Why are combined heating boilers that can run on both gas and wood gaining more and more popularity?

Combined heating boiler for wood and gas

When choosing a heater for your home, you need to rely on different product criteria and take into account its various parameters, as well as the essential features of your home. But start with accessibility. certain type of fuel at the place of the planned installation of the boiler, and from that, on which of the species will be the main rate.

It should be noted that combined boilers are currently being produced that can run on gas, solid or liquid fuels and electricity, and, the transition from one to another type of fuel occurs automatically. Such options are good because always there will be an alternative to one or another source of energy, and in any case it will be warm in the house. In addition, significant savings can be achieved.

If to the house let down gas, heating problems do not arise. There are a large number of heating boilers operating on this fuel on sale, so you can easily choose the right one. However, if there is no shortage of solid fuel in the area of residence and there is a desire to save on natural gas, then the market offers the widest selection of combined boilers that can heat houses, both on wood and on gas, they have a number of positive qualities.

Anywaywhen choosing a heater, it is better to rely on the knowledge of specialists with whom you need to consult by bywater characteristics and operation of a particular heating device.

Content

- At what point does a wood burning boiler turn into a gas boiler?

- The undeniable advantages of heating boilers on gas and wood

- Selection options, what to look for when buying?

- Boiler installation and safety

- Operation of the instrument, how to increase the service life?

- Heating boilers Kupper - the most efficient combined boiler for wood and gas

At what point does a wood burning boiler turn into a gas boiler?

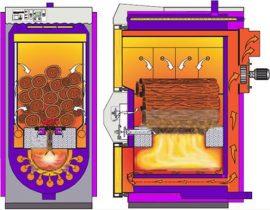

This boiler can work not only with the use of firewood, but also on another solid fuels such as briquettes, coal and pellets.

Combined boilers are heavy, as their design includes parts made of cast iron, for example combustion chamber. That's whywhen installing such equipment, it is possible have to strengthen the floors by making a separate foundation for them.

Gas-firewood boilers are manufactured in two versions:

- single-circuit, which are used only for heating the building;

- double-circuit, allowing not only bring the house is warm, but also provide the family with heated water.

The productivity of such a plant can reach 700—750 liters of heated water per hour.

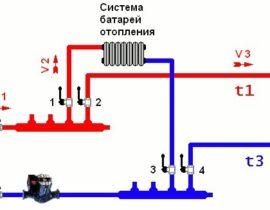

Combined heaters can be one- or two-furnace. In the second version at the bottom firebox there is a gas burner, and in the upper one there is a wood burner, often with pyrolysis afterburning. The heating of the furnaces takes place simultaneously, and the sedimentation of the combustion products is carried out on a tray intended for this, which is installed in case of use solid fuel.

The undeniable advantages of heating boilers on gas and wood

To the benefits given combi boiler can be attributed to the following characteristics:

- having two cameras — for gas burner and combustion solid fuel;

- the possibility of connecting several heating circuits to one boiler, those. at the same time, it is possible to heat not only the house, but also, for example, a bathhouse and a garage or other buildings adjacent to the house;

- independence of heating from power supply, and if necessary, then from gas supply;

- ease of installation and repair of this equipment — does not require special technical knowledge or high financial costs;

- The efficiency of such a boiler is 90—95%;

- boiler does not occupy a large area, although it is desirable that it be in a separate room — boiler room;

- insignificant and relatively safe release into the atmosphere.

Selection options, what to look for when buying?

What points should be paid special attention to when choosing a combi boiler?

- The first most important parameter — is the power of the device. It is she who speaks of the possibility ensure the temperature regime necessary for comfort in specific buildings. under standard conditions and calculations required 1 kW power on volume 30 cubic meters. These settings are good for insulated at home.

If an accurate calculation power, then have to turn to specialists. To do this, they need to provide a complete description of the building, which includes the region of location, climatic conditions, degree of insulation, types of heating that are already available, the purpose of the room and other parameters.

