In our time, efficient and economical use of fuel is very relevant.

Long burning wood stoves for home heating

After all, in the cold season, you often have to independently heat private houses, summer cottages, garages, greenhouses and other premises.

Many of us think about how to do it efficiently and with minimal financial costs. With one of these simple and effective solutions, we will get acquainted below.

Content

- What is "pyrolysis"? Using the effect of pyrolysis in furnaces

- Advantages and disadvantages of long burning stoves

- How to make a long burning stove yourself?

- Features of operation and maintenance

- Alternative fuel for long burning stove

- Video: Pyrolysis oven from a barrel

- Video: Homemade pyrolysis oven

- Video: Long-burning stove from a cylinder

What is "pyrolysis"? Using the effect of pyrolysis in furnaces

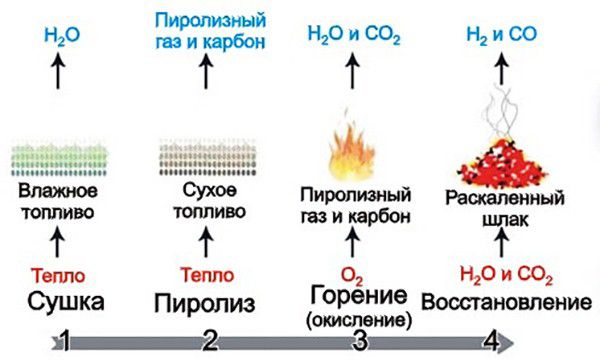

Before we proceed to a direct consideration of the subject of our article, it is necessary to get acquainted with such a term as pyrolysis. This is a process during which any complex chemical compounds are decomposed into simpler components.A prerequisite for this is the impact on the substance of high temperature, which is clearly indicated to us by the prefix "pyro", which is present in the term.

In a narrower sense, pyrolysis means the decomposition of fuel elements such as wood, coal, pellets (granulated fuel from wood or organic waste) and some others. Probably, many will be surprised, but when burning firewood, it is not wood that ignites, but gaseous products released during its heating. In fact, when kindling an ordinary fire, we still encounter the process of pyrolysis. But under normal conditions, combustion occurs in the presence of a sufficient amount of oxygen, which, ultimately, negatively affects the overall efficiency of our fire or stove. Full-fledged pyrolysis requires limiting the supply of an oxidizer and burning gases separately from smoldering wood or other fuel, for a more complete and economical use of fuel.

General scheme of the combustion process

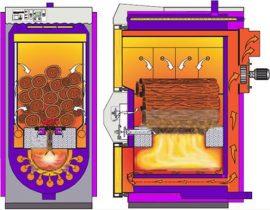

To date, there are many variations and design solutions that allow you to create a long-burning furnace. However, despite all the technical differences, the principle of operation of such heating devices remains the same. To ensure better and more efficient fuel consumption, a long-burning wood stove uses the pyrolysis effect discussed above. Thus, the main part of thermal energy is generated due to the combustion of gases released during the decay of wooden logs: methane, hydrogen and other substances. The smoldering of firewood is caused by specially dosing the supply of oxygen to the stove with the help of a regulator.First, the fuel is given the opportunity to flare up qualitatively for about half an hour, and then the access of the oxidizer to the furnace is minimized. Smoldering firewood in such conditions emit the maximum possible amount of flammable gases, which, burning in a separate chamber, provide heating of the pyrolysis furnace body and high-quality room heating.

You should not try to increase the efficiency of a conventional wood-burning stove by making it go into smoldering mode. The pyrolysis oven must be completely sealed! The usual one in the smoldering mode will simply release combustible gases through the chimney to no avail. And a worse option is also possible: carbon monoxide and other smoldering products will enter the house through leaky oven doors, creating a serious threat to your life.

