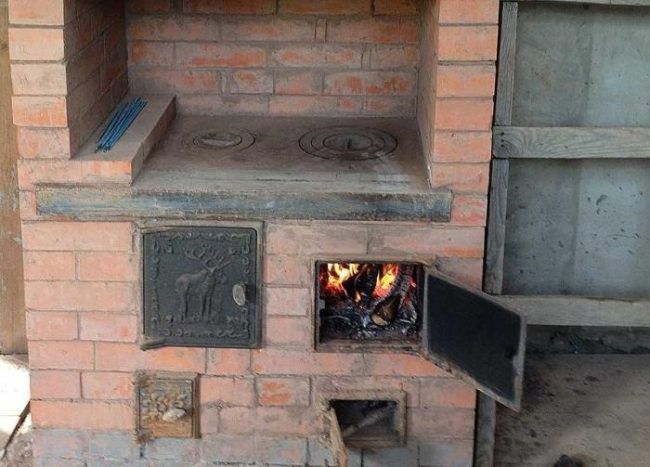

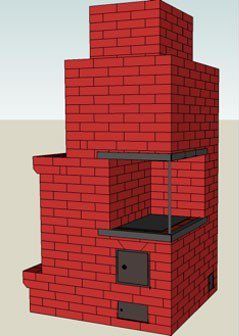

A Dutch oven with a stove is one of the most popular types of heating structures in the world. Compact, highly efficient and economical - it not only allows you to heat the house well in harsh winters, but also helps the hostess prepare dinner for the whole family.

Dutch oven

Let's take a closer look in this article on how to make a Dutch oven with a stove with your own hands. Order and basic rules will help you cope with this difficult task.

The history of the appearance of the Dutch oven goes back to the 15th century and since then it has undergone many modifications and has been improved. Over these six centuries, the shape of the Dutch woman and its size have changed a little. But what has really remained unchanged is its efficiency and compactness.

Type of dutch oven

The small size of the Dutch stove is partly due to the cramped houses in the Netherlands and the need to fit the heating and cooking structure into a room, the dimensions of which sometimes did not exceed 10 square meters.

Tiled oven

Cities in north Holland have always been densely populated, and local residents had to somehow adapt to urban conditions. And given the rather harsh climate and cold winters, it was impossible to do without high-quality heating of the home.

round oven

In addition, in the Netherlands in the Middle Ages there was a very high tax on the area, so the locals had to contrive, building the house up.Agree that not every oven is suitable for a multi-story structure.

It is easy to recognize the Dutchwoman among other designs of heating devices precisely by their shape: they are elongated and have a great height. At the same time, one stove can be enough to heat two or three floors of the house at once.

The first Dutch models were not equipped with a grate and a blower, and the hostesses did not know anything about the hob. However, over time, stove builders and engineers added these minor elements to the laying scheme of the Dutch stove, which made it possible to significantly increase its efficiency.

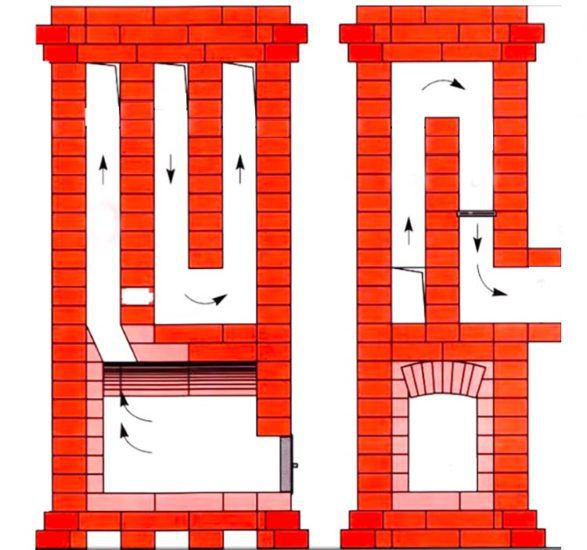

The movement of hot gas in the Dutch furnace traditionally occurs through 6 channels: 3 lifting channels and 3 lowering ones. And the bell system allows you to accumulate hot gas and increase the efficiency of heat transfer.

Also, another difference between the first models is the presence of an arched vault, which over time, for technical reasons, was replaced by a rectangular shape of the firebox.

