Arranging a stove in a country house or in the country is a very popular business today.

Bell-type furnace

Despite the appearance of modern heating appliances on the market, many prefer the good old brick stove, which for many centuries served as the only source of heat and cooking in the house. Such structures are especially relevant where there is no gasification.

Time does not stand still. The good old "Swedes" and "Dutch" ones were replaced by new and more advanced ones - bell-type furnaces, which are in no way inferior to their channel counterpart. The design of the bell-type furnace is distinguished by a fundamentally new method of using hot gas.

Content

The principle of operation of the bell furnace

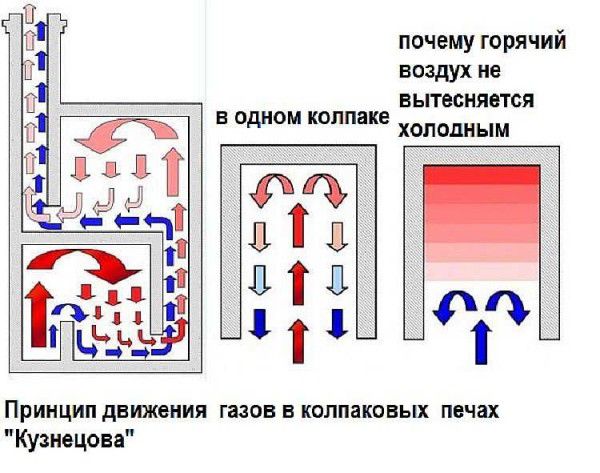

The Kuznetsov bell-type furnace (popularly referred to as "Kuznetsovka") was named after its creator, I.V. Kuznetsov, who started developing a new heating scheme in the early 60s of the last century.The unique technology of "free movement of hot gases" immediately gained recognition and became very popular all over the world.

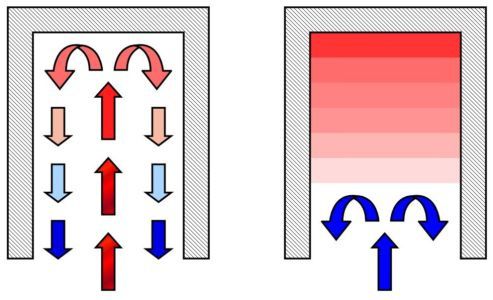

Kuznetsov's bell-type furnace: principle of operation

The peculiarity of "Kuznetsovka" is that the heated gases pass and circulate through the pipe due to their own gravity, in contrast to the "forced" movement through the chimney. We all know from physics lessons that warm air rises, displacing cold air. But, unlike channel prototypes, here the heat does not exit the pipe, but is collected under the hood. Gradually, it cools down there, and it is forced out by gusts of more hot air rising upwards.

The main difference between a channel furnace and a bell furnace is the principle of hot gas movement. In the first one, the smoke, as it were, is drawn up through the pipe, and in the hood, it is pushed out. The hood itself can serve as a container for heating water, cooking, drying, etc. Thus, the bell-type furnace can perform a dual function.

Furnace "Kuznetsovka"

That is, according to the functional characteristics, "blacksmiths" can be divided into:

- bath stoves;

- stoves for cooking (bread, cooking, under a cauldron, barbecue, grill, etc.);

- fireplace;

- furnaces for heating;

- combined type.

The most common are combined types with the possibility of cooking and heating the whole house. Despite the possibility of variation in style and shape, the principle of operation of the bell-type furnace remains unchanged.

Scheme of the movement of gases in the furnace

To make it easier to understand the basic principle of the Kuznetsov stove, imagine a fire kindled in the open air. Due to the unlimited access of air to the fire, the fire gives little heat.And now let's try to cover this fire with a metal cap, leaving a small gap below, so as not to extinguish the flame at all. Hot air will go up, heating the walls. Gradually cooling down, the air will begin to descend to the left opening while a new portion of hot air takes its place. This is the principle of the free movement of hot gases, which I.V. Kuznetsov successfully applied in his development.

Design features

Today, more than 150 types of designs can be found on the Web, but no matter what form, style of execution they may be, all furnaces are built according to the same method. The designer, creating a scheme for laying a bell-type furnace, set himself two tasks: the productivity and efficiency of the heating system.

It is not so easy to build such a structure. It is necessary to strictly adhere to the developed by Kuznetsov I.V. orders. The inventor pays great attention and attention to the location of the internal channels of the bell-type furnace.

The hood is a separate chamber for retaining heated gas, which contributes to fuel savings and increases the efficiency of the furnace.