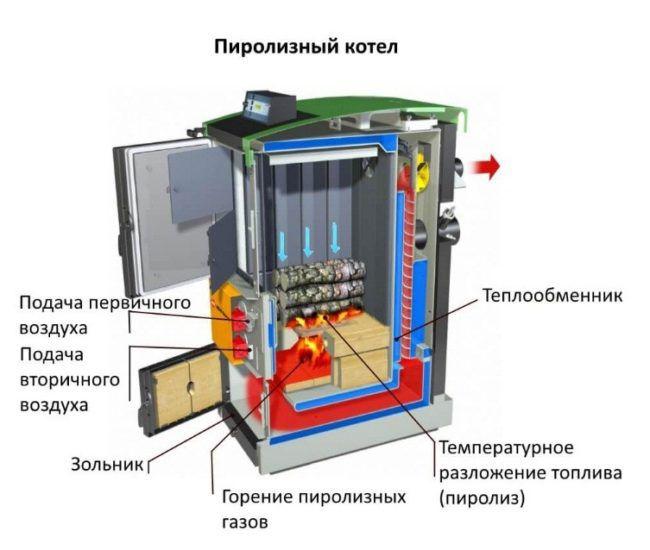

Often, the design of a pyrolysis furnace provides for the presence of a water cooling circuit, turning it into a full-fledged boiler for the heating system. You can see an example of such a boiler diagram in the figure below.

Schematic diagram of the pyrolysis boiler

Advantages and disadvantages of long burning stoves

Actually, let's start with the advantages of pyrolysis furnaces, since there are plenty of them in this design:

- Almost complete combustion of fuel. As a result, long-burning boilers have excellent efficiency indicators, reaching a level of 85%

Comparison of the efficiency of boilers of different types

- Cleaning and maintenance of long-burning stoves is quite simple, since there is practically no ash left after the fuel burns out.

- Environmental friendliness. With the complete combustion of any organic compounds, only water vapor and carbon dioxide are the products of oxidation.The unpleasant odor emitted during the combustion of organic waste is a consequence of incomplete combustion of fuel, when toxic under-oxidized compounds remain as a result. In a pyrolysis furnace, combustible materials decompose completely, therefore, various industrial wastes can be safely used as an energy carrier for it, the burning of which under normal conditions is only allowed at a considerable distance from residential areas at special landfills.

- Loading a new batch of firewood or other fuel must be done much less frequently, about once every 10-15 hours, which is twice as high as conventional stoves and stoves. Some industrial models of pyrolysis boilers can work even longer on one portion of fuel.

- High heating rate of the coolant in the presence of a heat exchange circuit for heating the house.

- The possibility of high-quality and precise adjustment of the power of the boiler. Under normal conditions, it is quite difficult to control the operation of solid fuel heating installations, unlike analogues using liquid or gaseous fuels. But since in the pyrolysis furnace the gas emitted by solid fuel is afterburned in a separate compartment, this problem is also quite effectively solved.

The disadvantages of pyrolysis plants include:

- The high cost of finished pyrolysis boilers. Self-manufacturing allows you to compensate for this shortcoming.

- More stringent fuel moisture requirements. If you use under-dried wood and try to put the unit into operation before it dries, the fire may go out and full pyrolysis will not start.

- Pretty impressive size.In addition, you will need to provide additional space for storing firewood or other fuel.

- The impossibility of completely autonomous work. Fuel will need to be loaded into the oven by hand.

- Industrial models of pyrolysis boilers often use additional blowing of the combustion chamber and pumps for pumping coolant in the heating circuit. Thus, the installation will need to ensure an uninterrupted supply of electricity.

- The risk of extinguishing the pyrolysis chamber under the influence of too much cooled coolant from the heating circuit. This situation is called reverse. To prevent such an incident, a bypass pipe is additionally installed in the structure, through which already heated water is mixed with the cooled water. As a result, the device of the boiler becomes more complicated, and the cost increases. However, a home-made pyrolysis oven without a connected heating system is devoid of this drawback.

How to make a long burning stove yourself?

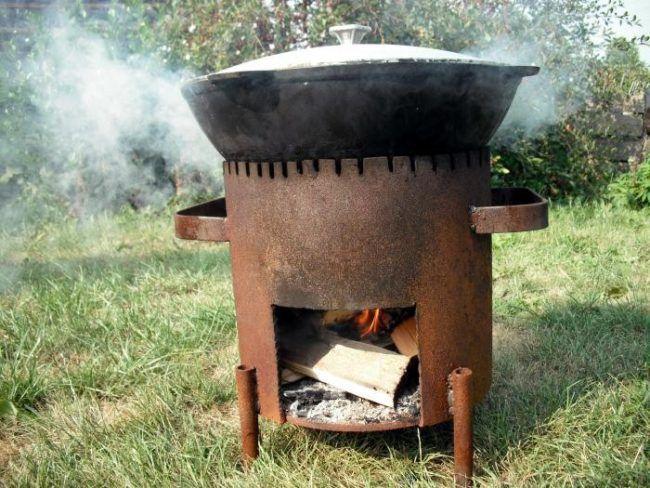

Of course, the easiest way is to purchase a finished oven, since the range of available models is very wide. However, if you want to save money and you are interested in making a pyrolysis boiler with your own hands, then you should definitely continue reading this article. You can make a long-burning stove from an old gas cylinder, a metal barrel, sheet steel, or other suitable improvised materials. And now we will learn how to do it.