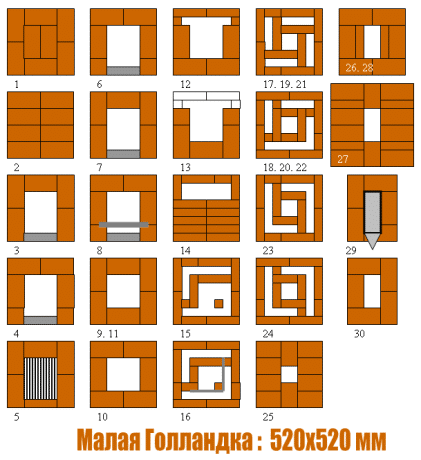

Today on the Internet you can find many different patterns of Dutch women equipped with an oven for baking bread, stove benches, a hot water tank, etc. We will dwell in detail on the scheme of laying a Dutch oven with a stove.

small dutch

Content

- The principle of operation of the Dutch

- Dutch design features

- Advantages and disadvantages of the Dutch oven

- Basic rules for arranging a Dutch oven with a stove

- Tools and materials used in the construction of a Dutch oven with a stove

- Do-it-yourself Dutch oven with a stove, ordering and masonry scheme

- Video. Do-it-yourself Dutch masonry.

The principle of operation of the Dutch

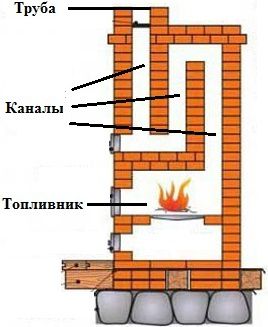

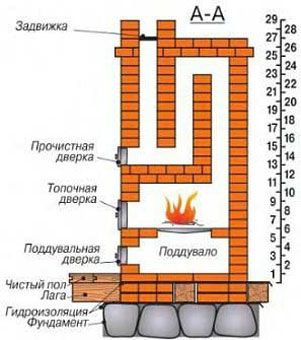

A distinctive feature of the Dutch stove is a six-channel chimney system through which heated gas circulates.

Leaving the combustion chamber, the smoke rises upward along the upward flow. During his journey, he manages to heat the walls of the furnace. Then it cools down and goes down to the firebox. When heated, it rises along the second channel, and so on. The sixth channel already brings the smoke out through the chimney.

Dutch work system

The six-channel system allows the oven to warm up evenly, without sudden changes and retain heat for a long time.

If we talk about the design of the Dutch woman, then here the main elements are:

- large firebox;

- chimney;

- 6 smoke channels.

Whatever the dimensions of the Dutch stove, its firebox is always large and has a rectangular shape, while the design of the Dutch stove itself can be semicircular, triangular, etc.

Dutch oven elements

A large firebox significantly increases efficiency and allows you to further supplement the design with a water heating system.

The chimney of the Dutch woman is connected to the side of the chimney, and a metal pipe acts as their connecting link.

If the oven needs to cool down quickly, it is enough to open the damper.

Standard furnace layout

Dutch design features

- Lack of grate.

- The presence of several smoke channels.

- The absence of a blower, due to which the fuel does not flare up intensively, but allows the firewood to slowly burn out, giving off heat to the room.

- Long elongated shape.

- The Dutch woman can be attributed to the designs of long burning, because due to the lack of a blower, firewood slowly smolders.But at the same time, if you do not close the view, the oven will instantly cool down. Only the firebox door allows oxygen to pass through.

- Rectangular firebox.

- The classic version assumes only a heating function. This is already after the passage of time, the craftsmen supplemented and modified the standard type of the furnace, adding the necessary elements in the form of a stove, oven, stove bench, etc.

Cooker is an optional feature

- The thin walls of the stove are only ½ brick, so the stove heats up quickly.

Advantages and disadvantages of the Dutch oven

Like every oven, the Dutch oven has its own advantages and disadvantages.

If we compare the design of a Dutch stove with a stove with the traditional design of a Russian stove, then the advantage will be with the first. It warms up much faster due to small walls, and its dimensions allow it to be placed even in a small cottage or in a country house.

Dutch woman with stove

In addition, if it takes you 1200-1300 bricks to build a small Russian stove, then for an impressive Dutch stove, you will need only 650-700 bricks. This factor alone makes the Dutch oven attractive, especially during periods of economic crisis.

Another advantage of the Dutch woman will be especially attractive to cottage owners who visit their country house from time to time. If a Russian stove needs to be heated for several hours before it starts to give off heat, then kindling a Dutch stove will take you no more than half an hour. It can be immediately loaded tightly and give maximum heat.

So, the advantages include:

- The possibility of modifying the oven with various functional additions in the form of a hot water tank, stove bench, oven, fireplace, etc.

- Compact and small size.You can, if you wish, build a good quality oven measuring 50 * 50 cm.

- Rapid heating of the room.

- The efficiency of the furnace does not decrease with its height.

- Small construction costs. From expensive refractory bricks, only a firebox can be folded, while even used material is suitable for arranging the rest of the structure.

Dutch Disadvantages:

But it would be unfair not to mention the disadvantages of the Dutch oven.

- Low efficiency compared to the Russian stove. Only 40-45%, subject to proper operation.

- The channels are arranged in such a way that they can partially draw in cold air from the street.

- Frequent heating of the furnace is required - at least twice a day.

- Not the most fuel efficient.

- You need to constantly monitor the view of the furnace. If you leave it open, the oven will instantly cool down.