The standard design of the "blacksmith" assumes the presence of two caps. The lower one is combined with the combustion chamber, and the second cap is located in the upper part of the furnace. The task of the first cap is to separate gases into cold and hot streams. This is what distinguishes the bell-type furnace from the channel one, where the heated air, under the action of draft, freely goes outside. Here, the hot gas flow leaving the furnace tends upward, where it lingers under the first hood and accumulates heat for a long time.

Further, the flow tends through the passage to the second chamber, where it also lingers under the second ceiling, since the passage is at the base.As a result, hot air accumulates heat in the furnace for a long time before exiting through the chimney. This gives a high efficiency - up to 95%. If compared with the efficiency of a traditional Russian stove (channel), then this is 45-50% more.

In addition to the free movement of gas, the bell-type furnace also involves mechanical flow control. For this, valves are installed in the structure. They, as needed, can delay and redirect hot streams. The "summer" valve is designed for the warm season, when the oven is used as a hob for cooking. Having opened the summer valve, the flow of hot air will rush up the chimney without going under the second cap.

Bell-type furnace for home heating

Benefits of a bell furnace

If we compare the blacksmith's furnace with other brick counterparts, then it has a huge resistance to deformation. It heats up quickly and retains heat for a long time. Even if the damper is not tightly closed, the generated heat can be stored in such an oven for a long time.

- long-term operation;

- small formation of soot and soot (it almost completely burns out, turning into ash);

- Efficiency - up to 80%;

- lightweight design that can be mastered even by a beginner;

- improved heating system in comparison with the channel analogue;

- simple and practical in care - there is no need to clean it often;

- does not crack;

- versatility of erection (in a house, apartment, bathhouse, etc.)

- a large selection of shapes and designs;

- no need to take into account the height of the chimney to ensure good draft;

- high speed of kindling;

- the design allows you to install a large heating element;

- there is a uniform heating of the furnace;

- the stove cools down longer compared to its brick prototypes.

Ignition of "Kuznetsovka"

Basic installation rules

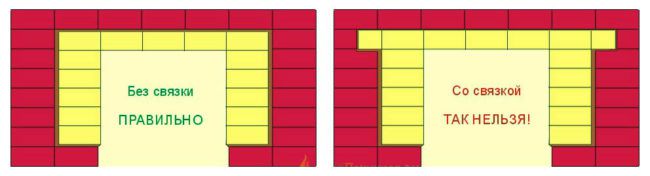

- The inner shell of the furnace must be surrounded on all sides by empty space, since the brick will become very hot during the operation of the furnace.

- The location of the oven heat source can vary depending on the type and shape, but it should always be at the bottom of the hood.

- Every third row of brickwork should be tied with metal wire. This will strengthen the bond and prevent further deformation of the furnace.

- The shape of the cap can be of any shape and size.

- When mounting the oven, take into account the fact that when heated, all metal elements (grid, door) will expand. Therefore, all these details of the furnace system must be installed with a margin for expansion. A refractory gasket must be installed between brick and metal.

- At the first kindling of an already finished furnace, it is not necessary to immediately give the maximum temperature. The furnace must be fired gradually, starting from low temperatures.

- After installation, the furnace should be treated with a refractory compound.

Today there are a huge number of varieties of bell-type furnaces, because progress does not stand still. Kuznetsov himself laid the foundation for this new type of heating system, and his followers around the world are already making their own adjustments and working on improving the furnace. Of course, it is much easier to build a stove at the stage of building a house. But often people think about the need to place such a heater after the walls have been erected. Here, when developing a scheme, it will already be necessary to take into account the height of the beams, the location of the partitions, the roof, etc.

If the stove is laid during the construction of the house, then it is better to arrange it in such a way that it heats 2-3 rooms at once.

It is simply physically impossible to describe the instructions for laying all types of bell-type furnaces, so in this article we will present the classic version of installing a bell-type furnace with our own hands. By following our instructions exactly, you will definitely be able to assemble a solid, beautiful and functional oven.

The dimensions of the furnace, of course, can be different - the volume of material will depend on this, respectively. But in no case should the order be changed!

What materials will be needed to install the oven

Before starting construction work, stock up on all the necessary materials. In order for the bell-type furnace to please you with its functionality and appearance for many years, the materials must be of good quality.

