Many owners of country houses unfairly ignore cast iron stoves. Meanwhile, these devices are made of a unique metal that has a thermal conductivity one and a half times higher than that of steel. That is, if we compare two furnaces of the same size, one is made of steel and the other is made of cast iron, then a cast-iron furnace will be one and a half times more efficient than a steel one in terms of its performance. In addition, the level of thermal radiation of cast iron is almost twice that of steel. At the molecular level, cast iron has a peculiar porous structure and remarkably accumulates the heat directed at it, then gradually releases it into the surrounding space. You did the right thing by choosing a stove made of this particular metal for yourself, now you need to figure out which type of construction you should buy? Let's figure it out together!

Content

Advantages of cast iron stoves

It should be noted that cast iron can be heated to very high temperatures without loss of properties. Consequently, cast iron oven will be able to withstand even a firewood fire with a high combustion temperature or even a bookmark hard coal. Steel furnaces using this type of fuel can simply burn out. The only caveat is that cast iron cannot be cooled quickly - this can lead to cracks.

Such furnaces serve their owners for several decades. These are quite budget devices, their purchase will not hit your wallet hard. And certainly buying a cast-iron stove will cost less than building a classic stone stove.

Cast iron stoves, as a rule, are small in size and fit perfectly into small dwellings. It is worth noting that despite their solid weight, their installation does not require pouring or installing a separate foundation.

The installation process of such a device is quite simple and will be described below.

As another advantage of cast iron stoves, the minimum time for kindling such a device can be noted. It is brought to operating temperature in just 15 minutes. After a quarter of an hour, it begins to intensively heat the room in which it is located.

The modern design of cast-iron stoves allows you to use the furnace material quite economically, and the maintenance and cleaning of such devices will not take you much time and effort.

What functions can a cast iron stove perform?

It is important that in addition to heating the room, cast-iron stoves can perform many other useful functions. Depending on their design, you can cook food on such stoves, use them as an oven for baking, dry harvested fruits or mushrooms.

The cast-iron stove is a rather massive structure and gives the interior some solidity.Since the tradition of space heating with stoves dates back to the Middle Ages, stove models can be made with amusing historical parallels, which will certainly decorate your interior. The most notable are the models recreated according to the drawings of the late 19th century, which are excellent examples of "Belle Epoque" - "beautiful era".

A cast iron stove has a solid service life and can be usefully used by your family for up to half a century.

Design features of cast iron furnaces

Cast iron stoves were most popular in the 19th century. However, since that time, engineering thought has not stood still and stoves have evolved from simple boxes of firewood to high-tech devices. Let's look at the most popular types that are currently on the market:

- Single heating furnace. The classic version, built according to the patterns of the 19th century. They are made both in a purely utilitarian design (classic "bourgeois stove"), and as copies of works of applied art that can serve as decoration for the interiors of even prestigious mansions. Simple models are in constant demand for heating small country houses. A small efficiency (up to 60%) is offset by ease of installation and use. But, by the way, in comparison with the "potbelly stove" of revolutionary times, such a stove looks like the crown of technical progress.

- Pig-iron furnaces of convection type. A more complex model in which a metal case is mounted around the firebox. Warm air rises between the iron and steel. This design increases the efficiency of the furnace up to 75%.

- Pig-iron furnaces of gas-generating type. The pinnacle of kiln technological art. There are two chambers in the furnace of such a furnace.The lower chamber contains smoldering solid fuel, which emits combustible gas, which rises up and burns in the upper furnace. The efficiency of such a system reaches 90%. Such furnaces can be equipped with automated control and mechanical fuel supply. Only on one tab, such a boiler will be able to heat your room for 10 hours.

- In addition, a cast-iron stove may well be combined with a fireplace. Usually in such a furnace there are two heating circuits. The firebox used as a fireplace can be closed or open. Firebox. Closed with tempered heat-resistant glass is more secure.

- Note that additionally cast-iron stoves can be equipped with devices for cooking or for ingots. In this case, it is a truly multifunctional equipment.

How to install a cast iron stove?

In general, the rules and methods for installing cast iron cooking and heating stoves are created on the basis of current building codes and regulations (SNiP). Consider in order the process of installing a finished metal furnace:

- Remove the stove from its factory packaging and inspect it externally. Cast iron is a fairly brittle material, and when inspecting, pay attention to possible cracks. Using a cracked oven may cause a fire.

