Despite the huge number of heaters on the market, a popular option is a long-burning solid fuel boiler.

Homemade TT long burning boiler

This unit can be used as the main source of heating in remote areas where gasification and electrification are not provided. Reliable, efficient and economical, it is an excellent solution for heating a country house, a cottage in the city or a summer house.

Unlike a conventional boiler, where the main heat comes from the flame itself, a long-burning TT boiler works on a completely different principle. This article will discuss how to properly make a long-burning solid fuel boiler with your own hands, and the drawings and installation diagram will help you not to make a mistake and do everything technologically correct!

Content

- The principle of operation of the long-burning boiler

- Design feature

- Advantages and disadvantages

- Useful tips for making a TT boiler

- Security measures!

- Step-by-step instructions for creating a solid fuel boiler for long burning with your own hands

- Step 1. Marking the case and making the case

- Step 2. Making a pipe

- Step 3. Making a pipe to the chimney

- Step 4. Making an ash pan

- Step 5. Preparing the air supply system

- Step 6. Making a heat exchanger

- Step 7. General assembly and installation of the boiler

- Step 8. Kindling the boiler

- Step 9Boiler installation indoors

- Step 10. We connect the boiler to the chimney.

- DIY solid fuel boiler - video instruction

The principle of operation of the long-burning boiler

In conventional solid fuel units, one bookmark is enough for 6-7 hours of burning. Accordingly, if the next portion of resources is not added to the furnace, the temperature in the room will immediately begin to decrease. This is due to the fact that the main heat in the room circulates according to the principle of free movement of gas. When heated by the flame, the air rises and exits.

The thermal resource of a long-burning boiler is enough for about 1-2 days from one laying of firewood. Some models can keep warm up to 7 days.

How is this cost-effectiveness and efficiency achieved?

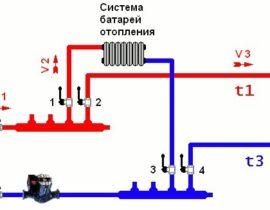

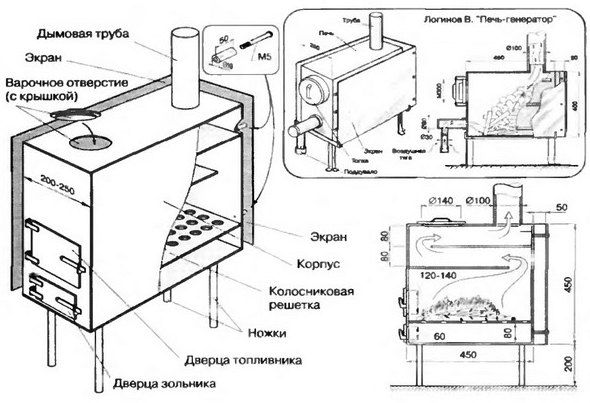

Boiler operation scheme

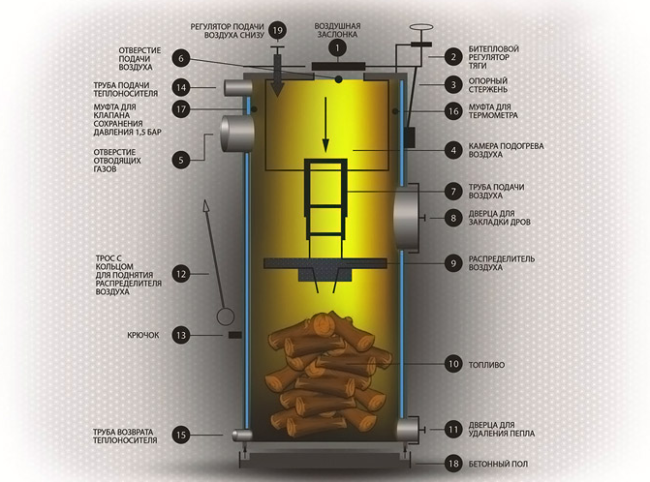

From a conventional boiler, a TT long-burning boiler is distinguished by the presence of two combustion chambers at once. In the first, the fuel itself burns as standard, and in the second, the gases released during this process.