Refractory mastic (ready mix) for laying fireclay | Refractory mastic (ready mix) for laying fireclay. |

fireclay brick | Refractory brick for firebox (fireclay) SHA-8. |

Brick M150 | Brick ceramic (brand not lower than M150). |

Cement | Clay, sand and cement for laying bricks and foundations. |

plywood sheets | Plywood for the construction of formwork. |

steel plates | Steel plate. |

fittings | Metal wire or reinforcing rod. |

corner | Steel corner. |

wooden bars | Wooden bars (50x50 mm) - 4 pcs. |

oven doors | Doors and latch. |

Foil | Foil under the first layer of brick (according to the size of the foundation). |

furnace stove | Furnace plate. |

Grate | Grate. |

Tools for laying a bell-type furnace

- construction mixer or drill with a nozzle;

- Circular Saw;

- pliers (for tightening the wire);

- Master OK;

- shovel;

- building level;

- Bulgarian;

- construction gloves.

Let's start installation: step by step instructions

Step 1. We think over the design of the bell-type furnace and draw a diagram on paper.

Before starting work, you must clearly know what width your oven will be. It must be drawn on paper, having calculated all the necessary parameters.

- Calculate the size of the hole for the foundation. Keep in mind that it should be 10 cm wider than the heating structure itself.

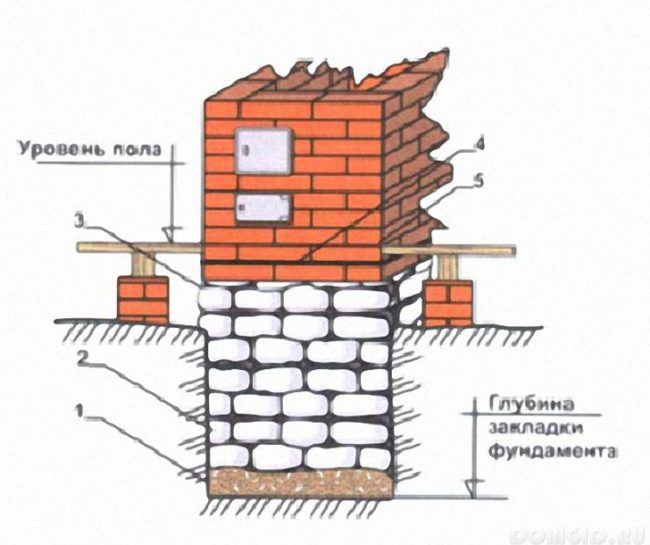

Furnace foundation

Step 2. Laying the foundation

Before installing the oven, you need to take care of the base. It must be firm and perfectly even so that cracking of the structure and deformation does not occur in the future. Laying the foundation is a very responsible step, which must be taken seriously.

For a concrete floor, the foundation will be a kind of platform, raising the oven itself 20-30 cm above the floor level. We make formwork according to the dimensions of the foundation and fasten its corners with wooden bars (50x50 mm). At the bottom of the foundation we pour sand 15-20 cm thick, we compact it well, and only then we slowly pour the solution. The foundation of the main house should not be connected to the foundation of the furnace. They have different weights, which means that shrinkage will be different.

Scheme of laying the foundation of the furnace

If you are making a wood floor oven:

- We draw the size of the future foundation with a marker on wooden boards and cut a hole around the perimeter with a circular saw.

If the stove is being built in a wooden house, then fire safety rules should be taken into account. It is necessary to lay a sheet of asbestos between the structure of the furnace and the ceilings.

Furnace foundation preparation

- We dig a hole 80 cm deep and 1.5 m * 1 m wide. Make sure all walls are even.For this, it is better to use a bayonet shovel. We pour sand at the bottom of the pit with a thickness of 15 cm, carefully tamp. It is necessary to wait for the sand to shrink (within 2 days).

- Let's start creating formwork. It is possible to use any old wooden doors, unnecessary boards for mounting the formwork, but, ideally, it is better to take plywood. We measure the length and width of the boards according to the dimensions of the foundation, lower them into the pit and connect them with screws. If the formwork is not all immersed in the ground, then we additionally connect the corners with wooden bars (50x50). If the formwork is immersed in the pit to its full height, then you can not do this.

- We reinforce with a metal rod.

In some wooden houses, the floor is already raised above the ground by 50-80 cm. In this case, you will need to dig a hole for the foundation by 20-30 cm. That is, you need to “go deep” anyway, but consider this difference already.

- We prepare a cement mortar (sand + cement + water) and slowly pour it into the pit. Try to pour in layers, each time stirring lightly with a shovel. This will allow excess air to escape and create a stable base. Let the base dry. It will take at least a week, but sometimes you have to wait 20-25 days for the solution to fully set. In this matter, you should not rush, since the operational properties of the furnace depend on the strength of the foundation.