- As a rule, along with the oven, instructions for operation and installation are also attached. Always follow the provisions of this manual, as different manufacturers of ovens may have different operating nuances.

- Check the completeness of the oven. Usually, all additional and attachments are stored in the firebox during transportation.

- In the event that the oven is equipped with removable legs - Being careful, turn the oven over and place it on the back wall. Attach the removable oven supports following the instructions. After that, put it on supports and check the stability.

- Check the completeness of the connection between the outlet pipe of the cast iron stove and the chimney. If necessary, purchase adapters of the appropriate configuration. Please note that some models of cast iron stoves may have an outlet pipe both on the top surface and on the back wall. In this case, the choice of the smoke outlet is determined by a removable plug.

- When moving a cast iron stove from place to place, lift and carry, rather than drag it. The supports of such equipment are quite fragile. When moving a cast iron stove, you may need the help of several people.

Rules for installing a cast iron stove

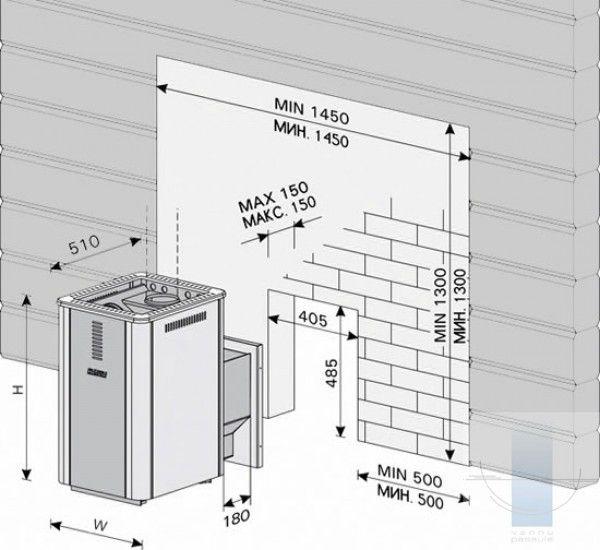

Before choosing a place to install the stove, check what building materials the surrounding objects are made of. It is not allowed to place a cast-iron stove in the immediate vicinity of flammable objects. At the same time, it is necessary to evaluate not only the external coating, but also the main material for the manufacture of walls and ceilings, as well as pieces of furniture.

So, if there is a wooden wall that is easy to ignite, the chimney pipe and the cast-iron stove should be located no closer than half a meter from its surface. Even for protected surfaces, the distance to the oven must be at least 15 centimeters.

Connecting the stove to the chimney

The quality of the material from which the chimney is made must be checked even before installation. It should not have any visible cracks or crevices.

Especially carefully check the behavior of the chimney during the first fire.It must be with a very intense fire. It is at this stage that the sufficiency of draft in the furnace of a cast-iron furnace is determined. If necessary, the chimney is equipped with a draft stabilizer. This device can regulate the burning rate of fuel in the furnace in a wide range.

Please note that a constant supply of fresh air is required for the furnace to fire. Otherwise, the oxygen in your room may simply be burned out and you will feel uncomfortable. This is especially true for modern country houses, which have double-glazed windows that reliably isolate the room. In this case, it will be necessary to provide for the installation of supply ventilation.

Place a non-combustible flooring under the oven. It can be either just a sheet of roofing iron, or a space trimmed with decorative tiles. It is better to install a small curb along the edges of such a site, which will prevent accidentally falling coals from rolling out.

For a cast-iron stove, it is recommended to install a chimney at least 4.5 meters high and with an internal section of at least 15 centimeters. Such parameters will provide good traction. At the same time, you should not strive to excessively increase the diameter of the chimney - in this case, the fuel in your stove will burn for nothing. The place of connection of the chimney - to the back or to the upper surface of the furnace has practically no effect on its performance. Inside the chimney, a special adjustable plug can be installed - a view, depending on the position of which the intensity of draft and fuel combustion is determined.

The cast-iron stove creates the most comfortable conditions if it is installed in the center of the room, but this is not always convenient from a practical point of view.

In conclusion, you can watch an informative video on choosing and connecting a cast iron stove.

Video: How does one cast-iron stove differ from another and which one is better?