Boiler long burning has become an excellent replacement for furnaces of various types, which require constant fuel supply. Its advantage lies in the long-term heat transfer to the room, and means, there is a saving not only in time, but also in fuel.

Such a boiler has other useful positive qualities that will help solve some household problems. There are many models of boilers of this class on sale, from which you can choose the one that suits you in terms of characteristics and price, but there are more one option — make such a heater yourself.

Content

Principle of operation

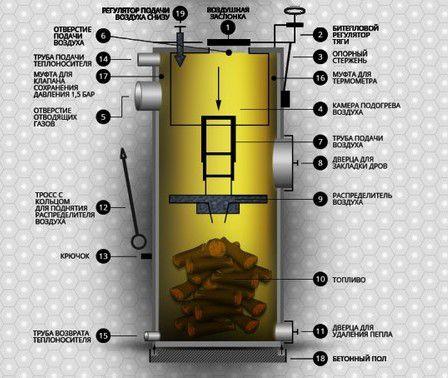

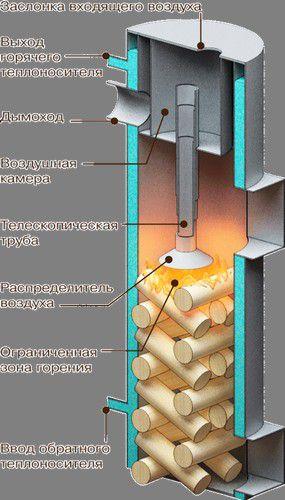

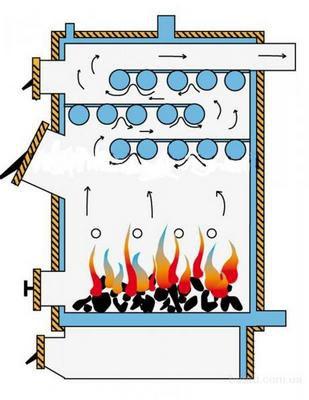

Long burning of boilers is achieved due to the design of the heater, which includes an additional combustion chamber dedicated in the process of burning wood fuel gas.

The principle is — the fuel placed in the furnace, in the almost complete absence of oxygen, is not subjected to active combustion by an open flame, but means, there is its long smoldering with heat transfer.In order to form a sufficient amount of gas, when burning fuel, after laying firewood, kindling the boiler and the appearance of an active flame, ventilation pumps are automatically turned on, which remove excess oxygen from the furnace and put combustion into a smoldering state.

In addition to the heat emanating from the fuel, gas is released during slow combustion, which enters the additional chamber through ceramic or metal pipes or nozzles. It happens in the chamber afterburning gas, assisted by the system blowing air. Here, the final combustion of the remaining products of fuel combustion, for example, soot and other heavy connections.

With the usual design of the furnace, the fuel after combustion leaves a lot of products (waste), which are also capable of producing heat when burned. This was taken into account by the developers of long-burning boilers. The chamber where secondary combustion takes place traps the released heat inside the structure, preventing it from immediately escaping into the chimney.

More one advantage of the combustion of emitted substances lies in the environmental friendliness of the smoke emanating from the furnace, since all toxic products from combustion are destroyed in an additional compartment afterburning.

Did they understand the text? Watch the video!

In addition, such boiler has one feature: if in all furnaces fuel combustion occurs from the bottom up, then in long-burning furnaces, on the contrary, from top to bottom. This factor also slows down the combustion process, preventing the fuel located below the fire from heating up quickly.

In such boiler a large amount of firewood is loaded at once, those. the combustion chamber is filled to the top. After ignition, it is hermetically sealed with a door.The amount of oxygen supplied is controlled by an air regulator.

The combustion chamber for combustion waste and exhaust gas can be located at the bottom, top or rear of the boiler — it depends on the specific model.

The fuel for this unit can be used: firewood and coal, sawdust and peat, as well as other materials. It doesn't matter which kind solid fuel will be used to load the boiler, but mainto keep it dry enough. Excessive humidity will reduce the power of the heating installation, which will be used to dry firewood, and reduce the production of secondary fuel — pyrolysis gas.

After the combustion of any fuel in a long-burning furnace remains a small pile of ash, so a very small door is provided to remove it.

