Among the huge number of types of heating equipment on the market, one of the traditional options for use in a private house is a long-burning boiler.

Solid fuel boiler for long burning

With the help of the latest scientific developments, engineers were able to build such a boiler that can work up to 7 days on one load! This is not fantasy, this is reality! Despite the rather large dimensions of the device and its bulkiness, this is the most practical and economical solution for heating a large area today!

A long-burning boiler can be used as the main source of combustion, which explains its great popularity in many remote areas of the country where there is no other option for heating a house.

TT long burning boiler for a large house

Unlike a classic boiler, where heat is given off by a flame during the combustion of fuel, a long-burning device works in a completely different way. The long-burning boiler is a completely new and improved design.

Solid fuel boiler device

In conventional TT boilers, one load of firewood or coal provides combustion for 6-7 hours, which is not very economical and requires constant monitoring in order to maintain optimal temperature conditions. Long-burning appliances can maintain heat for 7 days from one laying of firewood or coal.

What accounts for such a difference in consumption of raw materials and how is this productivity achieved? We will talk about this in this article.

Content

- The principle of operation of the long-burning boiler

- Design feature of the TT long-burning boiler

- Specifications

- Security measures

- Will the boiler really work all 7 days on 1 load of fuel?

- Proper installation of the boiler: step by step instructions

- Video. How to properly install a long-burning boiler in the house.

- Video. Connecting a solid fuel boiler to a chimney.

The principle of operation of the long-burning boiler

Solid fuel boilers appeared relatively long ago, but all of them, regardless of model and manufacturer, had one significant drawback. Fuel had to be constantly added as it burned out. It was inefficient and not economical. This situation continued exactly until the year 2000, when Stropuva found a way to eliminate this problem. It is to the engineer Edmuntas Shtropaitis that we owe such an invention as a long-burning boiler.

To date, this is the most practical and functional device for heating a private house or cottage, the performance level of which reaches 70, and sometimes 100%. But, unlike classic pyrolysis boilers, which also have good efficiency, such units can maintain heat for 7 days on just one batch of fuel!

What are its main technical features and why is this device so economical and efficient?