- You should not give the maximum temperature for the Dutch oven. If it is “overheated”, then carbon monoxide will be released, which can penetrate into the room.

Today there are many Dutch models:

- with fireplace;

- with oven and heating and cooking surface;

- with hot water tank;

- with a bed.

But basically, this type of design is chosen for its compact size and the ability to place it in a small house. If a room with a large area, many windows, then it is better to give preference to other types of heating structures: a Russian stove, bell-shaped or Swedish.

Basic rules for arranging a Dutch oven with a stove

Whatever option for arranging the furnace, dimensions and dimensions you choose, the principle of construction remains unchanged:

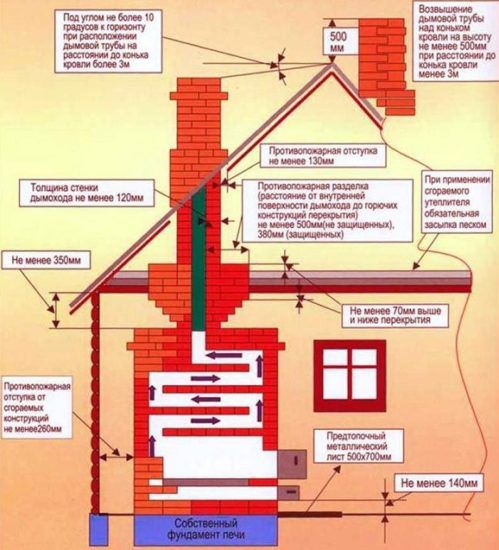

- The furnace is installed on a separate foundation. Of course, it is best to think about it at the stage of building a house.This will make it easier to correctly determine the place for the chimney so that it does not fall on the beams and roofing.

Separate foundation for the oven

If the idea of \u200b\u200bbuilding a Dutch woman came to you already in a residential building, then you will have to remove part of the flooring and build a solid foundation that does not connect to the main one. This rule should not be neglected, since, despite its small size, the Dutch oven has quite impressive dimensions.

It will create a lot of pressure on the foundation. As you know, the house shrinks during operation, and if the stove is made on a common foundation with the house, then there is a risk of deformation, displacement of the chimney, etc.

As a result of this, the sealing of the seams may be broken and carbon monoxide will penetrate into the room.

- The foundation must be covered with waterproofing material.

- When arranging the firebox, only high-quality refractory (chamotte) bricks should be used, which in no case should be tied up with ordinary ones.

- For laying the furnace, you need to purchase a heat-resistant clay mortar. You can, of course, do it yourself.

- The thickness of the seam when laying the combustion chamber should not exceed 3-5 mm. Beginners may find it difficult to stick to the same seam size.

- The laying of the entire Dutch oven must be done with a joint thickness of 5-8 mm.

Advice! To ensure that the seams are equally even, use wooden slats between the masonry.

Despite the fact that the Dutch woman has a high fire resistance, during her arrangement

it is necessary to adhere to the basic fire safety measures when building a Dutch oven:

Fire safety standards

- Before the stove, a sheet of asbestos slab must be said goodbye to prevent accidental ignition from sparks or coals.

- It is necessary to systematically clean the chimney channels from accumulated soot.

- Between the furnace and the wooden walls, it is also necessary to lay a sheet of refractory material.

- Nothing should stand at a distance of 50-55 cm from the stove: furniture, decor, other items, etc.

- The less metal parts you use to build a Dutch woman, the better. But when performing hanging masonry, which closes the opening under the cooking zone, you cannot do without metal corners.

Remember that nothing can be done close to the iron or put the iron on a bare brick. In all places where it is planned to join metal parts with bricks, it is necessary to lay a layer of mortar of 5 mm and lay an asbestos cord.

Dutch woman with stove

- When laying the hob on a brick, it is necessary to lay a layer of clay mortar on it. This will protect the brick from heating.

Tools and materials used in the construction of a Dutch oven with a stove

A prerequisite for a good oven is quality masonry mortar, which is recommended to knead from red clay and brick. The main composition for laying the Dutch is sand, red clay and water.

In this case, the ratio of proportions for each of the types of clay will be different. The smaller the amount of sand present in natural clay, the correspondingly less will be needed for the solution.

Clay

For oily clay, we take the proportion: 1 part clay and 2.5 sand.

For medium clay - 1 part to 1.5 sand.

For skinny, you need 1 to 1.

Materials for laying a Dutch oven with a stove:

- Chamotte refractory brick for the combustion chamber.

- Red ceramic brick.

- Mortar for laying the foundation (cement, sand, gravel and water).

- Mortar for laying bricks.

- Roofing material for foundation waterproofing.

- Boards for the construction of formwork.

- Grate.

- It blew.

- Metal door.

- damper.

- Metal rods and wire for reinforcement.

- Metal wire 0.8 mm for dressing.

- Asbestos cord.

- Cooking plate.

