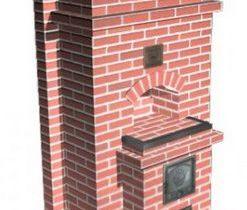

A classic means of heating in a country house in Russia has long been a brick stove.

Despite the rapidly developing technologies, the stove is still a reliable tool that effectively equips comfort in the home. Of course, now you can buy electric or gas heating or cooking appliances, but nothing compares to a traditional brick stove, with which you can heat your house and cook delicious food. They will fill your home with cozy warmth from a living dancing fire, and the food cooked on them will have a unique taste.

Content

Is it difficult to fold the heating and cooking stove for a beginner?

Since ancient times, professionals have been building brick ovens in houses. The secrets of craftsmanship were passed down from generation to generation and stove-makers have always been respected people in their area.However, a new information age has come and information about technologies is no longer passed on by word of mouth, but is widely distributed on the network. Of course, the construction of a brick oven requires certain professional skills, and without them you should not even take on a full-sized oven in the house.

But, having familiarized yourself with the basic principles of building brick heating and cooking furnaces, you may well build a small furnace in the summer forge to begin with. Also, knowing these principles will help you not get into trouble when talking with the contractor to whom you order the construction of such a furnace.

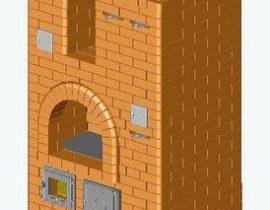

The design of the heating and cooking stove

The heating and cooking brick oven is a rather complex engineering structure. It is best to start its construction with high-quality design. A detailed project and the accompanying calculation will help you verify all the nuances of construction and avoid mistakes.

There are many projects of heating and cooking stoves on the Internet, but each individual drawing is only suitable for an individual house, and not for everyone. First of all, because of the geometric dimensions of the room. Therefore, it is best to create an individual solution that will satisfy you from the functional side and fit into your home.

We are starting to build a heating and cooking stove, but do we need a foundation?

By itself, a brick oven is a rather massive structure, but the need to build a foundation arises only for structures weighing over 750 kilograms. A theoretically lighter structure can be placed directly on a wooden floor, but on condition that it can withstand such a load.But brick and wood floors have a different service life and therefore even light brick ovens are recommended to be placed on the foundation.

The weight of the future furnace is calculated by calculations based on the size and weight of the building materials intended for use. If you don’t know how to calculate it, weigh one brick and multiply by the number of bricks in the structure. Add to this figure the weight of the mixture and water and all metal parts: doors, valves, pipes. to the received number add 50%, because you could not take into account something!

Please note that the foundation of a massive brick oven should not be connected to the foundation of the house itself. The fact is that the walls of the room and the stove can give different loads and different degrees of shrinkage, due to the mismatch of which cracks may appear in the structure, it’s good if the crack goes along the stove, but what if it goes along the wall of the house?

A strip or slab foundation is usually placed under the furnace. The principles of its construction are the same as for residential premises:

- Calculation in progress

- A place is marked on the ground, please note that the edges of the foundation should protrude beyond the dimensions of the furnace by at least 5 centimeters

- Digging a pit, about half a meter deep

- A sand and gravel cushion is laid at the bottom of the pit, which is then compacted

- A thin layer of liquid cement-sand mortar is poured on top of the pillow

- Formwork is being built, while the upper level of the foundation support is located 15 centimeters below the floor level

- Mounted reinforcing frame

- Concrete solution is poured

After the curing of the concrete mortar, which usually occurs within a few weeks, the surface of the concrete foundation must be waterproofed.For this, either a liquid waterproofing material or sheet roofing material is used. Ruberoid can be put in several layers.

