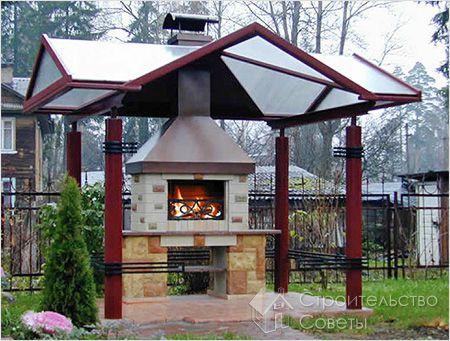

A gazebo with a barbecue built on your backyard can become not only the most favorite meeting place for your relatives and your friends, but also a kind of summer kitchen where you can cook a lot of wonderful, hearty and delicious dishes.

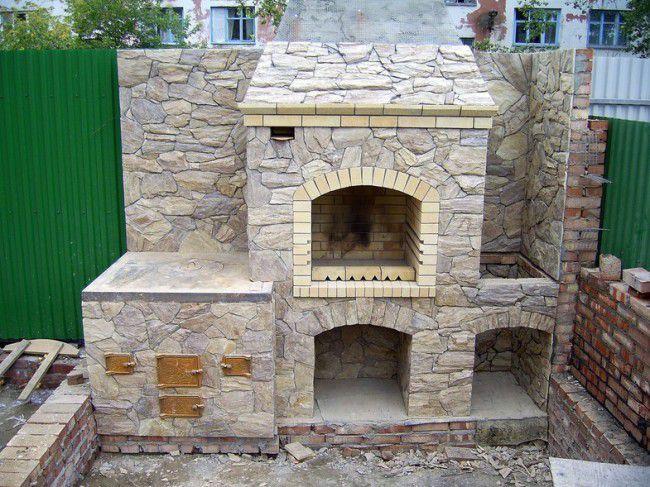

In the gazebo, in principle, you can install a temporary barbecue made of metal, but such a solution will not allow you to fully enjoy the whole process of summer cooking in the air. That is why many owners of suburban areas prefer to build capital stone stoves in gazebos and summer houses, which not only allow you to cook barbecue or grill, but are also equipped with a place for a cauldron, a cutting table, a sink, even a fireplace with an open fire - that is, everything that turns this building into a full-fledged summer kitchen. Not the last role in the quality of the built oven is played by a barbecue brick.

Content

- One Hundred Benefits of a Summer Barbecue

- Getting ready to build a barbecue

- Recommended oven dimensions

- Selection of bricks and mortar for building a barbecue

- Pour the foundation under the barbecue oven

- We begin laying bricks for the oven

- Watch the laying instructions in video format:

- Building a chimney for a barbecue oven

- The final stage of construction

One Hundred Benefits of a Summer Barbecue

Since ancient times, people have learned to cook food on an open fire. Pans and pans have not yet been invented, and our distant ancestors already roasted pieces of the meat of a hunted animal over smoldering hot coals or on a red-hot stone. This tradition is still alive today.

In order to organize yourself a full-fledged place for summer cooking on an open fire, it is enough to build a summer gazebo on your backyard and equip it with a classic brick oven. The possibilities of this device are truly endless. With a well-designed design, you can not only fry a barbecue, but also cook fragrant pilaf, bake or smoke meat or fish.

Outdoor ovens with this functionality have a common name - barbecue. Despite the fact that such a furnace is a rather complex engineering structure, you can easily build it yourself in a rather limited time.

Getting ready to build a barbecue

First of all, you need to choose a place to build. Any stove is a source of increased fire danger, so do not plan its location near buildings made of flammable materials. In addition, our stove will be equipped with a chimney, so calculate the location so that the smoke from the chimney leaves your site, and does not rush between the walls of nearby buildings. Consider the prevailing wind direction - the frying area must be protected from drafts on three sides. A brick barbecue oven must be positioned with a “back” to a constantly blowing wind flow.

Let's leave aside the gazebo construction project and see what materials we need to build a brick oven - a barbecue.

- The barbecue oven is built from refractory bricks. Usually they are full-bodied bars of red color.

- To fasten the bricks together, you need a glossy-sand mortar - stock up on these materials as well.

