Equipping a country house and a heating system with solid fuel, sooner or later everyone thinks about firewood for fireplaces and stoves. You can't leave firewood outside. Precipitation and capricious weather can destroy stocks prepared for the winter.

Metal firewood

Therefore, to keep them dry and unharmed, you need to consider a reliable storage system. Of course, you can transfer the entire supply of firewood to a barn or any household building, but a suburban area will take on a completely different aesthetic appearance if a firewood shed is specially equipped for firewood. This will solve the issue of storage, decorate the house and add comfort during operation of the stove or fireplace.

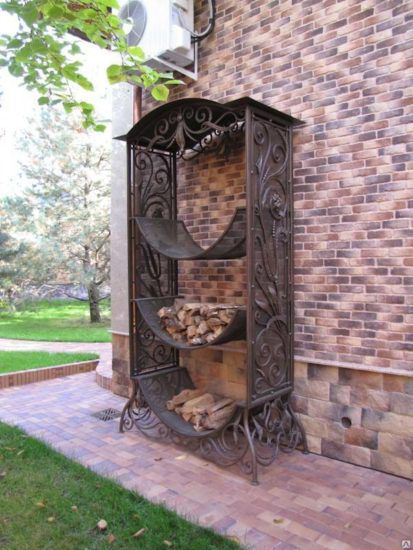

Wrought iron firewood for giving

What should be the firewood for the fireplace and stove and how to make it yourself?

Content

Types of firewood for summer cottages and at home

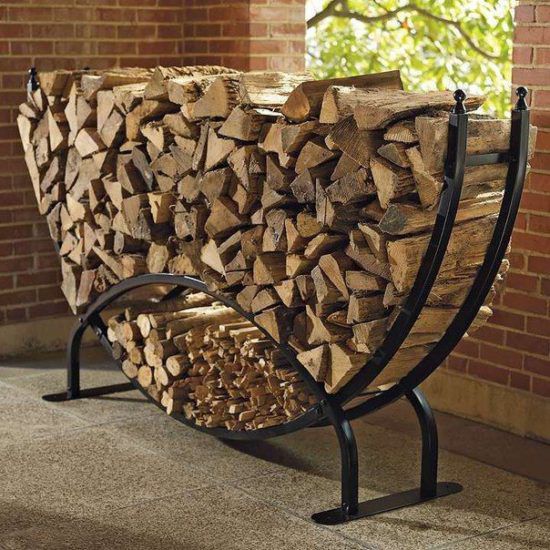

A firewood storage stand can be created from any material, but wood and metal are most often used. Concrete rings for wells, fittings, barrels - everything that is on a suburban area can be used as improvised means for creating a woodcutter. Look at the photo below, a minimum of metal and a large amount of firewood!

Firewood for giving

It all depends on where it is supposed to place the firewood - on the street or inside the house. We offer you several options for the construction of firewood, and you will already choose the most suitable design for yourself.

Firewood can be classified into four categories:

- for premises;

- for the street;

- portable (mobile);

- stationary.

Many, in the old fashioned way, prefer to use a regular shed for storing firewood. But experience shows that in such a room, where there is no constant air circulation, the firewood becomes damp, the tree rots. Yes, and a high probability of breeding rats and insects in such a barn.

A simple firewood rack looks much more stylish.

