Perhaps, no cozy private house can be imagined without a good stove or fireplace. In addition, to this day, many people living in non-gasified areas are simply forced to heat with firewood.

Brick mortar for kiln proportion

On the one hand, this is the most environmentally friendly way of heating, and on the other hand, it is cost-effective. Prices for alternative fuels and electricity continue to grow steadily, so it is necessary to look for the best way out of this situation.

Many people want to learn how to lay stoves, and this is due not only to the desire to save money on heating in winter. The practical skills gained during the training can be an excellent help in developing a personal business. The demand for furnace work is growing every year, creating prospects for a fairly high income.

Content

- Heat-resistant, heat-resistant, fire-resistant - what's the difference?

- What solutions are used when laying individual elements of a brick oven

- Types of mortars for masonry stoves and their main properties

- How to save on masonry materials?

- How to distinguish high-quality clay suitable for laying a stove from other fossils?

- How to find quality water used in stove masonry mortars

- What kind of sand is suitable for laying the stove? Sand preparation

- The proportions of the mortar for laying the furnace, how much sand, water and clay should be?

- Proportions and proper preparation of clay mortar, strength test

- Proper preparation of mortar for laying the oven: video lesson

- Video: How to prepare a clay composition for laying a furnace

Heat-resistant, heat-resistant, fire-resistant - what's the difference?

Beginning stove-makers often experience some difficulties in understanding the terminology correctly. With regards to mortars for oven masonry, the greatest confusion arises with the concepts of heat resistance, heat resistance and fire resistance of the material. These parameters are fundamental in the furnace business, so we will now try to clarify their meaning and clarify the understanding of this issue.

heat resistant is a material that can withstand heating to high temperatures. At the same time, during its subsequent cooling, the structure and chemical composition are preserved and there are no irreversible changes in shape. In addition, heat-resistant materials in the heated state are still able to withstand the original specified physical overload without the risk of possible destruction.

Main property heat resistant materials - resistance to temperature effects, provided that the original mechanical properties are preserved. Heat-resistant substances and compounds have an order of magnitude lower thermal expansion than heat-resistant ones.Such materials are used in the design of not only furnaces, but also mechanical devices operating in extreme temperature conditions, while being subjected to powerful dynamic effects.

Finally, refractory materials are heat-resistant or heat-resistant compounds that, among other things, can easily withstand the action of chemically active (often aggressive) substances contained in gaseous substances. Specifically, in the case of stove masonry, this can be smoke or products of thermal decomposition of fuel.

All solutions and materials used in the construction of furnaces must be heat-resistant and refractory. This requirement applies even to those elements that, in normal operation of the stove, do not heat up by more than four hundred degrees. No standard building mixture meets these parameters.

What solutions are used when laying individual elements of a brick oven

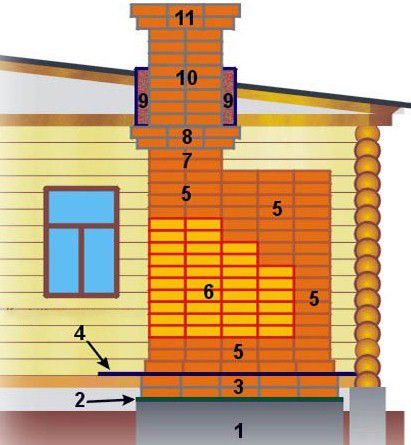

The choice of mortar for work must be carried out depending on which part of the stove it will be used for laying. Using the diagram below, let's take a closer look at each of them.

General structural diagram of a standard furnace masonry

- Reinforced concrete base furnace foundation, which is also called a pillow or root. It is made according to standard technology, however, without fail, in order to avoid unpleasant consequences, it must be physically separated from the foundation of the house itself. The need to comply with this condition is explained by differences in the degree of shrinkage of the building and the furnace in it.

- Waterproofing layer. To create it, roofing material is perfect, which must be laid on top of the foundation in several layers.

- Actually, the furnace foundation itself. Since it is not subjected to powerful thermal effects, it does not require the use of particularly heat-resistant mixtures during masonry. At the same time, the reliability of the entire structure depends on the quality of the assembly of this element of the furnace. There are cases when, due to errors in laying the foundation, it was necessary to completely disassemble the furnace and redo it in a new way. Complex, three- or more-component cement-lime mixtures are used for work. Well, as the main building material, red solid brick is best suited here.