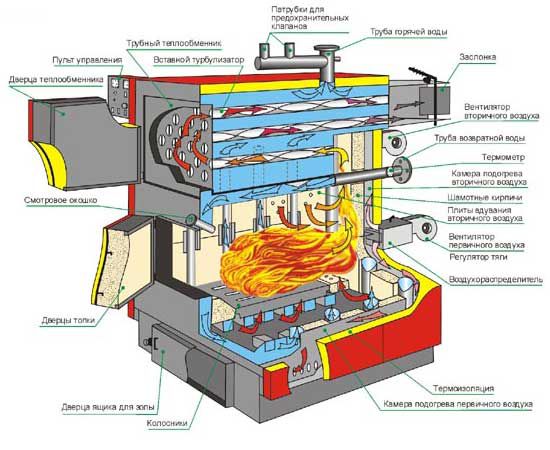

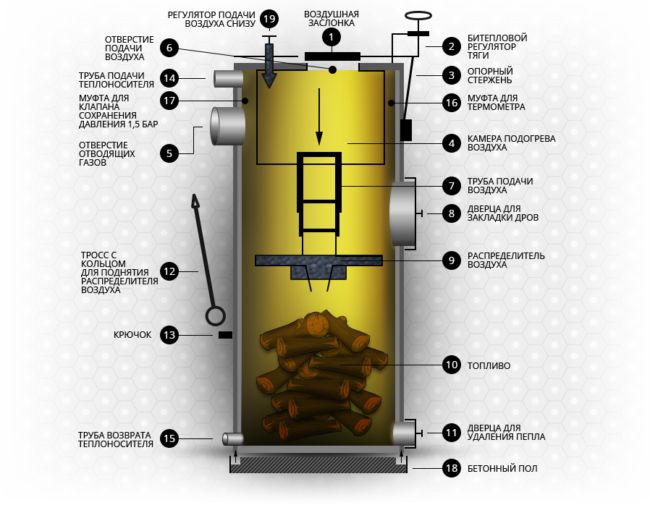

Long burning boiler device

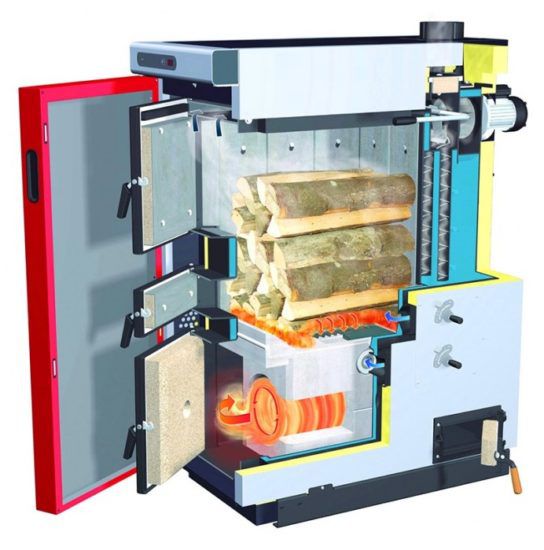

The principle of operation of a solid fuel boiler for long burning is similar to pyrolysis units. The main heat is generated not from the combustion of wood or coal, but from the gasification of solid fuels. The combustion process takes place in a closed space, from where wood gas is released through a special telescopic pipe.

After that, the gas is sent to the heater nozzle, where diffusion (mixing) takes place with the secondary air pumped in by the fan. Thus, a continuous process will occur until the coals or firewood are completely burned out. In this case, the combustion temperature sometimes reaches 1200 degrees.

Internal arrangement of a long-burning boiler

The effectiveness of this principle lies precisely in the fact that solid fuel is consumed very slowly, as needed, which significantly increases the efficiency of such a heater. But not only high performance is an advantage of this design.

Important. Solid fuel (pyrolysis) long-burning boilers have a very high efficiency compared to the classical design. It is equal to 95%.

As a rule, the whole point of long-term combustion lies in the fact that not the entire laying of coal or firewood burns out at the same time, but only the top layer. Due to the fact that air is supplied from above, and not from below, fuel burns out gradually, in its upper layer.

The principle of long burning

When this layer burns out, the air supply is turned on, and exactly as much as is needed to burn the top layer.This provides such a duration of burning and the ability to control the process.

It should be said that this version of the heater is acceptable only as a heating system. If you need to consider a domestic water heating system, then you should look for other options.

If the option is selected specifically for heating a large house, then such a device is an excellent alternative to electric and gas appliances.

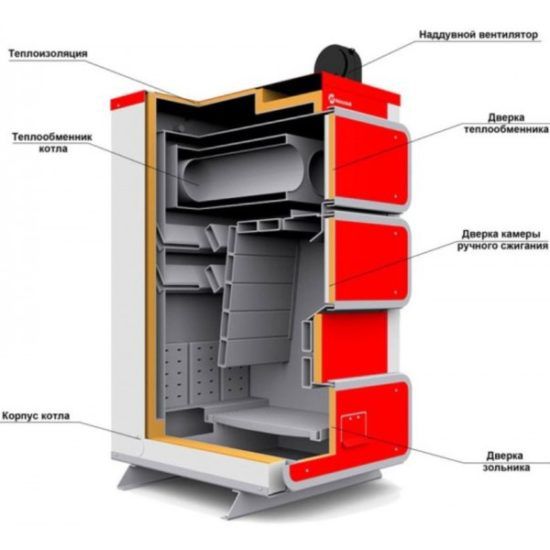

Design feature of the TT long-burning boiler

Usually, the design itself and the large dimensions of such a device already tell the consumer that it's all about the large volume of the loading chamber. However, the duration of burning here is determined not by a large amount of resources, but by slow smoldering.

TT boiler design

The duration of burning is ensured through the use of special techniques. Today, there are 2 main long-burning systems used in such devices. These are the Canadian system Buleryan and the Baltic Stropuva.

The second system is less common in our country due to the high price and a large number of technical parameters. But the Burelyan system is fundamental in the production of long-burning boilers, presented today on the modern market.

It is a small oven, which consists of two chambers. In the first (lower) chamber, solid fuel is burned, resulting in the formation of gas. He enters the second chamber, which is above the first. Here the hot gas is mixed with air and further combustion takes place. High heat transfer and good air circulation are provided by pipes located from bottom to top around the circumference of the boiler cylinder.

TT long burning boiler

Of course, the burning time of the boiler up to several days is determined by the need to load a large amount of fuel. For this purpose, the door of the loading chamber is located not at the bottom, but at the top of the boiler. The entire lower part is filled with fuel.

