Cast iron firebox with glass

The fireplace is a symbol of home and comfort. For a country house and a summer residence, this is also a way to heat the house, so in this article we will talk about how to choose the right cast iron fireboxes for fireplaces with glass and install them yourself.

Having decided on the arrangement of a fireplace in the country, people are wondering what kind of firebox to give preference to. There are many options on the market today, and each of them has its pros and cons.

One of the main details on which the efficiency of the fireplace depends is the firebox. It is she who is the "heart" of the fireplace, where the fuel is burned. The duration of the operation of the fireplace, its performance depends on the material, design and successful installation of the firebox.

Fireplace in the country

Content

- Types of fireboxes for a fireplace

- Advantages and disadvantages of a cast iron firebox

- How to choose the right firebox?

- Features of glass doors for cast iron furnaces

- Features of the installation of a cast-iron firebox

- Installing a cast-iron firebox: step by step instructions

- Video. Do-it-yourself fireplace with a cast-iron firebox.

Types of fireboxes for a fireplace

Before considering the variety of fireboxes, let's remember that the design of the fireplace includes the main 3 elements:

- chimney;

- external facing part;

- firebox.

The main elements of the fireplace

Fireboxes are of two types: open and closed.

The first option is more comfortable and romantic. It's so nice to sit in front of an open fire on a cold evening, admiring how logs burn in the fireplace. But this design has a number of disadvantages:

- Insecurity. You will not leave such a fireplace unattended.

- Inefficiency. Approximately 15% of the heat remains in the room. The rest escapes through the chimney.

Therefore, an open-type design can be safely called a decorative luxury, which allows you to create an atmosphere of warmth and comfort in the house. In addition, it will not work to regulate the power of burning fuel in such a fireplace. The only way to adjust is the view, which allows you to open or close the damper in the chimney, controlling the draft. As a heating system, such a design will not be used effectively.

Open firebox

But a closed fireplace is much more efficient to use for heating a country house in cold winter or in the off-season. It will perform not only a decorative function, being the main decoration of the living room, but also provide effective heating of the room.

Stylish closed hearth fireplace

The efficiency and high performance of a fireplace with a closed firebox is due to a completely different principle of operation compared to an open design. Heat accumulates inside the furnace, and does not go out with combustion products. As a result, a high efficiency is achieved. With a properly installed fireplace, the efficiency reaches 90-92%.

In addition, modern manufacturers equip closed fireboxes with a long burning system (firewood smoldering system), so that heat can be maintained up to 12-15 hours after one laying. This is not only efficient, but also very economical. You can adjust the degree of oxygen supply, which affects the intensity of combustion, using the knob.

closed fireplace

With such a heating system, you can safely go to sleep, and the fireplace will slowly give off heat. In the morning, the house will have a good temperature and atmosphere.

The advantages of a closed type of firebox include:

- High performance (up to 92% efficiency).

- Residual combustion products (ash and ash) are collected in a special ash pan, which guarantees cleanliness in the house.

- High fire safety. There is no chance of sparks on the flooring or furniture.

- Long service life.

- Fuel economy.

- The fireplace can operate in automatic mode without the constant presence of a person and control of the flame.

- The ability to adjust the intensity of combustion.

The disadvantages of the closed type of firebox include narrow glass in budget versions, which makes it impossible to admire the open flame.

Closed cast iron firebox

It should be noted that a closed type of fireplace can be made from an open structure. To do this, it is necessary to insert a closed-type cast-iron firebox into the overall design of the fireplace. The firebox itself is a fireplace insert (cassette), which is closed with a glass door.

This liner is connected to the chimney, from where the products of combustion are then removed.

Advantages and disadvantages of a cast iron firebox

Now that we have decided on the type of fireplace construction, we need to choose the material for the firebox. The firebox can be lined with fireclay bricks or made of cast iron, steel. Unlike steel structures, cast iron fireboxes are inexpensive and practical.

Cast iron fireplace in the country

The advantages of such cast-iron fireboxes include:

- fire resistance;

- resistance to deformation;

- ease of installation;

- low price;

- high performance;

- good thermal conductivity;

- excellent chamber tightness;

- the ability to heat a room up to 300 square meters;

- high heat storage capacity.

The special design of the cast-iron closed firebox with glass allows you to accumulate thermal energy and release up to 70% into the room.