- To build a foundation under a barbecue oven, you will need a cement-sand concrete mortar, gravel, boards for creating formwork and metal reinforcement for the frame.

- In our oven there will also be finished metal products, such as grates, a grill for frying.

- The chimney in the furnace can be made of brickwork, or it can be combined - in this case, you will need an asbestos-cement or metal pipe.

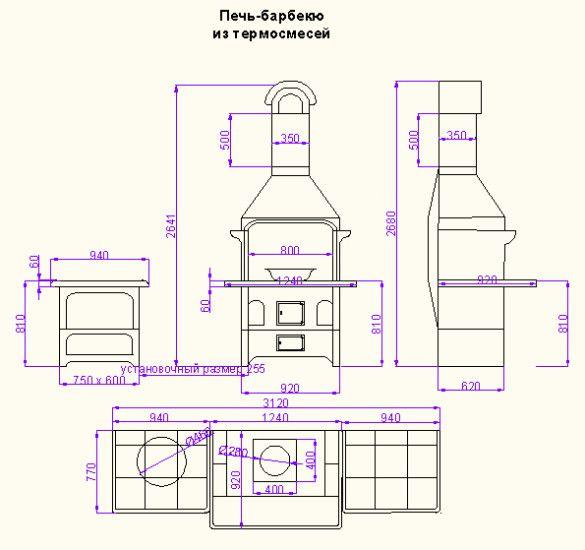

The drawing of each barbecue oven is performed independently. However, you can use ready-made drawings, creatively complement and expand them. A good drawing should have all the internal and external dimensions of the structure. It can be performed on a sheet of graph paper or with the help of a specialized computer program. In addition to determining the design of the future furnace, the drawing will also help you make the correct calculation of the necessary building materials.

Recommended oven dimensions

Like ordinary kitchen furniture, a barbecue oven must be calculated based on your own height. After all, this is your site and your oven. For example, it will be inconvenient for tall people to work on a cutting table with a height of 80 centimeters. You can also individually calculate the area of work surfaces, design a variety of shelves for spices and even lockers.

For convenience, the barbecue oven can be equipped with additional devices, such as a place to place blades, brushes for cleaning the grill. Such ready-made barbecue kits can also be purchased at specialized stores. However, a place to accommodate these tools with easy access to them must also be provided at the initial design stage.

Selection of bricks and mortar for building a barbecue

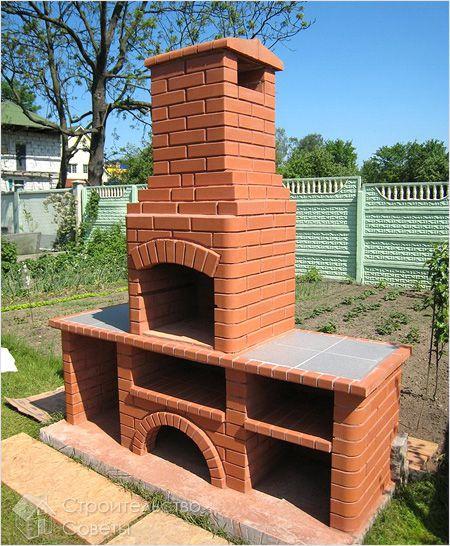

The body of the barbecue oven itself, as already mentioned, should be built from solid refractory red brick. In addition, facing bricks can also be used in the construction process - they are used for decorative finishing of external surfaces.

If you use two types of bricks, then you will need two types of mortar for masonry. Clay-sand mortar will be used to fix refractory bricks, and ordinary sand-cement mortar will be used to fix facing bricks.

Clay mortar for refractory bricks is made using the following technology. It is based on a red wedge, which is soaked in water for five days before kneading. After soaking, the solution is thoroughly mixed, which in its consistency should resemble jelly. After that, sifted building sand and about 10 percent of cement are added to the solution.

The resulting solution should not stick to the trowel, but slide off it when the tool is tilted 45 degrees. At the same time, the mortar should not spread over the brick surface. These characteristics are adjusted by adding soaked clay or sand. To prevent stickiness, sand is added, and to prevent spreading, we add soaked clay to the solution.

For laying facing bricks, a standard cement-sand mortar is prepared with a ratio of 3 to 1. For its preparation, cement with the brand "200" is used.