Differences of a double-circuit boiler

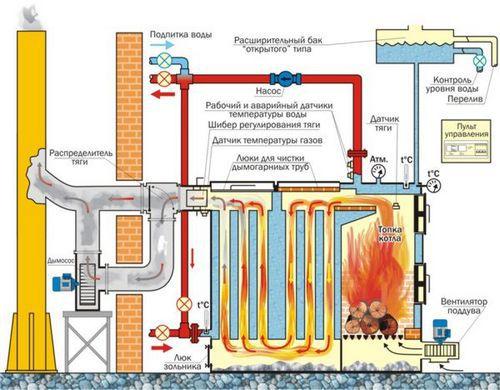

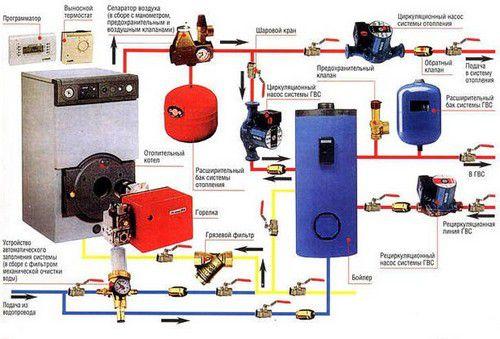

Boiler long burning may have not one circuit, but two. Thus, it can not only heat the room, but also heat water for household needs. Such units are equipped with a heat exchanger or a water jacket. — This section is where the water is heated.

The heat exchanger built into the system can have a flowing water system or in the form of a storage boiler. For the heating system, of course, the heat exchanger must work according to the flow principle, but for DHW it can be both flow-through and boiler.

For domestic hot water, it is more convenient to choose an indirect heating boiler of large volume. It will allow you to always have hot water, as it will be constantly heated, and keep the temperature even after the completion of the furnace for a long time.

In addition to the water circuit, the design of the boiler is no different from conventional boilers operating on this principle.

Combined boilers

Boilers operating only on solid fuel, install mostly, in buildings located in areas where other types of energy resources are not available. If it is possible to connect to the gas pipeline, it is better to use a combined boiler. It will be much more convenient to use and more economical financially.

The design of the combined options is supplemented by a gas burner and automation. They begin to heat the stove, for example, with firewood, and when they burn out and the boiler cools down below the set temperature, the automation is activated, and gas heating is turned on, which maintains the coolant at the desired temperature. Such boiler it can be single-circuit, but have a built-in boiler in the overall system.

In addition, there are models of boilers that run on electricity instead of gas.

Positive characteristics of the boiler

Any of the units described above has unifying and individual positive qualities, which is why today they are installed in country houses and replace old brick ovens with them.

- Long-burning boilers have good performance and have very high efficiency, which goes up to 90—95%.

- If in the boiler built in automatic fuel supply system, it maybe work for a long time without human intervention. The term of such work is indicated in the passport of the unit.

- The efficiency of the device is explained by the ability of the design during normal operation to reach temperatures up to 600—650 degrees.

- Boilers — environmentally friendly appliances, since not only the fuel is burned, but also carbon monoxide generated during its operation.

- It is always possible to regulate the intensity of combustion.

- Modern boilers are equipped with automation, which allows you to control them through the remote control, as well as through him receive a signal about problems that have arisen during operation.

- The convenience of combined boilers lies in the use of different types of fuel, which allows you to significantly German save.

- Boilers with a water circuit have the ability to control the water temperature, how for heating and hot water.

- With a large number of positive qualities of the unit, it has a very affordable price.

- Easy to install and operate, as well as unpretentious maintenance and the ability to do it yourself, without involving specialists.

- Compactness, in comparison with brick structures.

Objective shortcomings

The negative points in using the boiler include:

- Fuel is loaded into the device manually.

- In some models, there is no water temperature control, so when choosing a boiler, you need to pay special attention to this.

- Requires ample space to store firewood or other solid fuel.

- There are certain requirements for drying the furnace material.

- When using combined models, it will be necessary to allocate a separate room for the system — boiler room.

These are quite significant drawbacks for those who have a small area of \u200b\u200bthe house, but if you need to install heating, you can always find a way out.

Is it possible to build such a boiler with your own hands?

