it is quite stable. Its additional fastening is possible with the help of special brackets, but they should not provide a rigid connection with the roof, otherwise, if the roof is damaged, deformation and destruction of the pipe is possible, which threatens with fire.

Technology of roof cutting of brick pipes

Cutting is performed after installing the battens and waterproofing, on top of the counter battens made of planed boards. Adjacency strips are applied to the pipe walls and a contour is drawn along the upper protruding edge.

According to the obtained contour, with the help of a grinder and a diamond disc, a groove is made.

Sweep away the dust with a broom and wash it off with a stream of water, you can use a plastic bottle.

An abutment bar is applied from the lower edge of the pipe, its dimensions are marked with a marker, and with the help of scissors for metal, a vertical part of the abutment bar is cut out on both sides. Attach the junction bar to the pipe and carefully hammer its edge into the groove in the brickwork with a hammer.

The bar itself is attached to the crate with self-tapping screws using a screwdriver.

Mark the side strips in the same way, cut off the protruding vertical part. Fasten both side strips with self-tapping screws so that they are on top of the bottom. Fix the upper junction bar in the same way.

Seal all joints between the strips and the pipe.

A tie is installed and a gutter is bent on it in such a way that moisture that accidentally gets on it drains from the roof without falling onto the crate.

Roofing is laid using a special technology. Aprons are installed in the same sequence as the abutment strips: the lower apron, the side ones, and then the upper apron - it is placed so that it is under the overlying roofing sheet. If the pipe is close to the ridge, then the upper apron is brought under it.

Video - roof cutting of a brick chimney

Roof cutting of the chimney is an important stage of construction, when performing it it is important not to save on materials and follow the sequence of operations. Only in this case you are provided with safety and comfort, without fires and a leaking roof.

Hello, can you help with the purchase of roof cutting Roof slope angle of 60 degrees

Hello, unfortunately I can not help in choosing and buying. In any specialized store you will be helped to choose the right items and the best option.