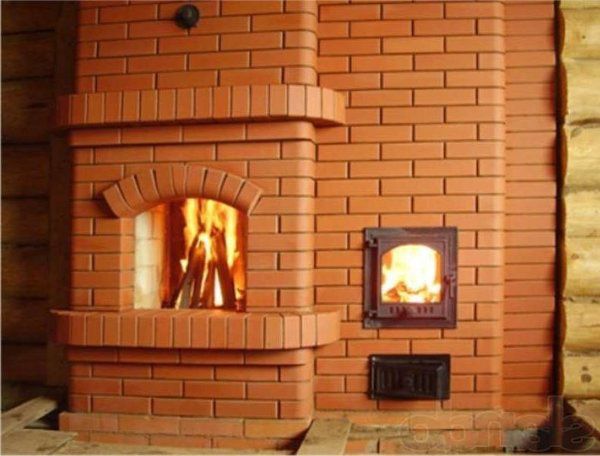

Despite the rapid development of new technologies and the improvement of home heating methods, the old proven brick stoves for wood-fired cottages still do not lose their relevance.

wood burning stove

Indeed, often in houses remote from civilization or located in areas where power outages occur, and gas supply is not expected at all, wood-burning brick stoves are the only possible means of heating the room.

Wood-burning stove

But sometimes people deliberately choose brick ovens for their country house, despite all the benefits of civilization. After all, they help to create that unique comfort, to give warmth and an atmosphere of solitude, which we are all looking for when going out of town.

About the advantages, the design principle and the features of laying a brick oven with your own hands - we will talk today in this article.

Content

- Types of brick ovens for summer cottages

- Design features of a brick oven for a summer residence

- Features of laying a brick oven with your own hands

- Laying a brick oven with your own hands: step by step instructions

- Step 1. Determine the location of the furnace.

- Step 2. We build the foundation for the furnace.

- Step 3. Preparing bricks for masonry.

- Step 4. We prepare the mortar for masonry.

- Step 5 We are building a furnace.

- Step 6. Laying the chimney.

- Step 7. Finishing lining of the furnace.

- Step 8. Drying the oven.

- Step 9. Kindling the furnace.

- Useful tips for laying a brick oven for a summer residence

- Video. Detailed laying of a brick oven for a summer residence.

Types of brick ovens for summer cottages

The experience of craftsmen and inventor engineers has given the world a considerable number of types of stoves, from which it is not difficult to choose the only one for giving, which will quickly warm up the room in the winter cold and help cook food.

But, despite all the variety of stone ovens, they can all be divided into 3 categories:

- cooking;

- heating and cooking;

- heating structures.

In addition, you can also find multifunctional designs that combine a fireplace, a water circuit, etc. Therefore, before proceeding with the construction of a brick oven in the country, you should immediately decide on the type of construction.

- Cooking type of construction. This type of stove is chosen by the owners of the cottage only if the house is used only in the summer. This option is well combined with a tank for heating water. Often, the owners install such a stove in a house where there is gas and electricity supply, but in order to save money, it is more rational to use a wood-burning stove in the summer.

Brick oven design

The design is a stove with a hob, a water-heating tank and an oven.

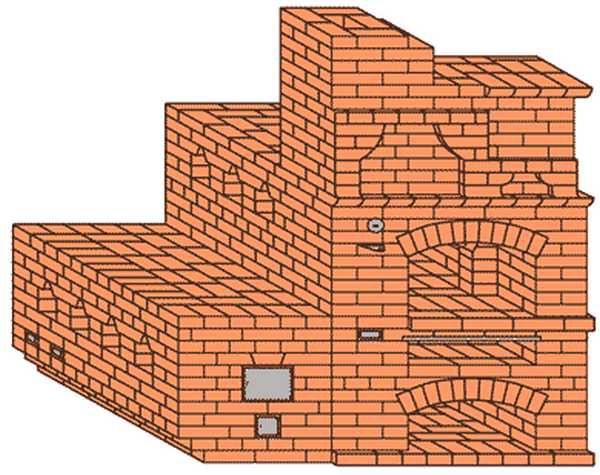

- Heating and cooking stove. This type of construction can already be attributed to the multifunctional. The stove includes a hob, an oven, a fireplace, a shelf for drying things, etc. Dimensions and functionality depend on the area of the room and on the purpose for which the cottage is used. Typically, this type of stove is installed in homes where no other type of heating is expected.

- Heating stove.As the name implies, this type of construction is installed exclusively for heating purposes. Installation is quite simple, as it is not particularly intricate. The design includes a combustion chamber, an ash pan, a chimney.

Stove with fireplace

- Stove with a fireplace. Of course, this design serves not only for decorative purposes, but also for heating. But such a stove can usually heat no more than one room.

Furnaces for summer cottages are also divided according to the type of construction:

- Russian;

- Dutch (Dutch);

- Swedish (Swedish).

Of course, today you can find many other variations of wood-burning stoves, but these are the most common, which have proven themselves due to their high efficiency, reliability and efficiency.

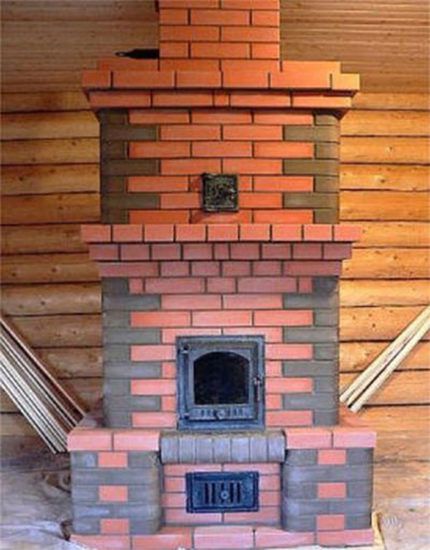

Russian stove

This design has been used by our ancestors for centuries, and its main feature is the arrangement of a bench and a shelf for drying shoes and clothes. If the house is operated all year round, then this option is very effective. But for a summer cottage, it is better to refuse a Russian stove.