From the tools prepare:

- Trowel for laying bricks.

- Building level, protractor and plumb.

- Construction stapler.

- Roulette and marker.

- Rule.

- Bulgarian for turning bricks.

- Shovel and bayonet shovel.

- Solution bucket.

- Construction mixer or drill with a nozzle.

- Rubber mallet for laying bricks.

- Construction hammer for the construction of formwork.

Do-it-yourself Dutch oven with a stove, ordering and masonry scheme

Scheme of a Dutch oven with a hob

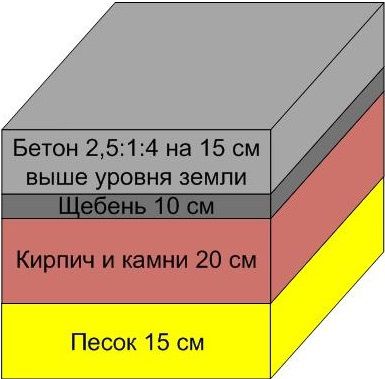

Step 1. Preparatory work.

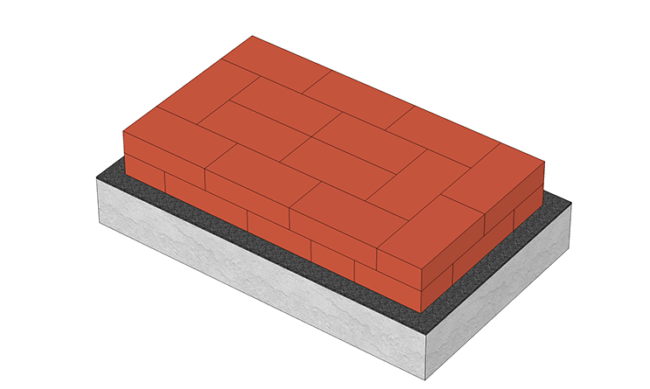

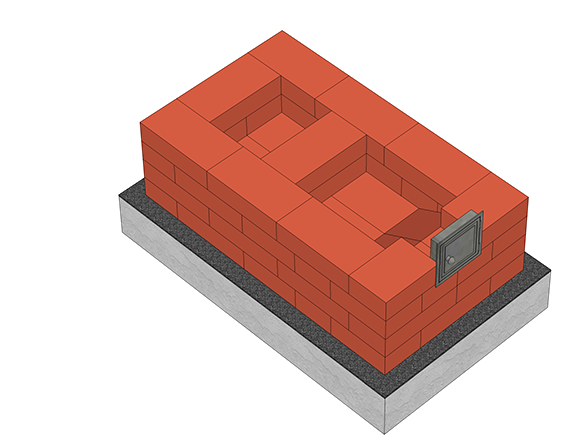

Preparatory work includes foundation pouring and wall insulation.

Given the large weight of the stone oven, it is recommended to use the classic version of the construction of a concrete foundation with the construction of formwork.

Foundation scheme for a brick oven

Implementation of the foundation.

- Mark out on the floor where the stove will be placed. Preferably, the door and window are not in a straight line. Also consider the construction of a chimney, which can be done through the roof or through the wall. Also keep in mind that the foundation in size should exceed the dimensions of the furnace by 15-20 cm on each side.

- With the help of a grinder, we cut out the boards in a wooden floor and remove them to the side.

- We carry out the construction of the foundation, fill the solution and cover with roofing material.We make a technological break of 20-25 days until the base is completely hardened.

The basis under the furnace and a waterproofing.

- The foundation is carried out to the floor, not reaching two rows of bricks. The upper part of the base must be made of brick, which is laid in a continuous row, with dressing.

Furnace base

- We carry out the base of the furnace. Before this, you need to perform waterproofing with a roofing material. Measure the desired size on a sheet of roofing material and cut it out with a knife. Take 2-3 layers of roofing material and connect them together using a construction stapler. Attach to the base.

The technical feature of the Dutch is that it gives off most of the heat to the floor, so the waterproofing stage is very important if you do not want the heat to go to the floor.

Waterproofing the base for the oven

If the house is located in northern latitudes and soil freezing reaches 1-1.5 meters, experts recommend that, in addition to roofing material, use an additional layer of basalt cardboard. This is an inexpensive and reliable material that will create good insulation.

- In order to be sure of the correct laying of the furnace, experienced stove-makers advise pulling vertical plumb lines.

Plumb lines for the verticality of the furnace

From each corner, pull a rope or thread that will serve as a beacon, preventing you from moving to the side during laying. If you are not going to do this, then after each row it is necessary to check not only the masonry with a horizontal level, but also use a goniometer with a vertical plumb line. Otherwise, your oven may be tilted to the side, resulting in reduced efficiency and poor draft.