Large loading chamber ensures long burning

The flue pipe is located at the top of the boiler, which is connected to the chimney. And at the very bottom you can see the ash pan, which is necessary for collecting ash and systematic access for cleaning.

If in conventional furnaces the ash pan plays the role of a blower, supplying a portion of oxygen, then here the ash pan plays only the function of collecting combustion residues, so its door is airtight. Where does the air come from? At the top of the boiler there is an air chamber, which simultaneously plays the role of a recuperator (here the flue gases heat its walls). That is, the air from the air chamber enters already heated.

TT boiler

At the top of the chamber is a damper that regulates the supply of air to the fuel. In order for oxygen to be dosed into the chamber, an air distributor is located in the boiler, which is connected to the air chamber by a long telescopic pipe.

As the fuel burns, the distributor descends along with the top layer of burning raw materials, which ensures a constant supply of oxygen. In order to return the distributor to its original position, it is enough to pull the cable with the ring up. By the way, the remaining fuel in the chamber can be determined by the position of the cable.

As a result of this design, manufacturers are able to achieve performance (efficiency) up to 85%, and adjustable power from 50-100%.

Video. The principle of operation of the TT long-burning boiler.

The principle of this design explains the high environmental friendliness of long-burning boilers. The percentage of carbon dioxide emissions into the atmosphere is very low.

The raw material for burning is usually coal, peat briquettes, firewood, coke. But in addition to ordinary firewood, you can use any waste from the woodworking industry. These wastes are crushed to a finely dispersed state, after which they are pressed into granules called pellets. Fuel can be combined - it all depends on the model.

pellet boiler

The large volume of the loading chamber and the insufficient supply of oxygen to the combustion chamber significantly increases the overall efficiency of the HT boiler, taking into account these factors, the smoldering process is extremely slow and can reach up to 7 days. Pyrolysis boilers are also good, but they are very demanding on the quality and moisture content of the original fuel. Yes, here performance will also decrease with wet wood, but not as much as in a pyrolysis boiler.

Many models work on the basis of loose woody substances (sawdust, chips), on peat briquettes or on the basis of wood pieces, cuts.

various fuels for the boiler

Due to the fact that oxygen enters the chamber in limited doses, the smoldering process is very slow. But at the same time, the resources loaded into the boiler are sufficient to obtain generator gas with high thermal conductivity. Through a ceramic nozzle, it rushes into the main combustion chamber, where the process of active combustion continues. In this case, the process is forced and supported by additional air, which creates a fan.

The flame itself is formed by mixing gas and air, and is enhanced by the use of fans.

Due to the complexity of the scheme and volumetric dimensions, such units are mainly used for heating large premises, large country mansions. For a small cottage or a one-story house, it is simply not economically justified to purchase such a boiler. The performance of such units is too high.

TT boiler for large rooms

The high performance of long-burning boilers is also achieved due to the good location of the heat exchanger, which is a water jacket. The design of the unit helps to evenly heat the water circuit around the entire perimeter. The temperature of the exhaust gases does not exceed 130-150 degrees. The heat released in the boiler heats the coolant as efficiently as possible.

When choosing a long-burning boiler for a home, let's go through its main technical characteristics and note the advantages and disadvantages.

Specifications

- Long-burning boilers, which can provide up to 7 days of operation, mainly operate on peat briquettes or wood shavings. There are also universal devices that allow you to work with different fuels, but its length should not exceed 40 cm. Otherwise, you will have to deal with self-harvesting firewood.

- The higher the moisture content of the feedstock, the lower the performance of the heater. Therefore, for combustion, manufacturers recommend using fuel with a moisture content of no more than 20%.

- 1 boiler load on average provides up to 7 days of continuous burning.

Wood moisture content

Advantages:

- High performance. Perhaps this is one of the main and significant advantages of such bulky units. The average efficiency is at least 90%.

- Environmental friendliness. Carbon monoxide entering the chimney is used as the main source of combustible gas formation.

- Relative availability and inexpensive price of solid fuel.

- Automatic workflow. Some models are equipped with a remote control that allows you to set the desired temperature.

- Saving time and resources.

- Autonomy of work. Can be used as the main heating device.

- High fire safety. Long-burning boilers are equipped with an alarm sensor that is triggered in any emergency.

- High design reliability. With proper operation of the equipment, the boiler will last for more than a dozen years.

But no matter how efficient, economical and productive these boilers are, there are some disadvantages of such devices.