An important role in this process is played by the timely supply of oxygen, which is provided by the fan.

This principle has been implemented relatively recently. In 2000, the Lithuanian company Stropuva presented this technology for the first time, which immediately gained respect and popularity.

Homemade long-burning boiler

Today, this is the cheapest and most practical way to heat a country house, where gasification is not provided and there are power outages.

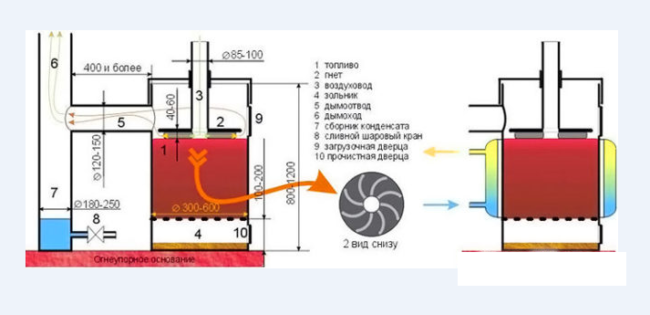

Such units operate on the principle of burning top fuel. As a standard, in all furnaces, the firebox is located at the bottom, which allows you to take cold air from the floor, heat it up and lift it up.

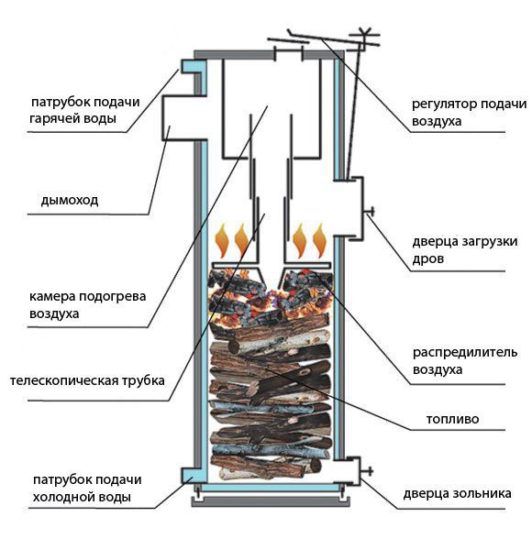

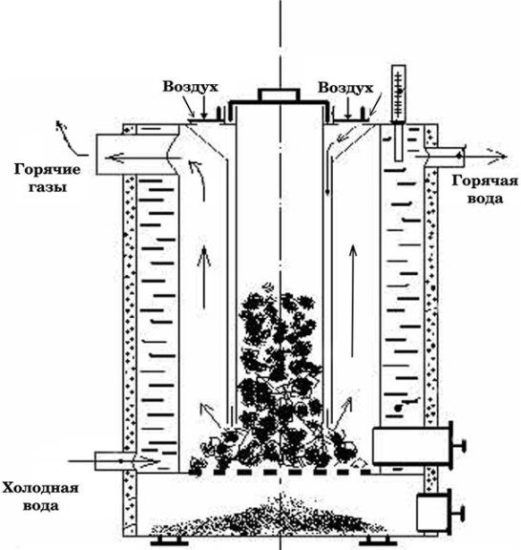

The principle of operation of this boiler is somewhat similar to pyrolysis.The main heat here is released not from the combustion of solid fuel, but from the gases released as a result of this process.

The combustion process itself takes place in a closed space. Through a telescopic pipe, the released gas enters the second chamber, where it is completely burned and mixed with cold air, which is pumped up by the fan.

TT long-burning boiler (diagram)

This is a continuous process that occurs until the fuel burns out completely. The temperature during such combustion is reached very high - about 1200 degrees.

As mentioned above, this boiler has two chambers: the main one is large and small. The fuel itself is placed in a large chamber. Its volume can reach 500 cubic meters.

Any solid fuel can act as a resource for combustion: sawdust, coal, firewood, pallets.