If desired and in the presence of some skills quite possible do boiler long burning for solid fuel on your own. For efficiency it doesn't matter at allwhat form will boiler — round, made from a barrel or gas cylinder, or welded from metal sheets. The main thing — well-organized internal system.

Video example construction of a home-made long-burning boiler "from Maxim"

The simplest design of a long-burning boiler

The proposed diagram clearly shows how in a completely simple way it is possible to create conditions inside the boiler to retain hot air, which will significantly prolong the cooling process.

Of all the options for boilers that you can do yourself, having a rectangular shape will be the most compact and aesthetic. He is excellent fit for heating a small room, and if it is somewhat modified, it will warm a large area.

The design of the boiler is quite simple and for her quite affordable materials will be required, and their quantity will depend on the size of the intended unit.

The meaning of the design is to prevent the heated air from going directly into the pipe.For this, devices are arranged inside, consisting of metal plates and pipes welded in a special way and creating a kind of labyrinth between themselves, through which the heated air should slowly leave. The upper compartments, with proper organization of the supply of additional air, will play the function of cameras afterburning. If desired, boiler from the inside, overlay with fireclay tiles or bricks installed on the edge. You can arrange brickwork outside the heater.

To make such boiler need to prepare: metal sheet at least three mm thick, steel angle 4×4 or 5×5 cm, cover for the hole in the hob, chimney pipe of the required configuration, length and diameter. All material is purchased based on a pre-compiled scheme.

- first step goes cutting of all metal parts after sizing according to scheme. Details must be cut carefully, then align the edges with a stripper grinder.

The following details are cut out: the bottom and walls of the boiler, panel grate, cooking panel, two or three internal panels to create a labyrinth exit of heated gases.

- Further, holes for the burner and chimney are cut out in the hob. Two rectangular openings are arranged in the front panel for the firebox and the blower. The cut plates are scalded — they will be used for the doors, and should close tightly. They are attached to hinges that are welded to the panel and doors. Then valves are fixed on them.

- Front panel work in progress — one plate is welded with her inner side. It should be smaller than the side walls on 7—8 centimeters those. it should not reach the back walls on specified distance. From the top bar her located at a distance of 10—12 centimeters.

- Further, goes work with back wall — on the her on the inside, two metal panels are welded, the same size as on the front. One of them is fixed at a distance from the top 5—6 centimeters, and the second 15—17. When assembling the boiler, the plate from the front panel must be located between the plates of the rear wall.

- On the side walls, for their entire length, one corner is welded, at the same height — in the future, they will serve as brackets for the grate.

- Legs made from a corner are welded to the lower part. For the stability of the boiler, it is better to weld metal round or square plates to their end.

- To make a grate panel, numerous holes are drilled in the prepared metal blank or long strips are cut out along the side walls. You can do it in another way — weld a grate from reinforcement. If you can find a cast-iron grate on sale, exactly matching the tedious size, this will be an ideal option. When designing a boiler, this issue can be thought out in advance.

- The decisive and final step is to assemble all the parts together. They can be connected using a corner, or you can butt weld the parts together, but this must be done very carefully, the seams must be even and tight.

- A branch pipe is attached to the finished structure by welding chimney pipes.

- To keep the design neat, you need to clean the welds and cover the entire boiler completely heat resistant paint.

After the paint has dried, tests can be carried out before installation.are experiencing boiler outdoors.

Video - original homemade boiler long burning

It has been previously reported on the simplest designs. However, creative ideas have no boundaries. Look at the step-by-step process of creating a boiler of a completely unusual design.

Installation

Installation the boiler must be carried out in compliance with fire safety rules.

- To install the boiler permanently, you need to prepare a surface for it. It must be flat and fire resistant. — it can be a concrete floor, brickwork or tile.

- The walls near the boiler are finished with heat-resistant drywall, tiles, brick or masonry. You can choose other non-combustible material.

- The room where it is located boiler must have a good ventilation system.

If a boiler manufactured do it yourself, you need to try to choose high-quality material so that the product lasts a long time.

When choosing a ready-made boiler, it is necessary to carefully familiarize yourself with its characteristics and functions so that it satisfies everyone queries that depend on it. If it is not necessary or possible to purchase boiler factory production, you can make it yourself or order from an experienced craftsman.