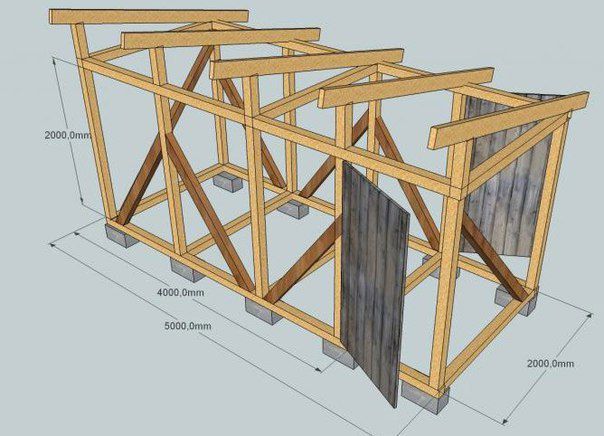

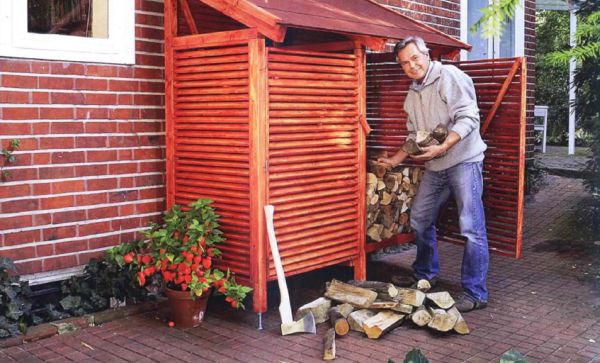

Wooden firewood shed

But no matter what material you choose for its manufacture, you must understand that no matter how stylish and decorative the firewood shed is, it must solve the following tasks:

- Provide air circulation between the firewood.

- Reliably protect logs from precipitation.

- Provide convenient operation.

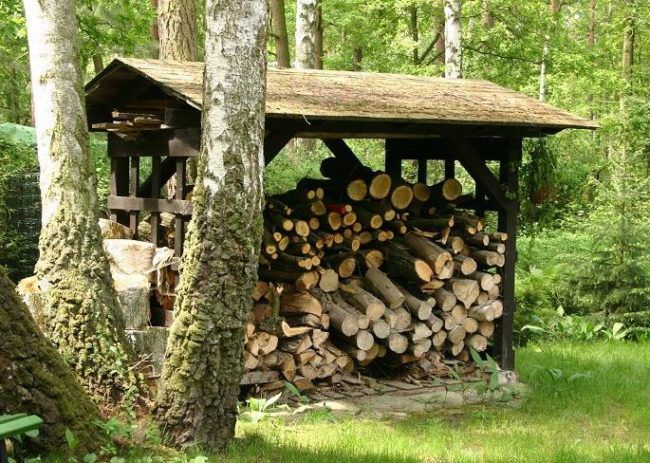

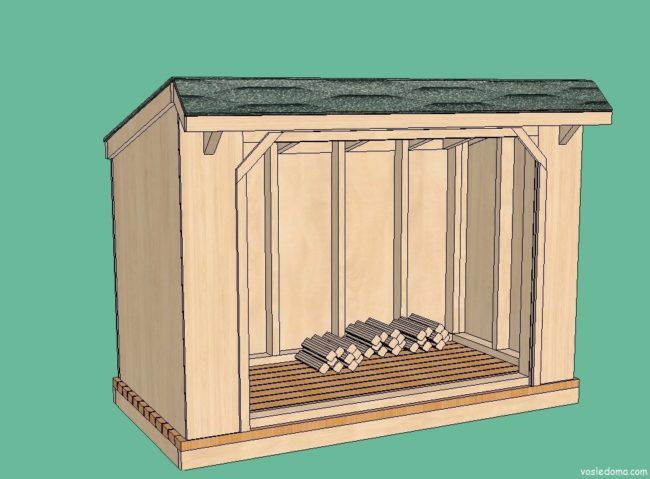

Outdoor firewood in appearance is very similar to a simple barn.

Stylish firewood shed for the street

Only the walls should not be closed tightly for good ventilation, and the floor should be raised above the ground so that the fuel does not dampen.

For the home, more elegant forms of firewood are used.

Mini firewood for the room

You can build a beautiful forged openwork firewood of small sizes. It rather provides an aesthetic function here and for convenience only a few logs are placed in it. At the same time, such a firewood rack can be made stationary and mobile. For the manufacture of forged firewood, a cold and hot forging method is suitable.

Firewood by the fireplace

A room firewood rack should fit well into the overall interior design.Safety and ease of use will ensure its stability. Forged products add the same country gloss and zest, for which everyone strives to escape to the country.

At the same time, it can have the most intricate shape and have a very stylish minimalist look.

Modern room firewood

The design of the outdoor firewood storage will be completely different. When making a supply of firewood for the winter, you must take care of their safety until spring.

Wooden firewood rack for outdoor storage

Here, for the construction of such a structure, you must be guided by the following rules:

- The distance between the ground and the base on which the firewood lies should be at least 10-15 cm. Otherwise, the lower layer may be saturated with moisture.

- If you plan to store a large supply of firewood, then it is advisable to make several floors in the structure. So it will be easier for you to keep order during operation, and during use, natural air circulation will occur, providing the firewood with optimal moisture.

