If the budget for the construction of a bathhouse in your suburban area is very large, then you can safely skip this article.

For a lot of money, you can both purchase a high-quality stove and sheathe the building with a spectacular finishing material. Actually, you can just buy a "turnkey bath". However, if you have to save money, then you can easily make a boiler for a wood-fired sauna with your own hands. Believe me - there is nothing super complicated in this. Enough to take:

- a good metal barrel;

- sheets of durable metal;

- piece of metal pipe of large diameter.

It is possible that such a boiler will look unsightly, but on the other hand, it will perform its functions at 100 percent, and this is exactly the goal you are pursuing!

Content

Boiler for a bath from trimming a metal pipe

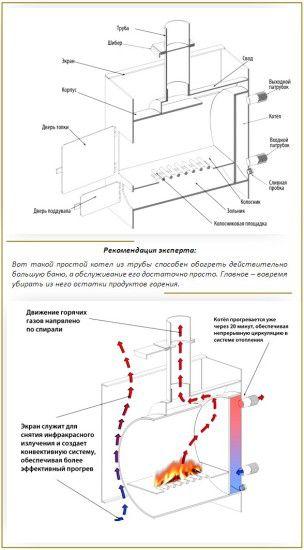

The easiest way to make a boiler for a wood-fired bath is to use a piece of durable metal pipe with a large diameter. There are two options for manufacturing a boiler from metal pipes: vertical and horizontal - both of them have their advantages and disadvantages.

In order to start manufacturing, stock up on the following tools:

- Electric metal welding machine,

- Angle grinder with a set of discs for cutting metal.

Horizontal boiler

In the first method, a piece of metal pipe is laid on the ground and a blind plug is installed on it on one side. On the opposite side, a stove door is organized in the plug. Also, in the area of \u200b\u200bthe blind plug, you can install another jumper, which forms a heating tank for hot water. Also, a water tank can be made in the upper segment of the stove. In this case, it is possible to make a system of constant water heating, when the used hot water will be regularly replaced by newly incoming cool, not heated water.

In the side part of a horizontally lying pipe or in its upper segment, you can also arrange a heater, that is, a shelf into which river stone is poured, which will further increase the power of the stove!

Vertical design

On the other hand, a piece of pipe can also be placed vertically. The entire internal volume of the pipe will be divided into two parts: the firebox itself in the lower part and the water heating tank in the upper part. When building such a structure, a shelf for stones can be placed on the side.

With a large wall thickness of the metal pipe, the furnace and the tank for heating water can be made separately. So it will be easier for you to handle massive structures. Keep in mind that thick metal is only needed to make the firebox, but thinner metal can be used on the heating tank. The thickness of the metal used to make the furnace directly determines the period of its further service: the thicker the walls, the longer the period of trouble-free operation.

A heater, that is, a shelf for stones in this design, can also be placed between the heating tank and the firebox. The chimney is mounted strictly in the center of the firebox. Pay special attention to the welding of the junction of the chimney pipe with the firebox and the heating water tank. For efficient operation of the stove in the pipe, it is recommended to make an adjustable damper.

The chimney in such a solid fuel boiler can also be made of combined materials, such as steel and asbestos. During installation, when joining a metal and asbestos pipe, be sure to take into account the different coefficients of thermal expansion of these materials when they are heated.

Such boilers made from scraps of metal thick-walled pipes will faithfully serve you for several years, until you decide to replace them with a more capital and expensive structure. Yes, even if you do not decide to replace, everything will function perfectly!

Boiler for a bath on wood from a metal barrel.

