The stove is folded, and the chimney proudly rises above the roof of the house. Do you think the work is done? Not at all - it's time to think about how to insulate the chimney pipe and protect the house from fire, and the roof from leaks. Well, if you thought about this issue even in the process of designing the furnace - in this case, the insulation of the chimney will be reliable and safe. It is more difficult to isolate an already built chimney, sometimes this work entails a change in the design of floors and roofs. However, the costs will be compensated by a sense of security and comfort.

Types of chimney insulation

It is necessary to isolate the chimney from two negative destructive factors: from overheating of the structures and from leakage at the joints. Therefore, in the article we will consider two types of chimney insulation:

- Fireproof thermal insulation;

- Waterproofing.

It is recommended to immediately carry out complex insulation, solving not only the main problems, but also improving the operating conditions of the furnace.For example, insulating a pipe running through an unheated attic reduces the risk of overheating wood roofing and reduces the risk of condensation, which can lead to excessive soot deposits, corrosion, or pipe failure. Waterproofing the pipe will help to avoid rotting of the truss system and ceilings, as well as the destruction of the pipe if it gets wet.

Ways of fire insulation of chimneys

The easiest and most reliable, but not always the cheapest way is to install a ceramic or metal sandwich chimney. In such chimneys, the inner pipe, which performs the function of removing smoke, is made of heat-resistant steel or ceramic and is thermally insulated with non-combustible heaters: mineral, stone or basalt wool. The outer layer of the sandwich chimney is made of steel or ready-made expanded clay concrete blocks.

Prefabricated chimneys are equipped with elements for fastening, revision, maintenance, as well as for connecting several heaters. Installation of such a chimney is not difficult, but requires compliance with the instructions, only then it will be completely safe.

Video - sandwich diaphragm for pipe passage through floors

Another insulation method used in the construction of the furnace is a brick chimney. Due to the low thermal conductivity of the brick, its walls do not heat up to dangerously high temperatures, so no additional measures to insulate such a chimney are required, except for the correct implementation of the fire-prevention cutting of floors and roofs. To save money and facilitate construction, a brick chimney is sometimes finished with a metal or ceramic pipe.In this case, they are thermally insulated according to the technology described below.

Thermal insulation of metal and ceramic single pipes is possible using ducts made of non-combustible materials and mineral non-combustible thermal insulation - stone or basalt wool. It is possible to operate such chimneys without thermal insulation, but the implementation of fire cutting according to all the rules is mandatory in any case.

Methods for waterproofing chimneys

Chimney waterproofing is installed at the point of its exit to the roof. The larger the pipe and the farther from the ridge it is located, the more difficult operating conditions await it: when it rains, more abundant water flows, in winter - increased snow load. Rain and melt water with insufficient waterproofing penetrates inside the house, leading to leaks, rotting of wood and destruction of concrete and brick structures, including the chimney itself.

The method of waterproofing depends largely on the shape of the pipe and the type of roofing. For round pipes, metal or polymer cuts are used, for rectangular pipes, metal aprons and junction strips are used. How to waterproof a pipe is described in detail in the article. "Roof cutting of the chimney", and then we will talk about the technology of thermal insulation of the chimney.

Chimney pipe insulation

Before proceeding with the insulation of the chimney pipe, it is necessary to check compliance with the requirements of SNiP 2.04.05-91 and, if necessary, correct the shortcomings:

- The height of the pipe to ensure good draft and allowable flue gas temperature at the outlet should be 5 meters or more;

- If the roofing refers to combustible materials - slate, ondulin, roofing material - a spark arrestor - a fine-meshed metal mesh - must be placed on top of the pipe;

- The distance between the chimney pipe and combustible structures - floors, walls, truss system - must be at least 250 mm;

- A fire-prevention distance must be maintained between the upper ceiling of the furnace and the ceiling. For metal stoves, it is at least 1.5 meters, for brick stoves with a two-row overlap - 0.5 meters, with a three-row ceiling - 0.25 meters, provided that the ceiling above the stove is finished with non-combustible materials;

- In places where a brick chimney passes through the ceiling, fluffing is performed - thickening the pipe. Fluff thickness - 1-1.5 bricks.

Plastering a brick pipe

The brick pipe does not heat up much from the outside, so it must be insulated as soon as possible in order to improve operating conditions and extend the service life. The most affordable way to insulate a brick chimney is to plaster with cement mortar or a mortar based on cement and lime. Instead of sand, you can add sifted slag chips to it.

The composition of the solution:

- 1 bag of cement (25 kg);

- 2 buckets of slaked lime;

- 10 buckets of sand or a mixture of sand with slag chips;

- 5 buckets of water.