Russian oven

The fact is that the high efficiency of the Russian stove is achieved only with a constant firebox. If you leave such a stove for the winter, then it will take more than one day to dry it later and “start” the stove into operation. Due to its technical features, it quickly gains moisture without a firebox.

In addition, during the first firing of wet bricks, it is possible that it will crack.

The Russian stove is a fairly massive structure, so it will not always be appropriate to look at a small cottage.

Modern Russian oven with stove bench

The only advantage is the unpretentiousness of the material itself for the construction of the furnace and a fairly simple masonry scheme.

Dutch

One of the most popular types of stone ovens, the design of which suggests the presence of a smoke channel. Thanks to this, the Dutchwoman effectively heats several rooms at once.

Dutch oven

The advantages include:

- small dimensions;

- high efficiency;

- economy of fuel consumption.

But the disadvantages of such a stove are high requirements for the quality of building material and the quality of firewood. In addition, at sub-zero temperatures outside the window, such a stove warms up for a long time, so it is better to constantly heat it.

Swede

Such a furnace enjoys well-deserved popularity in our country, as it was developed taking into account the harsh climate of the northern countries. The advantage of the Swede is compactness, high performance, fast heating and the ability to heat several rooms at once.

Swede oven

This is achieved due to the special design of the furnace. The back side with a fireplace usually goes into the living room, and on the front side there is an oven and a hob. For summer cottages, this type of stove is the best choice.

The only drawback of the Swede can be called high requirements for the quality of the material. If a Russian stove can be folded from the remnants of the material, then for a Swede you will have to purchase high-quality ceramic red bricks.

Also, high requirements are placed on firewood "Swedes". They must be well dried, otherwise the stove will not give off heat.

Design features of a brick oven for a summer residence

Depending on the type and design, the oven can perform the following functions:

- Cooking (frying, boiling, stewing, baking, etc.).

- Drying shoes and clothes, as well as preparing food for the winter (mushrooms, berries).

- Heating beds.

- Opportunity to admire the open flames on winter evenings.

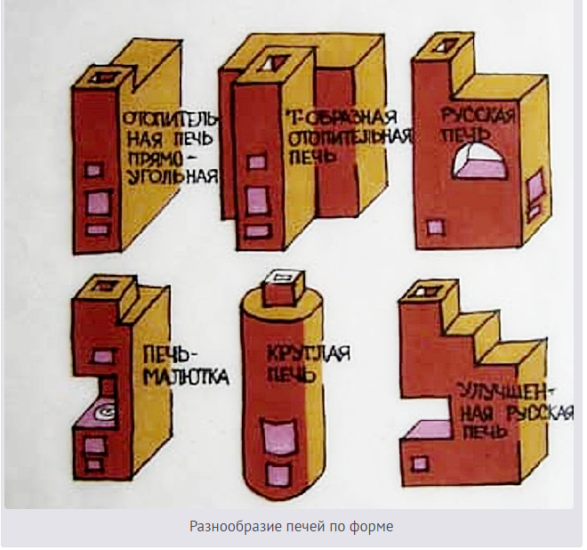

In addition to the functional classification, before building a brick oven for a summer residence, you need to decide on the configuration.

A variety of ovens in shape

- rectangular heating stove;

- T-shaped;

- round oven;

- Russian stove with stove bench;

- baby.

The size of the furnace is also important. The large, thick-walled furnace design is capable of distributing heat over 50 square meters. But in order to warm them up well, it will take at least two hours, which is not always convenient.

This is especially uncomfortable in the country, where the owners drop in only for the weekend. A cold house will warm up for at least 3-4 hours before the room temperature returns to normal.

A small stove cannot heat a big house. Its heat is enough for a room of 15-20 square meters. meters. At the same time, it will warm up in 30-40 minutes, giving off heat around. In addition, we should not forget about the efficiency of the furnace. For a large stove, you need to take care of the supply of firewood in advance and prepare a large one from the summer. firewood.

The stone stove also has a significant drawback - the impossibility of heating the distant premises of the house. That is why in large houses with several rooms, 2-3 stoves are placed, each of which has its own chimney and performs its function.

According to the principle of construction, brick ovens can be:

- Channel with forced movement of gases.

- Bell-type furnaces with free movement of gases.

Channel stoves include the usual "Dutch" or "Swede".The combustion of firewood takes place in the firebox, from which the smoke channel departs. Under the action of draft, combustion products are discharged through this smoke channel.

The main task of this design is to maximize the heating of the furnace wall, and after that the heat will spread throughout the room for a long time.

Channel furnace in section

Despite the simplicity of design, such a furnace has several disadvantages.

- It all depends on the traction force. The narrow channel obstructs the airflow and a sufficiently high chimney is required to overcome this resistance to the flow. In houses with low ceilings, this is not always convenient. And in the end, after arranging the furnace, the owners are faced with the problem of poor draft in the furnace.

- In addition, the principle of the channel structure of the furnace involves the concentration of hot air at the top of the furnace. That is, most of the heat is removed to the top. Because of this, below, near the floor, it is quite cold.

- The efficiency of such units does not exceed 60-65%. And the average, with standard traction, is even less - 40-45%.

- Due to the large design, such an oven heats up for a long time. To heat the structure from scratch, it will take 2.5-3 hours.