An important factor will be the gas pressure in the main line, since the efficiency of the boiler will largely depend on it. If there is a need, then calculation experts will include in the data and power shortages.

- Second, what must be taken into account — what you want to get from the boiler. If you plan to use it only as a heating device, a single-circuit option is selected. If you need to heat water, you can not do without a double-circuit model.

Double-circuit boilers can have a system of flow heating of water or, more perfect, cumulative, those. with built-in boiler. They take up much less space than a single-circuit boiler plus a boiler or column. yes and connection cost cheaper and easier. The built-in boiler, depending on the displacement, will always have a sufficient amount of heated water. With continuous heating warm water will flow only when the device is turned on for heating.

If a purchased single-loop boiler, then it is possible if desired, over time, connect a boiler to it.

- When purchasing a heating boiler, necessarily it is necessary to check the presence of the attached certificate certificate. Without this document, it will not be possible to obtain permission to connect to the gas supply system and register it with the relevant organizations.

Boiler installation and safety

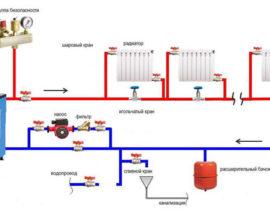

The room for the boiler room may be small, but it is necessary insulated. Its size must be agreed with special services that will help, if necessary, draw up a plan for wiring and connecting pipes.

Ventilation elements must also be taken into account in the room, since the removal of waste from fuel combustion is mandatory. To do this, chimneys are arranged, the structure of which directly depends on the power of the heating installation. Sometimes the chimney system goes complete with heating boiler.

As mentioned above, the surface on which to install boiler, should be strengthened, but other than that, her must be heat resistant. Sometimes floor under the device is left concrete, but it can be decorated with ceramic floor tiles.

If the floors in the room are wooden, but arranged reliably, you can proceed as follows: a concrete block 10 cm thick is laid, and an eight-millimeter sheet of metal is placed on top of it. Another option is to lay refractory boards. It is very important to perfectly level the floors for the installation of the boiler. This processss prcarried out using the building level.

The walls near which the appliance will be installed, also should be made of heat-resistant materials. The lower part of the wall is best finished with metal sheets or asbestos.

When boiler installed, it can be connected to a heating circuit or to two circuits — water heating and heating.

For every weekend or entrance boiler pipe, it is best to install a separate tap — this is necessary so that, if necessary, it is possible to dismantle the device, without draining water from all circuits.

If you decide to do the installation of the boiler yourself, then when you first start it, it is best to invite a specialist in this field who will check the correct installation and control the start of the system.

Operation of the instrument, how to increase the service life?

Boileroperating on mains gas and solid fuel — optimal variant dlI'm heating the house since the gas served constantly, and problems with the purchase of firewood and other solid fuel should not be. Firewood or coal should always be kept in reserve so that they can help you out in any situation.

In addition to fuel, for heating the whole house, one cannot do without water, with which the system is filled once. And the filling process must be slow in order to prevent the formation of air bubbles inside the circuit, which can damage the uniform supply of the heating medium to the entire system. Periodically, usually before the winter season, the system is supplemented with water to the desired level.

It is necessary to pay special attention to this particular model of the boiler, since it works not only on gas, but also on solid fuel. All heating appliances that use wood and coal require cleaning the chimney, as German soot and soot settle.

It is very important to use dry firewood for heating, at least its moisture content should not be more than 20%, so it is better to buy this fuel in a special store.

Thanks to the built-in boiler automation, uninterrupted supply of heated water will be provided to you anyway, because when burning solid fuel automatically turns on the heating of water with gas.

Heating boilers Kupper - the most efficient combined boiler for wood and gas

Boiler, running on gas and wood, can be called the most affordable and convenient heating for a private house or cottage. The device is convenient and easy to use, you can cope with it without much difficulty and additional training.It is also important that it requires almost no special maintenance.