For the manufacture of compact stoves or stoves with a large footprint (for example, a Russian stove), you can also use a conventional lime mixture.

- A layer of thermal insulation with a fire blind area. It is made from a mineral cardboard or asbestos sheet, on which an iron sheet is placed on top, covering the entire structure with a finishing layer of felt cloth soaked in the so-called clay milk (this is a solution of very liquid diluted clay, how to prepare it - we will tell below).

- A heat exchanger that accumulates the energy released during the combustion of firewood. It is one of the main parts of the so-called furnace body. During kindling, it rarely heats up above six hundred degrees, but it is subjected to a very active influence from the smoke and other gaseous substances emitted during combustion. It is not uncommon for destructive acid condensate to settle on the inner surface of the heat-retaining masonry. Brick is used here special: furnace, brand M150, full-bodied ceramic red. The bricks are fastened together with a simple one-component clay solution.It should be noted that the term "simple" refers only to the composition of the building mixture. Its preparation is a rather laborious process, the features of which we will consider below.

- The fire part of the body of the stove is also called the furnace. It is exposed to the average chemical influence of gases, but is heated to very high temperatures, up to 1200 degrees. For masonry, the so-called fireclay brick and refractory mortar of clay-chamotte type are used.

- Chimney source. It is made from the same brick and fastened with the same mortar, which is indicated in paragraph No. 5, since this element of the furnace is subjected to the same temperature and chemical influence as the heat-accumulating part of its body.

- "Fluffing" the stove chimney. Its task is to create a flexible mechanical connection that connects the ceiling and the chimney itself. Allows you to avoid a situation in which a subsidence of the ceiling is possible. The fluff can be repaired separately, it does not require a complete disassembly of the entire structure. Brick for masonry is taken as a standard kiln, and a lime-type mortar is ideal for laying this part of the kiln.

- Fireproof cutting is a special metal box filled with a non-flammable heat-insulating substance.

- Chimney pipe. This element is exposed to wind and precipitation. It heats up weakly, therefore the pipe is laid from a standard red brick. However, for greater reliability and heat resistance, lime mortar is used.

- Fluffing the chimney pipe (11). It is made from the same materials that are used when laying the main part of the pipe.

Types of mortars for masonry stoves and their main properties

After reviewing the previous paragraph of the article, you may have noticed that for laying various components of the furnace, it is recommended to use your own type of mortar that is most suitable for work. Let's look at each of them in more detail.

Clay mortar for laying the oven: the pros and cons

Clay mortar is the cheapest building material. It, as a rule, can be obtained and prepared at home on your own. We will consider this process in detail later, since the preparation of the composite components itself is quite laborious and requires a separate instruction. The strength of the clay solution, as well as its heat resistance, is medium. The composition is able to withstand temperatures up to 1100 degrees Celsius without consequences. As for fire resistance, here clay is practically unparalleled: it does not ignite, and only hydrofluoric and fluoroantimonous acid can dissolve it. It also has absolute indicators of gas density. A stove folded on clay mortar can be safely reassembled, since the mixture moistened with water will become sour again. In addition, such material is suitable for work for an almost unlimited period of time: a container with a solution covered with a damp cloth will not dry out even after a couple of months. On the other hand, this is also its disadvantage: clay is completely unsuitable for masonry outside the premises.

The appearance of the clay solution

How to make a clay mortar for laying a stove: video instruction

Lime and cement-lime mixtures: are they used for laying stoves?

Mortar

In any case, it will cost more than clay.To prepare it, you will have to purchase a special lime dough or lump quicklime. It should be noted that quicklime will allow you to save money, but later it will come back to haunt you with serious labor costs: preparing a solution from “boiling lime” is a scrupulous process, because you need to extinguish all the particles to the last. If quicklime is present in the mixture, then the masonry seam may then break. The mortar itself has a reduced heat resistance and fire resistance. It is able to withstand inactive flue gases with temperatures below five hundred degrees. Compared to the clay mixture, it has a lower gas density. On the other hand, lime mortar does not absorb atmospheric moisture, so you can work with it outdoors. The finished mixture is suitable for use within a relatively short (relative to clay) period of time: it can be laid on the oven from one to three days after kneading.