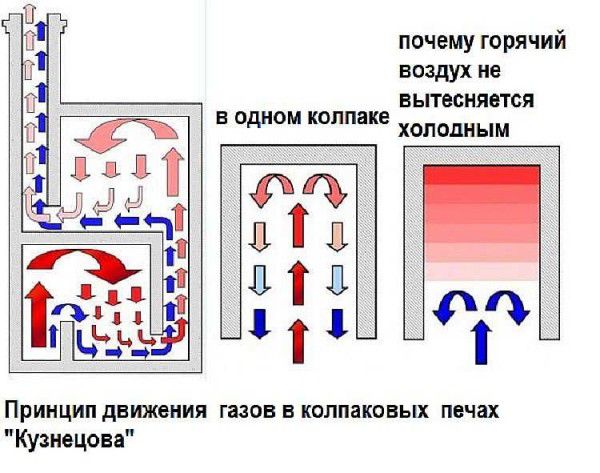

Furnaces with free movement of gases show themselves in a completely different way in everyday life. Their principle was first described by Lomonosov, and later modified by Kuznetsov, which is why in everyday life such furnaces were called "blacksmiths".

The principle of operation is based on the movement of free gases. As we know from physics, hot air rises, displacing cold air. In such a furnace, the furnace and combustion chamber are combined, and hot air circulates freely from one chamber to another.

Such furnaces also have a second and sometimes a third chamber, which are interconnected by a dry seam located at the bottom of the chamber.

The principle of operation of the bell-type furnace.

Features of laying a brick oven with your own hands

What are the nuances you need to know before proceeding with the laying of the furnace?

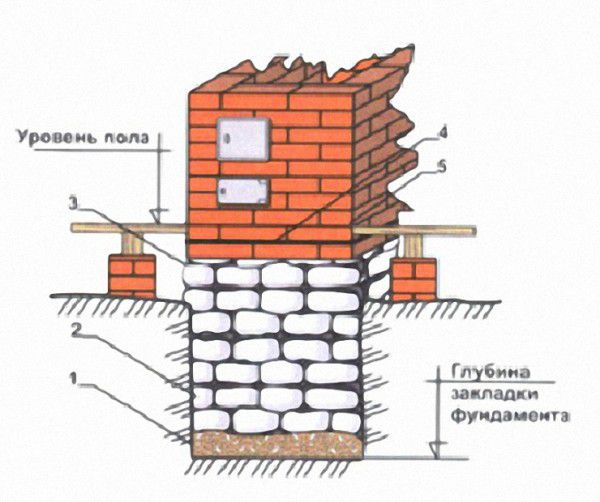

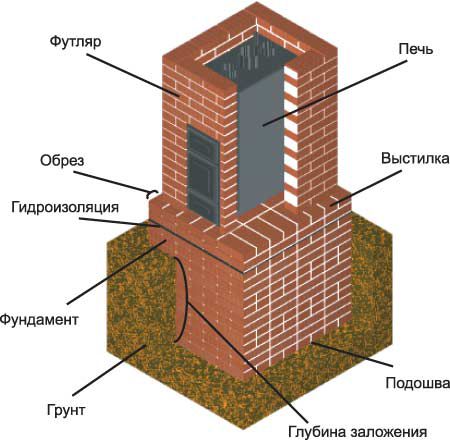

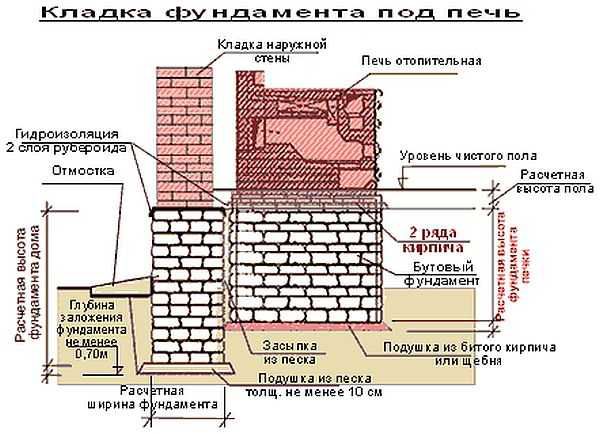

- The foundation for the furnace must be strong and solid. But at the same time, in no case should it be connected with the main foundation for the house. The fact is that the house shrinks over time, which is reflected in the foundation, so it is very important to separate these two elements. With seasonal shifts of the soil and general shrinkage of the house, the design of the furnace may suffer.

- The foundation must exceed the dimensions of the furnace by 15-20 cm on each side. It can be made of ordinary concrete, cement mortar or made of concrete blocks.

- For laying the furnace, it is necessary to purchase 2 types of bricks: ordinary solid ceramics and fireclay (refractory), from which the firebox, smoke channels and all heated elements will be folded. The cost of such material is much higher than the price of ordinary red brick, so usually only those surfaces that will have direct contact with fire are laid from it.

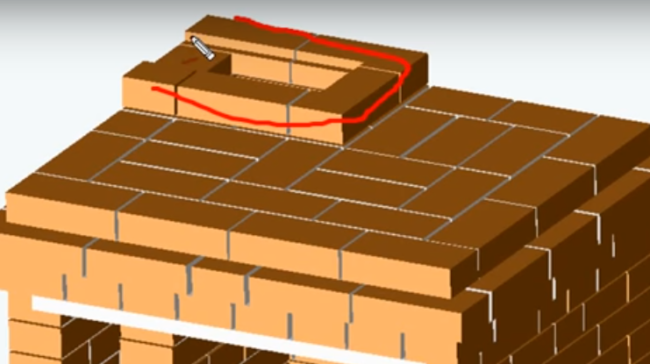

- All other elements are laid from solid red brick, while using a solution based on red oven clay. The composition of such a solution must necessarily include heat-resistant cement. But between ceramic masonry and fireclay bricks, it is imperative to maintain a gap of 5 mm. When heated, fireclay bricks will expand. Therefore, in order to prevent deformation of the furnace structure during operation, this gap must be taken into account.

- All purchased elements for the oven (grate, door, hob, oven, etc.) are set in accordance with the general scheme and purpose of the oven.

Grate

- When inserting the door of the combustion chamber or ash pan, it is necessary to tie it with annealed steel wire. In this case, one end of the wire is inserted into a specially designed hole, and the other end is twisted into a bundle and laid between the bricks, tightly clamped with mortar.

