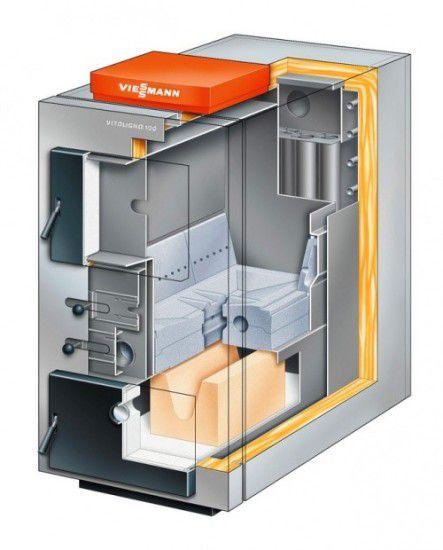

The most efficient way to use wood fuel is gas-fired wood-fired boilers.

Depending on the modification or manufacturer, the efficiency of such installations can reach 95 percent. In such devices, wood fuel burns almost completely, leaving no residue.

Gas-fired boilers were once used even for driving cars, but now they firmly occupy the traditional niche for boilers - they are used for space heating and water heating. What is the principle of operation of a gas-generating boiler, and how to choose a gas-generating boiler when buying?

Content

The principle of operation of a gas-fired boiler on wood

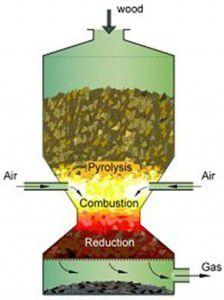

When operating a gas-fired boiler, wood is used principle of pyrolysis. After laying the fuel (firewood or special wood briquettes), they go through several stages of combustion. Consider them:

- Initially, wood fuel enters a special chamber, where it is dried.

- The wood fuel then burns while maintaining a temperature between 20 and 850 degrees Celsius. At the same time, practically no oxygen enters the combustion chamber.Thus, wood fuel is oxidized,

- The gas obtained as a result of oxidation enters the combustion chamber, where it is ignited and burns using burners.

Wood-fired gas-fired boilers used for heating purposes have a special water circuit. Inside it, water passes through two heating chambers, and only then enters the heating radiators.

Fuel for gas generating boilers

The undoubted advantage of gas generating boilers is the fact that they can operate on almost any type of solid fuel. That is, they can be loaded with ordinary chopped firewood, as well as any types of wood waste (sawdust, shavings) and briquettes, pellets and the like made from wood waste. In addition, gas generators are practically waste-free production: the fuel in them burns almost without residues.

Advantages of gas-fired heating installations

The installation of heating systems powered by gas-generating boilers operating on wood fuel has the following undoubted advantages:

- Extremely high fuel combustion efficiency. In any plant designed to burn wood fuel, but not using the pyrolysis effect, the efficiency cannot rise above 90 percent.

- Gas generator sets are non-volatile and can be installed even in buildings that do not have a connection to a stationary power grid. Note that during the war, gas generators were placed even on cars. The energy independence of the gas generator set also reduces the cost of its operation.

- Almost any type of wood fuel can be used in a gas generating plant, from classic firewood to wood waste. The use of wood waste, sawdust, wood chips and so on significantly reduces the cost of gas generating systems. However, remember that out of the total amount of fuel at a time, the percentage of wood waste should not exceed 30 percent.

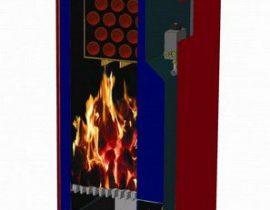

- Large volumes of the combustion chamber allow gas-generating boilers to operate for a long time from one fuel load, which facilitates the operation of such an installation.

Disadvantages of gas generating plants

Despite all the attractiveness of heating and heating systems based on gas generating installations, such devices also have certain disadvantages. The disadvantages of gas generating systems generally coincide with the disadvantages of conventional solid fuel boilers.

A solid fuel boiler, unlike automated liquid or gas systems, has limited autonomy. Such a boiler always needs a human operator who will add fuel as it burns. Also, the gas-generating boiler must be regularly serviced, cleaned of soot and soot. Despite the almost complete combustion of organic wood fuel in gas-generating boilers, decay products are still present in such systems.

The acquisition of a system with a gas-generating boiler is quite costly financially. According to rough estimates, a gas-fired boiler will cost you one and a half times more than a conventional solid fuel boiler.But the difference in cost should pay off after a few heating seasons, based on the higher efficiency of the gas-fired boiler.

Also, when operating gas generating installations, it is necessary to use only dry fuel. On wet wood or sawdust, the pyrolysis process may simply not start. Therefore, gas-fired boilers are often equipped with a drying chamber in which the fuel reaches the desired condition.

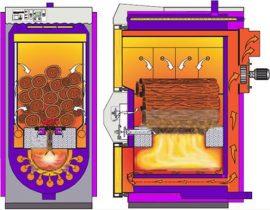

Comparison of gas generating and conventional boilers.

If we compare gas-generating boilers with conventional heating or heating boilers for solid fuels, then the following nuances can be distinguished.

The relatively low autonomy of the gas-generating boiler, which is the Achilles' heel of all solid fuel heating installations, can be corrected with the introduction of an automatic loading system. In this case, a kind of conveyor starts working in the gas-generating boiler, which, depending on the temperature in the device and the burning time, can send new portions of fuel to the furnace. In addition, the gas generating device can operate autonomously during the day only on one tab, which, in general, removes the question of the need for the constant presence of a stoker-operator.

In any case, the efficiency of gas generators significantly exceeds the achievements of all their counterparts. If conventional solid fuel boilers are unlikely to show an efficiency above 85%, then for gas-generating equipment this figure can reach 95%.

But a wood-burning gas-fired boiler is still a rather complex technical device.Unlike a conventional wood-burning boiler, it requires even simple, but still regular maintenance, in addition, there are certain requirements for the qualifications of personnel who work on gas generating installations.

The gas-generating boiler most critically perceives the humidity of the fuel entering it. Therefore, only pre-dried firewood is required for the efficient operation of a gas generating installation.

Selection criteria for a wood-fired gas generator

It is recommended to select a gas-fired boiler on wood based on the following criteria:

- First of all, it is necessary to take into account the degree of automation of the boiler, its non-volatility. You may want to purchase a boiler that can work for a long time without human intervention, and perhaps a gas-generating boiler will be enough for your purposes, which should independently, autonomously work out only one bookmark.

- For space heating, heating installations must generate at least one kilowatt for every 10 square meters of heated area. Based on this, you can choose the required power of the heating gas-generating boiler.

- In addition, wood-fired gas-fired boilers may have various additional equipment. It can be intended, for example, to provide forced circulation of liquid through the heating control or to automate the regulation of combustion processes of the resulting gas.

In any case, consultants in specialized stores will help you choose a gas-fired wood-fired boiler to your liking.

Gas-fired boilers on wood: video

An honest video review on the operation of the gas-fired pyrolysis boiler Dragon TA-15