This is what the lime slaking process looks like

Cement-lime mortar

It costs more than ordinary lime. However, this is partly offset by its increased strength. On the other hand, the resistance to heat here is about two times lower: the cement-lime mixture will withstand temperatures only up to 250 degrees without consequences. The gas density index of the solution is low. It is, in most cases, used for the construction of the furnace foundation. It dries rather quickly, so it retains suitability for work only within an hour after preparation.

Appearance of cement-lime mortar

Clay-chamotte and cement-chamotte solutions

Clay-chamotte solution

It has all the properties of a conventional clay mixture, but is more heat resistant (its maximum operating temperature reaches 1300 Celsius). This material, of course, is more expensive than clay, since for its preparation it is necessary to purchase special fireclay sand. Clay-chamotte solutions, for the most part, are used for the construction of a furnace furnace.

Cement-fireclay mortar

It is quite expensive, because it requires the use of high-quality components. In terms of strength, the mixture has equal indicators with cement-lime, while the heat resistance is like that of a clay-chamotte mortar. On the other hand, it has an average level of fire resistance. However, it is quite enough for laying the furnace part of the furnace. The shelf life of the finished cement-fireclay mortar is about forty minutes. It should also be noted that mixing of components in it is not done manually!

Appearance of cement-chamotte mortar

The names of multicomponent masonry mixtures are usually compiled in such a way that the name of the strongest binder comes first. In this case, the percentage of its content in the solution may be the smallest. For example, cement in a cement-lime mixture is 10-15 times less than lime.

Two terms used above require a separate explanation: "gas tightness" and "chamotte". Let's take a look at their meaning.

The term "gas density» indicates the ability of the material to pass gaseous substances. If the solution has a high gas density, then it will not let particles out and they will not, due to diffusion, get inside the heated room. It should be noted that gas density and hygroscopicity are not mutually exclusive concepts.Water vapor molecules are smaller and more mobile than smoke particles. A good quality solution must combine in optimal proportions both qualities, both gas tightness and hygroscopicity. The oven must "breathe", and at the same time, do not let smoke in. It is these requirements that are key to formulating furnace building mixtures.

As for the second concept under consideration,fireclay”is called a special refractory and heat-resistant material. It is produced by deep firing a mixture of special clay (the so-called "high alumina"), zirconium compounds, garnet crystals and some other components. Deep firing differs from the usual one in that it provides for the continued heating of the substance even after the complete release of all crystallization water from it, up to sintering and the formation of lumps.

This is what chamotte clay looks like

How to save on masonry materials?

The answer to this question, it would seem, is quite obvious: it is necessary to make the most of the materials at hand, which can be obtained for free right at the construction site of the furnace. In our case, on our own, we can get the following components: clay, sand and water. But, as practice shows, in reality everything is far from being so simple. You can’t just take any water, mix it with the first sand and clay that comes across, and as a result get a good quality mixture for masonry. A number of serious requirements are put forward for each component for creating a furnace mortar. Let's learn about each of them in more detail and learn how to select all the necessary components.

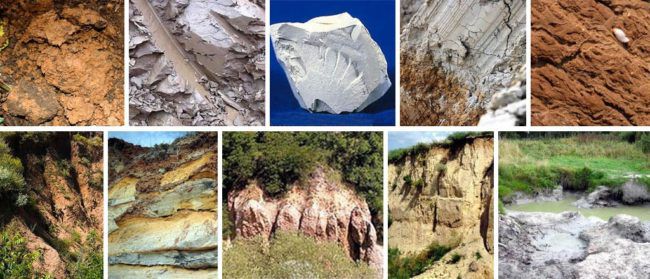

How to distinguish high-quality clay suitable for laying a stove from other fossils?

Quite often, broken clay can be purchased cheaply from local stove makers, but we do not recommend that you go the easy way. Such material is usually heavily contaminated with organic impurities. Subsequently, they will rot and decompose, worsening the consistency of the mixture and the quality of the finished seams. It is much more profitable to find good clay in the surrounding area and dig it yourself. The difficulty lies only in learning to distinguish high-quality deposits from contaminated ones.

Clay, in essence, is a mixture of aluminum oxide Al2O3 and silicon oxide SiO2 (in simple terms, sand). The main determining parameter for clay is its fat content. In turn, the strength of its structure, plasticity, adhesion indicators (the ability to stick to other surfaces), hygroscopicity and even gas tightness will directly depend on it. As a standard, the fat content of clay containing 62 percent alumina and 38 percent sand is taken equal to 100%, and the fat content of pure sand without impurities is taken as the zero reference point - 0%. To knead the mortar for laying the oven, we need clay with an average fat content, because the seams of a material with a too high fat content will crack during drying. "Low-fat", or as it is also called, "skinny" clay is also not durable.