The outer part of such a firebox is covered with a special protective paint that can withstand high temperatures up to 700-700 degrees Celsius. The front side is equipped with a glass door, which allows you to monitor the intensity of the flame, admire the hearth and throw firewood.

Cast iron firebox

And the lower part of any combustion chamber suggests the presence of an ash pan. This is the place where combustion products accumulate: resins, ashes, ash. Also, this part of the fireplace performs another function. As you know, the combustion process cannot occur without oxygen. It is through the ashpit that air enters the cast-iron combustion chamber.

The disadvantages of cast iron fireboxes with glass include:

- small view of the viewing window;

- the window is quickly covered with soot, which further reduces the view;

- all products are produced in black, which does not allow to vary the design of such a fireplace.

But the last point is easy to fix if you install a decorative grille on the fireplace in the form of a bronze openwork mesh.

How to choose the right firebox?

Having decided on the type of construction and material for the manufacture of the firebox, it remains a matter of small - to choose a model. By what parameters should you choose a cast-iron firebox, given that the market today offers many different models and manufacturers.

- Furnace power.

This is perhaps the main parameter on which the efficiency of the fireplace will directly depend. In order to choose a fireplace that will really heat the room, and not just perform a decorative function, you should correctly calculate the area of \u200b\u200bthe room. The power of the furnace we need will depend on this parameter.

The power of the furnace depends on the area of \u200b\u200bthe room

Also, the power of the firebox determines its weight, diameter and length of the chimney.

We calculate the total area of \u200b\u200bthe room using the standard formula:

We measure the length and width of the room in meters, multiply the results. Now that you know the quadrature of the room, you can determine the required power of the firebox.

We measure the area of the room

Important! Consider not only the total area of the room, but also the number of windows, their width, the presence of doorways. All this will increase the power requirements.

We take into account the number and width of window openings

For a room area of 50-100 m2, the power of the furnace should be at least 10-12 kW.

For premises over 100 m2, choose a furnace power of at least 15 kW.

- door material. The door is one of the most important parts of the firebox. In order for the door to withstand high temperatures of 750-8000 C, it is made from quartz heat-resistant glass or ceramic crystal.

Attention! Fireplaces with a transparent glass door are made of refractory ceramics. But models with cloudy yellowish glass are made from quartz heat-resistant glass.

Door made of glass

Today on the market you can find budget models with a small glass door, or you can purchase more expensive fireboxes with double-leaf or curved glass doors. Of course, the difference is purely in decorative functions, because it is much more pleasant to admire the reflection of fire when the fireplace is equipped with a firebox with a large glass door. Improved fireboxes are equipped with doors with automatic window cleaning. Due to the supply of hot air, the glass is easy to clean from dust, soot and soot.

- Form of a fire chamber: usual (frontal) and angular. Here the choice, of course, depends on the location of the fireplace. The front firebox, in turn, can be shaped like a trapezoid or a rectangle.

corner firebox

The advantage of a conventional front firebox lies in its affordable price and high performance. Due to the fact that the chimney is located next to the firebox, without unnecessary bends, the draft in such a fireplace will be better. But in a corner furnace, such performance is reduced due to the remote location of the chimney.

- Glass door shape: flat, circular or segmented. Of course, the most budget option would be to buy a firebox with a flat door. But if you want to give originality to your interior, then pay attention to stylish models with a circular spherical glass firebox.

Semicircular shape of the fireplace

You can also find a combined type of door, when one part is made of steel, decorated with decorative forged elements, and the glass part provides a view behind the fire.This style of stained glass will help bring a special touch of comfort and antiquity into the interior.

- Price. The final price of the firebox is greatly affected by the quality of the glass, so you need to carefully approach the choice of this product. It can be single-layer and multi-layer. It is also important to consider parameters such as service life and heat resistance. The product passport usually indicates the guaranteed operating time (indicated in hours). And the heat resistance of glass depends on its strength - a parameter prescribed in the technical data sheet in millimeters. Optimal in terms of price and quality is a glass thickness of 4 mm.

Features of glass doors for cast iron furnaces

As mentioned above, ordinary glass is not suitable for installing a glass door in the combustion chamber. It should have a high heat-resistant index.