A constant air supply is carried out by a built-in fan. The advantage of this method is that solid fuel is consumed extremely slowly.

This significantly increases the efficiency of such a heater. Why does firewood burn out so slowly compared to a standard stove?

The bottom line is that only the top layer burns out, since air is blown by a fan from above. Moreover, the fan adds air only after the top layer has completely burned out.

There are many models on the market today that work on the same principle, but, depending on the dimensions, material of execution, additional options, have different efficiency and economy.

Fuel versatility

Universal TT boilers operate on absolutely any fuel, which will greatly simplify their operation for the owners.A more budget option is a wood-fired TT long-burning boiler. It works exclusively on wood and cannot be loaded with any other fuel option.

Design feature

Any long-burning boiler is equipped with an impressive chamber where fuel is placed. The larger the boiler is equipped with a chamber, the more time the firewood will burn through.

Today you can find two technologies implemented in long-burning TT boilers that successfully compete with each other. These are Buleryan's principle and Stropuva's method.

Due to the high price of Stropuva and the complexity of the design, this method is not so popular in Russia. But according to the Buleryan method, craftsmen with great dedication design units for heating dachas and country houses.

TT boiler diagram

The boiler according to the Buleryan method looks like this: a metal case, inside of which there are two chambers. In the lower chamber, fuel is burned, and in the second chamber, the gas coming through the tube from the first chamber is burned.

The door for loading fuel is located in the upper part of the boiler body, since the entire lower part is reserved for a large resource tab.

At the top of the boiler is a flue pipe, which is connected to the chimney. An ash chamber is built into the lower part, through which the boiler is cleaned.

One more nuance should be mentioned. In standard ovens, the ash pan acts as a blower through which the air necessary for combustion is blown. Here, the ash chamber is absolutely hermetic, since the air enters through the upper air chamber, which plays the role of a heat exchanger.

The supply of oxygen to the boiler is regulated by a damper located at the top of the air chamber.As the firewood burns, the fuel gradually settles and the distributor lowers. This ensures a continuous supply of oxygen.

With a new load of fuel, simply pull up, returning the dispenser to its original position. By the position of this lever, you can easily determine how much fuel is left in the boiler and when to carry out the next load.

Separately, it should be said about the environmental friendliness of this heating option. Due to the complete combustion of fuels and gases, carbon dioxide is practically not emitted into the atmosphere.

The main elements of the TT long-burning boiler

The main elements of the TT boiler:

- Furnace chamber. This is the main element of any boiler and furnace where direct combustion of fuel takes place.

- Gas combustion chamber. Hot gases from smoldering firewood come here.

- Ashpit - here the ashes are collected. This unit must be systematically cleaned to keep the boiler in good technical condition.

- A chimney is a node through which combustion products are removed to the outside.

boiler device

All these nodes are enclosed in a steel case, which is made of sheet metal 5-6 mm thick.

Advantages and disadvantages

Due to the large dimensions, the complexity of the design scheme, it is rational to use such a unit for heating a large cottage. But for a small cottage, this option is not suitable, as it will not justify the economy.

pros

- high efficiency (about 95%);

- autonomy of the heating system;

- profitability;

- reliability and durability;

- high efficiency;

- fuel availability;

- environmentally friendly home heating option;

- versatility of fuel (coals, firewood, sawdust, pellets).

Read our material on which long burning boilers are better.

Minuses

- cumbersome design;

- under the device it is necessary to equip a special room;

- complexity of design and installation;

- the need for constant cleaning.

It is not necessary to buy a long-burning boiler ready-made, because its price is several times higher than conventional furnaces. Such a design can be done independently, if you have at least a little experience in construction and repair.

The appearance of a homemade design

A home-made design, compared with a factory counterpart, has a number of advantages:

- low cost;

- the ability to make the boiler universal for any type of fuel;

- the possibility of improving the design and adding power.

The only difficulty is giving a cylindrical shape to the boiler. It is very difficult to give such a shape to metal without a rolling machine.