Pour the foundation under the barbecue oven

Under the barbecue oven, you can fill in both a more reliable but expensive slab foundation, and a cheaper, but no less reliable strip foundation. The latter is made according to the following method:

- We mark the perimeter of the foundation on the ground. We monitor the derivation of the correct right angles and compliance with the project.

- We dig a trench under the foundation with a depth of 30 centimeters.

- At its bottom we pour out and tamp down a pillow of gravel and sand. A compacted pillow can be poured with a thin layer of concrete mortar.

- A wooden formwork is being erected along the perimeter of the future foundation, and a metal frame of reinforcement is formed inside it, which does not extend beyond the casting.

- After pouring concrete, it matures within a few weeks.

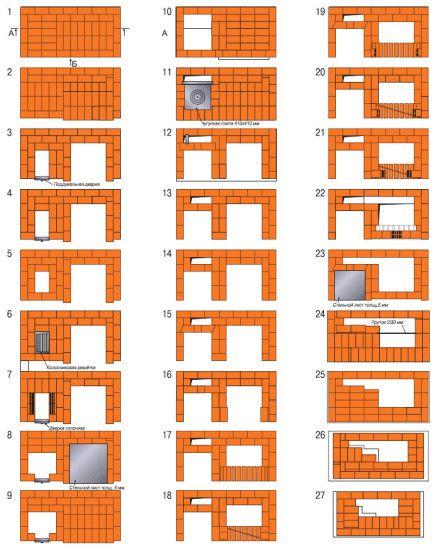

We begin laying bricks for the oven

At this stage, you need to decide whether you will have a conventional barbecue oven or you will equip it with additional options: a stand for a cauldron or a smoker.

In our project, we will build a barbecue oven with a nearby woodpile. The height of the barbecue is an example of 70 centimeters. The size of the woodpile can be selected individually, but usually it is built for the volume of firewood for 2-3 kindling.

The lower part - the pedestal of the furnace can be laid out from ordinary bricks. The width of the seam with brickwork is usually around 5 millimeters. After erecting the walls to the level of the furnace, we begin to use refractory bricks and clay-sand mortar. We make the first ledge on the surface for the bottom of the furnace. In the future, a metal sheet or a box for coals is laid on this ledge. After a couple of rows, we make another ledge - this time for the grill. Further, after a couple more, you can form a ledge next to it, on which the smokehouse will be placed.

To form brick rows, you will need not only whole bricks, but also their halves.Easily and quickly, with a smooth edge, solid barbecue bricks can be cut with an angle grinder.

The easiest way to complete the furnace space is to lay a regular rectangle, on the upper edge of which an extractor hood made of a bent and welded metal sheet is laid.

brick arch

More difficult, but also more aesthetically attractive, will be the formation of a brick oven arch. In this case, the back wall can be left vertical. The vault of the furnace looks especially attractive, the front part of which is laid out in the form of an arch. To build it, you will need a wooden template. It is inserted between the side walls and arch bricks are laid out on it. The last, central brick will serve as a kind of castle. After setting the fixing solution, the wooden template is removed. It is possible to strengthen the strength of the arch structure with the help of heating fittings.

The most optimal firebox size will be 5-7 bricks wide and 3 bricks deep.

Watch the laying instructions in video format:

Building a chimney for a barbecue oven

Like a firebox, a smoke oven is exposed to high temperatures and therefore it must be laid out of refractory bricks on a clay-sand mortar. It is necessary to place a furnace valve in the chimney.

The pipe can be laid out either simply from a brick, or an asbestos-cement or metal pipe can be placed in a brick "well". In this case, the gap between the brick and asbestos cement must be filled with concrete mortar.

The final stage of construction

You can attach a work table to a brick barbecue oven with a brick base and a wall for placing shelves and kitchen tools.The countertop can be purchased ready-made, or you can make it from thick plywood, covering it with ceramic tiles.

The lining of the furnace can be made of brick or heat-resistant finishing tiles. In front of the front surface of the stove, it is also necessary to lay out a protective platform from heat-resistant tiles.

A good solution would be to bring lighting and sockets to the working kitchen area for connecting kitchen appliances.

Barbecue Brick: Video