- When creating a canopy, make it at a slight slope. So snow and rain will flow freely from the roof, without collecting unnecessary condensate.

Simple wooden firewood for the street

- When constructing a structure for a large supply of firewood, make sure that the base is strong. Otherwise, due to weight, the floor of the woodshed can sag and then the moisture from the soil will spoil the first layers of solid fuel. To strengthen the structure, reliable beams are screwed into the ground.

Video. Some stylish ideas for outdoor firewood sheds.

For the construction of firewood, any improvised material is suitable. It all depends on your skills and imagination.

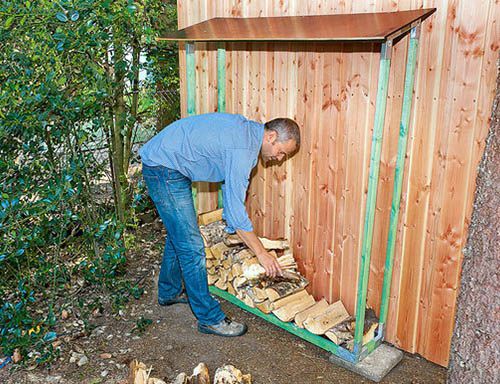

Woodshed with gate back wall

You can weld a small structure from the corners and attach it to the wall of the house.Thus, it will not be necessary to close the back wall. From above, it will be necessary to cover such a woodshed with a roof to protect it from precipitation.

Simple firewood from metal corners

A simple method is a frame made of wooden beams frame,. Covering it with a roof, as in the photo, you will reliably protect the firewood from rain and snow.

Firewood shed with roof

But there is one significant drawback here - the lack of a back wall, which is why in bad weather all the firewood can be flooded with water.

It is better to protect the structure with a metal shield from the profile. If you do not know how to cover such a firewood, then polycarbonate will be an excellent solution. Light freely penetrates inside, which means that the firewood will always be well dried.

A great idea for outdoor firewood storage would be ordinary concrete rings. The approach is very non-standard, but this option looks very stylish and original on a suburban area. In order to build such a woodshed in the country, you need to purchase ready-made concrete rings. You can’t do without assistants in construction, as they have an impressive weight.

In order to install such a structure, you need to decide on the installation site and prepare the base by filling it with gravel and compacting it tightly. Thanks to such a solid base, the rings will not be able to budge. A multi-level design will look even more impressive.

Firewood from barrels in several tiers

An alternative and very budget version of the previous firewood rack will be a construction from simple barrels. You can take just one barrel, put it on its side and securely fix it with wooden slats. And you can build a whole multi-level structure.

How to make a firewood for a fireplace with your own hands?

Today on sale you can find a huge range of stylish firewood from a variety of materials that will wonderfully fit into any interior and provide convenient operation.

Portable mini firewood

But it's always nice to do something with your own hands.

Of course, without certain skills and the appropriate tool, it will not work to make it with your own hands. If you want to make a firewood shed yourself, then we offer an easy way to create a firewood shed from plywood.

1. Firewood for the room

Do-it-yourself firewood stand

For the manufacture you will need the following materials and tools:

- plywood sheet;

- construction marker

- electric drill;

- jigsaw;

- 2 wooden slats. When all materials and tools are prepared, you can start construction work:

- Take a sheet of plywood and draw a small ellipse 90 * 40 cm on it with a marker.

Draw an ellipse on plywood

- We cut out the desired shape of the base with an electric jigsaw according to the intended landmark.

- Step back with two edges of 5 cm and drill two holes with a drill (approximate diameter 3 cm).

- Now to give the base a spherical shape, we need to make the plywood elastic. To do this, pour hot water into a large container (for example, a basin or bath) and place the cut out base in the water. Leave for 1 hour.

Leave plywood for 1 hour in water

- Now you can give the plywood a bent shape. Do this very carefully and slowly so as not to damage the material. If you feel that the tree does not give in, you can again lower it into warm water for 20-30 minutes.

Plywood bends after swelling in water

- We insert a wooden handle into the previously made holes.

- Outside, fix the handle with a dowel.

- So that the firewood rack does not swing on the floor like a cradle, we give it stability with the help of two rails. To do this, we attach them to the base with self-tapping screws.

This design is simple and at the same time convenient to use. You can easily move it to the place you need.