Flaws:

- Large dimensions.

- High price.

- The need for regular cleaning.

Security measures

In order for a long-burning solid fuel boiler to last a long time and not cause burns or accidents in the house, simple rules for operating this device should be followed.

- Do not overheat the system. Given the high inertia of the boiler, it cools down extremely slowly. Therefore, it is important to monitor the temperature control mark. This is especially true for pipes made of metal-plastic or plastic. If the outlet temperature is 110-115 degrees, then this will lead to sad consequences. Pipes can simply melt. To do this, it is necessary to use cooling heat exchangers and diverter valves when installing the heating system.

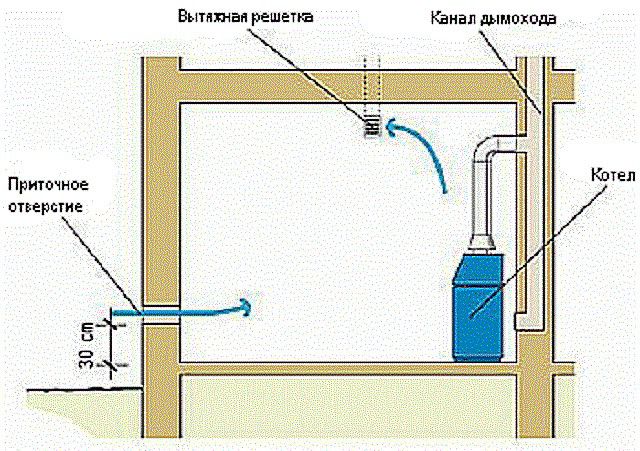

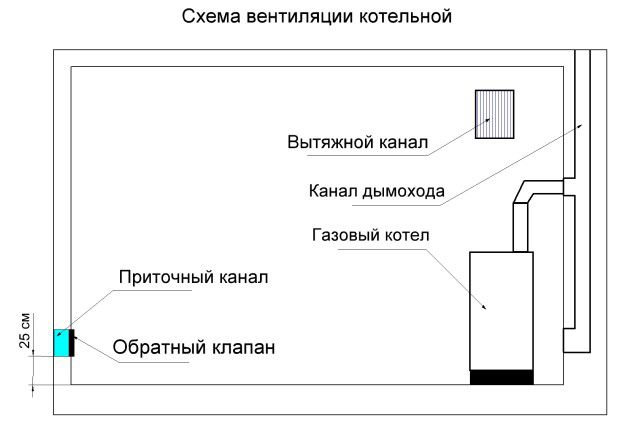

Indoor ventilation system

- Under no circumstances should a shut-off valve be installed in the pipeline between the expansion vessel and the boiler.

- The room must be ventilated for air flow.

Security measures

- Do not fire up the boiler if there is no water in the expansion tank.

- Do not place flammable objects on the boiler.

Will the boiler really work all 7 days on 1 load of fuel?

Owners of cottages and private houses, when choosing a solid fuel boiler, are most interested in such parameters as price, power and duration of burning from one fuel load.

TT long burning boiler

Here, let's take a comparative look and stick to these basic criteria to determine which of the devices will be the most effective.

- Type of fuel. The efficiency of the device largely depends on this. Not all raw materials are designed for long-term burning. Firewood, for example, gives maximum performance when burned quickly. But peat briquettes are able to give off heat for a long time, maintaining the optimum temperature. An excellent solution would be a universal model that works on several options at once.

- boiler material. It also depends on the raw material. When using coal, it is better to give preference to choosing a boiler made of steel, but cast-iron structures are more suitable for firewood.

TT steel boiler

- Boiler power. This parameter depends on the volume of the loading chamber. The larger it is, the longer the boiler can burn from one load.

- The weight of the structure determines the material. A cast iron apparatus will be almost 20% heavier.

- Product price. This is a very conditional parameter.But if the boiler is purchased for the purpose of the main source of heating, then it is still not worth saving, because the performance of the device and the comfortable microclimate in the house depend on it.

In any case, if the seller claims that this boiler will work for 7 days on one load of fuel, be sure to take the trouble to look into the technical data sheet, because no matter how much he praises the features and advantages of the device, it is in the passport that its standard burning time will be written.

The burning time does not always only depend on the chosen model. This parameter is affected by the type and quality of fuel, the area of \u200b\u200bthe room, the height of the ceilings, the quality of the insulation of the house.