- When installing a cast-iron firebox or cast-iron stove, it is necessary to lay an asbestos cord between the brick and the metal element to compensate for the different thermal expansion of materials.

- The chimney for the stove can be made of red ceramic bricks, or you can use a ceramic block chimney, which is purchased ready-made.

- Facing is the final stage in the construction of a brick oven. To give a beautiful aesthetic appearance, the stove can be lined with red ceramic bricks, clinker (under wild stone), decorative tiles. Such a coating gives a unique authentic look to the oven, and also protects it from the negative effects of the environment.

Materials that will be needed for laying the furnace.

- Red solid ceramic brick (M-150.)

M 150

- Chamotte (refractory) brick.

- Masonry mortar (sand, red oven clay).

- Foundation material (cement, graphite, sand).

- Ruberoid.

- Asbestos cord, galvanized wire.

- Boards for creating formwork.

- Reinforcing mesh.

- Grate.

- Cooking surface (stove).

- Ash pan and ash pan door (blew).

- Furnace door.

- Chimney flue.

- Chimney valve.

Tools that will be needed for laying the furnace:

- Building level.

- Owl shovel.

- Construction marker.

- Measuring tape (roulette).

- Construction slope.

- Goniometer.

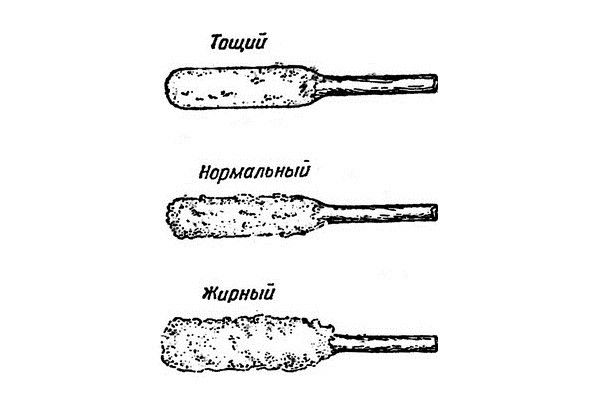

Important! A lot of things when laying a stove depend on the quality of the clay. It should be moderately thick and have an average fat content. Red river clay, which has lain in the open air for at least two years, is considered ideal for the construction of a furnace. Clay, under the influence of precipitation and natural factors, becomes plastic, homogeneous and will firmly hold the masonry.

Laying a brick oven with your own hands: step by step instructions

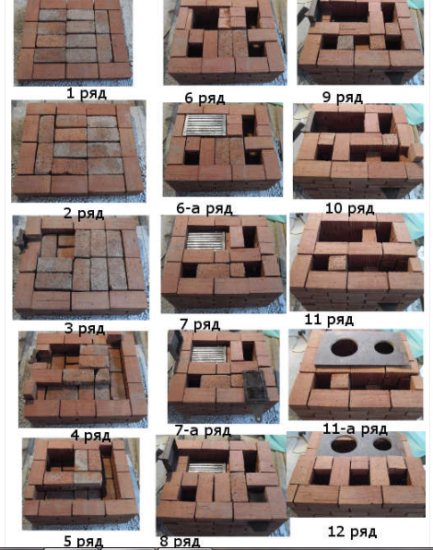

If all the conditions of the instructions are met, the laying of the furnace will take 30-35 days. Order is of great importance here. You should not violate it or try to introduce your own adjustments to the design. The laying of rows, their number and installation of elements are clearly calibrated and require strict adherence to the instructions.

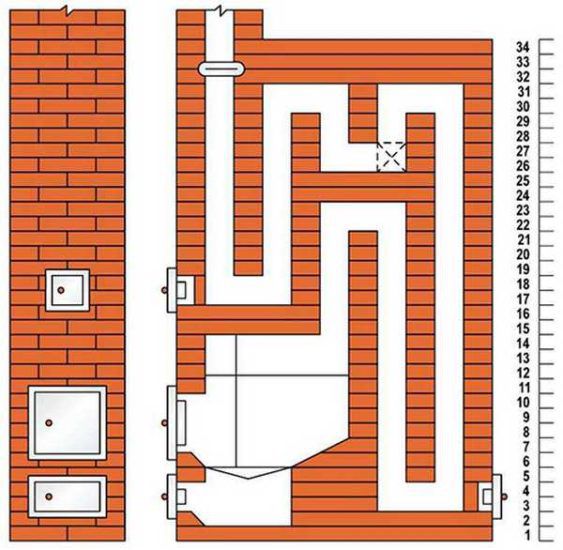

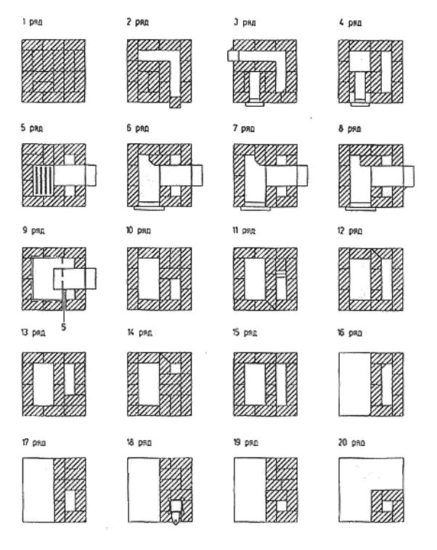

Below is a diagram of the ordering of a brick oven with a hob and an oven.

