Almost every owner of his own house or suburban housing faces the question of heating. This issue is also relevant for urban residents during the period of hot water shutdown. Parapet boilers are an innovative and efficient heating solution.

Heating systems with parapet boilers involve the use of parapet boilers, the fuel for which is gas. Such systems have a number of specific advantages:

- the console of a copper has several conclusions and works by the principle of "geyser". So one of the advantages is the possibility of acquiring a boiler with a different outlet of communication pipelines;

- the possibility of purchasing a boiler with variable power (15-40 kW). This is due to the different needs for heating rooms of various sizes;

- parapet-type boilers can be used simultaneously for heating water in a “hot” pipeline, as well as for heating water in heating radiators;

- an excellent combination of efficiency (the ability to adjust the cost of gas and heat transfer), functionality (control from an electronic remote control, etc.) and performance. Quality and reliability at a relatively low price;

- environmental friendliness and smokelessness, thanks to the closed combustion chamber and diffusers;

- excellent performance indicators.

First of all, the popularity of using parapet boilers in country houses and buildings is due to their ergonomics, the boiler is called a parapet boiler, because it can be installed in the kitchen in one of the headset cabinets, the boiler can also be placed in the wardrobe of the toilet room or simply under the windowsill in masonry.

Content

The device of parapet boilers

The entire design of the boiler can be divided into the main components:

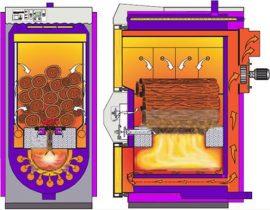

- heat exchanger, a unit in which the energy from the combustion of gas is converted into heat. Heat exchangers are small tanks made in a rectangular shape from two halves, which are connected by welds. The requirements for heat exchangers are in two main conditions: accessibility to the seams during repair, efficiency and complete homogeneity of the material;

- "turbine" for accelerating the flow of heat, gas and water through process pipelines. The "turbine" can be powered by gas flows, having a light alloy construction for speed of movement, or it can be forced on;

- combustion chamber, in which the combustion of liquid gas occurs. The gas enters the boiler via communication, where it is condensed and compressed in the reducer, after which the gas is supplied to the nozzles. Through the nozzles, injection occurs and subsequent ignition by piezoelectric elements in the combustion chamber. The combustion chamber has a non-linear perforation, that is, a perforation that is connected to a heat exchanger, this is done in order to discharge the pressure arising from the combustion of fuel;

- automatic relays that allow the boiler to turn off and on in automatic mode, maintain a constant supply and temperature;

- gas and water communication pipelines serve to supply fuel to the boiler and return heated water to heating systems and pipelines;

The entire design of the boiler and all the components is a box measuring about half a meter by 30 and 30. Small dimensions, however, do not speak against the boiler.

Do-it-yourself installation of parapet boilers: step by step instructions

First of all, when installing boilers of this type, it is necessary to remember several rules that form the basis of safety:

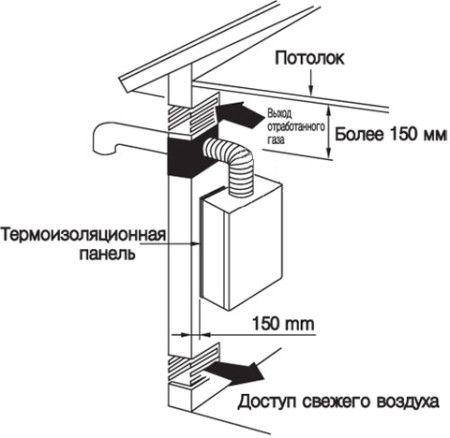

- although the boiler can be installed in any accessible place near communications, it is still necessary to adhere to fire safety measures: it is advisable to attach the boiler to a fireproof wall at a distance of 15 to 25 centimeters from flammable objects; it is also necessary to remember that gas boilers and columns require at least rare supervision and caution when using. Diagnostics and some “TO” are also needed;

- since the fuel for the boiler is gas, it is necessary to remember about the ventilation system and the tightness of the entire structure;

- The output of combustion products that may occur during the adjustment of the boiler or its incorrect operation, or the “active heat phase” is carried out through a coaxial pipe - a pipe that has several diameters. Therefore, it must be remembered that the chimney should not be removed through balconies or loggias, but should be placed inside walls or masonry on the leeward side.

These rules are basic and have a characteristic minimum that must be considered before installation.

Mounting process

The whole procedure can be laid down in several successive steps.

Well, of course, we purchase the boiler, unpack it, read the instructions and proceed as follows:

- first you need to decide on the place of laying gas and water communications in the house or lay communications with the calculation of the installation of the boiler. After that, next to the approximate installation site, we lay the grooves for the chimney of the coaxial pipe and the conclusions of the “active phase of heat” - the products of unburned gas to the outside;

- what is typical for parapet boilers is the presence of ball cut-off valves for all communications, which means that it is necessary to take care of tightness. This is the first security issue. To seal all threaded connections, you can use liquid sealant, Tangit tape or Fuma tape, which perfectly seals connections when screwing;

- the boiler must be installed on special spars that fix the boiler to the wall.

First start of the boiler

Absolutely all modern imported and domestic boilers are equipped with an automated start-up system, fuel supply and an emergency shutdown system.

Emergency shutdown system: this system is activated in the event of a sharp drop in fuel pressure, which is recorded on electronic pressure gauges. A sharp drop in pressure indicates a gas leak, which in itself is dangerous and requires an emergency shutdown of the "receiver", that is, the consumer-boiler.

Automated start: this function allows you to set the start of the boiler on a timer, as well as set the frequency of feeding. This greatly facilitates operation and saves fuel when the boiler operates in “sections” of 15-20 minutes and turns off for an hour or two, maintaining a constant temperature regime.

Automatic fuel supply allows you to constantly maintain the combustion mode in constancy.

For the first start-up of the boiler, it is necessary to observe all these parameters, using the installation data, which are given separately for each boiler in the instructions. The first start-up must be carried out with a minimum efficiency and increased gradually at regular intervals, this will allow the boiler to “ignite” and check the main operating parameters.

Parapet boilers are an excellent combination of quality, relatively low cost and unsurpassed functionality. Parapet boilers are the choice of thousands and thousands of homeowners.

Video - connecting and using a parapet boiler in a private house