Wood-burning boilers for home heating are still popular, despite the variety of models of gas and electric boilers, and there is a simple explanation for this: firewood is the most affordable type of fuel for country houses that are not connected to the main gas.

The efficiency of modern wood-burning boilers is quite high, their efficiency reaches 85%, while not only firewood, but also pellets, as well as woodworking waste can be used as fuel.

Wood-burning boilers used for heating a country house are easy to connect and use - they are even easier to handle than a stove. They are safe as long as they are properly installed and operated. The only serious drawback of wood-burning boilers is the low level of automation of the process: fuel must be loaded into the boiler manually. The way out of the situation can be a boiler with a long burning function or a combined boiler that runs on solid fuel and has an additional diesel or gas burner or an electric heating element.

Content

Wood boilers - device and principle of operation

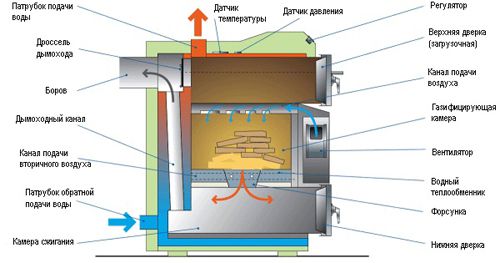

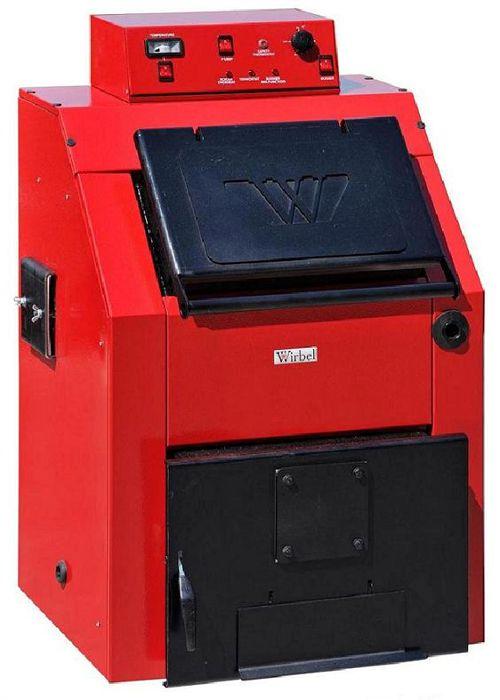

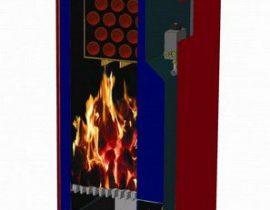

Despite the huge selection of models of wood-burning boilers, their device does not differ so much.Any wood-burning boiler for home heating necessarily has a fuel combustion chamber, a water heat exchanger, a chimney and an ash pan. The simplest wood-burning boiler resembles a potbelly stove with a water jacket: when wood is burned in the furnace, the water heats up and enters the heating system. The efficiency of such a boiler is low, and the consumption of firewood is significant, due to incomplete combustion of fuel, part of the money flies into the pipe in the literal sense of the word. The design of modern boilers with a long-term burning function is, of course, more complicated; the device of such a boiler and its main elements are shown in the figure.

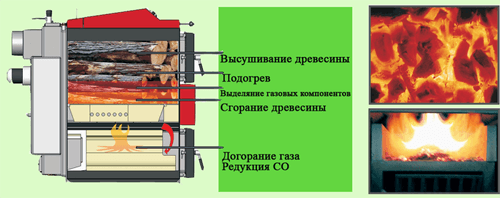

Firewood is loaded into the boiler through the top loading door at once in a large volume. The initial fuel combustion takes place in the gasification chamber. The flow of air, and with it the oxygen necessary for combustion, into this chamber is limited - this is how the intensity of combustion is regulated. In this mode, the firewood does not burn, but smolders with the formation of more heat, while the water is heated in the heat exchanger. But the combustion process does not end there: during smoldering, smoke is formed containing combustible gases. These gases enter the second chamber - the combustion chamber, which also serves as an ash pan. The air supply to this chamber is no longer limited, and with a sufficient amount of oxygen, afterburning of gases occurs. The combustion temperature of the gas-air mixture is very high, and the heating efficiency of the water heat exchanger in this chamber is also very high. As a result, the smoke is cleaned of ash and harmful combustible gases, which makes the new generation wood-burning boilers very environmentally friendly.

Video - the principle of operation of a long-burning wood-burning boiler

Smoke is removed through a chimney channel connected to the chimney and pipe. To supply cold and discharge hot water from the heat exchanger, the boiler is equipped with branch pipes. They are connected to the heating system according to the selected scheme. Boilers of the new generation are equipped with automation, which makes it possible to simplify the maintenance of the boiler as much as possible:

- a temperature sensor that sends a signal to the primary air supply fan;

- pressure sensor, signaling the excess of the normal value;

- water pressure sensors in the system.