Burning time depending on the type of fuel

Proper installation of the boiler: step by step instructions

Many consumers, when purchasing a solid fuel boiler and expecting from it the effect of a long and economical burning of raw materials up to the declared up to 7 days, after some time pay attention to the fact that the device does not provide the declared efficiency. And the point here is not at all the poor quality or marriage of the boiler, but the mistakes made when connecting.

Do-it-yourself installation of a TT boiler

Of course, given the complexity of the design and the responsibility of this event, many trust the installation of a long-burning TT boiler to craftsmen. However, following our detailed step-by-step instructions, you can install the boiler yourself, without outside help. Although you cannot do without an assistant in this matter, because the weight of the device is at least 50 kg.

At the stage of preparatory work, you should immediately consider where the boiler will be installed. Ideally, of course, equip a separate boiler room.

boiler room in a private house

Given that solid fuel still creates a certain amount of dirt, such a heating system must be produced in a separate non-residential premises. But if the boiler power is small (does not exceed 30-35 kW), then you can simply separate (zonate) the main room from the "boiler room".

Ventilation scheme in the boiler room

To ensure that people who service and ignite the boilers do not have breathing problems, the boiler room must be equipped with a ventilation system. Clean air must come from the street.

Prepare the following tools:

- Locksmith set (adjustable, open-end wrenches).

- Building level.

- Circular Saw.

- Screwdriver and a set of nozzles.

- Marker.

- Sealant gun.

Locksmith tool kit

In addition to the heating solid fuel boiler itself, it will also be necessary to purchase materials for connecting the boiler to the heating system.

- Steel coupling (3 pieces).

- Ball valve with a drive (2 pcs) with a diameter of 50 mm.

- Metal pipe for connecting the boiler.

- Sealant (refractory).

- Plumbing lining.

Stage 1. Preparation and protection of the premises.

The issue of fire safety should be approached with all responsibility.

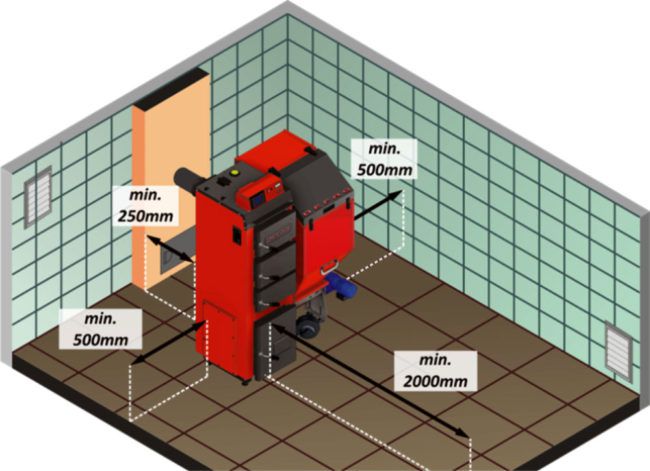

- We decide on the place where the boiler will be located. If the house is replacing an outdated model with a more modern and productive one, then the place, together with the chimney, has already been prepared. If the heating system is being designed from scratch, then you should immediately consider the gas exhaust system and the location of the boiler in the room. The location for the installation of the boiler must provide convenient operation and direct access. The room where the solid fuel boiler is installed must be non-residential.

Boiler location

- The base on which the boiler will be placed must be covered with a metal shield. In this case, the dimensions of the shield should be 25% larger than the device itself. If the power of the device exceeds 50 kW, then such a unit should be installed on a foundation of concrete screed. As a rule, the height of such a foundation should be from 100-150 mm above the floor level. In this case, the foundation must have a screed separate from the floor.

Installation of the boiler on a metal sheet

When installing a low-power unit, it is allowed to install the boiler on a rough concrete screed.

Be sure to check the level of the slope of the foundation. It must be perfectly level. If necessary (if the floor is not even), a brick foundation should be laid out.

- Draw with a marker or chalk on the floor the place where you will install the boiler and carefully double-check all distances. Observe the distance from the walls (regulated by SNiP). The distance from the furnace door to the wall must be at least 125 cm. The distance between the side parts and the back of the boiler and the wall must be at least 700 mm.

- The wall adjacent to the front of the boiler (where the firebox and the door are located) are covered with a layer of plaster 25 mm thick. Additionally, we install a metal sheet at a level above the boiler by 25-30 cm.

We protect the wall behind the boiler

- Remove the new boiler from its original packaging.