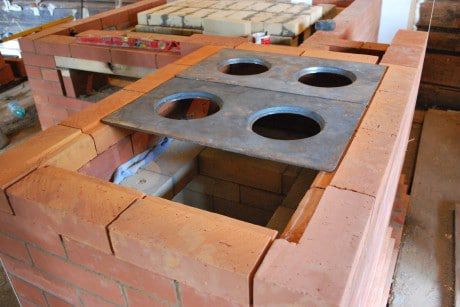

Preparation of bricks for laying and mortar.

- We select the bricks that we need for laying the furnace and make dry laying.

- We mix the clay solution. Make exactly as much solution as you can handle at a time. The next day, this clay-sand solution will no longer be suitable.

Place clay in a trough, add a little water and let it brew for 2 days. Do not forget to stir the material during this time so that no hard lumps form. We bring to the desired consistency with sand and mix well again with a construction mixer.

Important! If you started work on the construction of the furnace in cold weather, then prepare the brick in a securely sheltered place. For each row, immediately prepare the required number of bricks, adjust according to the scheme.

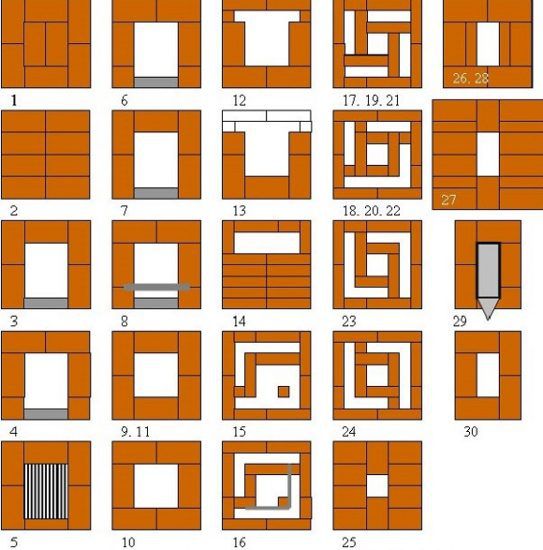

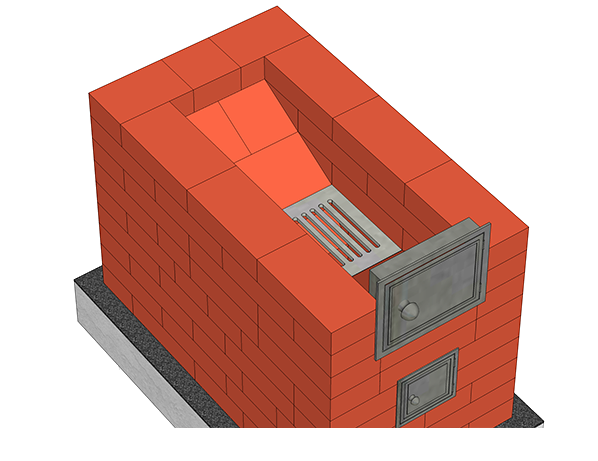

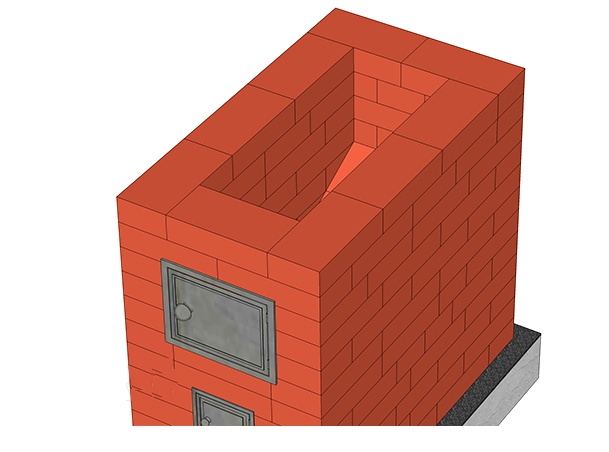

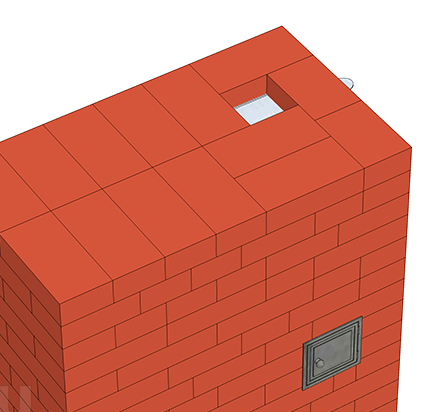

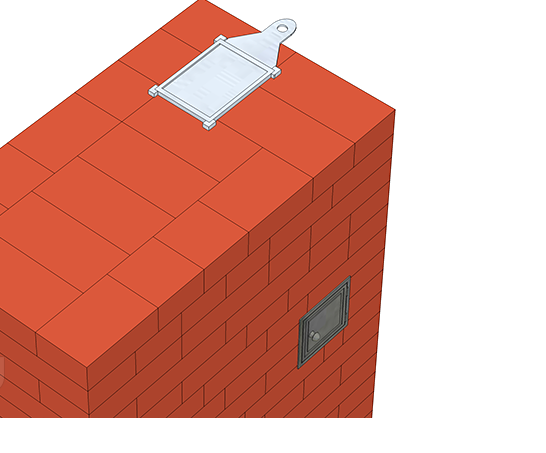

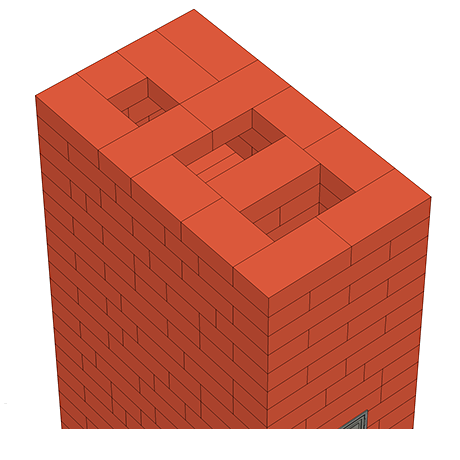

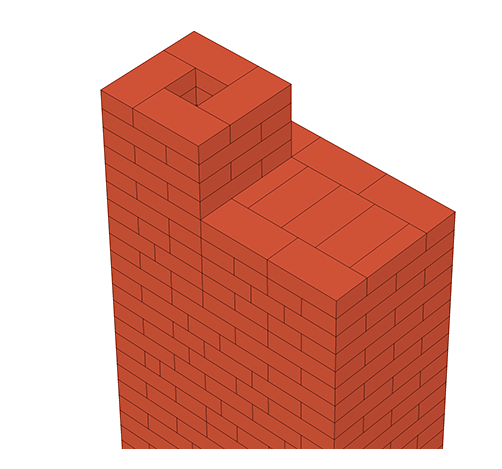

Step 2. Laying the stove.

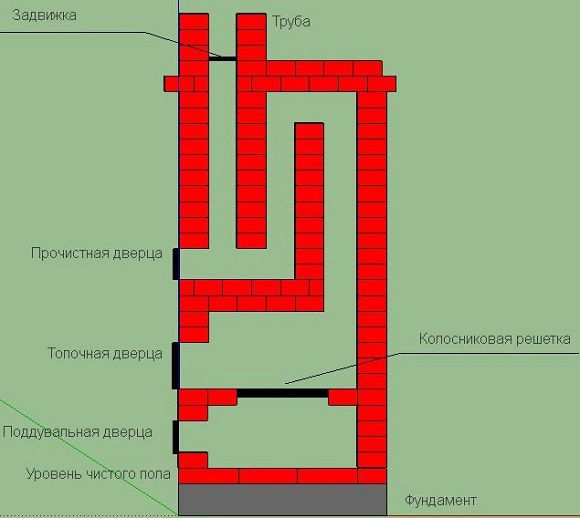

Ordering the stove with a hob