A typical brick oven with a hob

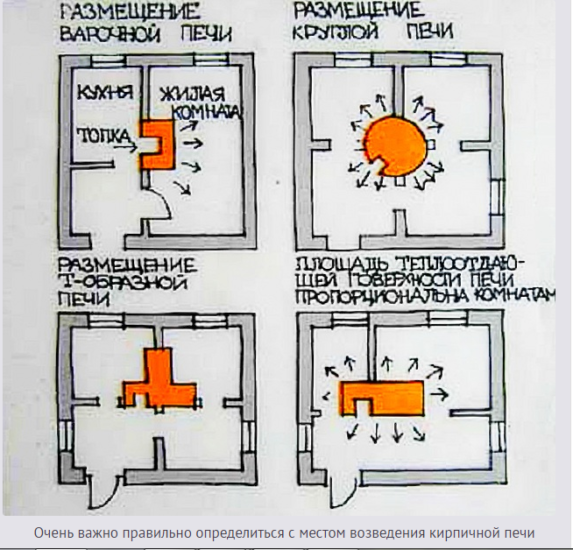

Step 1. Determine the location of the furnace.

Once you have decided where you will place the stove: in the corner, in the center or against the wall, you should clearly mark the location of the stone structure on the floor.

It is very important to decide on the location of the furnace

In order to clearly guess with the construction of the chimney and not to rest against the wooden roof beam when laying the pipe, we use a construction plumb line.

- We draw the layout of the stove and the location of the firebox, chimney, hob and oven.

- Consider the location of windows and doors that will prevent the free circulation of warm air.

In order for the stove to serve for a long time and please you with its maximum performance, we will give some recommendations regarding its placement.And the point is not only in the implementation of fire safety rules, but also in the efficiency of its work.

- The corner is an excellent solution for placing a brick oven. But at the same time, it is necessary to take into account the location of the doors. If a door is immediately opposite the corner, then it is better to refuse this place. The cold air that enters the room through the door will blow out all the heat and prevent the stove from warming up the house well.

- When choosing a place, consider the location of the chimney. The chimney must not touch the overlap of the beams on the roof. You can make a stove with a chimney in the wall, which will house the structure. Or you can build a chimney as a separate element, which will be located behind the rear wall of the furnace.

- A good place to build a stove in the country is the kitchen. When cooking, extraneous odors will not penetrate into the living room, and the heat emitted by the stove will be enough to heat adjacent rooms.

Oven in the kitchen

- The center of the room is the ideal solution for a stove that performs a purely heating function. This option will need to be abandoned if the design of the oven involves the presence of a hob or oven. On the other hand, the location of the structure in the middle of the room will allow you to evenly heat the room from all sides. And during installation, it will not be necessary to lay a layer of material near the wall.

- Pay attention not only to the location of the furnace structure, but also to the placement of the firebox so that you do not have to carry firewood through the whole house.

Today we propose to consider the features of a brick oven with a hob, since it is it that is very popular with summer residents.Our detailed ordering scheme will help you build brick ovens for wood-fired cottages.

Step 2. We build the foundation for the furnace.

The construction of any furnace begins with the construction of the foundation. This is a very important step, on which the strength, reliability of the structure and its efficiency will depend.

Laying the foundation for the oven

Ideally, of course, designing the stove even before the construction of the house. Then both the place and the ideal place for the furnace will be allotted, and the foundation will be laid out at the stage of erecting the floors. But often people think about laying a stove after they have built a house. Therefore, we chose this option so that you can build a foundation from scratch in an already finished house.

In no case should the foundation be connected with the main foundation of the house. When shrinking the house or other phenomena, the base of the stove should not be deformed.

The foundation must be strong

- We mark with a construction marker on the floor a rectangle along which the boards need to be cut.

Cut out a place in the floor for the foundation

Keep in mind that the size of the foundation should exceed the size of the oven by 10-15 cm on each side.

- By marking with a grinder, we cut out the boards and remove them to the sides.

- Now you need to “deep” into the ground by 70 cm in order to build a solid foundation for the stove. To do this, we use a bayonet shovel. Focus on the layer of soil that will freeze in winter. In central Russia, it can reach 80-100 cm. In this case, you will have to increase the depth of the pit. It is very important to insulate the perimeter of the foundation with high quality. If you are building a stove in an already finished house, where the common foundation is well insulated around the perimeter, then you can dig a hole of 30 cm. This will be enough.

Foundation depth

- After a pit is dug in the ground along the perimeter of the marking, we proceed to the construction of a wooden formwork. The formwork acts as a framework that forms the foundation. For formwork, you can use plywood boards, old ceilings, etc.

formwork

This will not affect the quality and strength of the foundation in any way. Measure the length and width of the dug hole and cut the boards to this size. Using nails, put together the formwork. It should end 14 cm before the start of the finishing floor.

- After the formwork has been built, it is necessary to protect the wood from the moisture that will be contained in the cement mortar. To do this, we lay dense polyethylene around the perimeter and connect it with a construction stapler to the walls. Waterproofing is the most important component of the work in the construction of the foundation. If the frozen, moisture-saturated soil comes into direct contact with the concrete base of the furnace, then a force equal to 25 tons per 1 square meter will press on the foundation, which leads to destruction

- Now you can start pouring the cement mortar, but before that you need to create a solid cushion that retains moisture. At the bottom of the pit we pour gravel of medium hardness and pour 10-15 cm of sand.

- We fill the foundation with cement mortar to the height of the formwork, not reaching the clean floor by 14 cm.

- We lay a reinforcing metal mesh on top.

We reinforce the foundation

Level the top well with a shovel and check with a building level how even the surface is. Now you need to wait 24-28 days, depending on the quality of the cement mortar, until the foundation is completely dry. In no case do not rush, and do not lay the stove before this time, otherwise it will deform in a few weeks.

- On a flat and well-dried concrete surface, we lay two continuous rows of bricks around the perimeter of the foundation. Thus, our foundation reaches the finishing floor.

Foundation

- Now it is necessary to lay a layer of roofing material in 2 layers on top of the masonry, which will perform the function of waterproofing.

We lay a layer of roofing material

- A solid base for a brick oven is ready - you can proceed directly to the masonry. But, before laying bricks on the mortar, it is better to lay out the entire structure, according to the scheme, “dry”. First, it will allow you to see if you have enough material. And secondly, even at the draft stage, you will be able to see difficult moments that you will have to pay special attention to.