The main task of such glass is to protect the house from fire, because the fireplace is always an increased fire safety. No matter how beautiful and romantic the process of lighting a fireplace and admiring an open flame, there is always a risk of ignition from the slightest spark.

Cast iron glass door

Installing such glass in a cast-iron firebox requires certain knowledge and skills.

The main difference between heat-resistant glass for a furnace and ordinary tempered glass is foundry expansion when heated. It does not form cracks, chips during operation. When purchasing glass for a cast-iron firebox, pay attention to its maximum temperature. A material of 600 degrees will withstand a long time, but if it is exposed to a temperature of 750-800 degrees, then such glass will not withstand even several hours.

The type of fuel affects the performance properties of firebox glass.Each type of fuel has its own technical characteristics and maximum combustion temperature. This must be considered before purchase and installation.

Cast iron glass door

To prolong the life of the glass for the firebox, you must adhere to the basic safety measures:

- You can not fill the flame with water in the fireplace. A sudden change in temperature can affect the technical characteristics of the glass.

- Do not use harsh abrasive substances when cleaning the door and combustion chamber. The scratch itself will not violate the technical characteristics of the glass, but soot will accumulate faster in the place of its formation, blocking the view.

- The service life is also affected by the correct installation of the door. If the draft in the fireplace is broken and the glass is constantly affected by the flame, then such a door will not last long, no matter how strong heat-resistant glass it is made of.

Attention! To ensure a beautiful aesthetic appearance of the glass door, you should monitor the quality of firewood. If you use well-dried logs, then the likelihood of soot formation will be minimized. If you throw extraneous garbage into the fireplace and use firewood with a high resin content, then the door will be constantly covered with soot, breaking the beautiful appearance.

Features of the installation of a cast-iron firebox

Of course, installing a fireplace and installing a firebox is a very tricky and tricky business. If you are not confident in your abilities and knowledge, then it is better to entrust such a thing to professionals. After all, improper installation of the firebox can be fraught with serious problems, ranging from poor traction to a fire hazard.

If you are confident in your abilities and want to independently install a cast-iron firebox with glass, then we suggest that you follow our detailed step-by-step instructions.

The finished design of the cast-iron firebox can be purchased at the store, or you can make it in advance. The latter option requires serious skills and a professional tool. Therefore, in this article we will dwell in detail on the installation and installation of a ready-made design of a cast-iron firebox.

The installation option also depends on whether you are embedding the firebox into an already prepared fireplace design with a chimney or equipping the fireplace from scratch. If you have decided for yourself to replace only the old furnace part with a new cast-iron part with glass, and the fireplace portal, together with the system for removing combustion products, is ready for you, then feel free to proceed to step 3.

We offer here detailed instructions on how to equip a fireplace with a cast-iron firebox from the very beginning.

Video. Step-by-step installation of a fireplace with a closed-type cast-iron firebox

Installing a cast-iron firebox: step by step instructions

Works on the installation of a cast-iron firebox

Before starting work, prepare the following tools and materials:

- building level;

- construction roulette;

- electric drill;

- trowel;

- rubber mallet;

- cast iron furnace.

From the materials you will need:

- cement-sand mortar;

- refractory mastic;

- brick;

- insulation;

- screws and self-tapping screws;

- a metal sheet;

- waterproofing material.

Step 1. We prepare a place for a fireplace.

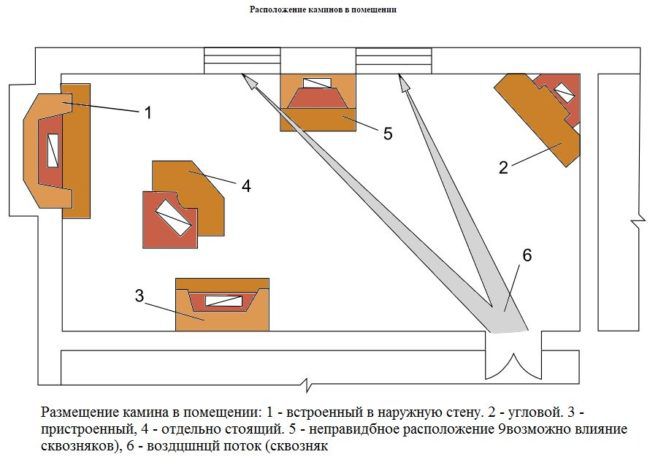

- We determine the place where the fireplace will be installed. It depends on a number of factors: the location of the doors, the area of \u200b\u200bthe room, the characteristics of the roof, etc.It is important not only to think about where it will look more spectacular, but also immediately take into account the installation of the chimney system, which can be done in two ways: through the wall or through the roof.