But there is a good solution. You can use empty propane tanks or any pipe of a suitable diameter. Pipes with a wall thickness of at least 5 mm should be selected.

For a village and a small cottage, you can fold a small brick oven and enjoy its effectiveness. But for a large cottage, this option will be less practical, as it will require a large supply of firewood for the winter. Caring for a conventional stove, compared to a long-burning boiler, is much more difficult, and large temperature drops in rooms remote from the stove do not at all allow organizing a comfortable microclimate in the house.

If you don’t have enough money to create a full-fledged heating system for your home, or the construction of such a system itself is impractical, it would be much more reasonable in this situation to make a long-burning solid fuel boiler with your own hands and not worry about its safety and aesthetic appearance.

Useful tips for making a TT boiler

- If you want to make a TT boiler universal in terms of the use of raw materials, then use a pipe made of heat-resistant alloy steel for the combustion chamber.

Alloy Steel Pipe for Boiler

You can significantly reduce the cost of building a unit if you take a seamless steel pipe of grade 20.

- Before installing the boiler in the place determined for this unit, carry out the first kindling on the street, equipping the boiler with a temporary chimney. So you will be convinced of the reliability of the design and see if the case is assembled correctly.

- If you use a gas cylinder as the main chamber, then keep in mind that such a unit will provide you with combustion for 10-12 hours due to the small amount of fuel being put in. So the small volume of the propane tank will decrease after cutting off the lid and ash pan. To increase the volume and ensure a longer burning time, two cylinders must be used. Then the volume of the combustion chamber will definitely be enough to heat a large room, and there will be no need to lay firewood every 4-5 hours.

- In order for the ash pan door to close tightly, preventing air from entering, it must be well sealed. To do this, lay an asbestos cord around the perimeter of the door.

asbestos cord

If you will make an additional door in the boiler, which allows you to “reload” the fuel without removing the cover, it must also be tightly sealed with an asbestos cord.

For the operation of a TT boiler, the diagram of which we attach below, any solid fuel is suitable:

- hard and brown coal;

- anthracite;

- firewood;

- wood pellets;

- briquettes;

- sawdust;

- shale with peat.

There are no special instructions for the quality of fuel - any will do. But keep in mind that with a high moisture content of the fuel, the boiler will not give a high efficiency.

Security measures!

In order for such a boiler to really be an effective and economical heating option, last a long time and not cause burns or accidents in the house, consider the main points of fire safety.

TT boiler

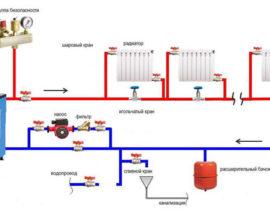

- It is necessary to monitor the temperature in the system and prevent it from overheating.

- A shut-off valve must not be installed on the pipeline.

- Do not keep flammable objects near the boiler.

- It is necessary to monitor the ventilation in the room.

- For the boiler you need to equip a separate room.

At the stage of preparatory work, consider the place where the boiler will be installed.

Ideally, of course, equip a separate boiler room, because the operation of a long-burning TT boiler is somewhat different from the usual wood-fired brick oven. And outwardly, this unit will not please the eye, and serve as a decoration for the house.

Given that solid fuel still creates a certain amount of dirt, it is better to install a long-burning TT boiler in a non-residential area.

But if its power is small (does not exceed 30-35 kW), then you can simply separate (zone) the main room from the "boiler room" using a brick wall.

Be sure to provide a ventilation system in the room where this boiler will be operated. On a constant basis, oxygen must be supplied from the street.

Step-by-step instructions for creating a solid fuel boiler for long burning with your own hands

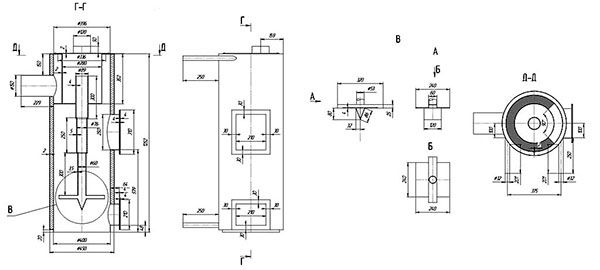

The project of a solid fuel boiler is not an easy task and it will not be easy for a beginner to cope with it. Before starting construction, prepare drawings and sketches.