- Place the boiler on the prepared foundation and again check with a level that the appliance is level. The gas outlet pipe must be at the same level as the chimney pipe. If the line is not straight, then traction may be impaired during operation.

- Insert all necessary elements of the boiler supplied separately (ash pan, doors).

Fire safety standards

Video.How to properly install a long-burning boiler in the house.

Stage 2. Boiler piping.

This stage is one of the most difficult. The security of the system will directly depend on it.

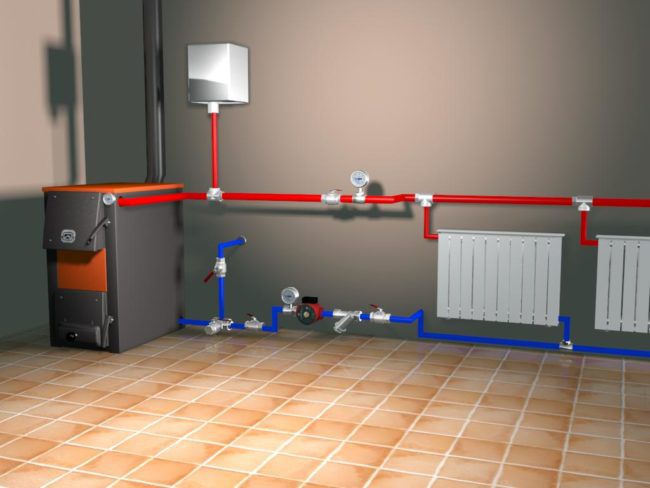

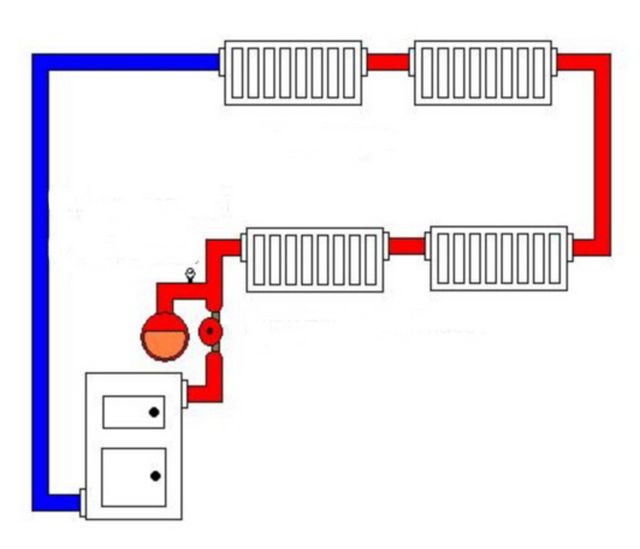

There are several boiler piping schemes: with forced and natural circulation of the coolant. In addition, there may be an open and closed heating system.

With a natural circulation system, water flows freely through all pipes under its own pressure. The forced scheme involves the installation of a pump that creates this pressure.

TT piping of a long-burning boiler

The choice of connection scheme largely depends on the number of floors of the house, the location of the boiler, rooms and the total area. So, it is advisable to use a scheme with natural circulation for one-story houses. But for rooms with several floors, it will be ineffective and it is better to purchase an additional pump in order to perform a forced circulation of the coolant.

But the most simple and understandable is the closed (forced) scheme.

Closed circuit heating system

It is produced through 2 nozzles. One is connected to the supply circuit of the heating network, and the second end to its return circuit.

Important! Whichever model of the TT boiler you choose, it does not come with a circulation pump and an expansion tank. All this, depending on the chosen connection system, must be purchased and installed independently.

To properly tie the boiler, be guided by the following rules:

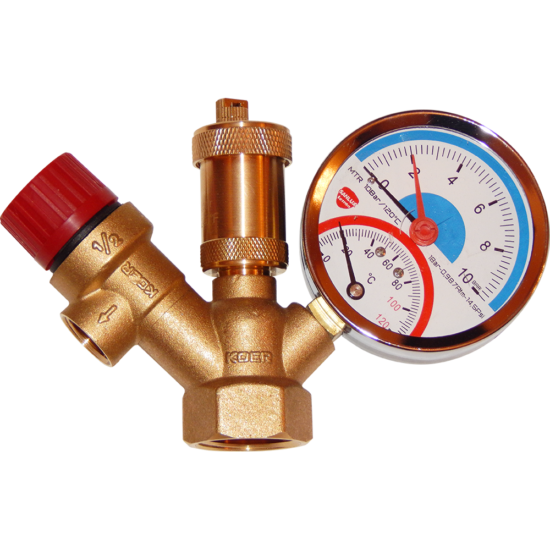

- The pressure should not rise above normal. You can monitor this indicator on the manometer.

pressure gauge

- The efficiency of the system depends on the tightness of all connections.