Determine the place under the fireplace

- The base under the fireplace must be strong and perfectly flat. The slightest tilt and skew can reduce the efficiency of the fireplace, breaking the draft. Therefore, if the floor in the house has irregularities, then the base under the fireplace should be strengthened and the ideal level should be achieved.

- We determine with a marker on the floor the place where the fireplace will be located, and measure the slope with a building level. We make markings with a marker, measuring the length and width of the future fireplace.

- If the wall to which the fireplace will adjoin is made of wood, it is recommended to lay a brick wall next to the fireplace. In this case, the brick wall must be installed on the same foundation where the fireplace will be located. Consider this when marking the floor (add in the width of the fireplace, the width of the brick wall).

Attention! If you do not have much experience in masonry, then it is recommended to lay the bricks dry before starting construction work. So you will see how much material you need, and you can correct any of your shortcomings at this stage.

- We carry out the foundation under the fireplace. According to technical standards, the width of the foundation for the fireplace should be 10-15 cm larger than the structure on each side.

Foundation-for-fireplace

Therefore, when marking the floor under the fireplace, draw an additional line under the width of the foundation.

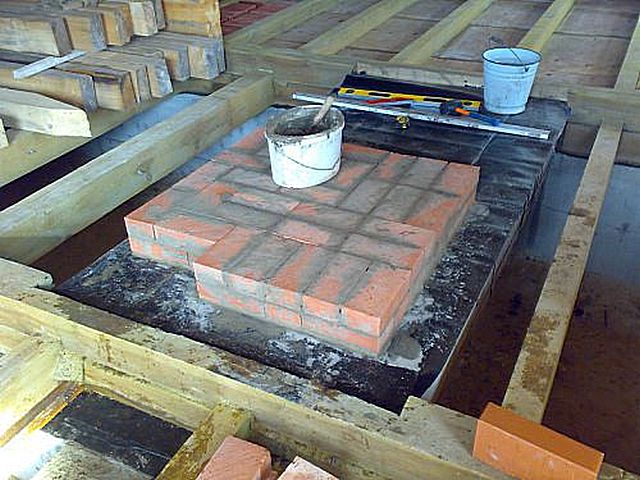

- We create formwork from boards. The depth of the foundation for a cast-iron firebox must be at least 50 cm. If the fireplace is installed in a house with wooden floors, then the foundation should never be placed on boards.By the size of the fireplace, we cut a hole with an electric saw or a jigsaw and deepen the foundation.

Mounting the firebox on a pedestal

- We knead the cement-sand mortar and fill the first layer of the foundation. We put a reinforcing mesh to securely fix the foundation, wait for the first layer of cement to dry and pour the second one. In principle, the foundation for the fireplace can be laid out of red brick. But for this you will need to securely bandage each layer of brick and make a concrete screed.

The base must be perfectly level.

- We check the slope of the foundation with a building level. If everything is perfect, let it dry. Depending on the technical properties of the solution, this may take up to 7 days.

Step 2. We install a pedestal under the firebox.

- When the foundation for the fireplace is ready, we proceed to the construction of a pedestal for the firebox. We lay out 4 rows of red brick, forming a U-shape.

Pedestal for firebox

If desired, the rows can be increased if a higher fireplace design is envisaged. When laying rows of bricks, connect them with a cement-clay mortar, and so that they “sit down” well, use a rubber mallet. After laying each layer, check the level of slope with a construction yardstick. Proceed with laying the next level only if the level shows "0".