Attention! It is also recommended to perform each new layer first "dry". This is especially true for beginners who first encounter the laying of the furnace. After laying a brick on the mortar, it will be difficult for you to correct your mistakes and inaccuracies.

Step 3. Preparing bricks for masonry.

Immediately measure the amount of brick that you need for the first stage of work. Please note that laying a furnace is a complex and time-consuming process and cannot be completed in a day. Be guided that beginners will be able to master 4-5 rows a day, no more.

Select a portion of red ceramic brick, clean it well and soak for 12 hours in water.

Masonry bricks must be soaked in water before starting work

When you lay out a fireclay brick firebox, it will be enough just to rinse it with water.

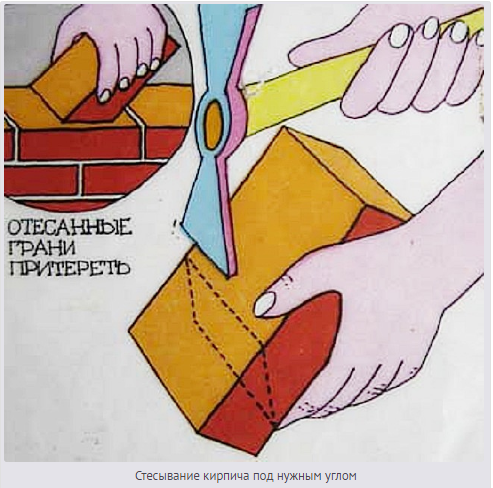

The process of preparing the material for masonry includes, and the division of the brick into ½ or ¼ parts, squeezing in the corners. See the diagram for what shape of brick you will need for each row.It is better to do this immediately, so that later, when laying a row, not to be distracted by these moments.

Cutting bricks at the right angle

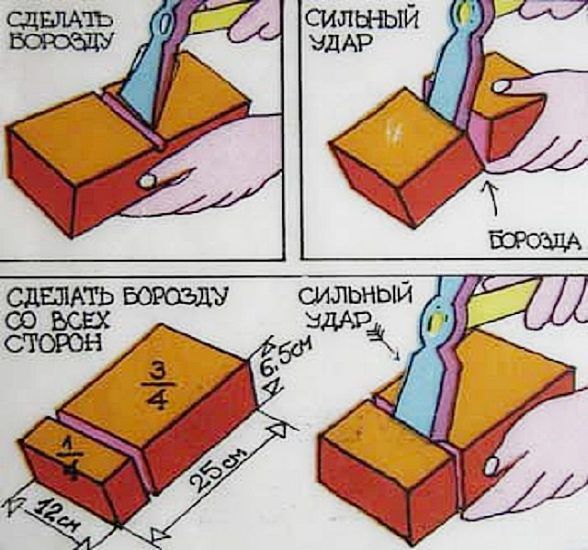

Brick splitting also needs to be done at this stage. Keep in mind that before you "beat off" the necessary part of the brick, according to the scheme, you first need to make a groove.

Brick splitting techniques

At the same time, one longitudinal groove is enough for ½ brick. But if you need to chip off 1/6 or 1/8 of a brick, then a groove is made on all sides of the brick.

Step 4. We prepare the mortar for masonry.

The correct mortar for laying the furnace is the key to its efficient operation. If you decide to lay a brick oven for a wood-fired cottage with your own hands, then it is better to prepare the solution yourself.

Video. Furnace lining. We make a solution of clay with our own hands.

Although on sale now you can find ready-made factory solutions for laying the furnace, which are of good quality.

To do this, you need sand and red river clay. It is clay that is the indispensable material, without which no masonry mortar is inconceivable. Due to its unique properties, soft and plastic, it, under the influence of fire, turns into a durable stone.

After firing, it acquires the strength of a brick and can endure the highest temperature. However, in order for it to really be strong and securely fasten the masonry, it is necessary to observe the correct proportion of all ingredients.

Determine the fat content of the solution

One of the main indicators of the quality of clay is its fat content. If you take "skinny" clay, then when heated, it can crack.

We will not indicate the exact amount of ingredients, since there is no ideal proportion. Depending on the quality of the clay, its fat content, the solution is made "by eye".

Clay is thin and oily

It should have the consistency of thick homemade sour cream, not dripping from the trowel. At the same time, in no case should there be grains in it, so the solution should be thoroughly kneaded.

We measure the required amount of clay that will be needed for masonry, and fill it with water. You do not need to immediately prepare the solution for the entire furnace, if you do not plan to finish the masonry in 1 day. Measure as much as you can.

- We wait 3-4 hours until the clay collects enough water and softens.

- Now we rub the clay through a sieve. Pour the filtered mixture with the required amount of sand and mix thoroughly.

The process of kneading clay for the oven

The solution must be viscous, plastic. If the solution does not stick to the trowel, but only slightly stains it, then this is a “skinny” solution and you need to add a little greasy clay to it. A lean mortar will crumble and crack badly. Such a mixture is fragile and bricks should not be laid on it.

Clay kneading

- If, on the contrary, it flies off the trowel in thick lumps, then such a solution is “fat”. You can add some water and sand to it. Such a consistency is considered normal when the mortar slightly protrudes from the joints during masonry.

Attention. Clay mortar is not suitable for arranging the foundation and chimney. Usually cement mortar is used for this.

Step 5 We are building a furnace.

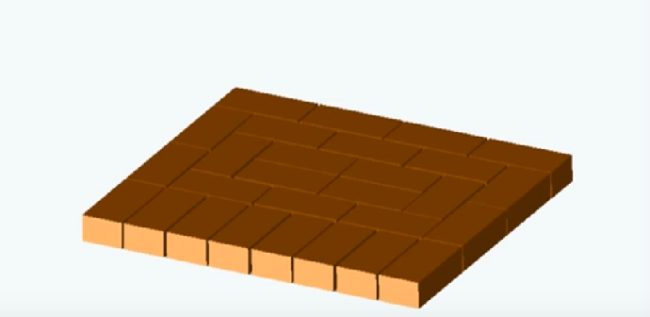

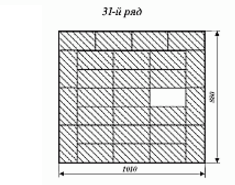

The first row is very important in the furnace and the whole form of the structure depends on it. Therefore, first lay out the first solid row “dry”, and put the building level on top. Keep straight corners. They can be checked in the process with a plumb line.