2. Portable mini firewood for the stove

Stocking up on firewood for the whole winter is, of course, good.

Portable firewood for stove

But after all, no matter what stock you place in the woodshed at home, sooner or later you will still have to go outside for the next portion. To make it convenient to carry firewood, we propose to build a simple mini firewood rack. It is not difficult to make it even for a beginner, but this option looks very stylish.

From materials and tools you will need:

- 2 metal rods with a diameter of 5 mm.

- 4 metal rods measuring 15 cm.

- Welding.

Work order:

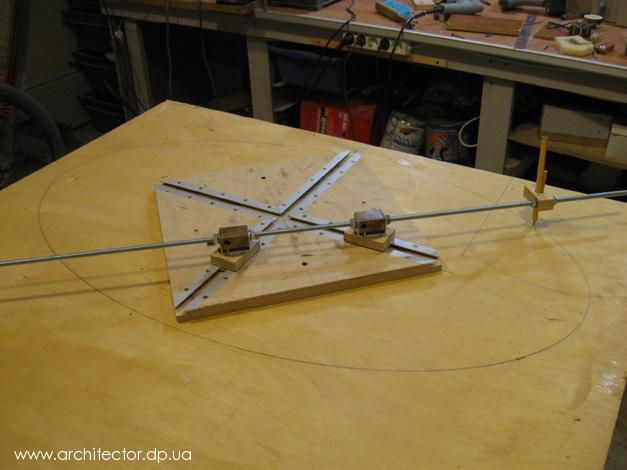

- It is necessary to make 2 blanks from metal rods. To do this, they must be bent to a diameter of 0.5 meters and connected each by welding.

We make 2 circles from metal rods

- Now we put these 2 circles side by side and weave the wire at the top point. After the upper connection point of the two metal circles is fixed, we separate the two circles from below in different directions at a distance of 10-12 cm. We fix it all on the table with a clamp.

- We fix two points on top by welding. At this point, it will then be necessary to make a handle for carrying the entire structure.

By welding we connect 2 rods

- It is necessary to make 2 blanks from metal rods. To do this, they must be bent to a diameter of 0.5 meters and connected each by welding.

- Now we need to stiffen the whole structure so that it can withstand the weight of firewood when carried. To do this, we toughen our firewood with additional metal rods - 4 pieces.The size of such rods depends on how far you spread the two circles. We weld them parallel to each other, as shown in the figure.

Weld metal hinges to the base

After the frame is ready, it is necessary to give it stability on a horizontal surface. You can use 4 metal loops for this, which must be welded to the base.

After that, you can paint the firewood shed to protect it from corrosion and give it a more beautiful look.

The video shows in detail how such a miniature firewood can be built from ordinary metal rods.

Video. Forged mini firewood with own hands

3. Option firewood from an old barrel

Another firewood option that can be used indoors and outdoors. An empty barrel is suitable for this.

Firewood from a metal barrel

- Using a grinder, prepare a circle 15-20 cm wide.

- We take a metal sheet and make a vertical line out of it, fixing it by welding.

Cut out the circle from the barrel

- On the left side of such a circle, you can create an additional shelf on which it will be convenient to put straw, kindling brushwood or any other tools.

- Now this base must be fixed on the floor. For this purpose, 2 wooden or metal slats can serve.

4. We build a firewood shed for the street from wood

A budget option for building a woodcutter in the country will be both a wooden and a metal structure. But the metal firewood has a number of disadvantages. The metal will not provide the necessary circulation of firewood, which means that there is a threat of high humidity and rotting of the wood.

Therefore, we propose to consider a simple and very economical option for building a wooden frame.

Wooden firewood

Of the tools and materials for construction, you will need:

- electric drill;

- wooden bars from lining;

- screws;

- wooden shield (pallet);

- film (roofing material);

- coating for wood processing (moisture protective impregnation);

- hacksaw;

- brushes;

- construction stapler;

- construction marker and level.