Drawing homemade solid fuel boiler

Also prepare the following tools:

- Welding machine.

- Tools for working with metal: pliers, grinding wheel.

- Electric drill.

- Building level and tape measure.

- Marker.

- Bulgarian.

- Gloves and eye shield.

Attention! When performing work on the manufacture of a home-made TT boiler for long burning, you should be very careful and have at least basic practice with a welding machine. Be sure to use protection when working with welding.

From the materials you will need:

- Empty gas bottle.

- Sheet metal.

- Asbestos cord.

- Steel pipe with a cross section of 60 mm.

- Metal hinges and handles.

- Metal corner or blades.

- Metal hood.

- Basalt fiber for the passage of the chimney.

Before starting production, we suggest that you familiarize yourself with the video instruction on how to properly cut an empty gas cylinder, watch carefully and do not neglect safety measures!

Step 1. Marking the case and making the case

Using a marker, mark out the propane tank according to the dimensions of the drawing.

We make a small rectangular hole under the ash pan door, through which the boiler will be cleaned.

On the top of the balloon (along the entire perimeter) we draw a straight line to cut off the top.

Using a grinder, cut off the top along the line.

Cut off bottle top

Now, in the center, we mark up the hole through which the pipe will pass. The hole, respectively, must be larger than the diameter of the pipe.

We cut a hole in the lid and weld on a metal ring that will tightly wrap around the pipe inserted into the cylinder.

Weld the ring around

We scald with a small sheet metal ring (4-5 mm) from the outer and inner sides the cylinder itself, on which the lid will be put on.

Step 2. Making a pipe

We take a metal pipe with a length of 80 to 100 cm. If you do not use a standard propane cylinder, but weld the body for the boiler yourself, keep in mind that the height of the pipe should be 20-25 cm higher. After all, the essence of the work lies in the fact that as the fuel burns out, the pipe inside the body will go down.

We weld a metal circle to the pipe in its lower part - an air distributor.

Cut off bottle top

We cut out fasteners from sheet metal, which we securely weld along the cut line of the cylinder, having previously laid an asbestos cord.

Weld the handles to the lid

We fix the cut top so that it can be easily removed and put back. Make metal handles and, for ease of removal, also weld them to the body.

Step 3. Making a pipe to the chimney

We make markings on the cylinder in its upper part under the opening of the pipe.

We weld the pipe

We cut it out with a grinder and weld a pipe to remove combustion products.

Then a steel chimney pipe is connected to this branch pipe.

Step 4Ash pan manufacturing

According to the previously made markings for the ash chamber, we cut out a hole with the help of a grinder.

Cut out the ash pan

Separately, we make a door from sheet metal, which then will need to be screwed onto the brackets to the boiler body.

Hole for ash pan door

For convenience, you can make a small loop of thick wire or a reinforcing rod and screw it on as a handle.

Step 5. Preparing the air supply system

Measure the inside diameter of the cylinder body. Now draw a circle on the sheet metal, the diameter of which will be 5 mm smaller than the inner diameter of the balloon.

Using a grinder, cut out this circle.

What does the air supply system look like?

We take a metal corner and cut it into 6 equal parts. The size of each part is equal to ½ of the diameter of the metal circle. For these purposes, an impeller with old blades is still well suited.

Making an air supply system

We weld metal circles in the same direction counterclockwise.

Step 6. Making a heat exchanger

We will make a heat exchanger designed according to the principle of a water circuit.

Making a heat exchanger

The size of this heat exchanger depends on your personal preferences. The larger it is, the more firewood you can put into it, which means that your boiler will have a longer burning time.

We cut out sheets from sheet metal 5-6 mm thick according to the scheme and weld them into a reliable case, inside which our gas cylinder will be located.