Before proceeding directly to laying bricks, we recommend that you read the detailed instructions and tips for building a furnace.

Video. Learning to lay a small stove.

Advice! Even seams may not work the first time. To do this, you can use wooden slats, equal in thickness to the thickness of the seam. They are laid on a row, after which the solution is applied and the second row is placed. Prepare so many slats that they are enough for three rows. By the time you have completed the third row, you will be able to remove the sizing tool from the first row and use it further.

Before laying the first row of bricks on the roofing material, make markings with chalk.

- The 1st row is solid, according to the ordering scheme. Check diagonally how evenly you laid out the bricks.

1st row solid

Advice! So that the stove does not go to the side during laying, and it is not necessary to check the vertical of the stove after each row, you can pull 4 sheer threads in the corners, which are fixed to the ceiling. They will serve as a kind of beacons as landmarks for the furnace.

4 strands vertical

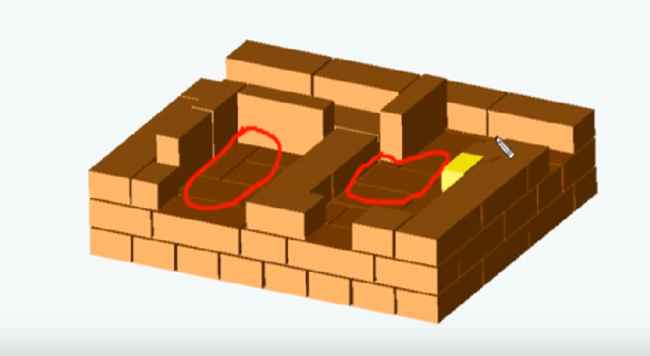

- 2nd row repeats the first. Watch the thickness of the seams. Here the blower door is installed.

Door installation

To do this, we pass the burnt metal wire through the holes and twist it into a bundle. The second end of the wire is laid between the bricks.

- The 3rd row forms an ash chamber in which all the ashes and ash accumulate.

laying the ash chamber

All gaps between bricks and metal elements must be filled with asbestos cord, which levels the temperature drop during the furnace.

1-12 row

- 4, 5th row begins to form a firebox with fireclay bricks.

- We install a grate on top. Keep a seam gap of 3-5 mm.This gap must be left taking into account the expansion of the metal at high temperatures. Fill this gap with sand. We block the door of the blower with a brick. Installing the oven.

Correct installation of the firebox door

- 6th row. We begin to form the chimney pipe and lay the base of the firebox, which we make from fireclay bricks.

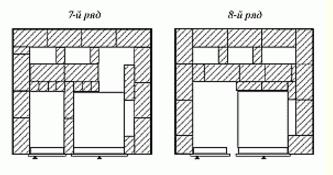

- 7th, 8th, 9th rows - laying the firebox with fireclay bricks.

7th and 8th row

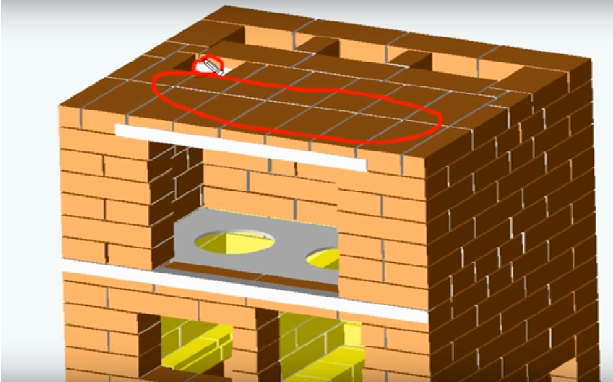

- On the 10th row, close the oven. We create a partition from a brick, raising it by 2 cm. On the oven, to the level of the partition, we apply a clay-sand mortar. Here we lay a metal corner (on the front side under the stove).

- On the 10th row we lay an asbestos strip before we install the hob on the next row. The fact is that metal elements tend to expand when heated, so it is important to lay a layer of asbestos.

Laying asbestos strip before installing the hob

- 11th row - install the hob. Please note that the slab is placed directly into the recesses on the brick. To clearly guess with the markings of these recesses, number each brick when you lay the row and mark with a marker the place where it is necessary to cut it with a grinder.

Putting the stovetop

After that, assemble a row for a solution. Keep in mind that the entire row is placed on a clay-sand mortar, but the hob itself is placed on a clay-asbestos grout. To prepare it, take a small portion of the prepared clay-sand mortar and add crushed asbestos, knead well.

Attention! If the burners of the hob have different diameters, then it is necessary to place larger ones above the combustion chamber, and smaller holes above the oven.

- 12-16th row - laying chimney channels.

flue channel

Attention! When laying out the smoke channels, make sure that the solution does not remain inside. Remove the remains of the solution with a washcloth or trowel, otherwise it will then interfere with the unhindered circulation of hot air.

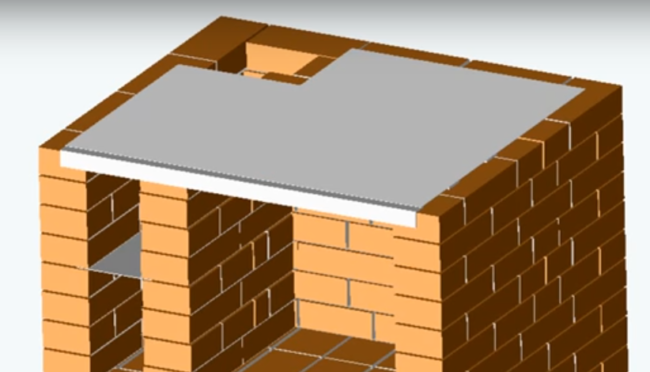

- 17.18th row. We cover the hob, carefully filling the seams with a 3-5 mm solution.