We give a standard scheme for laying a Dutch oven with a stove. To practice folding it, stove-makers recommend laying bricks on a dry one, according to the scheme. So you will see if you have enough material and those points that you should pay special attention to.

It is recommended to lay out immediately on a dry

Before you start laying, dip the bricks you need for this stage of laying into the water so that they do not draw moisture from the mortar.

- Now we proceed to the laying of the furnace, while the first row is considered to be the one that comes from the level of the finished floor.

Detailed Dutch oven masonry

We make the 1st row solid. I put it with a bandage. This row will serve as a guide for the entire structure, so it is very important to make it even. You can use a goniometer for this.

2-3 rows are also performed solid, maintaining horizontality.

2 rows of bricks to the level of the finished floor

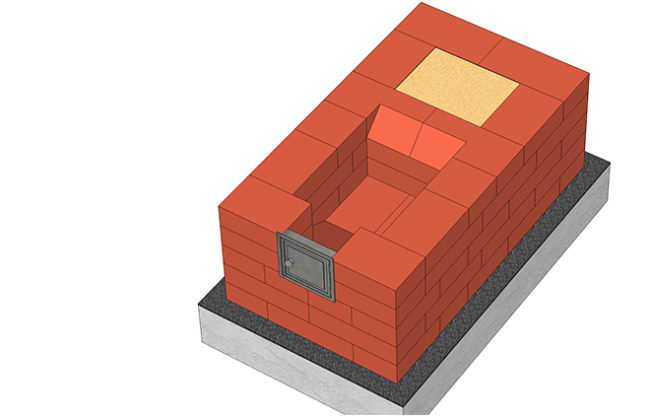

4 row - in this row we install a blower with a gap of 5 mm. The gap is filled with asbestos cord. When heated, the metal will expand. In order for it not to deform the brick, we will lay the asbestos cord where metal contact with the brick is expected.

