Modern heating systems are currently developing mainly in the direction of increasing their efficiency. The greatest demand due to the increase in energy prices is received by heating devices with a high level of energy efficiency - receiving maximum heat performance with an equal fuel load. Long burning coal boilers have become a real breakthrough in the development of energy efficient combustion devices.

Main characteristics of boilers

A modern long-burning coal boiler is able to work for a long time without human intervention. It does not need to be controlled, there is no need to constantly throw fuel into it. At the same time, a constant high temperature is maintained in the boiler for a long time, transferring heat to the heat exchanger to the coolant.

What is the effect of long burning?

The basic principle of operation of long-burning coal-fired boilers is the process of burning fuel from top to bottom. During the combustion process, all the incoming fuel is not burned at once, the process is extended, but the temperature in the furnace remains quite high.

Advantages of long burning boilers

Boilers of long burning on various types of solid fuels, including coal, have many undeniable advantages:

- Saving energy. In such a device, there is not a one-time combustion of all the incoming fuel, but a process that is rather reminiscent of smoldering, in which the fuel-coal that has entered the furnace is burned in layers, from top to bottom. The process of air intake for the chemical reaction of combustion is regulated by automatic devices. The gradual combustion process also leads to the fact that the fuel burns out almost completely, with unburned residues accounting for no more than 2 percent of the initially loaded mass.

- The long-term combustion boiler does not require the constant presence of the operator and constant maintenance. In some modifications of such boilers, up to 500 liters of combustible material can be loaded simultaneously. As a result, the combustion process of such a mass of fuel can take up to several days. Routine work is carried out in the intervals between fuel fillings. In addition, the automatic controlled combustion produces much less soot, which also results in a reduction in the maintenance time of the device.

- Usually solid fuel boilers are prone to overheating. This is due to the uneven combustion process. In a long-burning boiler, the whole process is controlled automatically, which leads to an even temperature distribution. This mode is most beneficial for heating systems, as it constantly maintains comfortable conditions in the home.

Disadvantages of long-burning boilers

But for obvious advantages, you have to pay with visible disadvantages.The presence of sophisticated automation significantly increases the cost of long-burning boilers and they can cost up to two times more than a conventional design with a similar capacity.

In addition, since the combustion process is fully automated, the operator cannot interfere with the operation of the boiler during the process itself. Thus, it is not possible to extend the period of coal combustion in such a device during the current cycle, which can create certain inconveniences during operation.

Physical foundations of the process of long burning

Modern boilers use all the same old laws of physics and chemistry that we all went through in school. Everyone knows that in order for any object to burn faster, it must be set on fire from below. Also, combustion accelerates with the influx of air into the lower part of the combustion area. Actually, on this fact, ordinary traditional fireboxes are arranged, which are equipped with grates from below to ensure air flow.

But if you supply air to the mass of fuel loaded into the furnace from above, and not from below, you can achieve a slowdown in the combustion process. To check this fact, take an ordinary match and light it. If you turn the match upside down, it will burn very quickly, but if you turn the match upside down, it will burn for a long time. The burning time of a match in this experiment is approximately doubled.

It is on a creative approach to this physical property that these heating devices are based.

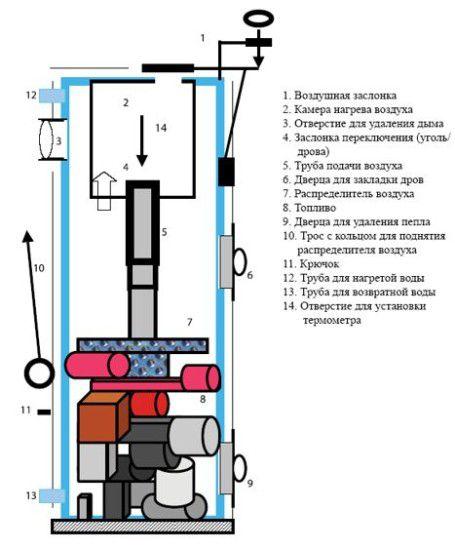

Step by step process from coal loading to ash collection

The process of long-term combustion in heating devices is provided in the following way:

A large amount of fuel is loaded into the combustion chamber. In some modifications, it can reach a volume of 500 liters.

Through the upper air duct of the device, an air flow is supplied to the combustion chamber. Air is supplied in a limited amount, which leads to smoldering, not burning with an open fire.

The heating system has a specially arranged heat exchanger. In traditional ovens, the heat exchanger is located in the upper part of the furnace - in the place of greatest heating. In the chambers, the heat exchanger coil runs along the walls of the entire inner surface of the combustion chamber. This leads to an increase in system efficiency of up to 95 percent.

The whole process of long-term combustion is controlled by sensitive automatic devices. Automation provides a uniform supply of air flow consistently to all layers of the combustible fuel, thereby ensuring its complete and uniform combustion. Complete combustion of the loaded fuel, uniformity of heat output increases the efficiency of devices compared to traditional ones up to 75 percent.

Where is the best place to install a long-term combustion boiler?

Boilers for long-term combustion on coal fuel are one of the most profitable alternatives for the undisputed leader - gas heating. This option for building an autonomous heating system can be recommended to owners of houses that are located in an area that does not have main gas supply. The natural choice would be for those areas of our country, near which there are deposits of this mineral.

However, when choosing an installation, you should also be aware of the negative aspects that arise:

Long-term combustion boilers must be connected to an electrical power source without fail. Actually the process itself is ensured by the work of complex automation, which works on electrical appliances and sensors. If electricity fails in your house, the boiler will automatically stop working, while the smoldering in the combustion chamber will stop.

A long-burning boiler has a rather high cost. A good modification of the boiler will cost you a starting amount of a thousand dollars. Therefore, such devices, as a rule, are placed in country houses intended for permanent, year-round use. Installing such a boiler in a small country house is simply unprofitable from an economic point of view. However, the entire price of the device payback in five years simply due to significant savings in the volume of purchased fuel.

Necessary equipment

In addition to the boiler itself, when installing an autonomous heating system based on such a device, you will need the following additional equipment:

- Uninterrupted power supply unit. A UPS can help you deal with power outages and stay warm when your heating system shuts down.

- The pump for circulation of the heat carrier. A number of boilers use the natural fluid circulation process. But in a row of buildings, the natural flow of the coolant is simply impossible. If you forcibly drive the coolant with a circulation pump, the efficiency of your heating system will increase significantly.

- Consider installing an indirect heating boiler.In this case, you will be able not only to provide heat supply to your building, but also to create a hot water supply suitable for domestic use. This will certainly increase the level of comfort in your home.

Such systems are the pinnacle of modern technological thought, and engineers from leading concerns are constantly working to improve these devices and increase efficiency.

Long burning coal boiler ТТ (40 kW)