Making an overlap

- 19th and 20th row - on the right side we install the doors through which the oven will be cleaned.

- We make the 21-23rd row according to the ordering scheme of the chimneys.

- 24th row - we lay out the last steel plate on top of the bricks, which ensures the zigzag movement of gas in the smoke channel.

- 25th row - put a metal sheet.

Covered with a metal shield

- On the 26th row, we mount the valve, taking into account a gap of 5 mm, between which we lay an asbestos cord.

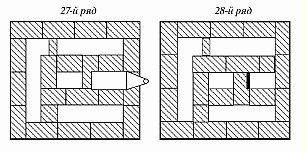

27, 28 row

27-28th row - lay out a hole for the chimney.

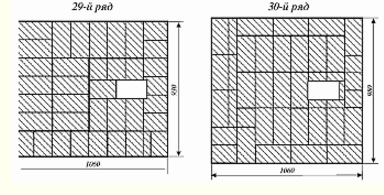

- On the 29th row, the masonry is expanded by ¼ brick to create a cornice. Here we block all channels, leaving only the pipe.

29

- On the 30th row, we make an additional extension of 5 cm.

- On the 31st row, we reduce the size of the furnace to its original form.

31

Step 6. Laying the chimney.

The location of the chimney is indicated at the design stage of the furnace. But in any case, for normal draft, the height of the chimney should not be less than 5 meters.

We begin to build a chimney

Also make sure that there is no residue of the solution inside, otherwise it will interfere with normal traction.

Taking the pipe out of the house through the roof, consider the height of the visor. It must be 50 cm below the top of the chimney, otherwise turbulence may form around the chimney.

We complete the laying of the chimney with a metal grate that prevents debris from entering the chimney. You can also install a cap (umbrella) on the top of the chimney, which will reliably protect the pipe from precipitation.

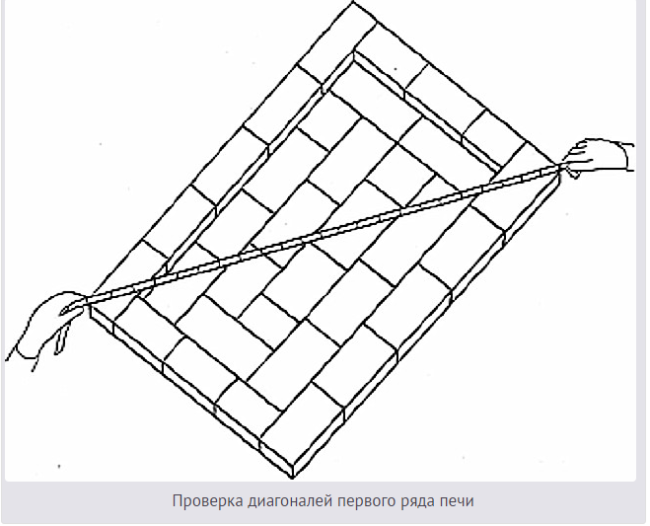

Step 7. Finishing lining of the furnace.

After the oven is completely laid out, you can proceed to the finishing lining. As an outer layer, you can use facing decorative stone, ceramic tiles, red brick.

Finishing with ceramic tiles

Remember that any additional material applied to the outside of the stove will reduce heat output.

Before and after cladding

Therefore, if you are more interested in the efficiency of the furnace than its appearance, you can simply cover the brick with a layer of decorative plaster.

Step 8. Drying the oven.

Having completely finished laying the furnace, it is necessary to dry it well, since it now contains a large amount of moisture from the solution.

To do this, open the door of the combustion chamber and leave the stove for 7-10 days. Brick and clay-sand should dry well, otherwise the “raw masonry” may be deformed due to high temperature.

If you build a stove in warm weather, then it will dry naturally. In cold weather, use a fan.

Another option for forced drying is a 200-300W electric light bulb, which is installed inside the firebox and left to burn for 7-10 days. But this is a forced measure that must be taken only if the temperature outside is less than zero degrees Celsius.

Step 9. Kindling the furnace.

When all finishing work is completed and the oven is well dried, it is necessary to carry out the first test kindling.This is not a tricky thing, but it’s better to follow our advice to avoid trouble and maximize the efficiency of the furnace:

Kindling in the oven

- Do not use garbage or glossy magazines for kindling.

- Keep flammable items away from the oven.

- Close the firebox door tightly before the flame ignites.

- Do not immediately apply strong heat to the oven. You need to warm it up gradually.

- Use only high-quality, well-dried firewood.

Useful tips for laying a brick oven for a summer residence

- Always keep an eye on the thickness of the seam during bricklaying. It should be 5 mm.

- Check the first row not only with the building level, but also diagonally.

Checking diagonally 1 row

- Start laying each new row on the previous row only when you check it horizontally with a building level, and vertically with a building plumb line. For evenness of corners - use a goniometer all the time. Then it will be difficult to correct your mistakes.

- When laying a cast iron hob on a brick, it is necessary to lay a layer of clay mortar on it. This will protect the brick from heating.

- To ensure good traction and prevent the formation of condensate, it is necessary to make a short gas outlet path. The so-called summer move. Through this path, gases enter the chimney. After the stove flares up well, the damper is closed.

- Start each row from the corner.

- When laying out each new row, make sure that the new brick overlaps the joint of the previous brick.

- The size of the chimney and chimney must have the same diameter.

At the end of the article, we recommend that you read the instructions for laying a wood-burning stove for a summer residence.

The video describes in detail the process of laying on a dry simple brick oven

Video.Detailed laying of a brick oven for a summer residence.