Video: pyrolysis boiler from an old gas cylinder

Preparation of materials and tools

So, from the materials we need:

Metal barrel 200 l | Large metal barrel.Its estimated capacity should be about two hundred liters. Its walls must be durable, made of steel or cast iron, without rust and other visible damage. |

A large fire extinguisher is a good base for a stove | Old large volume fire extinguisher |

Thick wall steel pipe | A piece of wide metal pipe with thick walls; |

The old balloon can still serve you | Used gas bottle |

The thickness of the sheets must be at least 5 mm | steel sheets |

| For a boiler with a round base, support legs will be required. They can be made from: | |

Armature legs | pieces of reinforcement; |

Pipe legs | Pieces of a thin pipe; |

Metal profile legs | Metal profile (channel); |

In addition, you will need:

| |

As for the tools, their list is quite small. In our work we will need:

- Ax with a hammer;

- Electric welding portable (or stationary) installation;

- Bulgarian or its substitute in the form of autogen;

- A standard set of marking and measuring tools in the form of a level, plumb line and tape measure;

The choice of the room in which the installation work will be carried out is also important. You must have constant access to electricity, good lighting and ventilation.You should choose spacious rooms with high-quality sound insulation, which will be protected from the effects of precipitation and where it will be possible to safely store all manufactured elements of the pyrolysis oven.

Wood stove assembly instructions

The installation algorithm for a long-burning pyrolysis furnace consists of the following steps:

Barrel with lid removed | We remove the lid from the barrel. If a fire extinguisher or a cylinder is used as the basis, then its top must be carefully cut off with a grinder (or autogen). The sawing of the cylinder should be done by first opening the valve and pouring water inside. Remember that the top part will still be useful to us later, do not rush to throw it away. |

Square ovens are more stable | When making a furnace from sheet steel, keep in mind that a square body will have more stability, rather than a round one. |

Pyrolysis furnace from a barrel with legs | On the round bottom of the base of our furnace, we weld support legs from pipes, fittings or a channel. |

General scheme of a long-burning furnace | We make a clamping circle. It is cut from a steel sheet in such a way as to freely pass into the barrel. |

Clamping ring welded to the pipe | We connect the circle with the pipe. To do this, cut a hole with a diameter of 10 cm in the center of the pressure circle and weld it to the circle so that when the resulting part is placed inside the barrel, the pipe protrudes 15 cm above its level. |

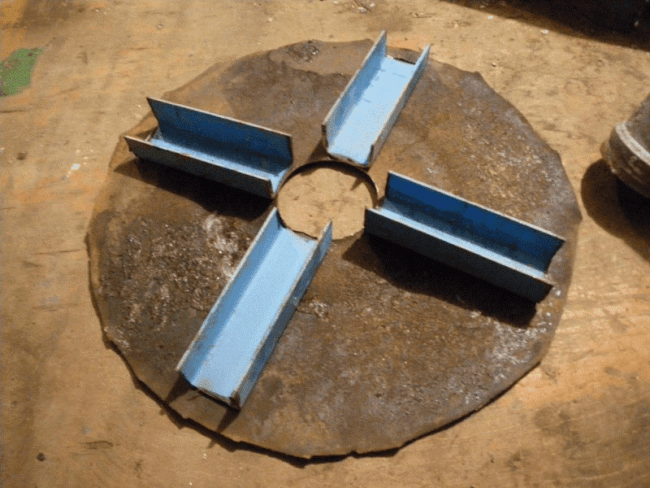

Channels welded to the circle | On the reverse side of the circle, we weld channels crosswise, which will contribute to a better pressing of smoldering firewood. |

Barrel oven lid | We make a lid for our oven. It can be either the upper part cut off at the first stage, or the second steel circle.We also make a round hole in the lid so that the inner tube with the pressure circle moves freely under its own weight and at the same time fits snugly against its edges. |

oven door | We mount the door. In the lower part of the base of our pyrolysis oven, we cut a hole for the door and fix it so that after the firewood burns out, the ash can be easily removed. |