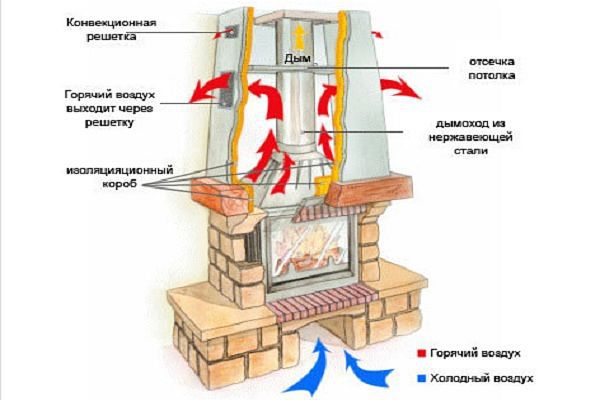

Why is it necessary to mount such a complex pedestal? This design will increase the heat transfer of the fireplace.

Fireplace design

The convection of air masses works in such a way that warm air from under the woodshed will come out, mixing with cold.

- Now, on the side parts of the brick laying, we install metal corners with the ribs up.

Overlapping from metal corners

Bricks will stand on them, acting as the basis for the firebox.

- We take bricks and make grooves in them with a file.

Base for firebox

We seat bricks on metal corners. We strengthen all this with a cement-clay mortar. We check the horizontal slope again with the building level. And for the vertical we use a plumb line. Let the mortar dry well and harden.

- A cast iron firebox requires the organization of the correct space under its lower part. About 30% of all the heat generated by the fireplace will go through the bottom, so there must be space under the firebox. It is not recommended to install a cast-iron firebox directly on a brick pedestal.

- Pay attention to the design of the ash pan.

Ash pan

This is an important element of the fireplace, in which ash and ashes accumulate. Access to it should be convenient so that the operation of the fireplace is easy and practical. The ash pan must be equipped with a special door through which it will be necessary to systematically clean the fireplace. In some models of cast iron fireplaces, an ash pan with a door is supplied, but it may have to be purchased separately.

Step 3. Mounting the firebox.

Now that the base for the fireplace is ready and the mortar has hardened, you can proceed directly to the installation of the cast-iron firebox.

- We cover the prepared brick base with refractory mastic and carefully install the cast-iron firebox. You will need help, as the design is quite heavy.

Installing the firebox on the base

- You will need to carefully lower it from top to bottom and immediately fix it securely. At the same time, the firebox should not reach the back of the brick wall by 4-5 cm. This is a very important parameter and do not ignore it.Be careful and careful during installation, as it will be difficult for you to correct this stage of work later.

Step 4. Installation of the chimney.

When the firebox is securely installed and fixed on a brick base, you can proceed with the installation of the chimney. Its design and location was determined by you even before the start of work, so use a pre-designed construction scheme.

Chimney installation

Installation of sandwich pipes

The simplest and most practical installation option is a chimney made of double-circuit sandwich pipe.

The store sells ready-made designs. You only need to buy the right number of elements and assemble the entire structure. Keep in mind that the fewer bends the flue structure has, the better the performance of the fireplace will be in the future.

Attention! When designing a gas exhaust system, take into account the technical established fire safety standards. According to SNiP, if the height of the chimney does not exceed 5 meters, then the vertical deviation angle should not exceed 45 degrees. If you ignore this fact and make it more, it will affect traction. Also, during operation, smoke can enter the room.

- Before installing the entire chimney, connect the two pipe structure (outer and inner layer) . Each knock of the elements must be carefully treated with a sealant, otherwise the smoke may enter the room, and on the street the heat will go outside.

- The first pipe of the chimney must be put on the outgoing pipe of the firebox in a locking way. Close all joints with sealant.

- Use a splitter to direct the smoke flow.

- In order to clearly fix the chimney structure in a vertical position, it is necessary to install a bracket on the outside of the house.

- Connect a tee, the lower part of which acts as a condensate collector.

Mounting the chimney on the bracket

- To fix the chimney, use clamps that tighten the structure and fasten to the wall with brackets. In no case should it rest with all its heavy weight on the structure of the firebox.

- If you want to beautifully decorate the fireplace, giving it an antique look with a classic stone chimney, then you need to build a metal profile box around the sandwich chimney. Four metal profiles are mounted in a vertical position between the fireplace stove (mantelpiece) and the ceiling. Secure them with screws and metal corners. They will act as a frame.

- The frame is first sheathed with heat-insulating mats made of non-combustible material. In this case, they should be attached to the firebox and chimney with the foil side.

frame

- The outer part is sheathed with drywall. For these purposes, in principle, any material can be used: wood, asbestos-cement slabs, etc. We provided fire protection with the help of heat-insulating mats, and drywall or any other material here performs a more decorative function.