In the upper and lower parts of the body, we make branch pipes for connecting the supply and return lines.

In the central part, it is necessary to provide a hole through which fuel will be placed.We carry out the markup using a marker and cut it out with a grinder.

Step 7. General assembly and installation of the boiler

We fasten the ash pan door to the firebox.

We mark on the body of the heat exchanger the place where access to the ash pan will be made and cut it out with the help of a grinder. We also equip this opening with a door, which should close very tightly, blocking the access of oxygen to the body.

Assembling the boiler

We insert the balloon inside the heat exchanger.

Using a welding machine, we weld the tank from above, as a result of which we get an absolutely sealed case, inside of which there is a round firebox.

The essence of the TT long-burning boiler is the limited air supply from above, the function of which is performed by the oxygen supply system.

Fuel (wood, coal, briquettes) should be loaded very tightly so that there is as little space as possible between the layers. If the firewood is different in size and it is impossible to pack them tightly, then between the layers you can fill it with wood chips or paper. The denser this solid fuel mixture is, the longer the firewood will burn.

Boiler load must be tight

How will such a boiler be loaded?

- we take out the air supply restrictor from the case;

- We load fuel through a special door. It is better to pre-sprinkle the fuel with a special ignition fluid;

- put back the pipe limiter;

- inside the boiler we throw a lit match;

- after making sure that the fuel gradually begins to smolder, close the door tightly.

As the firewood burns out, the pipe inside the cylinder will gradually lower. By its height, you can always find out how much firewood you currently have inside.

Step 8. Kindling the boiler

You can make such a simple boiler right on the street in the warm season and test it outdoors by equipping it with a temporary chimney.

Boiler kindling

If the area of the room exceeds 30-40 square meters, then two cylinders can be welded vertically, thus increasing the amount of firewood.

Step 9. Installing the boiler in the room

Be very serious about the fire safety of the boiler.

Under it, it is better to allocate a separate room or make a small fence from the residents to prevent burns. Still, the body of the boiler is metal and, unlike a stone stove, there is a high probability of getting burned.

Install in a place where there is a possibility of chimney outlets. There are two ways to remove the chimney: through the roof or through the wall.

Keep in mind that you must have direct access to the boiler, so nothing should stand at a distance of 50 cm next to it.

- Make a brick base for the boiler, laying solid bricks in 2 rows. Check the slope of the base with a building level.

- Observe the distance from the walls (regulated by SNiP). The distance from the furnace door to the wall must be at least 125 cm. The distance between the side parts and the back of the boiler and the wall must be at least 700 mm.

- If the walls in the house are made of wood or any other combustible material, it is necessary to protect the place where the boiler adjoins the ceilings with sheet metal or basalt. It is possible to use ordinary bricks as thermal insulation, which should be laid around the perimeter of the junction of the boiler to the wall.

In the place where the chimney exits through a wall or roof, it is also necessary to ensure proper thermal insulation.For this, basalt fiber is suitable, which should be tightly laid between the chimney and the ceiling.

- Place the boiler on the prepared foundation and again check with a level that the appliance is level. Keep in mind that the gas outlet pipe must be at the same level as the chimney pipe. If the line is not horizontal, then traction may be impaired during operation.

Step 10. We connect the boiler to the chimney.

Attention! It is imperative to lubricate the joints of the joints of all parts of the chimney with sealant.

We connect the chimney pipe to the TT pipe of the boiler. The diameter of the chimney must not be smaller than the TT socket of the boiler. If these parameters are not observed, then the throughput of the gas outlet will decrease.

Chimney connection

As you can see, doing everything with your own hands you can get excellent, everything is not as difficult as it seemed at first glance! If you strictly followed the instructions, then you will quickly appreciate the high performance and efficiency of a long-burning solid fuel boiler, which is several times superior to its competitors with the open flame principle. This will allow you to maintain a comfortable microclimate in the house with minimal maintenance.

DIY solid fuel boiler - video instruction