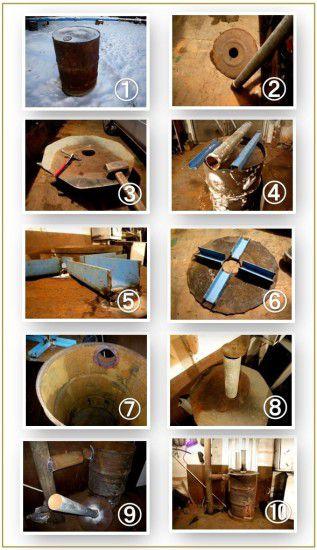

This is perhaps the best and most economical way to make a boiler for a wood-fired sauna. The basis for that boiler should be an old metal barrel. Modern barrels are not suitable for this purpose - they are made of very thin metal - almost from foil.

In an old barrel with a chisel or an ax, we cut down the top cover. Then we cut off a piece of metal pipe about 15 centimeters long - this will be the base of the chimney.

Then we take another large barrel, with a volume of about 200 liters. From it you will cut out the cover located along the bottom. In the center of the cut out cover, we punch a hole for a chimney pipe with a diameter of about 10 centimeters.The chimney itself will have a cross section of 10 centimeters and a height slightly higher than the height of the barrel.

We weld the chimney pipe to the cut off barrel lid, and on the reverse side - four segments from the channels.

We cut out the boiler cover from the metal sheet, placed on top. In it we cut a round hole for a pipe with a diameter of 10 centimeters. Then we attach the assembled boiler to the chimney, having previously insulated it with non-combustible materials, such as asbestos.

A normal load to test such a stove will be about a third of the volume. A lid with a pipe is placed on top of the firewood. It can move along the height of the barrel. From above, the structure is closed with a top cover.

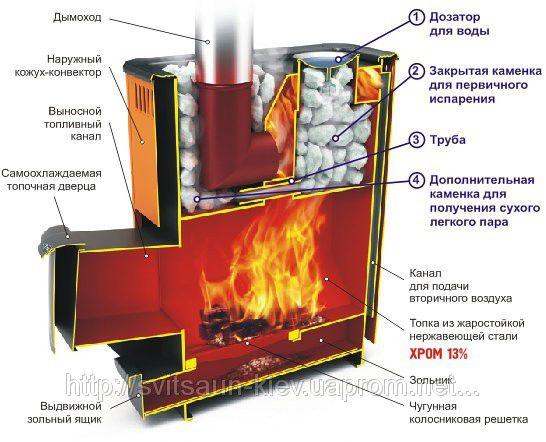

How to make a boiler for a bath with a long burning function?

An ordinary, standard solid fuel boiler will “digest” the firewood put into it for no longer than 2-3 hours. But if you like to take a steam bath for a long time, with arrangement and rest, it makes sense to think about creating a boiler with a long burning function. Its design will save you from having to constantly run from the steam room and put new firewood. In a high-quality long-burning boiler, a batch of firewood can burn up to 20 hours. This is achieved by limiting the flow of air into the furnace.

The principle of operation of such a boiler for long-term combustion of solid fuel is as follows. A little above the middle of the body of such a stove is a loading hatch. A batch of firewood is placed in it. Firewood is set on fire from above. Above them is an air supply restrictor, resting with a conical shank on burning firewood.As soon as the firewood starts to burn out, the limiter drops lower and lower, showing you that the next batch of fuel needs to be loaded into the stove. A nice bonus in the construction of such a boiler is the fact that you can heat it not only with ordinary firewood and almost any type of solid fuel.

Such a boiler is made from metal pieces of pipes with thick walls. Dimensions of the pipe section: cross-section of approximately 30 centimeters. The essence of the design is that the combustion zone of solid fuel is artificially limited, firewood or other combustible material is compacted in it, and combustion processes slow down.

A stove of this design will have not only a loading hole, but also a door for removing ash and other residues of burnt fuel. By the way, this design of the furnace will significantly reduce the number of combustion products and soot formed in the furnace.

Here, in fact, there are the simplest ways to build a boiler for a wood-fired bath with your own hands. Draw drawing, take the raw materials and the welding machine in your hand and go ahead, you will definitely succeed!

Video: Testing a homemade boiler for a wood-fired bath