- To prepare the solution, 3.5-4 buckets of water are mixed with a bag of cement and 2 buckets of slaked lime - fluff. After thorough mixing, sand and slag chips are added in parts, as well as the remaining rate of water.The resulting composition should be used in cool weather for 5 hours, and in hot weather - for 1-2 hours, so you can cook it in parts.

- With large irregularities in the pipe, the plaster layer turns out to be quite thick, therefore it is recommended to first close up all the cracks and differences with the indicated solution, and then cover the pipe with a reinforcing mesh.

- Plastering is carried out in two layers. For the first layer, the solution is diluted somewhat stronger, to a creamy state, and applied by spraying: a certain amount of mortar is taken on a trowel or spatula and sprinkled on a brick surface cleaned of dust and slightly moistened. The first layer is not leveled.

- For the second layer, a thicker solution is needed. It is applied with a trowel and rubbed to a smooth surface. It is necessary to plaster the entire pipe from the floor to the ceiling or roof.

Sheathing of brick pipes with asbestos-cement sheets

This method exceeds plastering in terms of heat saving by 2-2.5 times and consists in gluing asbestos-cement boards on cement-lime mortar on the outer walls of the pipe.

- According to the above technology, a plastering solution is prepared.

- The pipe is reinforced with mesh and the first layer of mortar is sprayed on. Dry it out.

- Cut asbestos-cement sheets to the size of the pipe. A second layer of mortar is applied to asbestos cement sheets and glued to the surface of the chimney.

The disadvantages of this method include the low environmental friendliness of asbestos - it releases carcinogens, so it is impossible to use this method of isolation in living rooms.In a non-residential attic, thermal insulation of the chimney with asbestos will reduce the temperature difference between the inside and outside of the chimney and significantly reduce the formation of condensate, as well as improve its fire protection.

In addition, a brick pipe can be sewn up with sheet iron using a layer of insulation. How to do this, you can learn from the video.

Video - sheathing the pipe with sheet iron

Insulation of metal single pipes

The most dangerous version of the chimney in terms of fire protection is a metal pipe that is not protected by a heat insulator. The distance from such pipes to wooden and plastic structures should not be less than 0.6 meters. But even observing this distance will not protect you from burns if accidentally touched, so it is better to insulate the pipe without waiting for problems.

The easiest way to insulate a single pipe is to wrap it with a layer of non-combustible insulation, such as basalt wool, and protect it from above with metal or plaster. The melting point of this material approaches 1000 degrees, which is much higher than the temperature of the smoke.

- Basalt wool mats with a thickness of at least 5 cm are wrapped around the pipe with an overlap and fastened by wrapping it over with steel wire.

- They wrap the heat-insulated pipe with a reinforcing mesh, fix it, and plaster it according to the technology described above in two layers with a cement-lime composition.

- Plaster can be replaced with thin sheet iron by rolling it along the diameter of the insulated pipe and riveting it at the junction of the edges.

Insulation of passages through floors and roofs

The most critical sections of the chimney insulation are passages through the floors, so they are given special attention. It is necessary to isolate the passages when using any chimney: both a sandwich pipe, and brick, and metal in isolation.

Passes are carried out subject to the following conditions:

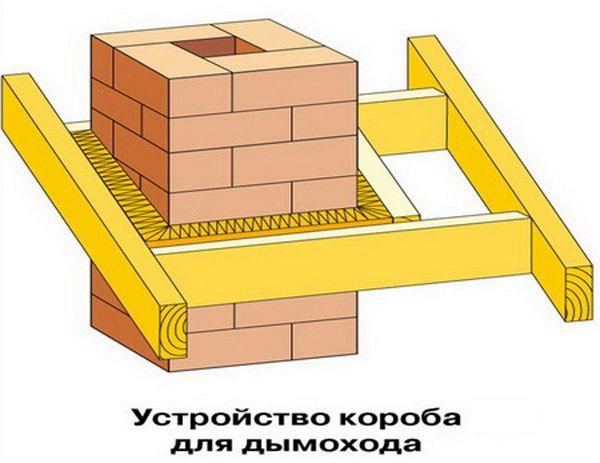

- In the ceilings and roof, holes are made for the passage of the pipe in such a way that there is a distance of at least 25-35 cm from its edges to the walls of the pipe.

- The edges of the hole are treated with asbestos-cement or metal sheets, a box is arranged for thermal insulation.

- The space around the pipe is filled with stone or basalt wool without the formation of voids and gaps.

- Wooden structures located in the immediate vicinity of the chimney passages are treated with flame retardant compounds.

Having figured out how to insulate the chimney pipe, you can easily do this work, but remember that even an insulated chimney pipe requires proper operation: clean soot at least three times a year, remove ash from the furnace in a timely manner, do not burn in it not intended for the firebox materials and objects (garbage). All this is the key to a long and safe service of the chimney.