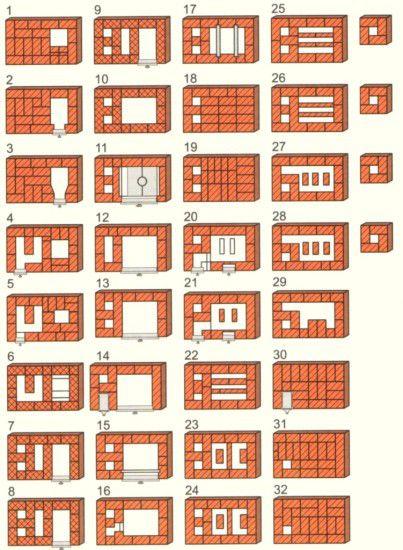

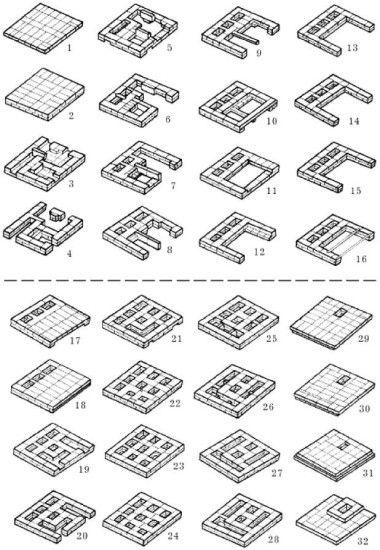

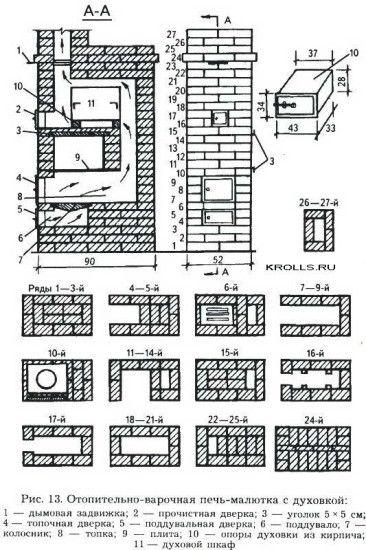

Ordering the most popular heating and cooking stove in Russia

The first rows of a brick oven are laid out with a continuous tape. Usually the base of the furnace is 2-3 rows of bricks.

The next rows of the oven form an ash pan, which is accessible for cleaning. A grate is laid on the upper row of the walls of the ash pan. It serves to organize the flow of air to the combustion chamber, and the burned-out firewood falls into the ash pan.

The next "floor" is the furnace compartment. To organize the hob directly above the furnace compartment or slightly away from it, a section is laid out to accommodate the hob.

Design features of the chimney of a heating and cooking stove, what are the significant differences?

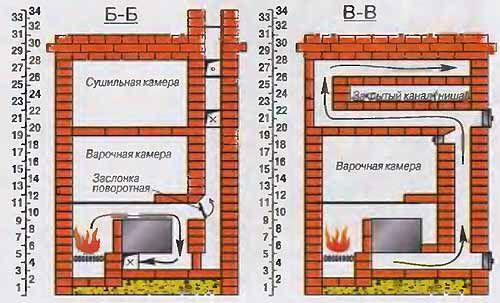

After construction, a chimney begins to form above the furnace compartment. The design of the chimney is usually a complex structure. It should provide for either horizontal sections or peculiar caps. This is due to the fact that the flow of smoke must linger inside the chimney compartment and heat the surrounding walls, which transfer heat to the room air. This design of the chimney, unlike a straight chimney, allows you to spend less fuel to heat the room.

In addition, a good brick oven can have two ways to remove smoke in its design: summer and winter. The direction of the flow of hot smoke is determined by a special damper.On summer days, hot smoke is directed along the shortest path so as not to create excessive overheating of the room. But on cold winter days, hot smoke goes along a long winding path, completely giving up its heat to the bricks of the chimney, and therefore to the room.

Also on the chimney there may be a valve that switches the chimney to work only the cooking or only the combustion compartment.

From the possible equipment of the furnace, one can also note a hot water tank, doors with access to various areas for cleaning and an air intake channel to create traction.

And where to put such an oven?

A brick heating and cooking stove is recommended to be placed in a wall or at the junction of interior partitions. With this arrangement, you can provide heating for several rooms without installing a bulky and expensive water or steam heating system. However, the stove should not be located close to the walls of a wooden frame.

Materials used in laying the stove

The main part of the construction of the heating and cooking furnace is assembled from solid red bricks. The same building material is also used to form the chimney. A special refractory brick is used to form the firebox and the base for the cooking hob. In order to place the cast-iron hob, a groove is cut out in the body of the brick, or a row of bricks with a ledge is formed. Between themselves, the bricks in the oven are fastened with a mixture of sand from clay in combination from 1 to 2 to 1 to 5. To prepare the solution, the sand is sifted through a building sieve, and the clay is placed in water for a couple of days to soften.The final consistency of the solution should not spread over the surface of the masonry, but also not stick to the trowel. Sand is added to compensate for spreading, and clay is added to compensate for sticking. The seam between the bricks should be around 5 millimeters after drying. To determine the desired consistency of the mortar, you can lay out a test masonry of several bricks. The use of a cement-sand mortar can lead to cracking of the joints in the high temperature zone.

Cast iron is the best material for making an oven, hob, valves, doors and grate. When using steel elements, there is a risk of premature burnout.

Gaskets made of materials that are immune to fire are placed between the cast-iron elements and the brick body of the furnace. It is allowed to use asbestos sheet or similar cord, basalt cardboard. To securely fix the cast-iron element in the brickwork, a knitting steel wire is inserted into the seams.

Fire safety

A brick heating and cooking stove is a design of increased fire hazard. To protect against falling coals, a sheet of roofing iron is mounted on the floor in front of the firebox door. When the chimney passes through a wooden floor, it is insulated with non-combustible material. At the same time, building codes determine that the design of the chimney should be located at a distance of at least half a meter from combustible materials.

Double-bell heating and cooking stove: video of the masonry process