- Under no circumstances should combustible materials be used for piping the boiler.

The installation of a pressure gauge is a prerequisite for piping the boiler, as this device will control the maximum pressure value.

- We tie the outlet pipes of the boiler with flax. After the flax is wrapped tightly around the outlet pipe, go over it well with plumbing sealant.

- We take a corner and carefully wind it on top.

Boiler piping diagram

- Now we connect the barrel and nipple. We tightly dock these parts and connect them to the crane. Be sure to seal all connections with plumbing sealant to prevent leakage.

Joint sealing

- With a threaded connection using a coupling and a nut, we connect the water circuit to the outlet and inlet pipes. Make sure you put the pieces together carefully. Linen tow wrap

Stage 3. Connection to the chimney.

All solid fuel boilers must be connected to a chimney. If the house is already equipped with an effective gas exhaust system, then you just need to connect the new structure to it.

Chimney installation options

If you are equipping the heating system in the house and the chimney from scratch, then choose the construction method: through the roof or through the wall.

Ideally, use double-circuit pipes for installing a chimney (sandwich type).

Sandwich pipe

- The channel between the boiler and the chimney must be at least 1 meter. The performance of the device and the safety of the inhabitants of the house depend on this. Ideally, the chimney should have a minimum number of bends, because each additional bend creates an obstacle to the natural draft of gases, and reduces the performance of the boiler.

Connecting the TT boiler to the chimney

As for the inclination of the horizontal section of the pipe leading from the boiler to the vertical chimney structure, it is ideal to maintain an angle of 45 degrees. If, for technical reasons, this cannot be done, then it is allowed to place the horizontal section at an angle of 15 to 30 degrees. In any case, it cannot be made even, otherwise it will interfere with normal traction.

Chimney connection

Attention! It is necessary to process the joints of the connection of all parts of the chimney with a sealant. This will help prevent smoke leakage.

- We connect the first pipe of the chimney to the boiler nozzle. The type of connection depends on the selected boiler model. A prerequisite is the observance of the diameter of the chimney and the furnace nozzle. The diameter of the chimney pipe must not be less than the branch pipe of the solid fuel boiler. If these parameters are not observed, then the throughput of the gas duct at maximum power will decrease.

Video. Connecting a solid fuel boiler to a chimney.

- Set up a security group. The main task of this group is to relieve pressure in the network during its critical growth. The safety group is mounted directly at the outlet of the supply pipe. Normal pressure is 2.9-3 bar. If it is exceeded, the safety valve should work. In addition to it, the security system includes a pressure gauge that serves to control pressure and an air vent.

Security group

Attention! In no case should a shut-off valve be installed on the pipeline section between the boiler and the safety group.

Stage 4. We connect the boiler to the heating system.

- According to the SNiP standards, it is necessary to carry out a hydraulic pressure test with a holding time of 24 hours before starting the boiler.

To do this, open the valves, all taps and connect the water. Raise the pressure with the control valve to 1.3 atm. This test should show you that there are no leaks. Pay special attention to threaded and welded connections.

- We fire up the boiler.

To set fire to firewood or peat, you need to put wood chips or paper in the chamber. After melting the boiler, close all doors tightly. After a steady flame has appeared, you can open the door and load the main amount of firewood. Never use flammable liquid for ignition.

First firing of the boiler

- On the first test run, an unpleasant chemical start may be present. This may be due to the fact that the remnants of the factory oil burn out. The odor will soon disappear.

If you connected everything correctly, then the pressure should not drop during the test period and, accordingly, there should be no leaks anywhere. Now you can put the boiler into operation. If, during the test period, any problems were identified, then you should disconnect the boiler from the system, wait for it to cool completely and proceed to eliminate the errors.

With proper installation and connection of the boiler, you will quickly appreciate its high performance and efficiency, which will allow you to maintain a comfortable microclimate in the house. A video instruction will help you take into account all the necessary nuances of installing the boiler.

Video. Proper connection of a solid fuel boiler for long burning.