4 row

Pay attention, as shown in the figure, the scheme of laying a metal wire in a mortar between bricks.

Correctly fasten the metal door and blower

Row 5 is performed similarly to the fourth. Perform laying from right to left. Consider here the dressing of the seam in 1/2 brick.

5 row

6 row - here it is necessary to partially block the blower and ash pan. To do this, we saw the brick along and lay a steel strip 35 mm * 4 mm in size under the brickwork.

7 row - we begin to form a combustion chamber from fireclay bricks. Here, in this row, we install the furnace door.

7 row

We lay the grate, while making a seam gap of 3-5 mm. We mow the bricks for the back wall according to the order. The gap can be filled with sand or ash.

Installing the furnace door

8 row - Also in this row, the blower door is closed, which finally forms the ash chamber.

9-14 row - the firebox is laid out in a similar way, laying out fireclay bricks.

The combustion chamber is formed

10 row. We block the firebox with bricks. In the same row, it is necessary to put prepared bricks under the installation of a metal plate.

fuel chamber

This row should be given special attention, since it is on it that the cooking metal surface will lie.

In the same way that bricks were prepared for the installation of a grate, we make grooves on the bricks under the stove. The notch should be 5 mm.This will allow the metal to expand freely when heated.

In the resulting gap we lay an asbestos cord, which we protect with paper cardboard. During operation, this cardboard will gradually burn out, and the cord will constantly compensate for a sharp temperature drop.

Plate

We carefully lay the metal plate. For reliable fixation, we fix its edges with metal corners.

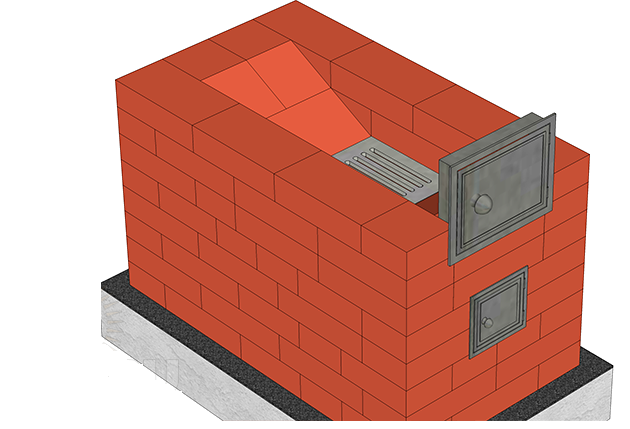

11-13 row we begin to form a zone above the slab, laying out bricks according to the scheme.

The 14th row is laid out similarly to the previous one, but here we already put bricks in which we make small grooves. We insert metal corners into them, on which bricks of the 15th row will rest.

15 row. We cover the space above the surface of the plate.

Cleaning installation

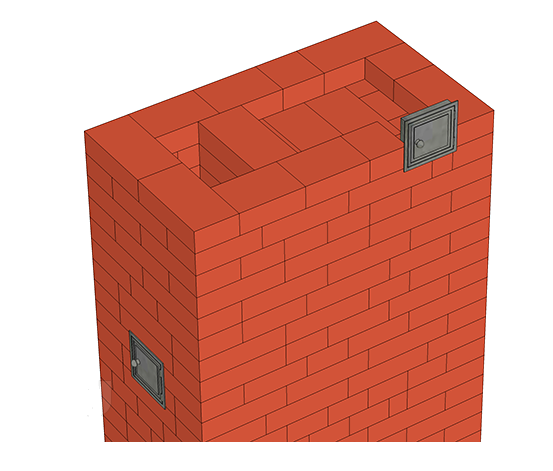

16, 17 row. We lay out a row, similar to the 15th, but here we install a door for a cleaning hole. In the same way as in the row with the blower, we make an expansion gap and lay an asbestos cord.

18-22 row. Lay out the rear smoke return channel.

Covering the smoke channel

23 row. Here it is necessary to install a valve under the smoke channel. Bricks for this need to be adjusted, and an asbestos cord should be laid between the metal element and the brick.

Valve installation

24.25 row. Laid out in order. Here we combine 2 channels: lowering and lifting.

26 row. We begin to form a chimney. Here you need to ensure that no solution remains on the inner surface of the chimney. To do this, it must be immediately cleaned off, otherwise during operation, the dried solution will interfere with normal traction.

27.28 row. We continue the formation of the chimney, shifting all the bricks by 4 cm, so the chimney narrows.

Smoke channels are underway

29-30 - We are laying smoke channels and installing a valve here to control draft. We take into account a gap of 5 mm for the expansion of the metal into which we lay the asbestos cord.

31 row. Resize to original size.

Step 3. Laying the chimney

From the 32nd row, the laying of the chimney begins.

Chimney masonry

Here the masonry comes with continuous dressing in several rows.