- While the solution is still damp, it is necessary to clearly determine by the building level how level the site turned out to be. Correct if necessary.

- To do this, we take the building level and check the place where the furnace will be installed.

- When the solution is completely frozen and the foundation is ready, you can start laying the furnace. Do not rush with the construction of the furnace. The foundation must be strong and solid, the further operation of the furnace depends on it.

- We lay a layer of reflective foil under the first layer of brickwork. This will prevent heat loss and redirect the direction of heat flow from bottom to top. Take the material a little more than the perimeter of the foundation. After laying the brick, then it will be exactly necessary to cut off the edges with a knife.

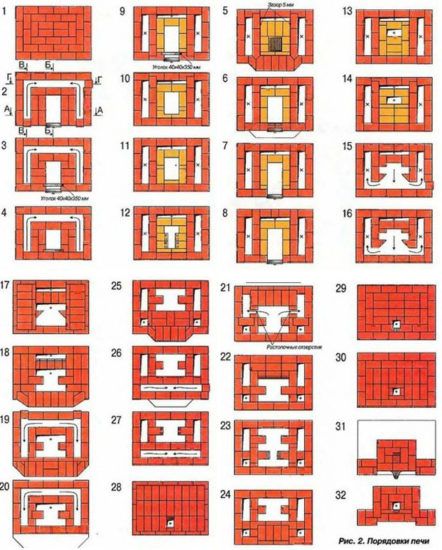

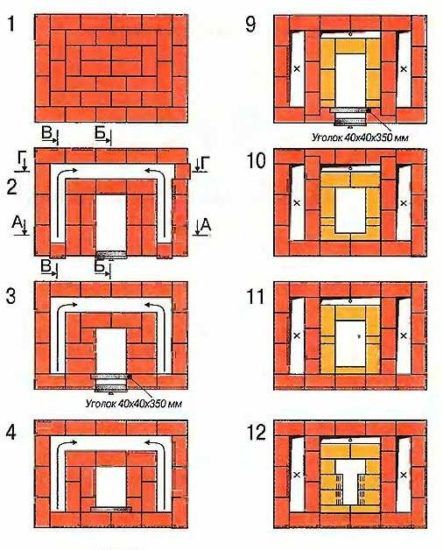

Ordinal scheme of furnace masonry

Video. Masonry brick "Kolpakova" furnace

Step 3. Preparation of clay-sand mortar for bricklaying. We will use clay as the basis, as it has heat resistance up to 1000 degrees.

On the video you can see visual instructions for kneading the solution.

Video. Preparation of clay mortar for kiln masonry

In a large metal container, it is necessary to combine the clay with water and soak it for 2 days. After that, pour the sand into the container and mix well with an electric drill with a mixer attachment. When the mixture is well mixed and 2 materials do not separate in it, check the density of the mortar with a trowel. If the mixture slowly slides off the tool, then the solution is ready. You can start laying bricks.

Step 4

Masonry of the 1st level of the furnace

Before you start laying bricks on the cement mortar, it is better to immediately lay out each row, according to the ordering scheme, on the floor “dry”. The diagram shows that in some rows you will have to divide the bricks into ½, ¼. Where you have to grind bricks, use the manual method so as not to violate the technical properties of the material and its aesthetic appearance.

- Row number 1. The brick will spread evenly over the entire area of the oven. The first row is solid, keep even corners. Start from the side walls of the blacksmith, laying out with a spoon method, move from right to left. (Figure 14). The brick is laid longitudinally in length.We lay each next layer with an edge in the center, and report the missing part, having beaten off the required size from the new brick.

- Lay row number 2 bricks. At this level, we install a blower (according to the previously developed scheme) and a window for cleaning the furnace (there may be 2 of them). The design of the bell-type furnace allows you to place the door for cleaning and the blower anywhere, but the window must be below the firebox. Here it will be necessary to divide one brick in half and install them so that they protrude from the general row outward. When you lay the second row, you should not connect them with a solution. Upon completion of construction work, you will need to clean the furnace from fallen clay. And after you clean the oven, then fix them with a solution.

In order to properly install the blower doors and windows, it is necessary to thread the knitting wire into the existing holes, make a loop and twist it with a bundle. Insert between bricks. If there are no holes in the factory parts, then they must be made with a drill with a drill bit for metal. Use pliers to twist the loop as tight as possible. While the doors for stability must be fixed with bricks, but not connected with mortar. This will need to be done after laying the third row.