- Later it can be covered with decorative plaster, which will allow you to fit the fireplace very harmoniously into the interior of a country house.

Metal box around the chimney

All branches and bends create an additional obstacle to draft, impairing the operation of the fireplace, so it is best to avoid them if possible.

Attention! A prerequisite for installing the frame around the chimney is to make a hole, because the heated air inside the metal box must go somewhere.

Step 5. Finishing facing.

Video. Do-it-yourself fireplace cladding with a cast-iron firebox

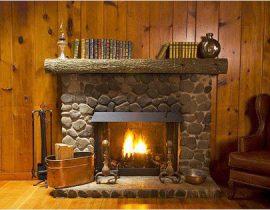

When the chimney structure is assembled and the firebox is installed, you can proceed to the finishing work, which consists in decorative cladding. Facing the firebox with brick solves not only a decorative problem, it improves the heat transfer to the fireplace, allows the heat to remain longer, warming up the room. In addition, with a brick, you can achieve any shape of a fireplace, giving it the most intricate shape.

Brick fireplace cladding

If the interior of the room does not involve the installation of a massive stone fireplace, then you can limit yourself to installing a stylish cast-iron firebox with glass and connecting it to the chimney. In this case, you just need to decorate beautifully the base for the combustion chamber.

If you want to enjoy the beauty of a classic fireplace, then red brick or decorative stone is suitable for this purpose. It all depends on your individual preferences, interior and budget.

Mantel

The most practical solution for the external cladding of the fireplace is the choice of fireclay bricks. It has high heat-resistant properties and is able to withstand up to 1000 degrees Celsius. In addition, due to its low thermal conductivity, it can retain heat for a long time. Even after complete combustion of the fuel, a fireplace lined with fireclay bricks can give off heat to the room for another 2-3 hours.

If fireclay bricks will simultaneously perform a decorative function, and no other finish is expected, then this material must be carefully sorted before laying. Lay out on the floor those parts that will be the front part of the finish. Pay attention not only to the shape of the bricks, but also to their color, structure. This will allow you to get beautiful seams and achieve excellent decorative effect.

Facing with aerated concrete

If you chose aerated concrete blocks for the exterior finish of the firebox, then their inner part must be insulated with basalt wool, because such material does not have high heat resistance.

Otherwise, during operation, aerated concrete blocks may crack, violating the technical properties of the fireplace and the overall aesthetics. It should be understood that aerated concrete blocks are not a finishing coating and then they will have to be covered with decorative plaster or artificial stone.

Another cladding option is the installation of a metal frame, followed by plasterboard sheathing.

Facing with aerated concrete

From the inside, this design is also laid with basalt fiber to make it fire resistant. This option is easy and economical to install.

We propose to consider the classic version of the lining with fireclay bricks.

- For lining the fireplace, the usual step-by-step order is used. If you need to make additional decor by decorating the fireplace with supports, then you will need to customize the brick in shape, making it semicircular.

Gap chalk firebox and outer masonry

- When laying out the outer shell of the fireplace from brick, make sure that it does not come close to the combustion chamber.There should be a gap of 2-3 centimeters between its wall and the lining.

Treat all brickwork joints with sealant or refractory mastic.

- As a finish, you can use plaster or simply open the red brick with varnish.

As a decoration, you can also install a beautiful forged grate, which will serve as an additional barrier and increase the fire safety of the fireplace.

Forged screen

The final touch will be the stylization of the fireplace with accessories in the form of candles and stylish items in the form of a poker, tongs, firewood sheds, which can also be made by hand.

Fireplace decor

Black openwork forged elements give a very stylish and beautiful look to a country interior.

For the first time, when lighting a fireplace, keep in mind that for the first few days there may be an extraneous smell from the factory sealant of the cast-iron firebox. But if you feel burning and foreign smell in the room, then the technology for installing the fireplace may have been violated.

In this case, check the tightness of all seams, draft in the chimney.

The fireplace adds coziness and sophistication to the cottage

It is not necessary to lay a large amount of firewood during the first kindling, let the firebox heat up well and “burn out” for some time. And next time, use the amount of firewood that you need to create warmth and comfort in the house.

Video. Do-it-yourself fireplace with a cast-iron firebox.