Clay deposits of various types

Clay has several fossil twins that are often confused with it. However, furnace work with other mineral materials is not possible, so it is important to be able to distinguish them from what we need.

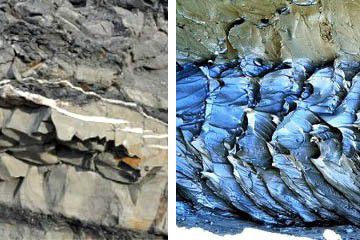

Clay shale and marl.The material is a brittle stony rock. It lies in horizontal layers that are visible to the eye and have rounded edges. In addition, if you take a sample of shale and break it, then the resulting section will clearly show the shale structure.

Appearance of shale

The most difficult to identify is bentonite, also known as bentonite clay (bentoglins). This is a valuable mineral resource, but it is completely unsuitable for use in the furnace business. Sometimes there is bentonite of bright colors, which is actually identical in appearance to the clay we need.

Bentonite clay, consisting of sodium-calcium compounds, montmorillonite and other impurities, has found its use in pharmacology, medicine, perfumery, winemaking and even in mining. The uniqueness of this mineral compound lies in its ability to absorb moisture. Bentonite saturated with water can without consequences increase in volume by a dozen times, passing into a gel-like state. But, unfortunately, it does not possess the properties of ordinary clay, such as fire resistance, gas tightness and heat resistance. It is quite easy to distinguish bentoglin from the building material we need. It is enough to take a small test sample and place it in a glass filled with water. After a short period of time, bentonite will absorb moisture and noticeably increase in size. After waiting a sufficient period, you will be able to see the transformation of the sample into a bentonite gel, which looks like jelly, somewhat similar to jelly. Clay in water will not turn into anything like that.

Appearance of bentonite clay

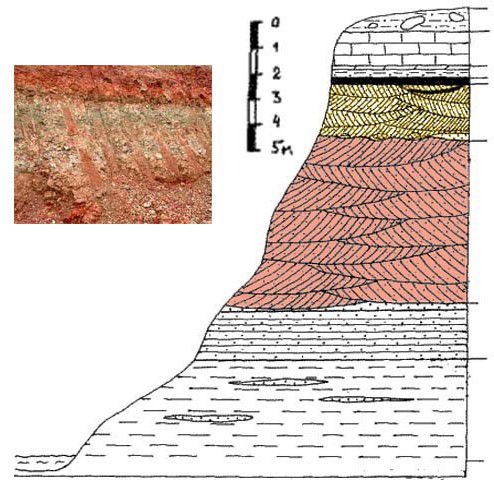

In the figure below you can see a schematic section of the soil structure typical for our country. Clay located in the upper layers of the earth is heavily polluted with organic impurities. From above, the main layer of clay deposits is covered with the so-called loam - a layer of soil with a significant admixture of alumina and sand. In the diagram, loam is indicated in yellow. Actually, the main layer of clay has uneven fat content: it is minimal from above and grows as it sinks deep into the soil.

Scheme of arrangement of clay layers

We will determine the fat content of clay using a special sample. Raw materials for analysis must be collected after passing through a layer of loam. In this situation - starting from five meters from the surface of the earth.

The clay test itself is very simple: we take in our hands a lump of material with a volume of half a fist. We wet our hands with water and begin to knead it like plasticine, gradually giving the sample the shape of a ball.

Sample ball rolled from clay

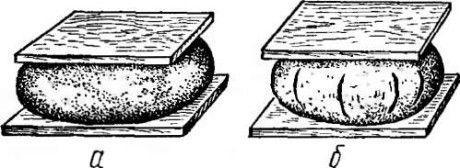

After the ball is ready, we begin to slowly press it with two flat boards on both sides exactly until the first cracks form. If you managed to compress the ball by at least a third of the diameter, then such clay is quite suitable for our tasks. We take about another five kilograms of material in a bucket and carry it home for further tests, which we will talk about later.