Scheme of kiln masonry

- We put number 3 in the same way as the previous one. From the 3rd row, we begin to raise the firebox itself, laying it out of heat-resistant bricks. Between the front wall of the stove, lined with red brick and the firebox itself (made of fire-resistant brick), we lay basalt cardboard or corrugated foil. After burning out, it will create a perfectly even thermal gap of 5 cm.

The main feature of the Kuznetsov furnace is the "floating" furnace.That is, it should be a separate module, separated from the furnace body by a dry seam. Refractory bricks (chamotte) should not be included in any protrusions in the ordinary brick of the furnace body.

Features of the laying of the Kuznetsovka furnace

- We make row No. 4 a little narrower (by 1.5 bricks) to reduce the connector for falling combustion products (you can see it in the diagram). We design in such a way that a partition appears in the far corner from the firebox leading to the upper compartment.

- Row number 5 is laid out similarly to the 4th row, only a grate must be placed on top of the reset rim. We put it without mortar, and fill the gaps with sand.

- Row number 6 is laid in the same way.

Here we begin to install the furnace door with a gap of 5 mm. We set it carefully on a plumb line to control the level deviation. In the same way as in the 2nd row, when you installed the ash pan, you need to fix the door in the brick with metal wire.

In order not to move the door while you continue to lay a row, fix it with bundles and press down the ends of the bundles with a brick from above. This will allow you to continue working without worrying about the door being level.

- Row number 7. We bring the chimney 0.5 bricks wide from the furnace into an adjacent air chamber.

- Row number 8 is laid similarly to the seventh.

- Row number 9. We display the walls of the furnace with fireclay bricks. Here, a passage is formed between the furnace and the first hood for the removal of combustion products (seen in the diagram).

- Row number 10 is laid out by analogy with the previous one.

- On the 11th row, half-brick work goes into the masonry of the whole.

- Row number 12 - a lattice of fireclay is laid out. Again, we continue to lay in half a brick according to the above ordering scheme.

- Row number 13 - the same styling as on the 12th row.

- Row number 14 - remove the crate and leave 2 chimneys.

- 15th row - similarly, but for 16 we use whole bricks instead of halves. We block two chimneys into the air compartments.

- 17th row. We block the movement of smoke with a steel plate. Thus, the channel that you created on the laying of row number 4 now remains the only one.

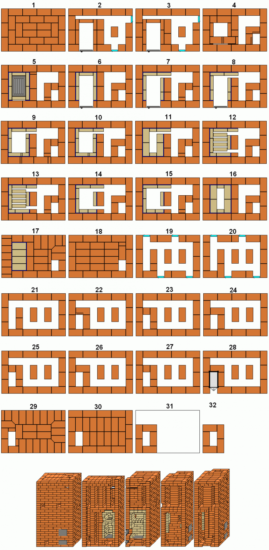

Scheme of kiln masonry

Step 5. Laying the second level of the furnace.

- Row No. 18 is laid similarly to the 17th, but on this row we fasten the intake plate, which is fixed on three sides with cement mortar.

- Row number 19. We build a column under the very top of the structure. Behind the stove we make a small sinus (the width of a brick) so that the smoke leaves through the pipe.

- Row number 20. We stack in the same way as the 19th row.

- Row number 21. This row is laid so as to block the channel leading to the pipe. The smoke will come out through the bosom that you left below (on the 19th row).

- Row number 22. From a quarter of a brick, perform an extract that comes from a steam collector. We cover the steel part of the ceiling.

- Row number 23. We put it similarly to row No. 22.

- Row number 24. In this row, it is necessary to connect the chimney with a steam collector with a closed channel

- Row #25-26. We lay similarly to the previous row.

- Row number 27. Fence plate installation.

- Row number 28. We cover the structure with a brick roof.

- Row number 29. We make an additional layer similarly to the previous one.

- Row number 30. The row is almost completely covered with bricks.

- Row number 31. Lays the base of the pipe. We bring out a pipe with a diameter of 1 brick.

- Row number 32. A chimney pipe is formed.

Step 6 To make the stove look attractive, you can carefully round all its edges by hand grinding. This must be done after the completion of construction work.

Step 7. We process the created furnace with a refractory compound.

Step 8. We melt the stove.No need to immediately give the maximum temperature. The oven should gradually “burn out”. Start with the minimum temperature, and then add heat.

That's all! Following the instructions, and most importantly, without violating the masonry order, you will definitely be able to assemble a reliable beautiful stove that will last for decades.

At the end of this article, we suggest watching a video in which you can see the stages of laying out the Kuznetsov furnace.

Video. Do-it-yourself Kuznetsov oven masonry