The efficiency of solid fuel boilers directly depends on the type and quality of fuel. If the boiler is designed to work on wood, coal and peat briquettes must not be loaded into it! This will reduce the efficiency of the boiler and may damage it. It is also not recommended to use poorly dried firewood and softwood for burning a wood-burning boiler - they burn with the formation of a large amount of steam, tar and soot, and the boiler will have to be cleaned much more often.

Wood boilers - choice

The choice of a wood-burning boiler must begin with the calculation of the required power - this parameter is indicated in the passport for the boiler and is measured in kilowatts. One kilowatt of boiler power is enough to heat ten square meters of a well-insulated room. For example, in the middle lane, a boiler with a power of 10 kW is needed to heat a house with an area of 100 square meters. For frosty days and poorly insulated rooms, a power reserve of 20-30% is required. When choosing, it is worth paying attention not only to the rated power, but also to the entire range in which the boiler can operate - in autumn and spring it is not advisable to heat the boiler at full power.If you plan to use the boiler also for hot water, then you will need an external boiler and an additional boiler power reserve based on the number of people permanently living in the house.

An important role is played by the material of the boiler - steel or cast iron. Steel boilers are lighter and have a simpler design of the furnace, which is easier to clean - just remove the ash from the ash pan. The smoke channel of steel boilers is longer, so the heat carrier is heated more efficiently. In cast iron boilers, the smoke channel is shorter, and a large heat exchange area is achieved due to the ribbed surface in which combustion products settle; the cast iron boiler will have to be cleaned using brushes, scrapers and a poker. At the same time, the heat capacity index of the boiler itself is higher for cast-iron models.

Electric wood boilers can be distinguished as a separate type, which, with the help of electricity, further increase efficiency. Modern automation monitors the combustion process and influences it with the help of valves that regulate the flow of incoming air into the furnace, so you can control the temperature in the furnace at a given level!

An important indicator is the ratio of the volume of the loading chamber to the power of the boiler. In simpler terms, how many times a day you will have to approach the boiler to load fuel. For steel boilers, this figure is usually higher - an average of 1.5-2.5 l / kW versus 1.1-1.4 l / kW for cast iron ones - therefore, loading is carried out less often.

Be sure to check the availability of an emergency cooling system and clarify how it works. This system may be needed in case of overheating of the boiler and boiling water in the heat exchanger.Boilers with a separate emergency cooling circuit are safer, but if emergency cooling is arranged by abruptly draining the water from the heat exchanger and replacing it with cold water, make sure that the boiler is resistant to thermal shock.

Protection against burns is an important indicator, especially if unauthorized people or children have access to the boiler room. A useful option is heat-insulated firebox handles, protective casings and grates, thermal insulation of the most heated surfaces of the boiler.

Wood boilers - installation requirements

Efficient and safe operation of a wood burning boiler is not possible without proper installation. How to install the boiler with your own hands without violating safety rules?

Installation location

Any wood-burning boiler consumes a fairly large amount of air during operation, therefore, for small-capacity boilers that can be installed in the common areas of the house, supply and exhaust ventilation is performed, and with a boiler power of more than 50 kW, it is necessary to equip a separate boiler room with a useful room volume of 8 cubic meters. Wood boilers are installed on a solid, even base with a fireproof coating - concrete, tile, porcelain stoneware. The walls must also be lined with non-combustible materials. The boiler room is equipped with forced ventilation.

Chimney Requirements

The chimney for a wood-burning boiler is made of stainless steel, ceramic or thick-walled metal pipe. Sandwich stainless steel chimneys are the best choice. They are easily assembled from various elements - pipes fastened with clamps, roof passages, unloading platforms.When bending such a chimney, bends at a certain angle are used. It is allowed to lead the chimney of the boiler not through the roof, but through the wall of the building. The height of the straight part of the chimney for stable draft in the boiler must be at least 6 meters for a 16 kW boiler and at least 10 meters for a 32 kW boiler, with a pipe diameter of 200 mm.

Service and Maintenance

It is also necessary to clarify the terms of service and warranty service of the selected boiler model, the proximity of service centers and the possibility of calling specialists for installation and repair. It may happen that the maintenance of a cheaper model will cost much more than that of analogues of well-known companies that have service centers in large cities.

Video - self-installation of solid fuel boilers

Wood boilers for home heating after installation are connected to the water heating system. For uninterrupted operation of the system, you can additionally install a heater tank on electric heating elements in it, in this case you do not have to throw firewood during a night's rest or absence from home.