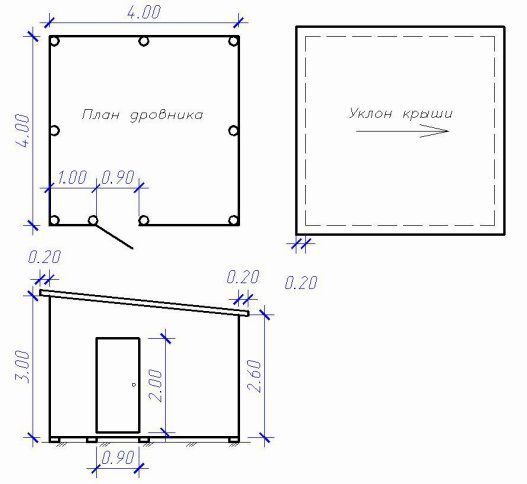

- We draw a plan diagram of the future firewood. You must immediately take into account the height of the walls and the width of the building. When calculating the size of the firewood shed, consider such parameters as the required supply of firewood for the winter.

Firewood scheme

For an approximate calculation, be guided by the following figures: to heat a standard room of 100 square meters, you will need at least 2 cubic meters. meters of dry wood. This parameter also depends on the quality of firewood. Birch logs usually require 15-20% less.

- Decide on the place where the woodshed will be erected and draw a sketch where the slope of the roof and the size of the walls will be clearly calculated. Keep in mind that firewood must lie in this place for more than one year and at the same time retain its properties. On the sketch, take into account the slope and the roof and that it should extend beyond the frame by about 30 cm. Otherwise, the outer row of firewood may get wet during rain.

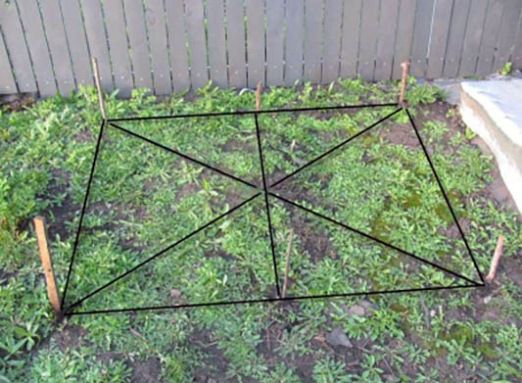

Marking for firewood

Make a mark on the ground where the canopy will stand with the help of pegs and rope. Keep in mind that this area should be without a slope, otherwise the firewood shed, under a load of firewood, may tilt.

- We make the base of the firewood.

- Dig 4 holes with an earthen drill or a regular garden shovel (in the places where the pegs are) 60 cm deep each.

- Deepen the wooden beams into the ground by 20-25 cm. At the same time, it is better to cover the underground part of the wooden block with resin so that it resists moisture and stands quietly for 15-20 years.You can use any antiseptic for these purposes, and wrap the base with roofing material on top. Fill the holes tightly with gravel or clay. Tamp down so that the posts are securely fixed. In order for the earth to tightly fix the wooden beams, it is better to alternate sand, clay and fine gravel in layers, 10 cm each. And to compact each layer tightly, use a metal pole.

Burying a wooden block

Lay a layer of film on the ground to prevent moisture from penetrating.

- We make the base of brick, connecting it together with cement mortar. You can do it easier and build a base from a wooden shield, but keep in mind that it must first be properly impregnated with a hydrophobic solution.

Base for firewood

Consider the slope of the roof, which will ensure the drainage of rainfall. The height of the wooden poles must be initially different and take this fact into account. The minimum height difference should be 13-15 cm.

- Now it is necessary to ensure the rigidity of the structure. To do this, the first row of pillars must be connected to the back row. We take two bars and with the help of screws and an eclectic drill we securely connect the structure.

- We sheathe the structure with wooden beams or shields.

We connect the bars

We make the wall of our firewood. You can use a wooden shield, but the most economical option would be a slab. Leave small gaps between the slabs of the slab so that there is a constant natural circulation of air in the firewood.

- Let's start installing the roof.

We mount the roof

The roof of the woodshed can be made from the same slab with which you sheathed the back of the building, but first you need to complete the base of the roof.From above, we cover the structure with a film or roofing material, connecting the slab with the film using a construction stapler. Slate or polycarbonate can also be used as a roof covering.

- Treat the wood well with an impregnation that protects the wood from decay and moisture.

Soak wood well

To give a beautiful look and decorativeness, you can cover the entire structure with varnish, paint, braid with ivy or any curly flowers.

Video: How to make a firewood for the street with your own hands

A reliable storage for firewood is ready and now you can not be afraid of a cold winter!