Checking the clay sample with boards

How to find quality water used in stove masonry mortars

It is necessary to check the quality indicators of the water that we plan to use to create the furnace solution in the very first place.Only so-called “soft” water, or at least water with medium hardness, is suitable for work. Hardness is measured in units called German degrees. One such degree means that in each liter of the studied water there are 20 milligrams of calcium and magnesium salts. Kneading the furnace solution can only be done if the water hardness is below ten such degrees.

| An experiment that allows you to determine the parameters of water will require the purchase of about 0.2 liters of distilled water in a pharmacy. We also take a piece of laundry soap and crumble it into small pieces. It will be our indicator, since soap neutralizes the salts dissolved in water. One gram of standard 72% soap neutralizes about 7.2 milligrams of hardness salts. Until the water softening process is completed, the soap solution will not foam. This is what will show us how “hard” the water is. | |

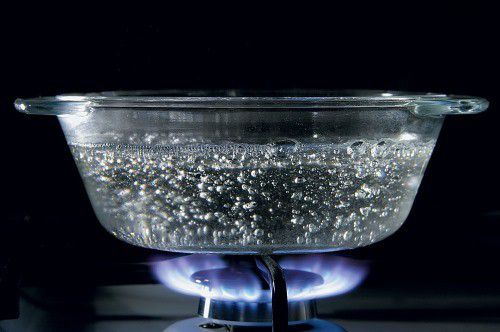

Heat water and add soap crumbs to it | We heat distilled water to about 75 degrees and carefully dissolve the soap in it. This operation should be carried out carefully, avoiding foaming of the mixture. The proportions in which our "indicator" must be added will be as follows:

|

Draw a soapy solution into the syringe | As a result, after everything has cooled down, we will get the so-called "titration mixture". With the help of a beaker, we collect about 500 milligrams of the tested water, and with a syringe (without a needle) - 20 milliliters of the resulting soap solution. |

Water with soap dissolved in it | Drop by drop, add the solution to the water to be tested, gently stirring it at the same time. First, soap, interacting with calcium and magnesium salts, will begin to precipitate in the form of characteristic gray flakes. We continue the process until a foam with rainbow-colored soap bubbles begins to form. With the appearance of bubbles, we stop adding soap dissolved in the distillate and look at how much solution we needed to completely neutralize all the salts. Next, we perform simple calculations and find out the hardness of water. |

| Let's say we used pure 100% soap, 10 milliliters of which contains one gram of soap. This amount of soap in 500 milliliters of tested water should have precipitated 10 milligrams of Mg and Ca salts. This means that one liter of water contains 20 mg of impurities of hardness salts, which corresponds to one German degree. And if we spent 80 milliliters of soapy titration solution, then the water hardness is 8 degrees and it is also suitable for oven masonry. The main thing is not to cross the limit value of stiffness of 10-11 units. | |

What kind of sand is suitable for laying the stove? Sand preparation

As for the sand, there is no need to take samples of it. Next to the clay deposits, you can always find interlayers of white quartz sand and yellow, containing feldspar. The first is suitable for creating any furnace structures, and the second can be used in the laying of all elements, except for the hottest part - the firebox. Remember that preparing sand for work will require a significant amount of water. That is why you should take care in advance of resolving issues regarding uninterrupted water supply.

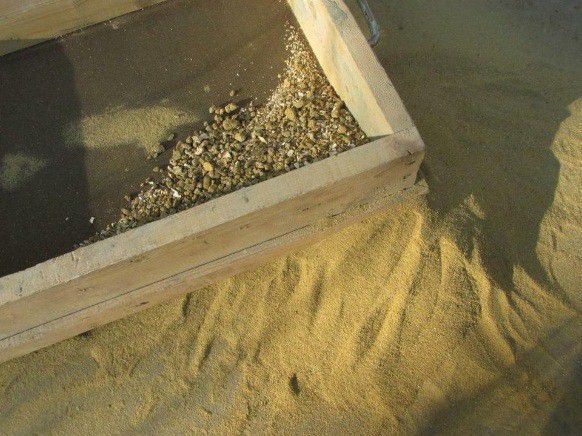

The sand accumulated on its own must first be passed through a sieve with a mesh size of 1-1.5 millimeters. This allows you to get rid of various large debris and get the necessary set of fractions. The biggest problem for self-digged sand is organic impurities and various living microorganisms living in it. The sand must be cleaned of them, otherwise the masonry seams may deteriorate over time.

Sifting sand with a sieve

There are many industrial sand cleaning methods, but all of them are associated with significant energy costs. We, in order to save money, will use a simple and accessible washing method for everyone.