3 rows before the roofing, we perform the "fluff" of the pipe. This will protect the wooden structure from fire. Stick to one pipe thickness of 1.5 bricks.

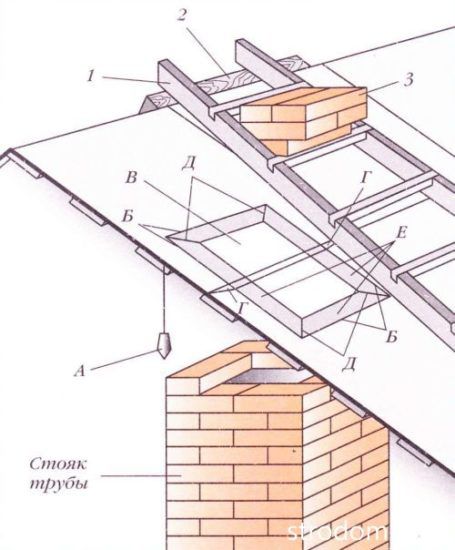

Chimney outlet through the roof

Ideally, lay the design of the furnace and, accordingly, the chimney, even at the stage of building a house or during a major overhaul. Then you will not have any particular difficulties with the construction of a smoke well.

Chimney masonry

If the Dutch stove is being built in an already finished house, then you will have to cut a hole in the roof for the passage of the chimney.

- It is necessary to remove the roofing in the place where the pipe will be removed (slate, tiles, corrugated board, etc.).

- We install jumpers at a distance from the ventilation pipes.

- If the coating is from a continuous coating that cannot be partially dismantled, then we measure the hole of the desired size and cut it out with a grinder or a jigsaw.

- We lay a heat-insulating layer between the chimney and wooden floors with asbestos sheets, which we attach to the rafters with self-tapping screws or a construction stapler.

- We carry out the laying of the chimney through this hole.

It is very important to carry out all fire prevention measures during the construction of the chimney. Namely, keep a distance of 38 cm between the chimney and the nearest ceilings.

In order to maximize traction, we round the corners of the brick. If you do not cut corners, then the turbulence will weaken this thrust.

In addition, the fluff prevents the wind from entering the chimney, which will also protect the draft.

We bring the chimney above the roof to a distance of 60 cm.

We bring out the chimney

The penultimate 2-3 rows come with an extension. This is called an "otter" which protects the roof from water penetration. On the last row, we narrow the chimney to its original form.

We install a metal cap on top, which prevents precipitation from entering the pipe.

To correctly calculate the height of the pipe outlet above the roof, focus on the location of the ridge.

If you are making a hole in an attic that is well insulated, it is enough to carefully cut an opening in the crate and heat insulation using an electric jigsaw or grinder.

After you have brought the chimney through the roof, you must carefully close the opening between the pipe and the ceiling. To do this, you can fill the entire space with heat-insulating material. Stuff the insulation tightly. It is best to use stone wool or foam glass for this.

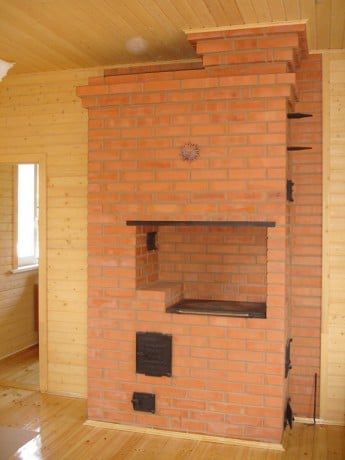

Step 4. Finishing work and lining of the furnace.

Finishing work includes lining the furnace and the first kindling.

Clinker tiles, tile tiles, decorative plaster, etc. can act as a facing material.

If you have chosen a high-quality red ceramic brick as a construction, then you can not veneer anything on top.

Dutch veneer

After the complete lining of the furnace, it is necessary to take a technological break for 10-14 days until the structure is completely dried. To do this, leave the combustion chamber door open.If the laying of the furnace was carried out in cold weather and the house is damp, you can put a lamp inside the furnace, which will help speed up the drying process.

Step 5. The first test firebox of the furnace.

Only after complete drying of the masonry mortar and lining, you can proceed to the first firing of the furnace. Take your time and do not ignore this point, as premature kindling of a damp furnace can lead to its cracking and violation of technical properties.

For a test firebox, use 1/5 of the usual amount of firewood. No need to immediately lay large logs. Use chips, shavings. Such kindling will help to dry the oven qualitatively. Open all latches and dampers.

Dutch woman's fire

Fire the furnace in this mode for the first week, while the maximum temperature should not exceed 600FROM.

As you can see, putting together an efficient and compact Dutch oven with a stove with your own hands is not at all difficult. The main thing is to be patient and follow our advice exactly.

But after the completion of the work, you will experience incomparable pleasure from the warm stove of your own production and from the cozy atmosphere in the house that it gives.

Video. Do-it-yourself Dutch masonry.