Chimney installation | Fixing the chimney. We cut a circle with a diameter of 15 centimeters in the upper part of the stove body and fix the chimney pipe by welding. Remember that the minimum length of the pipe must be greater than the cross section of the barrel or other base. |

| It is advisable to provide a valve for the chimney, which will allow you to further adjust the level of draft. So that it can be cleaned, many make this element of the furnace design collapsible or mount a special door for cleaning. Condensate is more actively collected in the chimney of pyrolysis furnaces, so it is advisable to insulate it. For example, you can cover the pipe with a heat-insulating material and put on top another one of a larger diameter. In addition, thermal insulation should also be provided in places where the chimney passes through the walls, ceiling and roof of the house. The end of the pipe, in order to prevent atmospheric precipitation from entering, must additionally be protected with a reflector. | |

After assembling the pyrolysis oven, it is advisable to lay a brick around it, which will accumulate heat and help protect the surrounding interior items from excess heat.

Features of operation and maintenance

A long-burning wood-burning stove, in view of its structural differences, has a number of individual features associated with the operation and maintenance of the finished product.Let's look at them in more detail.

Kindling a long-burning stove

It is necessary to melt the pyrolysis oven as follows:

- We remove the lid and take out a pressing circle with a welded pipe from the inside of the barrel.

- We load firewood (or alternative fuel). The maximum level of wood loading will be at the lower edge of the chimney. Logs should be stacked as close as possible to each other, with minimal gaps. From above, on a layer of firewood, we throw a few small dry branches, which we cover with rags soaked in kerosene (or other kindling liquid). If there is no rag at hand, plain paper can replace it.

Ignition of the pyrolysis oven

- Install the clamping circle and close the barrel with a lid. After that, we set fire to a piece of rag or paper and throw it inside the pipe with a pressure circle.

- Matches will not work for you to ignite a long-burning pyrolysis stove, because during the time they fly inside the pipe, the fire at their end will go out.

- About half an hour later, after the firewood flares up well, we restrict air access to the stove with the help of a damper and enjoy warmth and comfort for many hours.

The nuances of operating a pyrolysis furnace

When installing the stove in a room, observe the following rules:

- Since the long-burning stove is very hot, any fusible and combustible materials should be placed away from it.

- There should be plenty of free space around the pyrolysis oven. Place it away from walls and furniture to avoid damage due to excessive heat. However, as already mentioned above, this and the previous problems are partially solved by installing brickwork around the perimeter of the furnace.

- Always leave a small layer of ash after cleaning the oven. This will save our unit from premature burning of the bottom and boiler failure.

Alternative fuel for long burning stove

Of course, dry logs will be the best fuel for a pyrolysis boiler. But, since one of the main goals of installing a stove is to save on space heating, some other combustible materials that are constantly at hand are quite suitable.

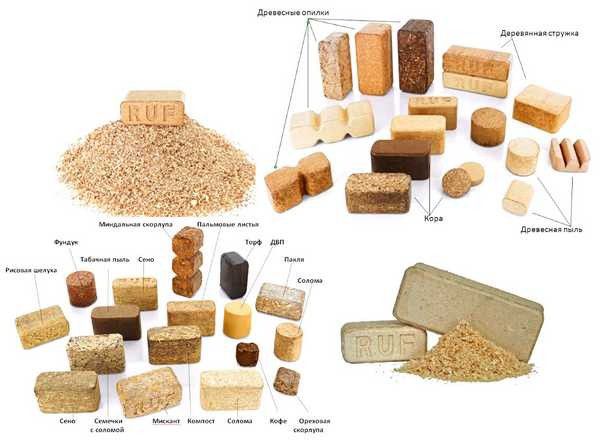

Alternative fuel for long burning stoves

Firewood can be replaced by inexpensive pellets (fuel pellets) made from pressed wood and agricultural waste, such as cones, sawdust, wood chips, seed or onion husks, as well as other environmentally friendly materials. Coal is also suitable, however, it is necessary to take into account the fact that this type of fuel gives off a very powerful heat. It can be loaded into furnaces with a thick steel body, otherwise the pyrolysis furnace will quickly become unusable.

Video: Pyrolysis oven from a barrel

Video: Homemade pyrolysis oven

Video: Long-burning stove from a cylinder