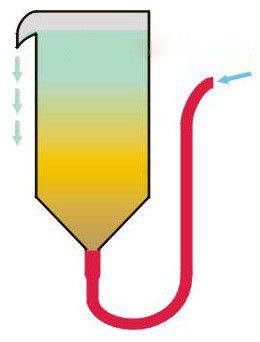

For the manufacture of a cleaning apparatus, we need a piece of pipe 15-20 centimeters in diameter. Its height should be about three times its thickness. We fill up a third of the volume with sand and supply water from below under high pressure. The power of the water jet must be selected in such a way that the washed sand swirls, but does not flow into the drain located on top. After clean water flows into the drain, we wait another ten minutes and finish the procedure. The first batch of cleaned sand is ready. It remains only to dry it.

Scheme of the apparatus for washing sand

The method of filtering sand by washing also allows you to remove from it various inclusions of alumina that we do not need.

The proportions of the mortar for laying the furnace, how much sand, water and clay should be?

An important step in the preparation of a building furnace mortar is to determine the optimal proportion between sand and clay. After we bring home the clay sample selected according to the above algorithm, it is necessary to divide it in two.We set aside the first half, and again divide the second into five identical pieces. We place each of them inside a separate dish and add water there (hardness up to 11 German degrees), about a quarter of the volume of the clay itself.

Next, leave the clay to limp in the water. Typically, this process takes approximately 24 hours. After a day, stir it thoroughly and pass it through a sieve with a mesh size of three millimeters to weed out large lumps.

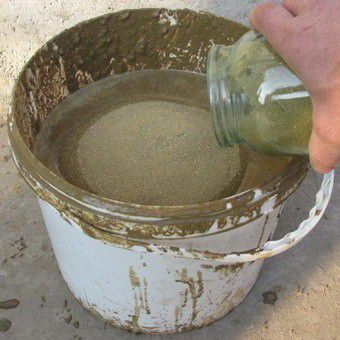

Clay sagging in water

We put the container with the strained solution on the sludge again. When a muddy slurry (the so-called “sludge”) appears on the surface of the solution after settling, we remove it by pouring it onto the ground.

Everything, now you can start adding sand to each container with prepared clay. This must be done in the following proportions:

- The first container - do not add sand;

- The second is one part sand to four parts clay;

- The third is two parts sand to four parts clay;

- Fourth - 3 parts of sand and four parts of clay;

- Fifth - sand and clay are added in the same amount.

Adding sand to each of the containers must be done gradually, in small portions, in several approaches (optimally - at least three and no more than seven). You need to mix everything very carefully. Do not rush to add the next portion of sand before the previous one is completely evenly dissolved in the mixture. It is quite easy to identify a well-mixed clay-sand mortar: just try to rub it between your fingers. If the roughness of individual grains of sand is not felt, then everything is done correctly.

Add sand to clay

The next step in the preparation of the clay-sand mortar will be the production of prototypes.We take clay in each of the five containers and alternately do:

- Two bundles of about 35 centimeters in length and a centimeter and a half in diameter;

- We fashion a ball with a diameter of five centimeters;

- A round clay cake with a thickness of 12-15 millimeters and a radius of 7.5-8.5 centimeters.

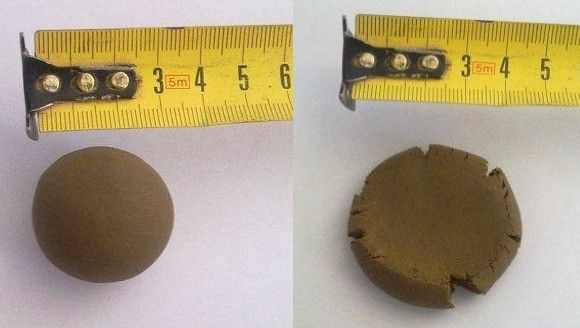

As a result, we will have exactly 20 samples on hand, which must be marked and left to dry inside the building. For normal drying, the samples should not be exposed to drafts and direct sunlight. Usually the tows dry out in a couple of days, but the cakes and balls may take up to two dozen days. If the ball does not wrinkle, and the cake has ceased to bend in half, then the material has completely dried up.

Clay ball and cake

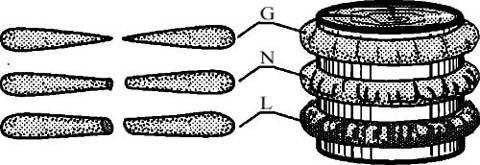

When the samples are ready for testing, we proceed to the next classic experiment, which allows us to determine the fat content of the clay solution. To do this, we wrap a clay tourniquet around the shovel handle, then tear it apart and observe the results:

- Greasy clay, indicated in the figure G (from German "greesy" - greasy) practically does not crack, and when the tourniquet is torn in half, the gap will have drop-shaped ends.

- Clay of normal fat content (marked as N) will have a cracked top dried layer and, after breaking the tourniquet, its thickness at the point of separation will be equal to about a fifth of the original. These are the samples we need to select.

- Dry (skinny) clay, designated as L (from German "Lean" - lean), will be marked by the maximum number of deep cracks and, when broken, will have the largest area at the point where the pieces of the tow are separated.

As a rule, after the selection, several (usually 2 or 3) seemingly suitable samples remain.

Determination of fat content of clay

Dried balls and cakes will help us to carry out the final "clay casting". We drop samples from a height of a meter above the bare floor. The most durable of them will indicate the required consistency of sand and clay. If, after falling from a meter, all the samples remained intact, we begin to gradually increase the height until we can determine the most durable of them.

Checking the clay-sand mortar using the example of a cake

Checking the quality of a clay-sand mortar using the example of a ball

The next step in preparing the mortar for laying the oven will be the calculation of the required ratio of water to the proportion of sand in the mixture. The physical limits in which the clay mixture will have a normal fat content are quite wide. Our main task, since we are building the oven for ourselves, is to make the construction as strong as possible, with excellent indicators of the gas tightness of the material of the connecting seams.

First of all, we sift the clay remaining during the trial sampling. We push the clay through a sieve with small cells so that it evenly mixes with the sand. Add the required amount of prepared washed sand. We learned the proportions of sand and clay earlier thanks to the experiments. We begin to add water and gradually knead the solution. Remember that water must meet the hardness parameters that we talked about earlier.

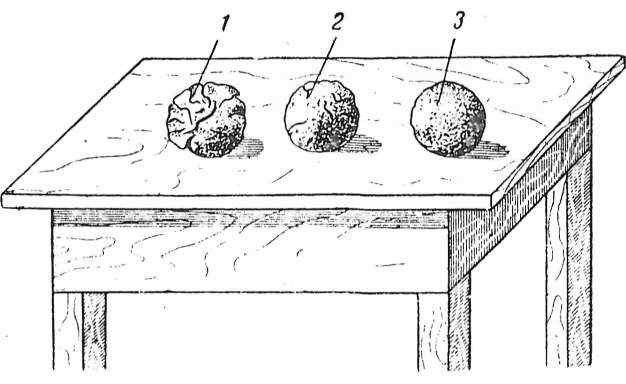

Next, we take a trowel in our hands and make a hollow on the surface of the mixed solution.

The trace from the trowel (trowel) will help determine the readiness of the solution

- A torn hollow indicates that there is not enough water (Fig. 1)

- If the hollow immediately behind the trowel begins to swim, then they overdid it with water (Fig. 2) We defend the solution, remove the sludge in a separate bowl. The difference in volume between the filled water and the squeezed out sludge will show us the required optimal proportion.

- In the case when you immediately guessed with the required amount of water, the trowel will leave a clear, well-distinguishable even mark with highlighted edges on the surface of the mixed solution (Fig. 3).

Proportions and proper preparation of clay mortar, strength test

To find out whether our clay mortar will be sufficiently strong and have the necessary degree of adhesion, the so-called cross test will allow. This final experience will show how correct the results of all our preparatory material checks were and how well we cleaned the constituent components of the oven mixture.

To check, we need a couple of bricks, one of which we lay flat on the ground and cover its largest plane (the so-called “bed”) with a thin layer of the prepared test clay mortar. We put a second brick on top, and, having tapped it with a trowel, let the mixture dry for about ten minutes. After that, we grab the brick located on top with our fingers and pull it up. Having raised it to a certain height, we shake the structure on weight: if the lower brick did not come off at the same time, it means that all the preparatory work was carried out carefully and we correctly calculated all the proportions of the clay mortar.

If you still do not understand the individual details of preparing the mortar for laying the furnace, we recommend that you watch this video:

Proper preparation of mortar for laying the oven: video lesson

Video: How to prepare a clay composition for laying a furnace